Overview

This article presents essential strategies for building a resilient supply chain in today’s dynamic environment. It underscores the significance of advanced technologies, collaborative efforts, and proactive risk management. By leveraging real-time data and AI-driven analytics, organizations can enhance their supply chain resilience. Furthermore, fostering public-private partnerships is vital for effectively navigating disruptions in a rapidly changing market. These elements are crucial for Operations Managers seeking solutions to their challenges.

Introduction

In an increasingly interconnected world, the resilience of supply chains stands as a pivotal concern for businesses aiming to navigate disruptions and uncertainties. This landscape presents organizations with a unique opportunity to bolster their operations through innovative strategies, cutting-edge technologies, and collaborative partnerships. Yet, as companies grapple with the challenge of adapting to swift market changes and potential vulnerabilities, a crucial question emerges: what are the most effective strategies for constructing a resilient supply chain? Such a supply chain not only withstands current challenges but also positions businesses for future success.

10X ERP: Cloud-Based ERP for Real-Time Supply Chain Management

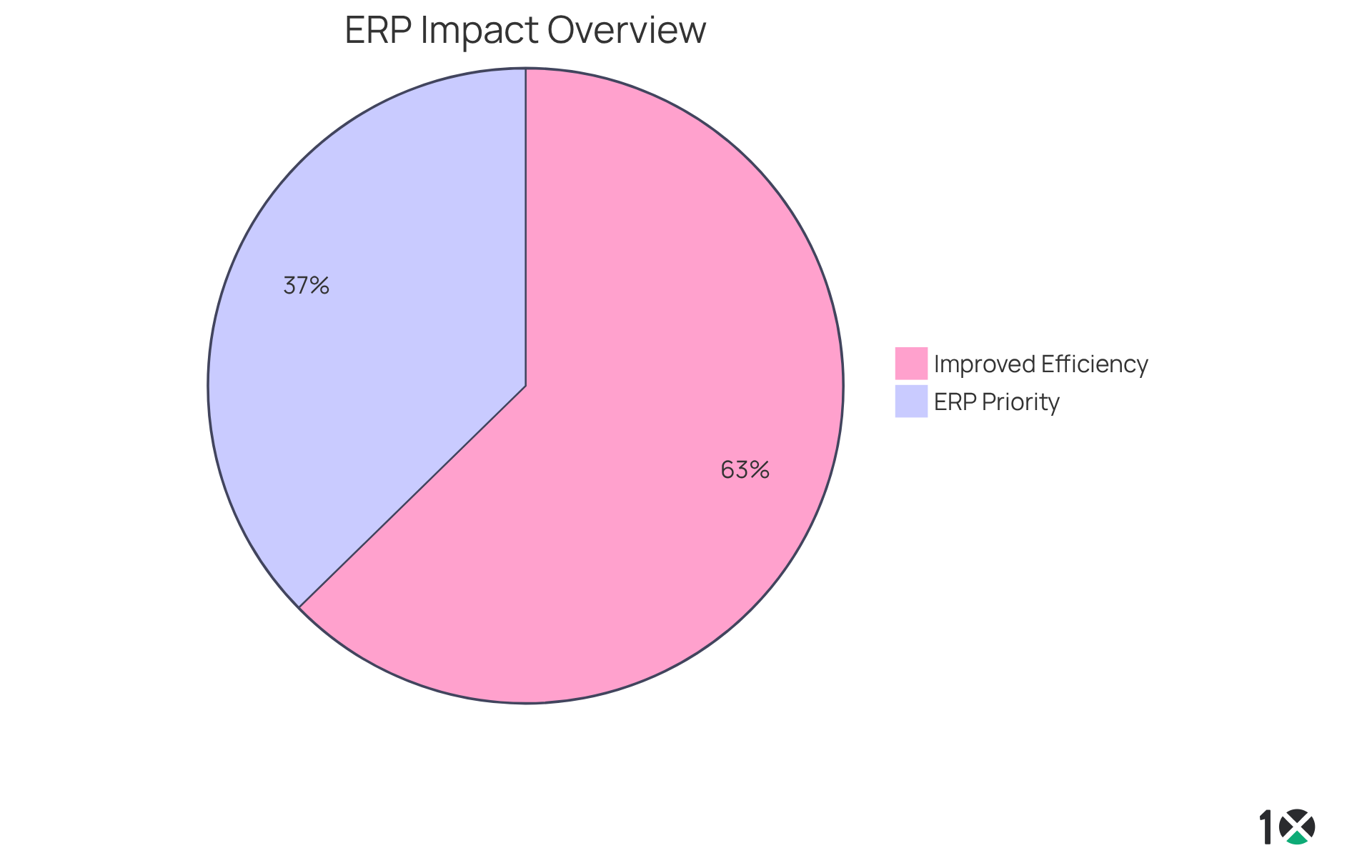

10X ERP presents a robust cloud-based system that empowers distributors to manage their logistics through real-time data processing. This capability provides businesses with immediate insights into their operations, enabling informed decision-making and swift responses to market fluctuations. Companies leveraging 10X ERP have reported notable enhancements in operational efficiency, with 89% of ERP users identifying improved efficiency as a primary advantage.

Moreover, the platform’s customizable inventory management and seamless app integrations allow distributors to optimize stock levels and streamline logistics processes. As we approach 2025, the demand for cloud-based ERP solutions is anticipated to escalate, with 53% of businesses prioritizing ERP as a crucial investment. This trend underscores the vital role of in bolstering a resilient supply chain, as organizations that utilize such capabilities can navigate disruptions more effectively and maintain a competitive edge.

IBM Supply Chain Solutions: Enhancing Agility and Adaptability

IBM’s logistics solutions lead the way in enhancing agility and adaptability through advanced analytics and artificial intelligence. By leveraging these technologies, organizations can proactively anticipate disruptions and optimize their logistics operations. Emphasizing real-time information and machine learning facilitates the creation of a responsive system that swiftly adapts to evolving market conditions.

In 2025, a significant 74% of logistics executives are expected to increase investments in automation and AI technologies, reflecting a growing recognition of their importance in tackling challenges such as labor shortages and visibility issues. Notably, 90% of logistics leaders believe their organizations lack the necessary talent and skills for digitization, underscoring a critical area where AI can drive transformative change.

