Overview

This article highlights ten essential benefits of supply chain management that significantly enhance distributors’ efficiency. Key advantages include:

- Improved inventory management

- Precise demand forecasting

- Stronger supplier relationships

These benefits are further amplified by the capabilities of the 10X ERP system, which offers:

- Real-time data processing

- Streamlined communication

- Robust analytics

Such features empower suppliers to make informed decisions, reduce costs, and ultimately elevate customer satisfaction and operational agility.

By leveraging the 10X ERP system, distributors can transform their operations. Real-time data processing allows for immediate insights, while streamlined communication fosters collaboration among supply chain partners. Robust analytics provide the necessary tools for accurate demand forecasting, enabling distributors to align inventory levels with market needs. Consequently, these enhancements lead to a more agile and responsive supply chain.

In conclusion, adopting effective supply chain management practices, supported by advanced ERP solutions like 10X, is crucial for distributors aiming to thrive in a competitive landscape. Embracing these strategies not only improves operational efficiency but also positions businesses to meet evolving customer demands with confidence.

Introduction

In an increasingly competitive marketplace, the efficiency of supply chain management has emerged as a critical factor for distributors seeking to thrive. By leveraging advanced technologies like 10X ERP, companies can unlock a multitude of benefits that enhance operational performance, streamline processes, and ultimately drive profitability. However, the challenge lies in understanding how these tools can be effectively utilized to meet the dynamic demands of the market.

What specific advantages does supply chain management offer? How can distributors harness these benefits to not only survive but excel?

