Overview

Custom gaskets significantly enhance operational efficiency by providing tailored sealing solutions. These solutions not only reduce leaks but also minimize downtime and lower maintenance costs across various industries. Consider this: custom seals improve machinery performance, decrease energy consumption, and ensure compliance with safety regulations. Ultimately, these factors lead to increased productivity and substantial cost savings.

Incorporating custom gaskets into your operations can transform efficiency. By addressing specific sealing needs, businesses can prevent costly leaks and enhance the longevity of their machinery. This proactive approach not only safeguards equipment but also contributes to a more sustainable operational model.

As Operations Managers, the choice to implement custom gaskets is not just a decision; it’s a strategic move towards optimizing performance and achieving significant financial benefits. Are you ready to explore how these tailored solutions can revolutionize your operations?

Introduction

Custom gaskets are essential for enhancing operational efficiency across various industries. They seamlessly integrate with machinery to prevent leaks and optimize performance. By investing in these tailored sealing solutions, businesses can achieve significant cost savings and waste reduction while ensuring compliance with stringent regulatory standards.

But how can these custom solutions be effectively leveraged to tackle specific operational challenges and drive long-term success? This inquiry is crucial for any Operations Manager seeking to enhance their processes.

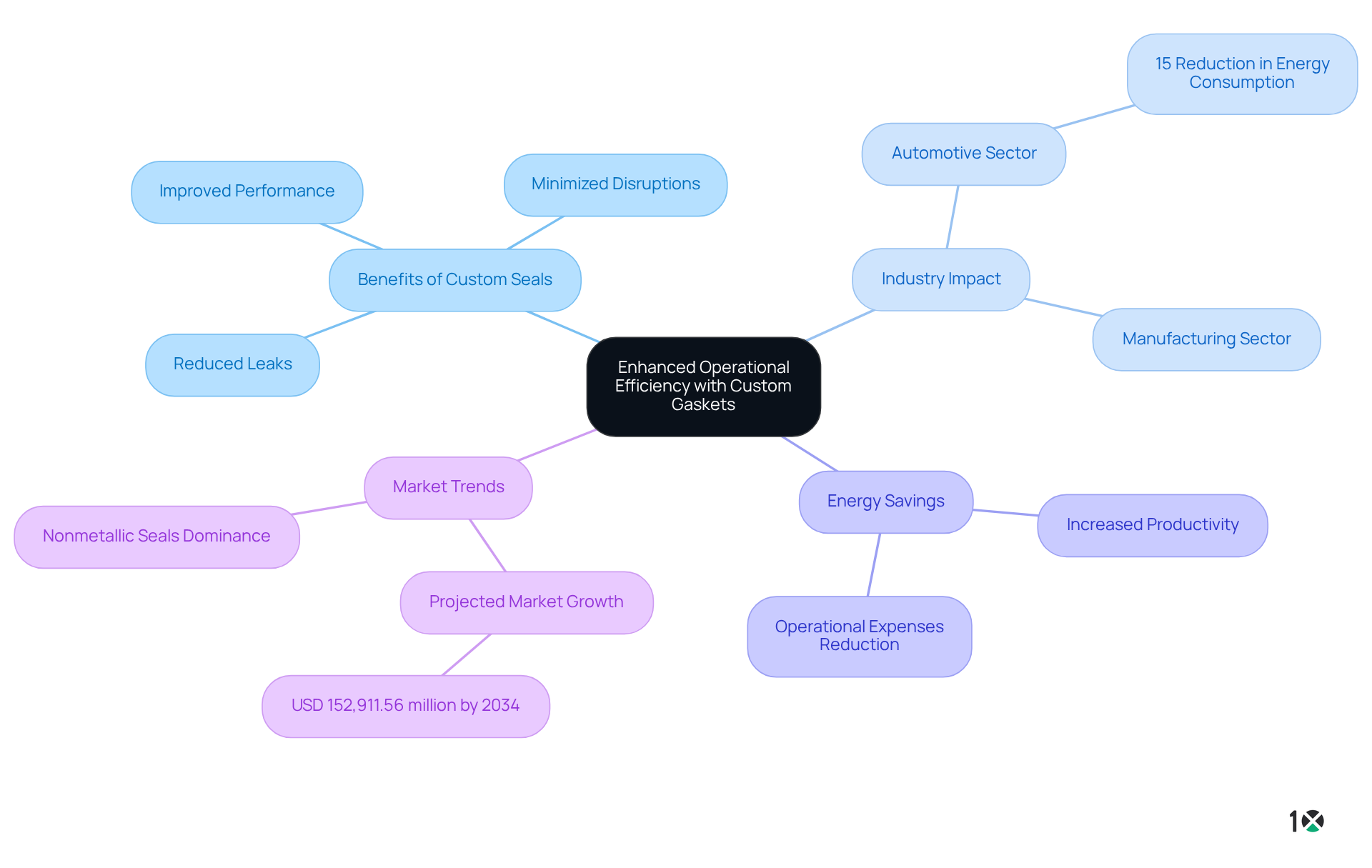

Enhanced Operational Efficiency with Custom Gaskets

Custom seals are meticulously engineered to match specific machinery and equipment, ensuring an optimal closure that significantly reduces leaks and enhances overall performance. This tailored approach not only leads to but also minimizes disruptions caused by seal failures.

For instance, in the automotive and manufacturing industries, the accurate fit of tailored seals can lead to significant decreases in energy usage and operational expenses. A case analysis from the automotive sector showed that applying custom seals resulted in a 15% reduction in energy consumption, leading to significant cost savings and enhanced productivity.