Moreover, IBM’s innovative applications of AI have yielded measurable benefits, including reported savings of $388 million through reduced inventory costs and optimized shipping processes. The implementation of AI in logistics management has the potential to , further illustrating the financial impact of these technologies.

The AI logistics market is projected to reach $41.23 billion by 2030, highlighting the increasing importance of AI investments in the sector. As Dave Waters, a leading voice in logistics and AI, notes, “Artificial Intelligence will be prevalent in the digital network.” This strategic focus not only enhances operational efficiency but also empowers companies to develop a resilient supply chain to thrive in an increasingly complex logistics landscape.

Operations managers should consider initiating pilot projects to integrate AI into their logistics strategies, ensuring they remain competitive in this dynamic environment.

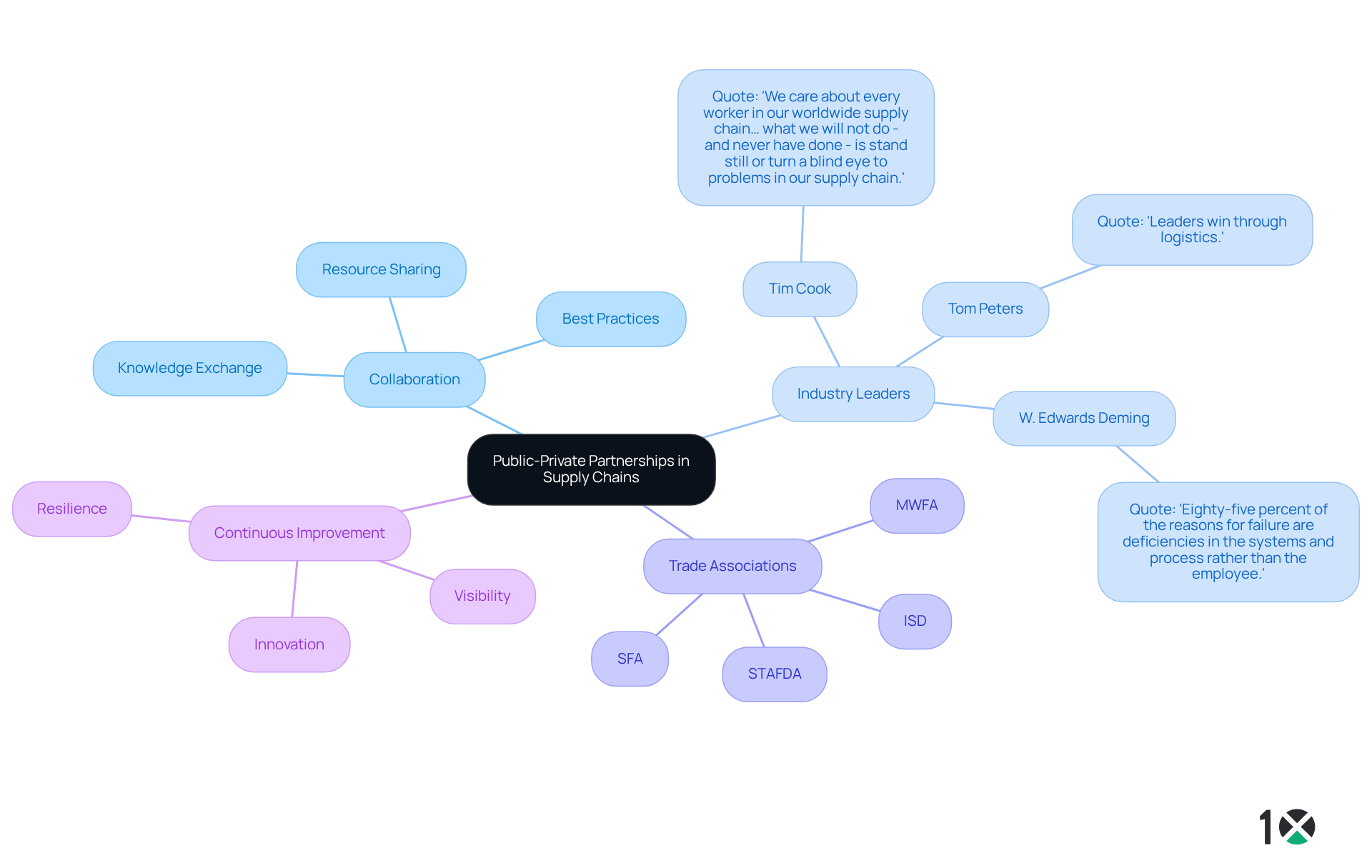

OECD Insights: Strengthening Supply Chains Through Public-Private Partnerships

The OECD emphasizes the critical role of public-private collaborations in strengthening logistics. By fostering cooperation between government entities and private companies, organizations can effectively share resources, knowledge, and best practices. This collaborative approach not only enhances resilience but also creates a that can better manage disruptions and uncertainties.

For instance, during recent global challenges, various governments and private sectors united to streamline logistics and improve operational efficiency, demonstrating that collaboration can yield innovative solutions and heightened responsiveness. Industry leaders echo this sentiment, with Tim Cook underscoring the need to proactively address logistical challenges, asserting, ‘We care about every worker in our global network… what we will not do – and never have done – is remain stagnant or ignore issues in our network.’

Furthermore, as W. Edwards Deming pointed out, ‘Eighty-five percent of the reasons for failure are deficiencies in the systems and process rather than the employee,’ highlighting the essential need for effective collaboration. Additionally, Tom Peters stated, ‘Leaders succeed through logistics,’ reinforcing the idea that strategic alliances are vital for sustainable resource management.

In this context, trade associations such as ISD, MWFA, SFA, and STAFDA play a pivotal role in enhancing industry connections for distributors. By collaborating with these associations, 10X ERP can leverage valuable resources and insights, such as industry standards and best practices, to further strengthen its cloud-based ERP solutions and real-time data processing capabilities.