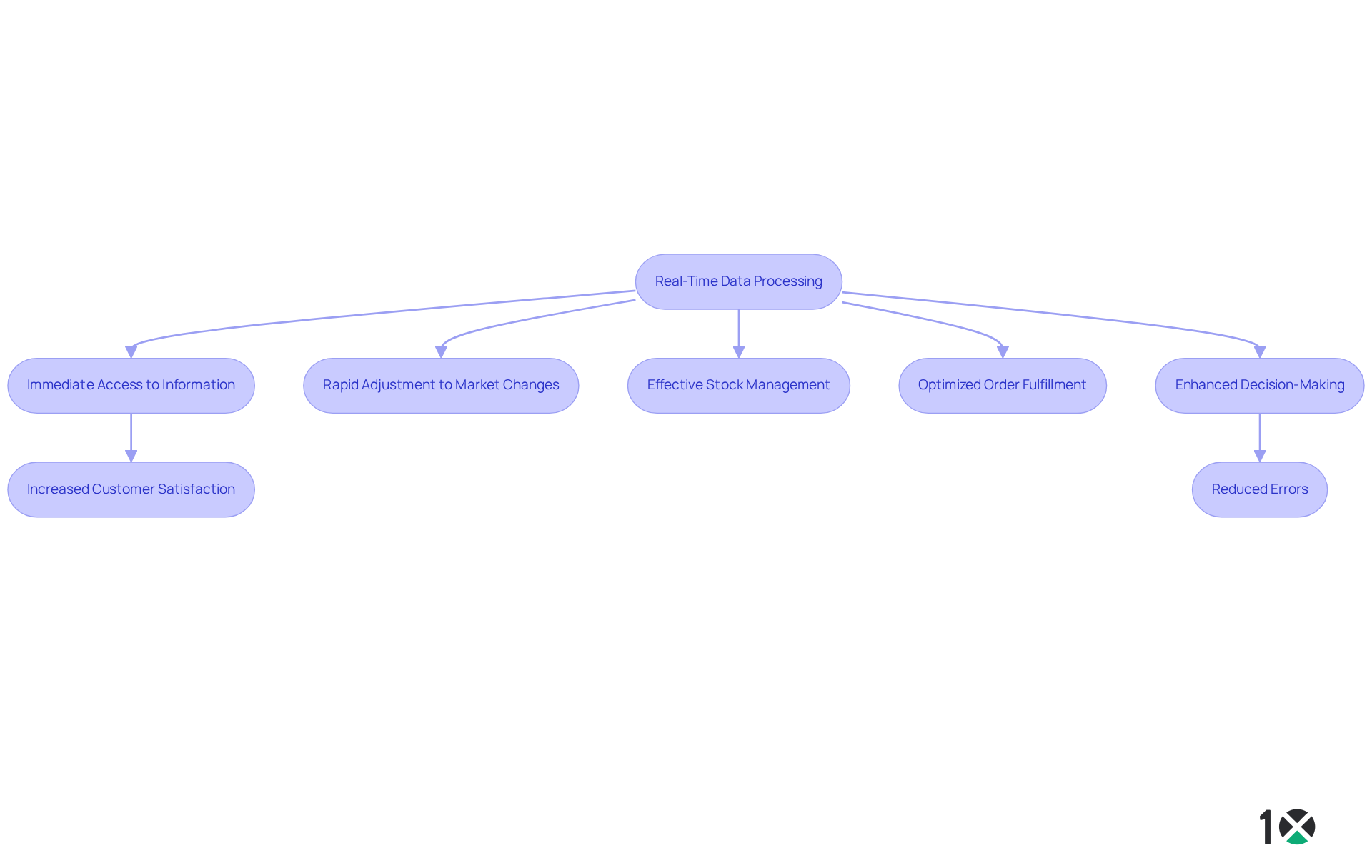

10X ERP: Streamline Operations with Real-Time Data Processing

10X ERP empowers suppliers with a modern, cloud-based platform that offers real-time data processing, enabling immediate access to critical information from any device. This capability facilitates rapid adjustment to market fluctuations, effective stock management, and optimized order fulfillment processes. By harnessing real-time insights, suppliers can significantly enhance their decision-making capabilities, ensuring competitiveness in a rapidly evolving market.

For instance, when a supplier identifies a sudden increase in demand for a particular product, they can swiftly modify stock levels and supply orders to satisfy customer expectations without hesitation. This agility is crucial for maintaining high customer satisfaction and operational efficiency.

Moreover, the real-time data processing feature of 10X ERP reduces the likelihood of errors linked to manual data entry, resulting in more accurate reporting and forecasting. With over 75% of organizations acknowledging that untimely data has led to missed business opportunities, the importance of real-time insights cannot be overstated. Additionally, the flexible user permissions and roles, along with a complete audit trail, further enhance operational control and accountability. By incorporating real-time data analysis, suppliers can proactively oversee their operations, ultimately fostering growth and improving overall performance.

Improved Inventory Management: Optimize Stock Levels and Reduce Costs

10X ERP revolutionizes chain supply management by providing suppliers with essential tools for monitoring stock levels, managing reorder points, and assessing turnover rates. The platform’s flexible features and lot/serial tracking capabilities provide comprehensive visibility into stock, which is essential for effective chain supply management and empowers suppliers to make informed, data-driven decisions. Furthermore, customizable user permissions and roles guarantee that stakeholders can access necessary information while ensuring security and control over sensitive data.

For instance, by analyzing sales trends, a supplier can identify slow-moving items and adapt purchasing strategies accordingly. This proactive approach in chain supply management minimizes excess stock and associated costs, which ultimately improves cash flow and allows companies to reinvest in growth opportunities. The integrated reporting capabilities further bolster decision-making processes, enabling stakeholders to harness real-time data for strategic planning.

Moreover, the integration of stock management with real-time data processing in chain supply management enables suppliers to swiftly respond to shifts in demand, significantly enhancing operational efficiency. Consequently, effective stock management not only streamlines operations but also contributes to increased profitability, establishing it as a fundamental pillar of success in the distribution sector.