Moreover, industry leaders stress that the appropriate seal can improve machinery performance, with one expert mentioning that ‘custom seals are vital for preserving the integrity of high-performance machinery.’

The seal market is projected to rise to USD 152,911.56 million by 2034, indicating a growing demand for effective sealing solutions. Furthermore, nonmetallic seals represent the largest segment in the U.S. market, highlighting their significance in various applications.

By investing in tailored sealing solutions, manufacturers can attain enhanced operational efficiency and reliability, ultimately boosting productivity and profitability.

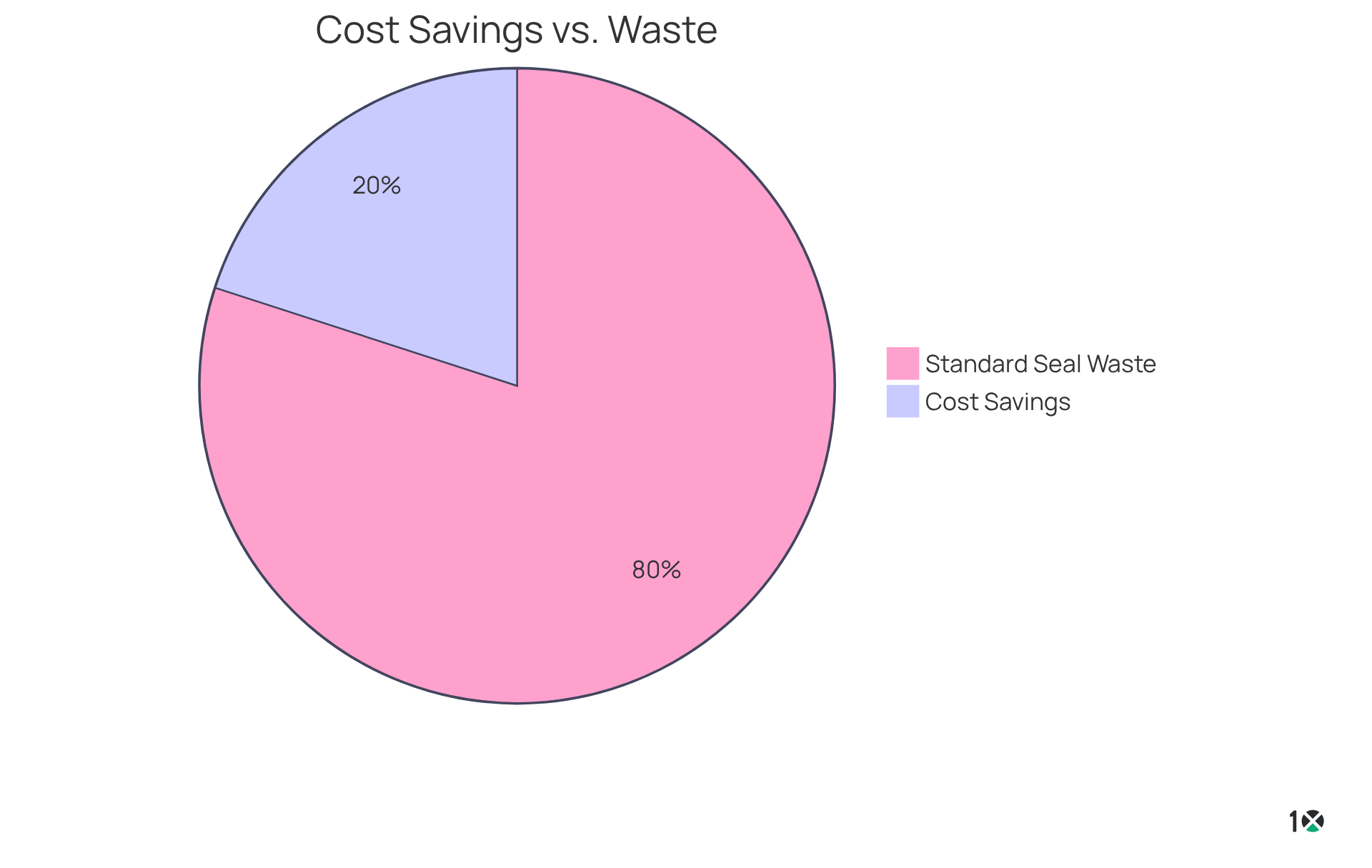

Cost Savings Through Waste Reduction with Custom Gaskets

Utilizing tailored seals allows companies to significantly while enhancing safety and promoting environmental conservation. Unlike standard seals, which often necessitate modifications and result in excess material waste, tailored seals are crafted to precise specifications. This approach guarantees that every component is effectively utilized, leading to a reduction in waste and the costs associated with purchasing and disposing of surplus materials.

For instance, producers transitioning to tailored seals can experience a reduction in material costs by as much as 20%, translating into substantial long-term savings. Additionally, tailored seals establish reliable barriers against gas or liquid leaks, preventing harmful fluid escapes and contributing to a more sustainable manufacturing process.

Through rigorous testing and quality control, these seals ensure high performance and reliability, further boosting operational efficiency. As one producer noted, ‘Transitioning to tailored seals not only lowered our material expenses but also enhanced our safety criteria and ecological impact.’

This comprehensive strategy underscores the critical role of tailored seals in modern operations.