By integrating these insights and emphasizing the importance of visibility, resilience, and continuous improvement, organizations can attain a clearer understanding of how a resilient supply chain contributes to the value of public-private partnerships and industry collaborations in enhancing performance.

NIST Strategies: Overcoming Supply Chain Challenges for Manufacturers

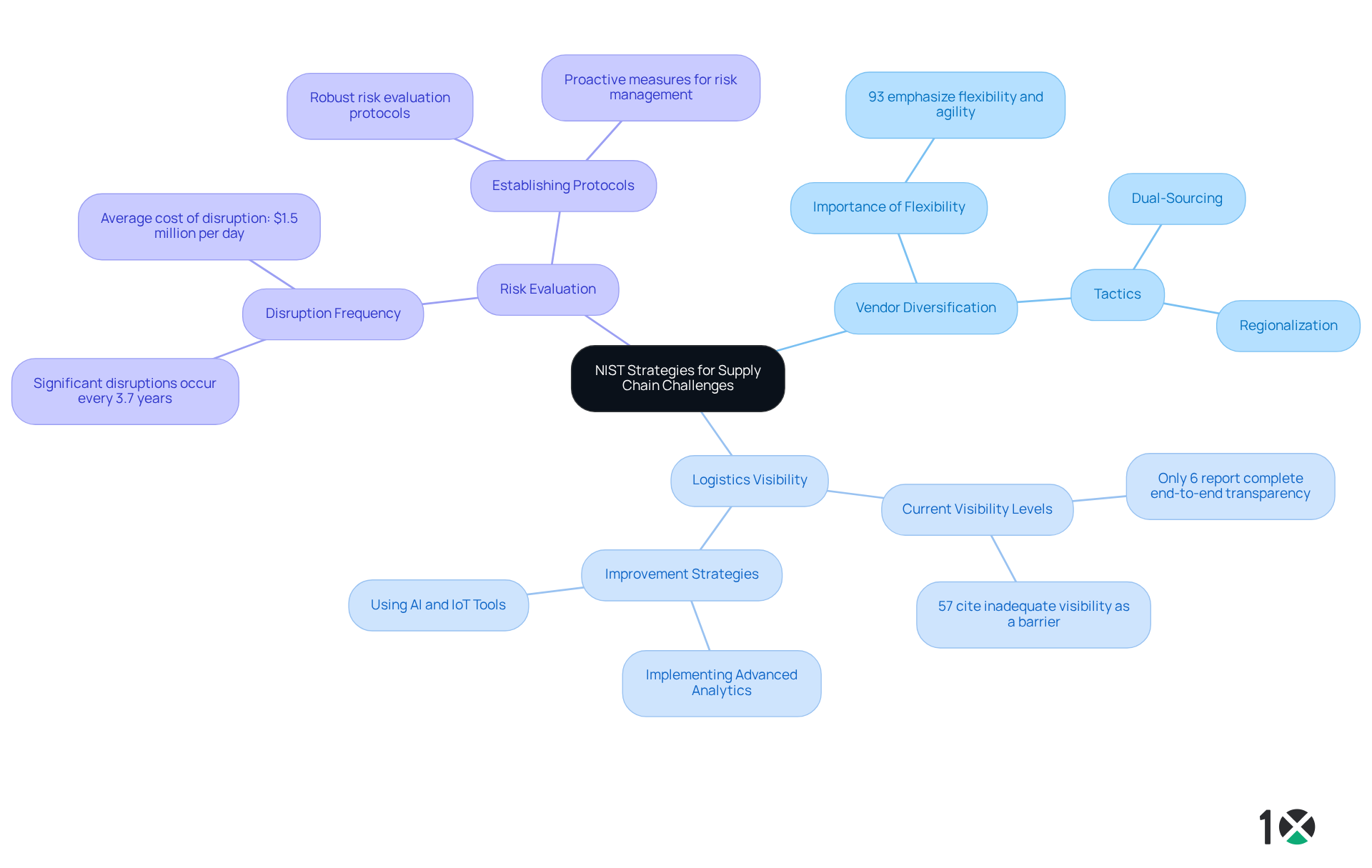

NIST outlines a comprehensive framework enabling producers to effectively navigate resource challenges through strategic planning and efficient risk management. One key strategy for enhancing resilience is vendor diversification, which is vital for building a resilient supply chain. In fact, 93% of senior logistics executives emphasize the importance of flexibility and agility in their networks to adapt to disruptions. This adaptability can be achieved through approaches such as dual-sourcing and regionalization, which are essential for establishing a resilient supply chain that enables companies to reduce risks associated with dependence on single suppliers.

Moreover, improving logistics visibility is essential, as only 6% of businesses report complete end-to-end transparency. Notably, 57% of professionals in the field identify inadequate visibility as the primary barrier to their operations. Establishing robust risk evaluation protocols is equally critical for maintaining a resilient supply chain, especially considering that significant disruptions in logistics occur approximately every 3.7 years, with the average cost of a disruption estimated at $1.5 million per day. This reality underscores the necessity for .

Real-world examples illustrate that manufacturers implementing these strategies not only mitigate risks but also position themselves for sustainable growth in an increasingly complex landscape. By adopting these practices, organizations can not only safeguard their operations but also thrive amidst challenges.