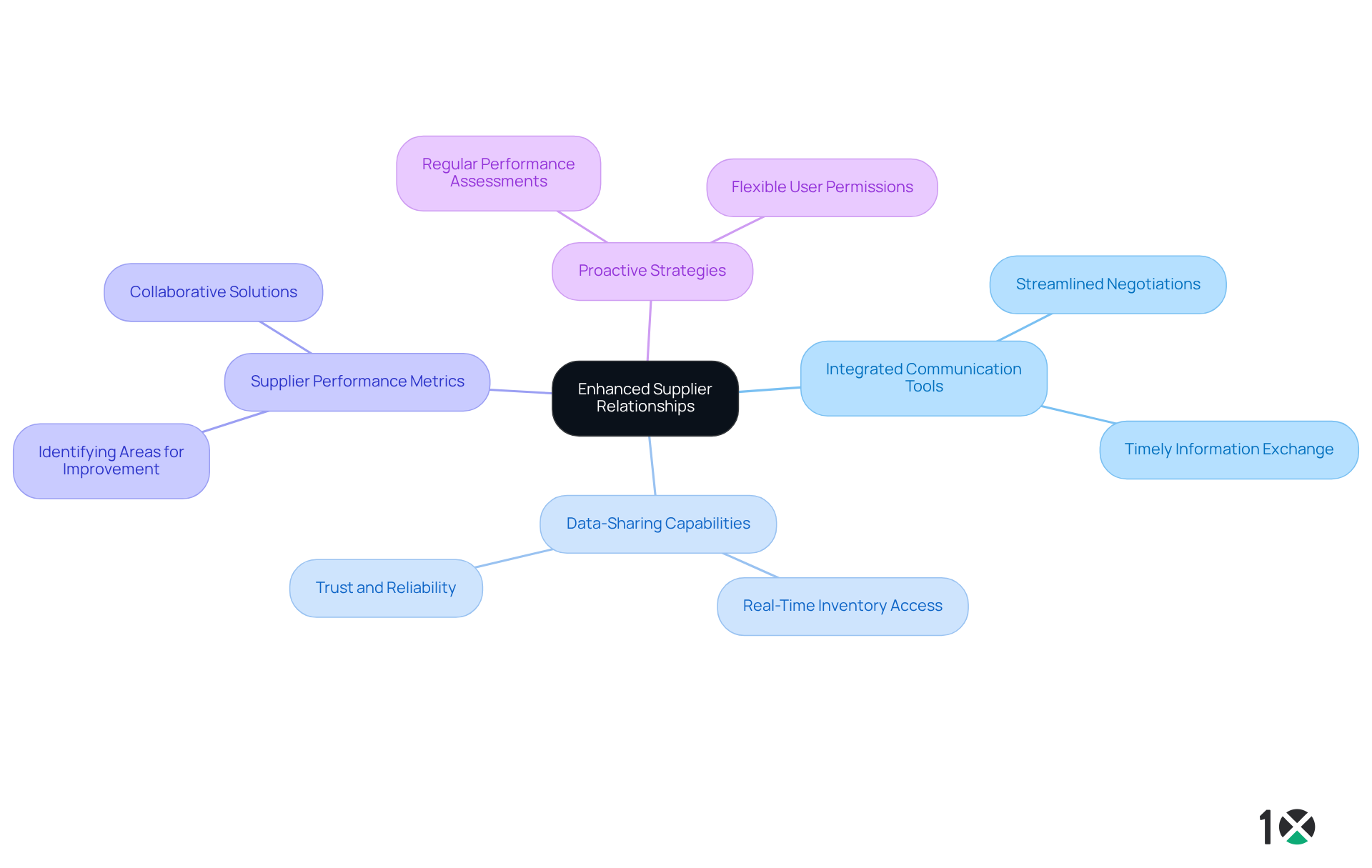

Enhanced Supplier Relationships: Strengthen Negotiation and Reliability

10X ERP significantly enhances supplier relationships through its integrated communication tools and robust data-sharing capabilities. By providing a centralized platform for managing supplier interactions, it enables suppliers to streamline negotiations and facilitate timely information exchange. Access to real-time inventory information empowers wholesalers to negotiate more advantageous terms with suppliers, leveraging precise demand forecasts. This level of transparency fosters trust and reliability, ultimately leading to stronger partnerships.

Moreover, monitoring supplier performance metrics allows wholesalers to pinpoint areas for enhancement and collaborate on effective solutions. This proactive approach not only solidifies relationships but also boosts overall chain supply management efficiency. Additionally, the flexible user permissions and roles feature ensures that all stakeholders have immediate access to necessary information, enhancing decision-making and operational efficiency. To maximize these benefits, providers should regularly assess supplier performance metrics and adjust their strategies accordingly.