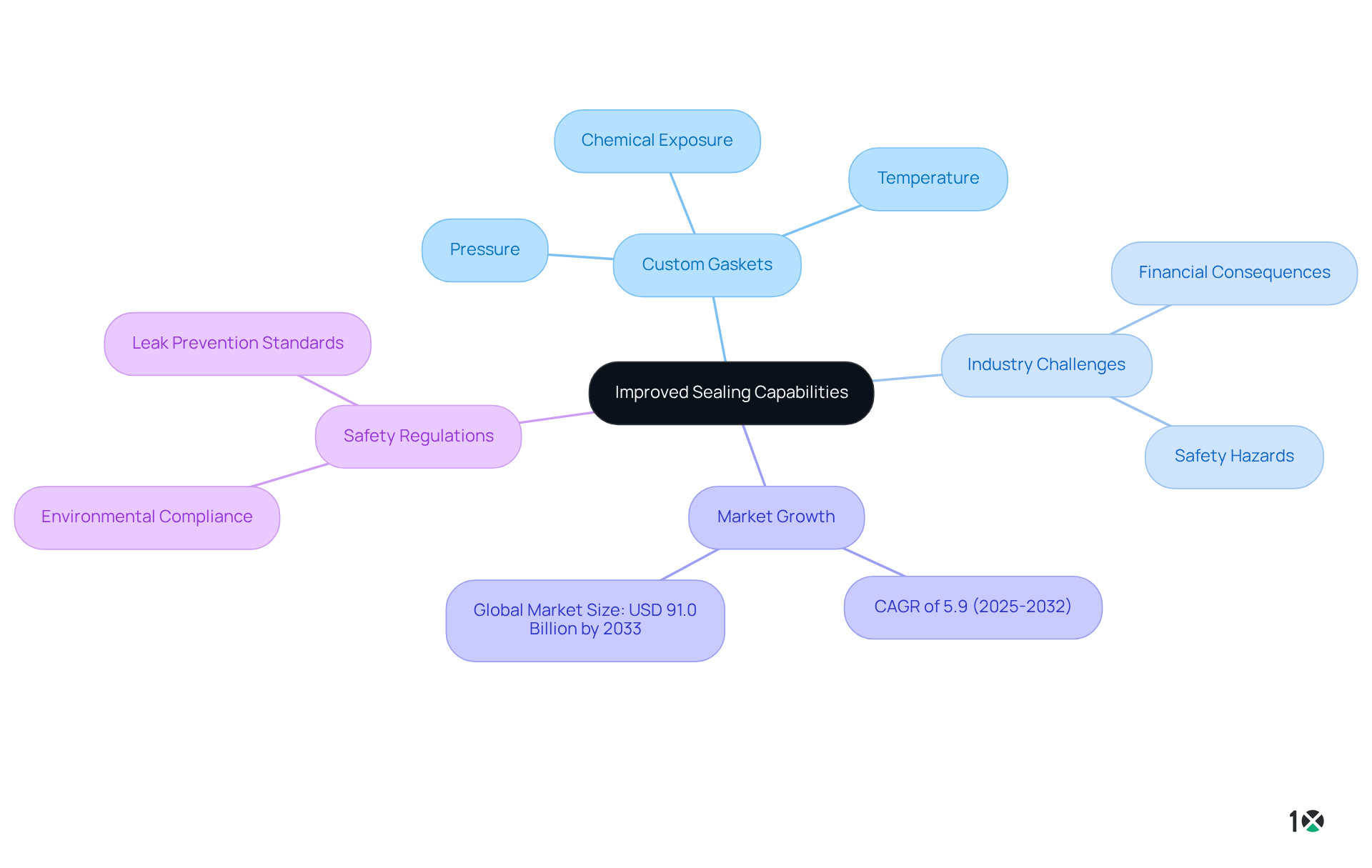

Improved Sealing Capabilities for Reliable Operations

Custom gaskets are carefully crafted to deliver exceptional sealing capabilities that are tailored to specific working conditions, such as differing pressures, temperatures, and chemical exposures. This level of , particularly with custom gaskets, is crucial in high-stakes sectors like oil and gas, where even minor leaks can lead to severe safety hazards and significant financial consequences. For instance, the oil and gas industry encounters considerable challenges in operations, with leaks potentially resulting in losses that can surpass millions of dollars each year.

According to industry reports, the global seals market is anticipated to expand at a CAGR of 5.9% from 2025 to 2032, emphasizing the rising need for dependable sealing solutions. Regulatory bodies underscore the necessity of reliable sealing solutions to maintain safety standards and prevent environmental damage. By investing in tailored seals, businesses not only improve their efficiency but also guarantee adherence to strict safety regulations. This investment is vital for protecting their assets and reputation, ensuring long-term operational success.

Tailored Solutions for Specific Operational Needs with Custom Gaskets

Custom gaskets are meticulously engineered to meet the precise demands of diverse applications, including high-pressure systems, extreme temperatures, and specific chemical environments. This tailored approach empowers companies to effectively tackle their with custom gaskets.

In the food processing industry, for example, specially designed seals crafted from food-safe materials are crucial for preventing contamination and adhering to stringent health standards. Industry insights reveal that seal failure rates in food processing equipment average 12-15% annually; however, the implementation of custom gaskets can significantly reduce these rates, thereby enhancing overall operational efficiency.

This adaptability positions custom gaskets as essential components for organizations aiming to refine their processes and ensure compliance in a competitive landscape. Moreover, the custom gaskets segment is anticipated to expand at a CAGR of 4.1%, reaching a market value of USD 10.6 billion by 2028, underscoring the growing significance of these solutions.

As Geoff Dunn, Product Marketing Manager at Tillsonburg, articulates, “Food and beverage is a key growth area for us; with our outstanding products, commitment to quality control, and now NSF 51 certification, we are poised to be the industry benchmark.