ResearchGate Analysis: Identifying Vulnerabilities in Supply Chains

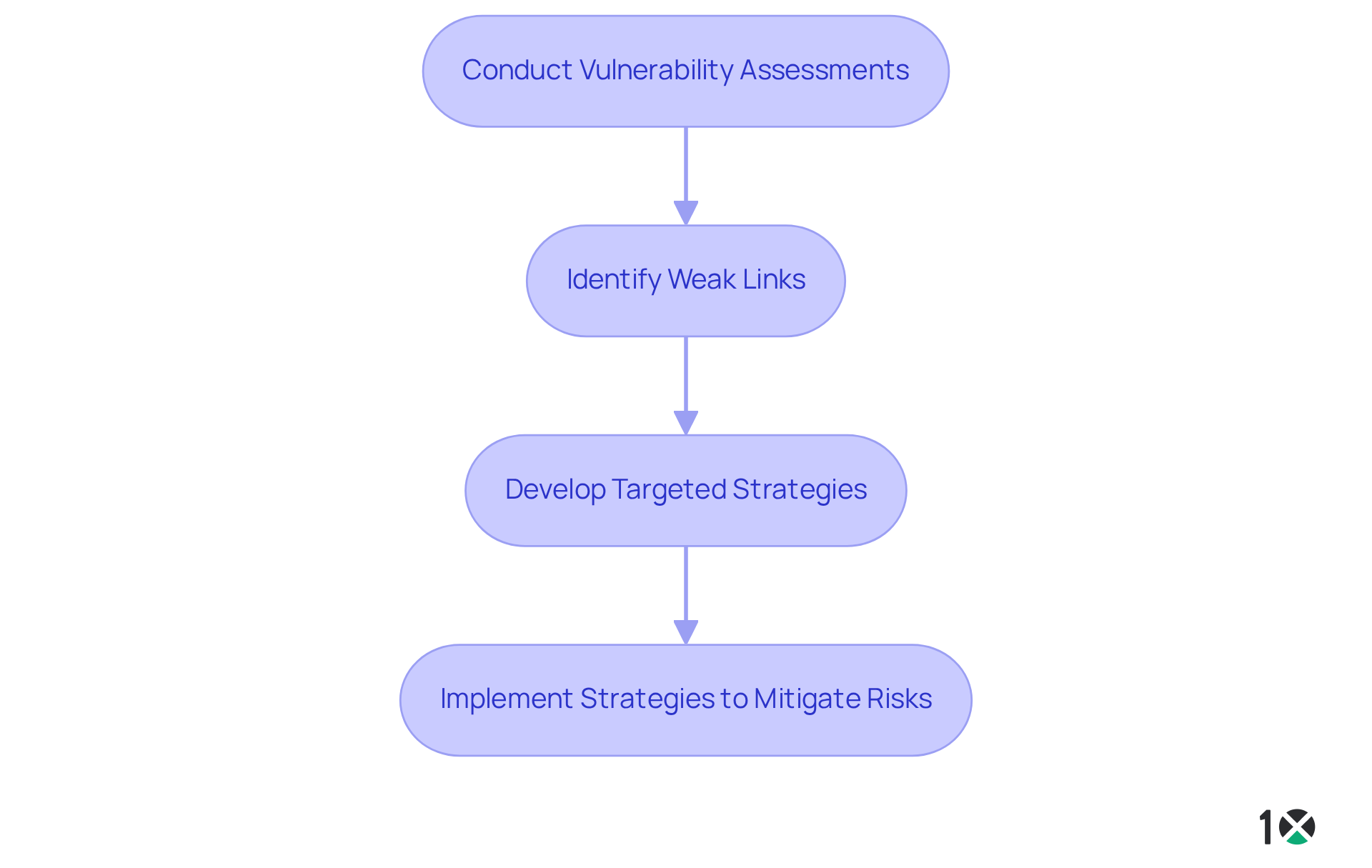

ResearchGate underscores the critical necessity of recognizing weaknesses within distribution networks to bolster a resilient supply chain. By implementing thorough assessments and analyses, organizations can effectively identify weak links and develop targeted strategies to mitigate risks. This not only minimizes potential interruptions but also fortifies the overall structure of the resilient supply chain.

Real-world examples demonstrate that companies conducting regular vulnerability assessments have markedly enhanced their risk management capabilities, allowing them to adapt swiftly to unforeseen challenges. The emphasis on proactive evaluations is essential, as it empowers organizations to anticipate vulnerabilities before they escalate into significant issues, ultimately enhancing operational efficiency and safeguarding against potential risks.

ScienceDirect Review: Comprehensive Strategies for Supply Chain Resilience

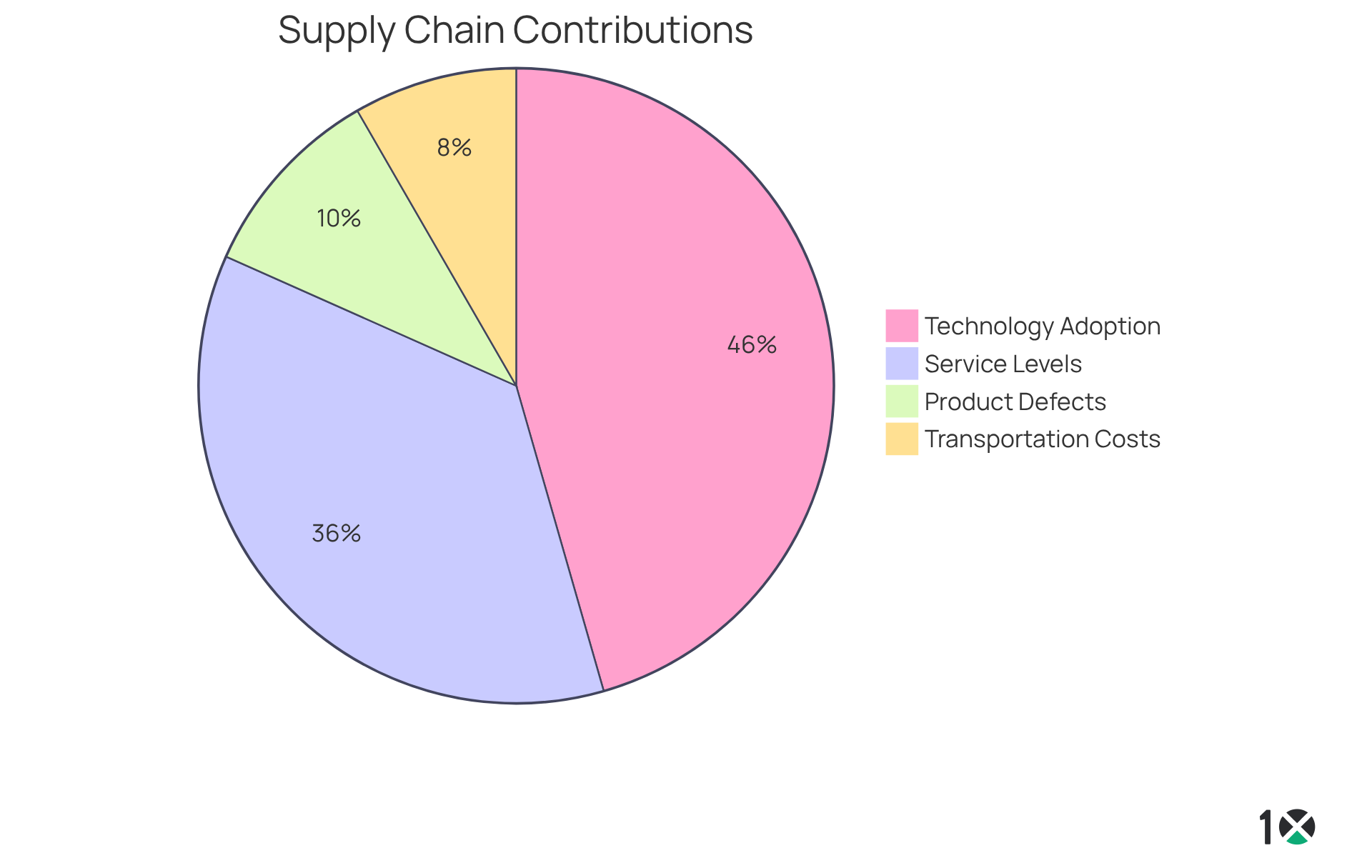

An examination of extensive approaches for improving logistics resilience underscores the critical role of a resilient supply chain, which includes advanced technologies and strong supplier connections. Organizations that embrace cutting-edge solutions, such as AI-driven quality control systems, have reported an 18% reduction in product defects. This showcases how technology can significantly enhance operational efficiency. Furthermore, 82% of logistics organizations have adopted these technologies, leading to an impressive 65% improvement in service levels, crucial for meeting customer expectations in today’s fast-paced market.

Equally vital is the cultivation of robust supplier relationships. Businesses that prioritize collaboration with providers can enhance their logistics resilience, thereby building a more resilient supply chain that ensures better communication and reliability. In fact, 90% of logistics leaders assert that strong partnerships are essential for effectively managing disruptions. The trend toward balanced multi-shoring sourcing strategies, with 50% of companies predicted to adopt this approach, further underscores the necessity of diversifying supplier bases to mitigate risks associated with reliance on a single source.

Integrating sophisticated stock management systems, such as those offered by 10X ERP, can further bolster a resilient supply chain. With features like customizable tracking, lot/serial item tracking, simplified item types, and powerful cross-referencing, organizations can maintain . The API-first approach of 10X ERP ensures seamless integration with existing software, thereby enhancing operational efficiency and user experience for distributors.

Real-world examples underscore the effectiveness of these strategies. Companies that have incorporated AI into their logistics operations reported a 15% decrease in transportation costs, illustrating how technology can optimize shipping and storage functions. Moreover, the retail sector’s reliance on AI for logistics optimization, which accounted for a 24.1% market share in 2024, highlights the growing trend of leveraging advanced technologies to enhance competitiveness.

By implementing these tactics, including the use of advanced stock management systems like 10X ERP, companies can establish a resilient supply chain that is capable of adapting to disruptions and evolving market demands. This ultimately leads to improved performance and heightened customer satisfaction.

Throughput World: Leveraging AI for Enhanced Supply Chain Resilience

Throughput World underscores the transformative role of AI in enhancing the resilience of a resilient supply chain within logistics. By leveraging AI-driven analytics and automation, organizations can significantly improve forecasting precision, optimize stock levels, and streamline operations. This technological integration not only boosts efficiency but also empowers companies to respond swiftly to disruptions, thereby strengthening their resilient supply chain.

Advanced stock management solutions, such as those offered by 10X ERP, directly address these challenges with customizable tracking and a robust API-first approach for seamless software integration. With and reliable stock management, 10X ERP equips distributors to tackle challenges effectively, ensuring a resilient supply chain. The customizable features of 10X ERP enhance operational flexibility, enabling businesses to adapt their inventory strategies in response to evolving market conditions.