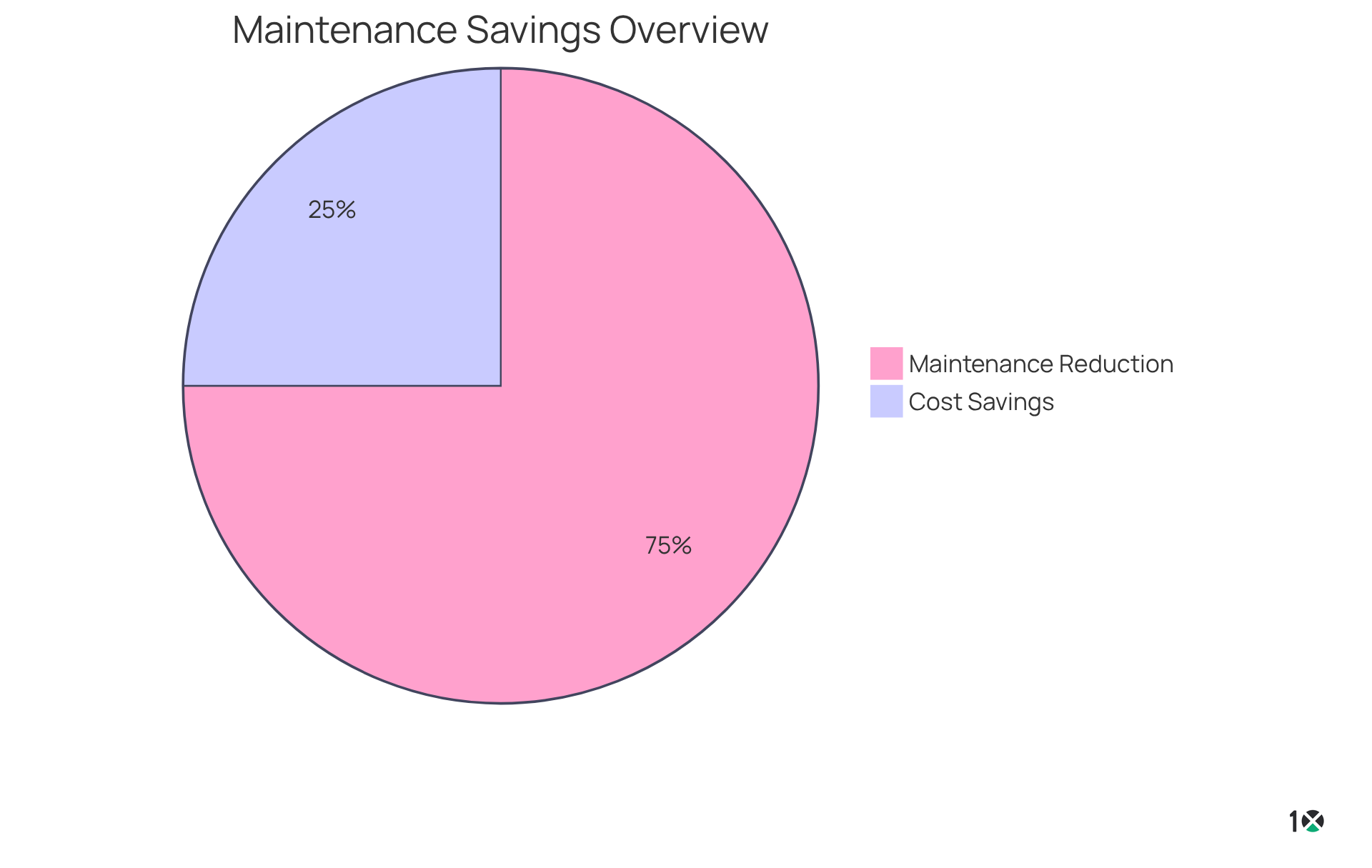

Increased Durability Leading to Reduced Maintenance

Tailored seals, crafted from high-quality materials, significantly enhance longevity, enabling them to endure severe operating environments. This remarkable durability translates into an extended service life compared to standard seals, resulting in a notable decrease in replacement frequency and substantial .

For instance, businesses adopting tailored seals can experience up to a 30% reduction in maintenance frequency, leading to lower labor costs and minimized downtime. Furthermore, predictive maintenance can yield cost savings of 8% to 12% compared to preventive maintenance, underscoring the financial benefits of investing in superior tailored seals.

Maintenance supervisors have reported that utilizing these durable sealing solutions not only streamlines their processes but also boosts overall efficiency. As one maintenance manager noted, ‘The dependability of tailored seals has transformed our maintenance strategy, allowing us to focus on critical tasks rather than routine replacements.’

This decrease in maintenance frequency conserves financial resources and empowers maintenance teams to direct their efforts toward other essential operational activities.