SAP Solutions: Integrating Technology for Agile Supply Chains

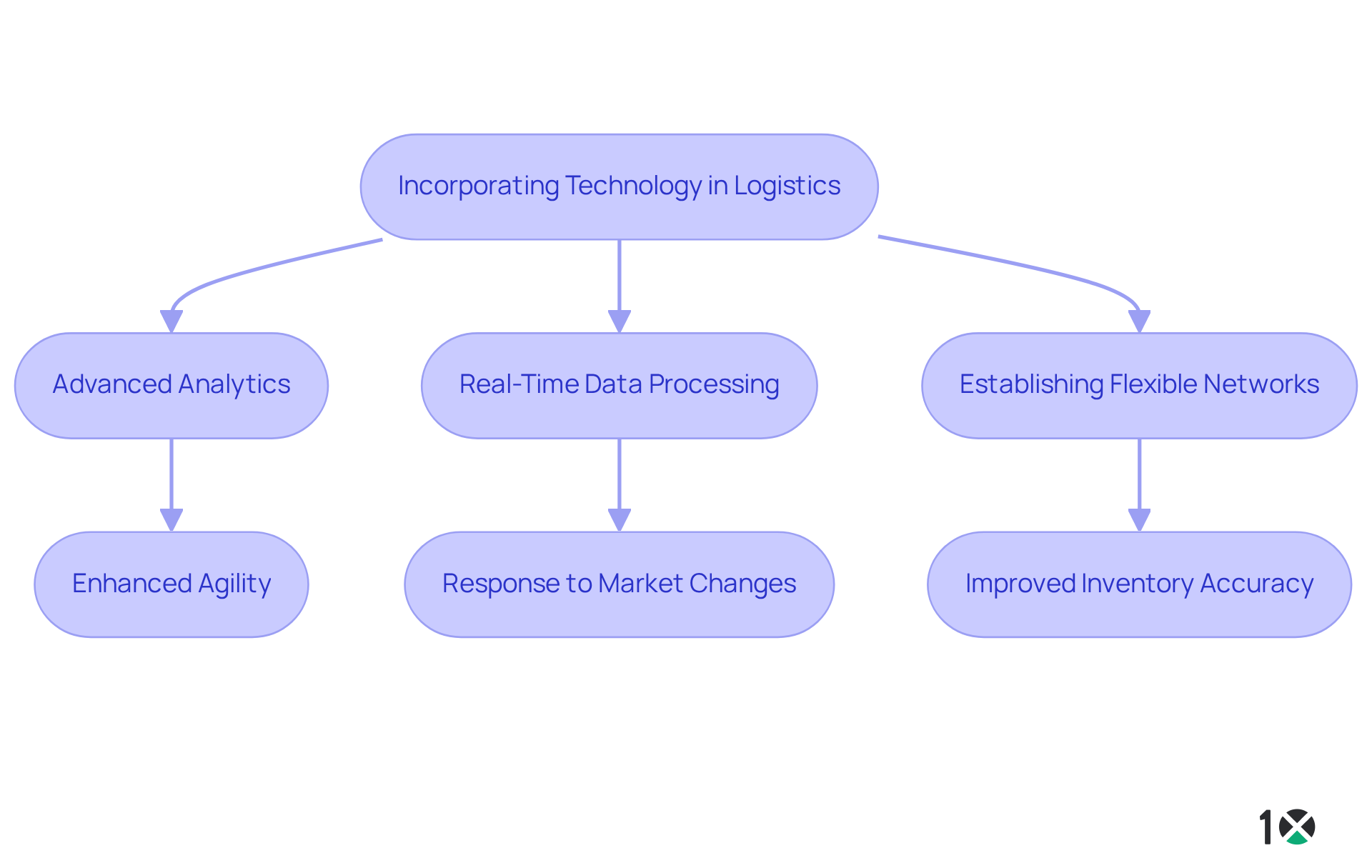

Incorporating technology into logistics management is essential for enhancing agility and responsiveness. By utilizing advanced analytics and real-time data processing, businesses can establish flexible networks that swiftly react to market changes and shifting customer needs. Notably, 93% of senior logistics executives plan to enhance their networks to be more adaptable and robust, underscoring the importance of agility in today’s landscape. This shift is supported by the fact that 63% of entities have already adopted technological solutions to oversee and evaluate efficiency in logistics.

10X ERP exemplifies this technological integration with its comprehensive cloud-based solution tailored specifically for distributors. The platform offers a seamless user experience, rapid onboarding, and a transparent pricing model, enabling organizations to leverage real-time data processing and resource management efficiently. With features like , 10X ERP ensures that businesses can adapt quickly to changing demands while maintaining data accuracy.

Real-world examples underscore the effectiveness of these strategies. A significant case is AJG Transport, which identified four essential daily logistics KPIs—cost reduction, production service rate, turnover, and production time. By monitoring these metrics, they were able to benchmark processes and pinpoint bottlenecks, leading to enhanced overall efficiency. Furthermore, the adoption of RFID technology has elevated inventory accuracy to approximately 95%, significantly minimizing human error and improving fulfillment precision.

Experts assert that digital transformation is not merely a trend but a crucial element for contemporary logistics. As highlighted by SAP professionals, the integration of real-time data processing and advanced analytics is vital for organizations aiming to thrive in a competitive landscape. This transformation empowers companies to anticipate obstacles, refine operations, and ultimately deliver exceptional customer experiences, reinforcing the pivotal role of technology in logistics management. Marijn Overvest emphasizes that leveraging statistics can lead to cost optimization, further underscoring the financial advantages of data-driven decision-making.