Versatile Applications Across Multiple Industries with Custom Gaskets

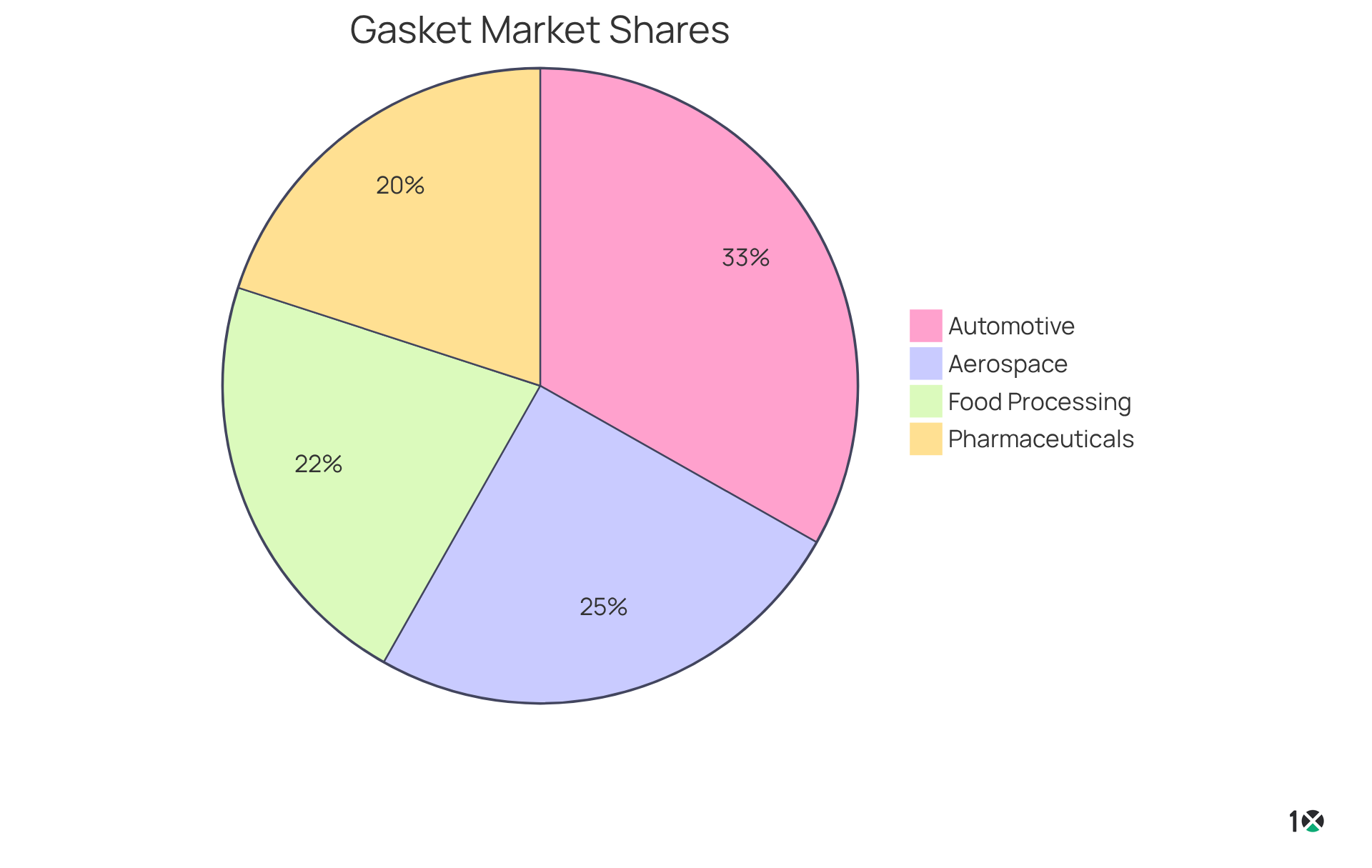

Custom gaskets are indispensable across various sectors, including automotive, aerospace, pharmaceuticals, and food processing, due to their adaptability to specific requirements. In the automotive industry, tailored seals are essential for enhancing engine performance and preventing leaks—critical for preserving efficiency and safety. Notably, the automotive sector accounted for the largest market revenue share of 33.2% in 2023, underscoring the significance of these specialized seals. As the automotive sector transitions towards electrification, the demand for multi-functional seals is on the rise, necessitating innovative sealing solutions for battery packs and effective thermal management.

In the pharmaceutical sector, tailored seals play a vital role in maintaining sterile conditions, crucial for adhering to strict health regulations. The customizable nature of custom gaskets enhances their value proposition, making them essential for maintaining product integrity and safety.

The global market for seals and related products is projected to reach USD 63.08 billion in 2024 and USD 75.83 billion in 2025, reflecting the increasing demand for tailored seals. The broadens their market presence and reinforces their importance in industries that require precision and reliability. As industry leaders emphasize, ‘Continuous innovation in sealing materials and designs is essential for addressing the changing needs of these sectors,’ ensuring that custom gaskets remain pivotal to operational efficiency.

Regulatory Compliance Support Through Custom Gasket Solutions

Custom seals are meticulously engineered to meet stringent regulatory standards, particularly those established by the FDA for food and pharmaceutical applications. By utilizing materials that comply with these safety regulations, businesses not only safeguard product integrity but also mitigate the risk of substantial fines associated with non-compliance.

For instance, seals used in food processing must adhere to specific FDA regulations to effectively prevent contamination, thereby ensuring that the final products are safe for consumption. This not only shields the business from potential legal repercussions but also enhances its reputation in the marketplace, fostering trust among consumers and stakeholders alike.

As compliance officers emphasize, the importance of tailored seal materials cannot be overstated; they are vital for maintaining operational efficiency and regulatory adherence in today’s competitive environment.

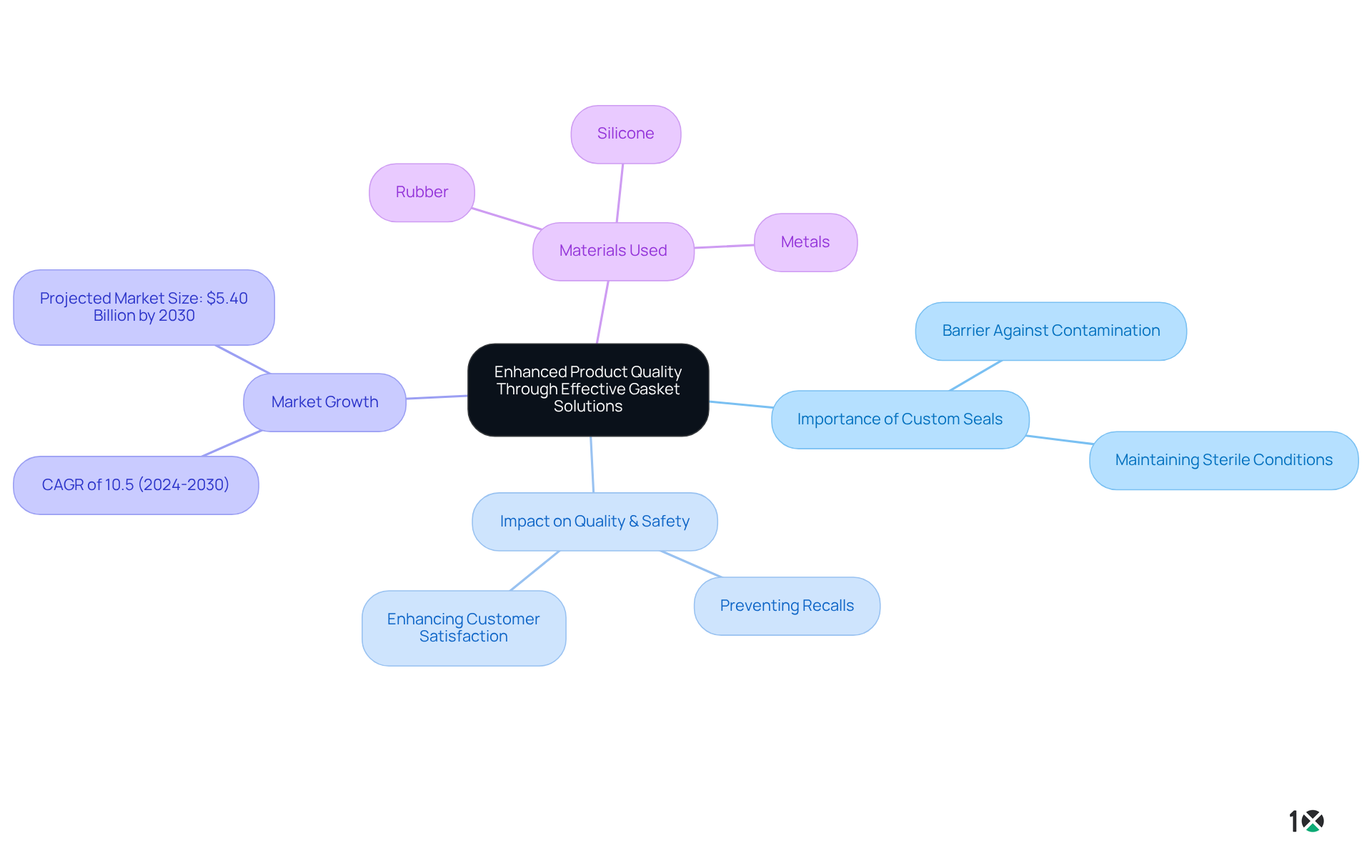

Enhanced Product Quality Through Effective Gasket Solutions

Custom seals are vital in ensuring the quality of pharmaceutical products, acting as a reliable barrier against leaks and contamination. This is especially critical for maintaining sterile conditions, which are essential for product integrity. The pharmaceutical sector relies heavily on tailored seals to uphold stringent quality standards, as even minor breaches can lead to significant safety concerns and regulatory hurdles. Alarmingly, statistics reveal that over 4,500 batches of pharmaceutical products are recalled each year due to contamination and process failures, highlighting the necessity for effective sealing solutions.

Quality assurance experts emphasize that the reliability of seals has a direct impact on the overall quality of pharmaceutical products. A well-crafted seal not only aligns with customer expectations but also cultivates brand loyalty and trust. By effectively preventing contamination, tailored seals ensure that products remain safe and effective, ultimately enhancing customer satisfaction.

With the market for projected to grow significantly, boasting a compound annual growth rate of 10.5% from 2024 to 2030, the demand for high-quality sealing solutions, including custom gaskets, is poised to rise, underscoring their indispensable role in the industry. Additionally, materials such as rubber, silicone, and metals are commonly employed in the manufacture of these seals, further enhancing their efficacy in preserving product integrity.