PMC Research: Inventory Management Strategies for Resilience

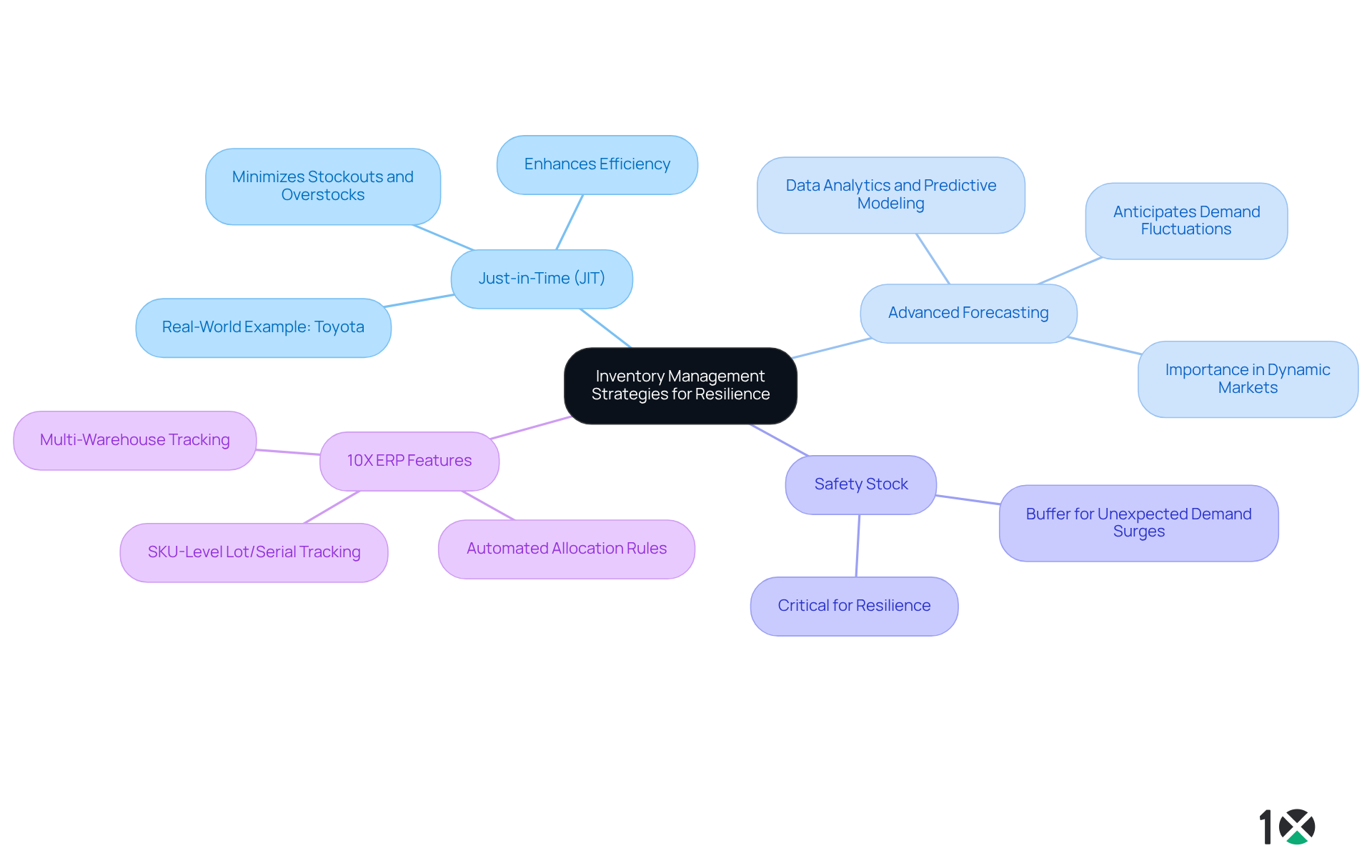

Effective management techniques for resources are essential for creating robust networks, as emphasized by PMC Research. Among these strategies, just-in-time (JIT) stock practices stand out for their ability to align stock levels closely with demand, thereby minimizing excess supplies and reducing associated costs. Industry leaders assert that JIT practices not only enhance efficiency but also improve responsiveness to market changes. A notable quotation from a supply chain specialist underscores this point: “Minimizing stockouts and overstocks can decrease total stock expenses by as much as 12%.”

Real-world examples illustrate the successful implementation of JIT practices. Firms such as Toyota have long been recognized for their effective JIT strategy, which enables them to maintain minimal stock levels while guaranteeing prompt production. This approach has proven successful in mitigating risks associated with excessive dependence on stock, particularly during disruptions.

In conjunction with JIT practices, advanced forecasting methods play a crucial role in stock management. By leveraging data analytics and predictive modeling, organizations can anticipate demand fluctuations more accurately, allowing them to proactively adjust inventory levels. This flexibility is vital in today’s , where logistics disruptions can arise from various factors, including geopolitical tensions and natural disasters.

Moreover, maintaining safety stock levels is a critical component of resilient logistics networks. While JIT practices aim to reduce stock levels, having a buffer ensures that organizations can respond swiftly to unexpected demand surges or delivery delays.

10X ERP enhances these strategies with its robust features, including SKU-level lot/serial tracking, automated allocation rules, and the capability to track products across multiple warehouse locations. Additionally, the software supports the definition of kits and assemblies, further streamlining inventory management. As the global distribution network continues to evolve, the integration of these strategies with the strengths of 10X ERP will be essential for firms striving to enhance their operational resilience and build a resilient supply chain to maintain a competitive advantage.

SCMR Trends: Future-Proofing Supply Chains for Resilience

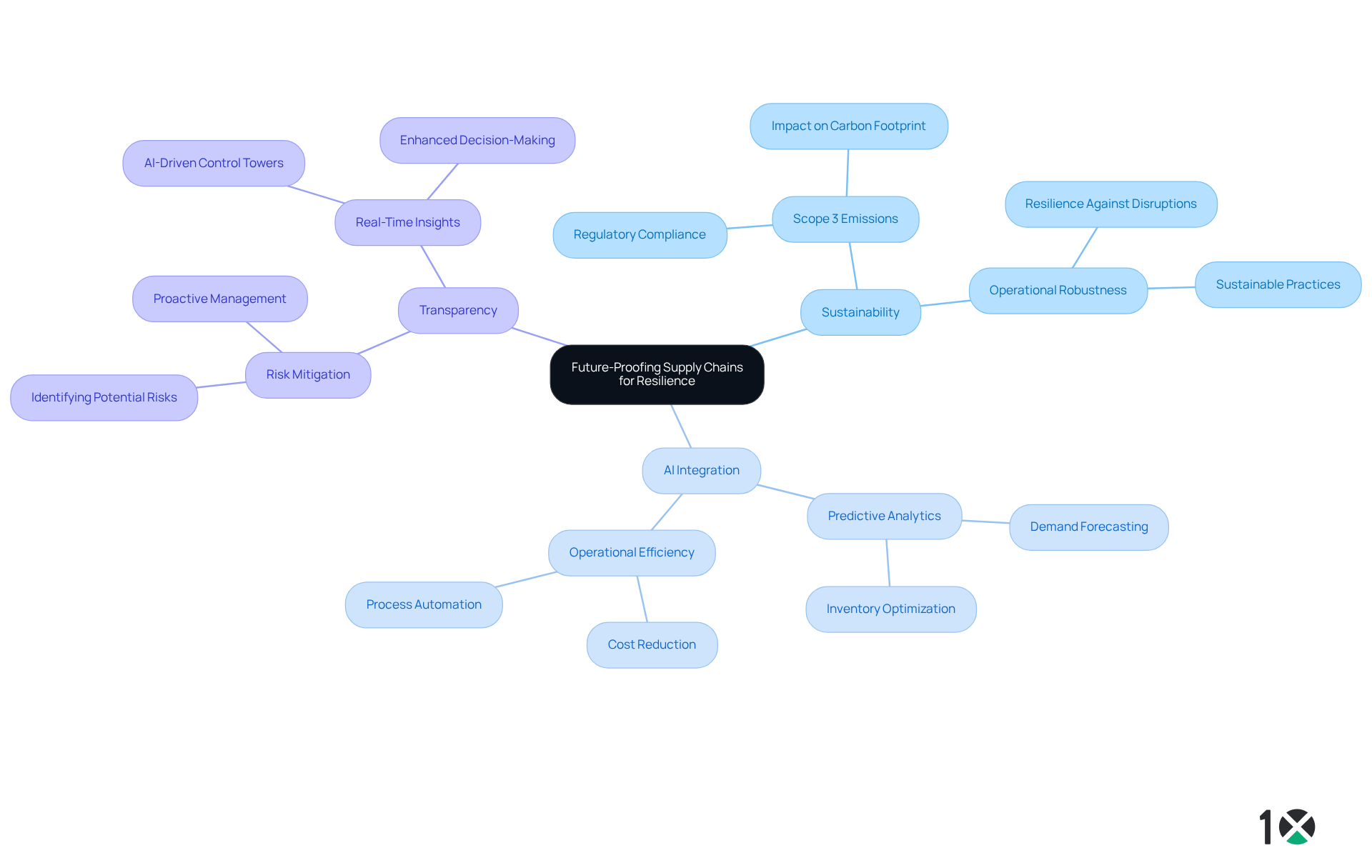

Present trends in logistics management underscore the necessity of future-proofing operations through strategic planning and the integration of advanced technologies. A significant focus on sustainability is increasingly recognized as a cornerstone of building a resilient supply chain in logistics. Companies are prioritizing sustainable practices not merely to comply with regulations but to bolster their operational robustness by developing a resilient supply chain against disruptions. For instance, Scope 3 emissions, which can account for up to 70% of a company’s overall carbon footprint, are emerging as a critical area of focus as organizations pursue transparency and accountability in their networks. Addressing these emissions is essential for companies aiming to enhance their sustainability initiatives and develop a resilient supply chain in logistics.

The incorporation of AI and machine learning represents another pivotal trend reshaping logistics. These technologies facilitate , thereby enhancing decision-making and operational efficiency. AI-driven platforms can forecast demand fluctuations, optimize inventory management, and refine logistics operations, significantly boosting the resilience of a resilient supply chain. Companies utilizing AI for predictive analytics have reported remarkable enhancements in their responsiveness to market changes, achieving operational efficiency gains of up to 50% in targeted tasks. The AI segment within the logistics market is projected to reach USD 50.01 billion by 2031, with a CAGR of 22.9%, underscoring the growing importance of these technologies in the sector.

Moreover, the emphasis on improved transparency within distribution networks is vital for identifying potential risks and mitigating disruptions. Organizations that deploy AI-driven control tower solutions can achieve real-time insights, empowering them to proactively tackle logistical challenges. As noted by industry experts, ‘Real-time decision-making by AI reduces risk and enhances customer satisfaction, service quality, and overall responsiveness of the logistics network.’

By aligning their strategies with these trends, organizations can create a resilient supply chain that is capable of withstanding present challenges while being well-prepared for future uncertainties. The retail and food & beverage sectors, significant end users of AI in supply chains, are anticipated to propel market growth, further highlighting the imperative for companies to embrace these advanced technologies.

Conclusion

Building a resilient supply chain is not merely a strategic advantage; it is a necessity for organizations aiming to thrive in an unpredictable market landscape. This article outlines ten essential strategies that businesses can adopt to enhance their supply chain resilience, emphasizing the critical importance of technology integration, collaboration, and proactive risk management. By implementing these practices, companies can effectively navigate disruptions and maintain a competitive edge.

Key insights from the article highlight the role of cloud-based ERP solutions, such as 10X ERP, in facilitating real-time data processing to improve operational efficiency. The integration of AI and advanced analytics, exemplified by IBM’s logistics solutions, enables organizations to anticipate challenges and optimize their logistics operations. Furthermore, fostering public-private partnerships and adopting vendor diversification strategies are crucial for establishing a robust supply chain capable of adapting to unforeseen circumstances.

Reflecting on the broader implications, it is evident that organizations must prioritize resilience in their supply chain strategies to safeguard against future uncertainties. Embracing advanced technologies, fostering collaboration, and continuously evaluating vulnerabilities will empower businesses to not only survive but thrive in a dynamic environment. As the logistics landscape evolves, the adoption of these strategies will be instrumental in building a resilient supply chain that meets the demands of tomorrow.

Frequently Asked Questions

What is 10X ERP and what are its main features?

10X ERP is a cloud-based system designed for distributors to manage logistics through real-time data processing. Its main features include customizable inventory management, seamless app integrations, and the ability to provide immediate insights into operations.

How does 10X ERP benefit businesses?

Businesses using 10X ERP have reported significant enhancements in operational efficiency, with 89% of ERP users identifying improved efficiency as a primary advantage. The platform enables informed decision-making and quick responses to market changes.

What is the projected demand for cloud-based ERP solutions by 2025?

By 2025, 53% of businesses are expected to prioritize ERP as a crucial investment, indicating a growing demand for cloud-based ERP solutions.

What role does real-time data play in supply chain management?

Real-time data is vital for building a resilient supply chain, as it allows organizations to navigate disruptions effectively and maintain a competitive edge.

How do IBM’s logistics solutions enhance agility and adaptability?

IBM’s logistics solutions utilize advanced analytics and artificial intelligence to help organizations anticipate disruptions and optimize logistics operations, creating a responsive system that adapts to market conditions.

What are the expected trends in logistics investments by 2025?

By 2025, 74% of logistics executives are expected to increase investments in automation and AI technologies, reflecting their importance in addressing challenges like labor shortages and visibility issues.

What financial benefits have been reported from implementing AI in logistics?

The implementation of AI in logistics management has led to reported savings of $388 million through reduced inventory costs and optimized shipping processes, with potential decreases in transportation expenses by 15%.

What is the projected market value of AI in logistics by 2030?

The AI logistics market is projected to reach $41.23 billion by 2030, highlighting the increasing significance of AI investments in the sector.

How can public-private partnerships strengthen supply chains?

Public-private partnerships enhance logistics by fostering cooperation between government entities and private companies, allowing for resource sharing, knowledge exchange, and improved operational efficiency.

What insights do industry leaders provide regarding logistical challenges?

Industry leaders emphasize the importance of proactive measures to address logistical challenges, highlighting that effective collaboration and strategic alliances are essential for sustainable resource management.

How do trade associations contribute to logistics and supply chain management?

Trade associations such as ISD, MWFA, SFA, and STAFDA enhance industry connections for distributors, providing valuable resources and insights that can strengthen cloud-based ERP solutions and real-time data processing capabilities.