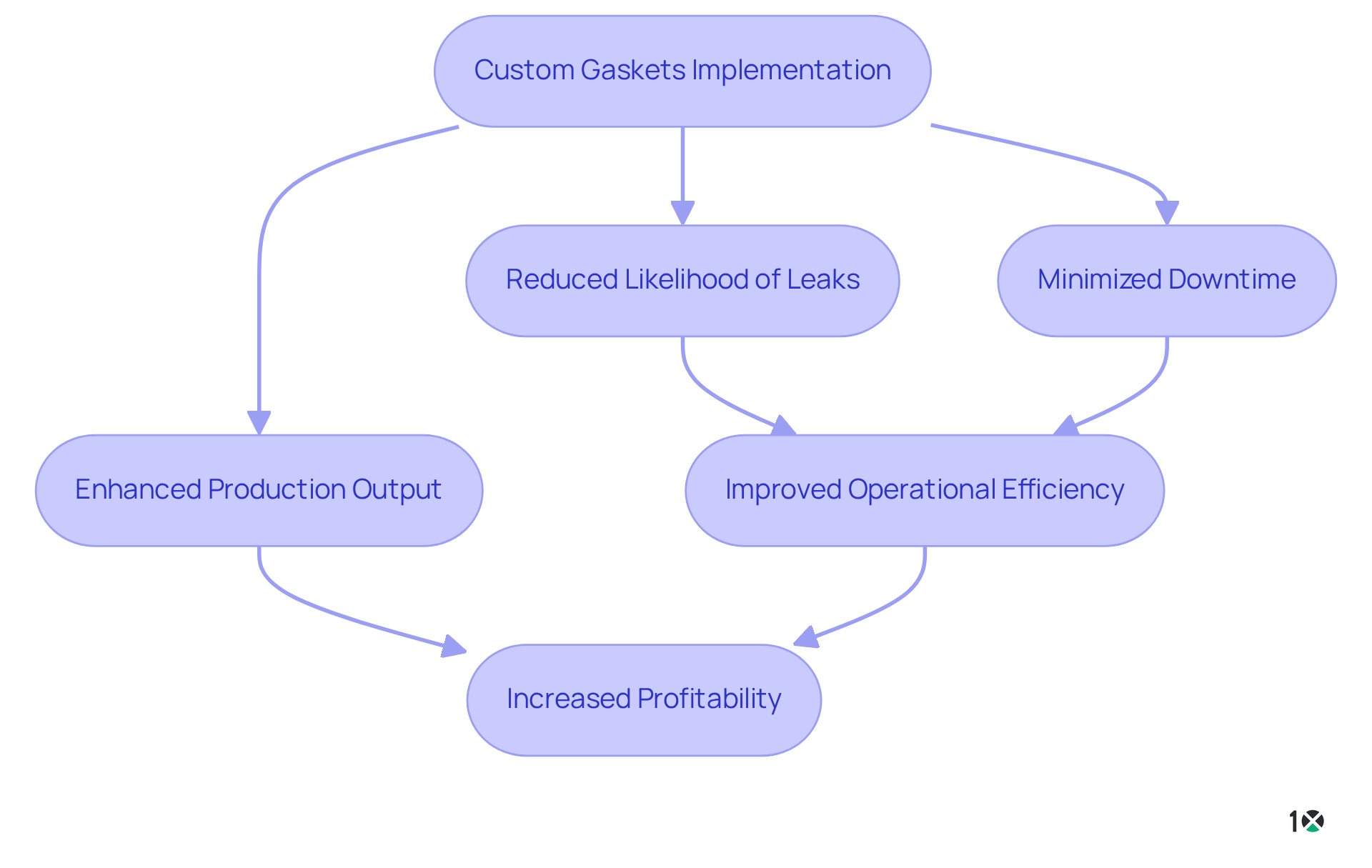

Minimized Downtime with Reliable Custom Gasket Solutions

Custom gaskets are designed to provide dependable sealing solutions that significantly reduce the likelihood of leaks and failures. This reliability is essential for , enabling machinery to operate continuously without disruptions from gasket-related complications.

For instance, a manufacturing plant that transitioned to custom seals reported a substantial reduction in unplanned downtime, which directly correlated with enhanced production output and profitability. In critical sectors such as automotive and aerospace, where every operational minute counts, the impact of seal reliability on production efficiency is paramount.

Operations managers consistently assert that improved seal performance leads to smoother workflows and heightened overall productivity, highlighting the necessity of investing in custom gaskets. As one operations manager noted, “Dependable seals have revolutionized our production line, significantly decreasing downtime and enhancing our output.”

Moreover, with 82% of businesses encountering unexpected interruptions, the importance of customized seals in mitigating such challenges becomes increasingly evident.

10X ERP: Streamlining Operations with Custom Gasket Integration

Incorporating tailored seals into an ERP system like 10X ERP significantly enhances operational efficiency. By leveraging the ERP framework to monitor seal usage, inventory levels, and maintenance schedules, businesses can streamline their supply chain processes and reduce costs. For example, real-time information on sealing component performance enables informed purchasing decisions, ensuring that businesses maintain optimal inventory levels. This integration not only boosts operational efficiency but also fosters improved decision-making and resource allocation.

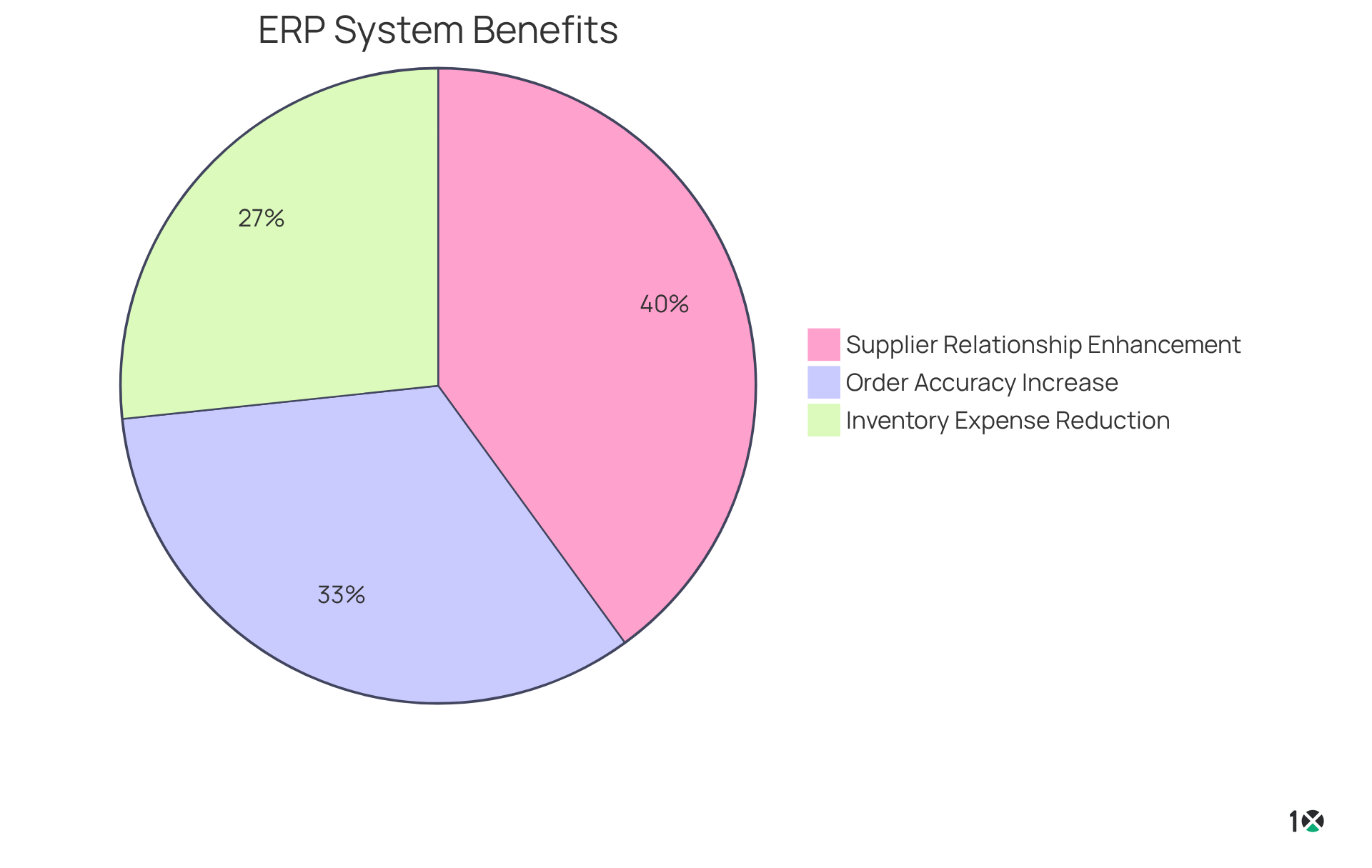

Statistics reveal that efficient inventory management via ERP can reduce inventory expenses by as much as 20%. Companies utilizing ERP systems experience a 25% increase in order accuracy and a 30% enhancement in supplier relationship management, underscoring the critical role of real-time insights in effective inventory management. Operations managers have noted that access to real-time data is vital for optimizing management, as it allows for timely adjustments and proactive maintenance, ultimately leading to increased productivity and reduced downtime.

As one operations manager articulated, ‘Real-time data transforms how we manage our custom gaskets, allowing us to respond swiftly to changes and maintain efficiency.’ This perspective highlights the of real-time data in operational strategies, encouraging businesses to adopt such systems for sustained success.

Conclusion

Custom gaskets are essential for enhancing operational efficiency across various industries. By providing tailored solutions that fit specific machinery and environmental conditions, these seals ensure optimal performance, reduce leaks, and minimize downtime. Investing in custom gaskets not only improves machinery performance but also leads to significant cost savings through reduced material waste and maintenance requirements.

The article highlights key benefits of custom gaskets, including their ability to enhance sealing capabilities, support regulatory compliance, and improve product quality. Their versatility allows them to meet the unique needs of industries such as automotive, pharmaceuticals, and food processing. Additionally, integrating custom gaskets within ERP systems can streamline operations, facilitating better inventory management and decision-making processes.

In conclusion, adopting custom gaskets is crucial for businesses aiming to boost operational efficiency and profitability. By prioritizing tailored sealing solutions, organizations can enhance their performance and contribute to sustainable practices and regulatory adherence. Embracing these innovations is vital for maintaining a competitive edge in today’s fast-paced market, ultimately fostering long-term success and reliability.

Frequently Asked Questions

What are custom gaskets and their purpose?

Custom gaskets are specially engineered seals designed to fit specific machinery and equipment, ensuring optimal closure that reduces leaks and enhances overall performance.

How do custom gaskets improve operational efficiency?

Tailored gaskets lead to smoother operations and minimize disruptions caused by seal failures, resulting in decreased energy usage and operational expenses.

Can you provide an example of cost savings from using custom gaskets?

In the automotive sector, applying custom seals resulted in a 15% reduction in energy consumption, leading to significant cost savings and enhanced productivity.

What is the projected growth of the seal market?

The seal market is projected to rise to USD 152,911.56 million by 2034, indicating a growing demand for effective sealing solutions.

What advantages do tailored seals offer in terms of waste reduction?

Tailored seals minimize material waste by being crafted to precise specifications, which leads to a reduction in waste and associated costs from purchasing and disposing of surplus materials.

How much can producers save by transitioning to tailored seals?

Producers can experience a reduction in material costs by as much as 20% when transitioning to tailored seals, resulting in substantial long-term savings.

Why are custom gaskets important in high-stakes industries like oil and gas?

Custom gaskets provide exceptional sealing capabilities tailored to specific conditions, which is crucial in preventing leaks that can lead to severe safety hazards and significant financial losses.

What is the expected growth rate of the global seals market from 2025 to 2032?

The global seals market is anticipated to expand at a CAGR of 5.9% from 2025 to 2032, highlighting the rising need for dependable sealing solutions.

How do tailored seals contribute to safety and environmental conservation?

Tailored seals establish reliable barriers against gas or liquid leaks, enhancing safety and promoting environmental conservation by preventing harmful fluid escapes.