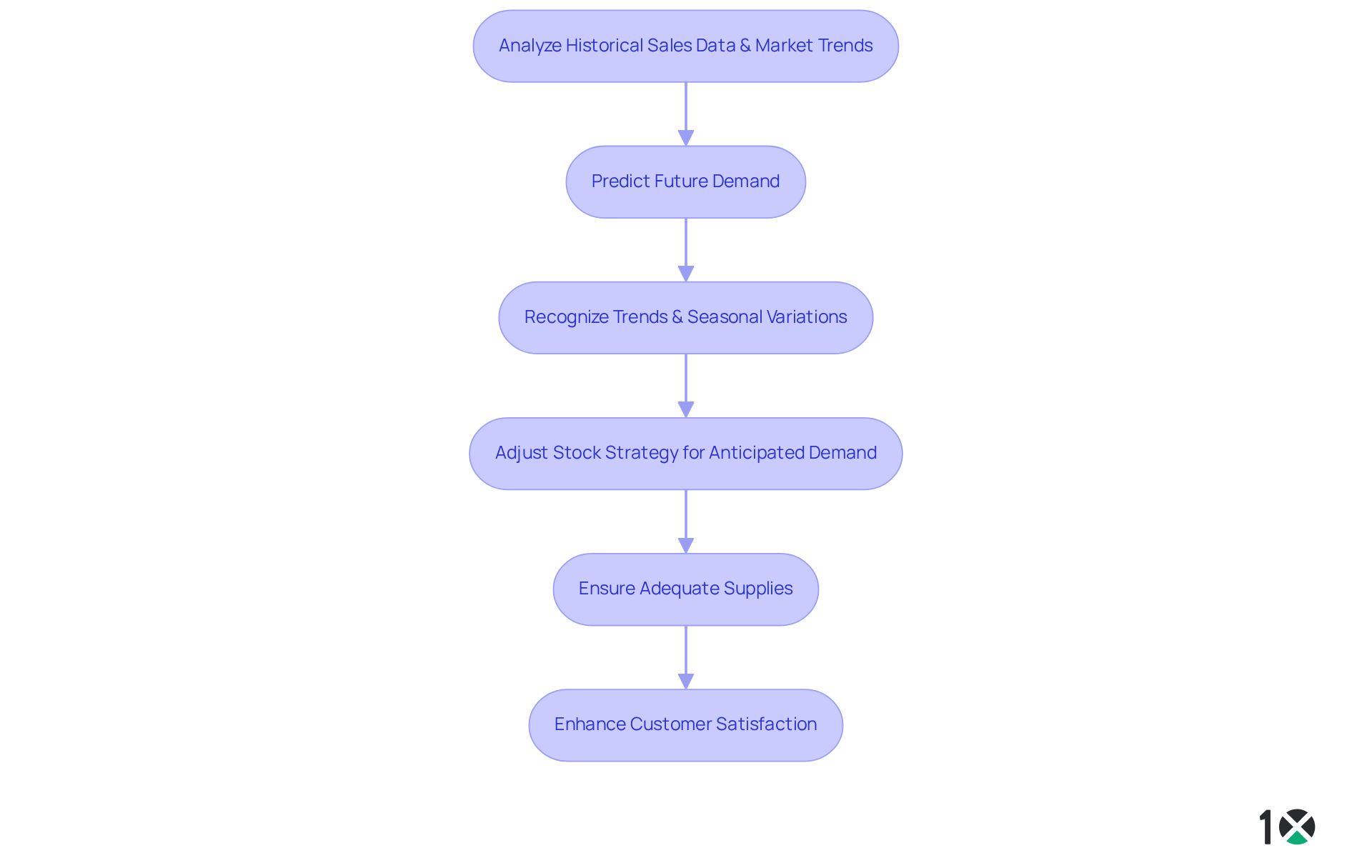

Accurate Demand Forecasting: Align Inventory with Market Needs

10X ERP leverages sophisticated demand forecasting tools that analyze historical sales data and market trends to accurately predict future demand. By recognizing trends and seasonal variations, suppliers can efficiently align their stock levels with real market demands. The robust accounting capabilities of 10X ERP—featuring real-time data processing, integrated reporting, adaptable user permissions and roles, and a comprehensive audit trail—enable stakeholders to make informed decisions based on current stock status.

For instance, when a supplier anticipates a spike in demand for a seasonal item, they can proactively adjust their stock strategy, ensuring adequate supplies to meet customer expectations. This foresight not only minimizes the risk of stockouts but also significantly enhances customer satisfaction.

Moreover, accurate demand forecasting, supported by 10X ERP’s customizable monitoring and lot/serial item tracking capabilities, empowers suppliers to make informed purchasing decisions, thereby reducing excess stock and associated carrying costs. By adopting a proactive approach to inventory alignment, suppliers can navigate market dynamics more effectively, ensuring they remain competitive and responsive to customer demands.

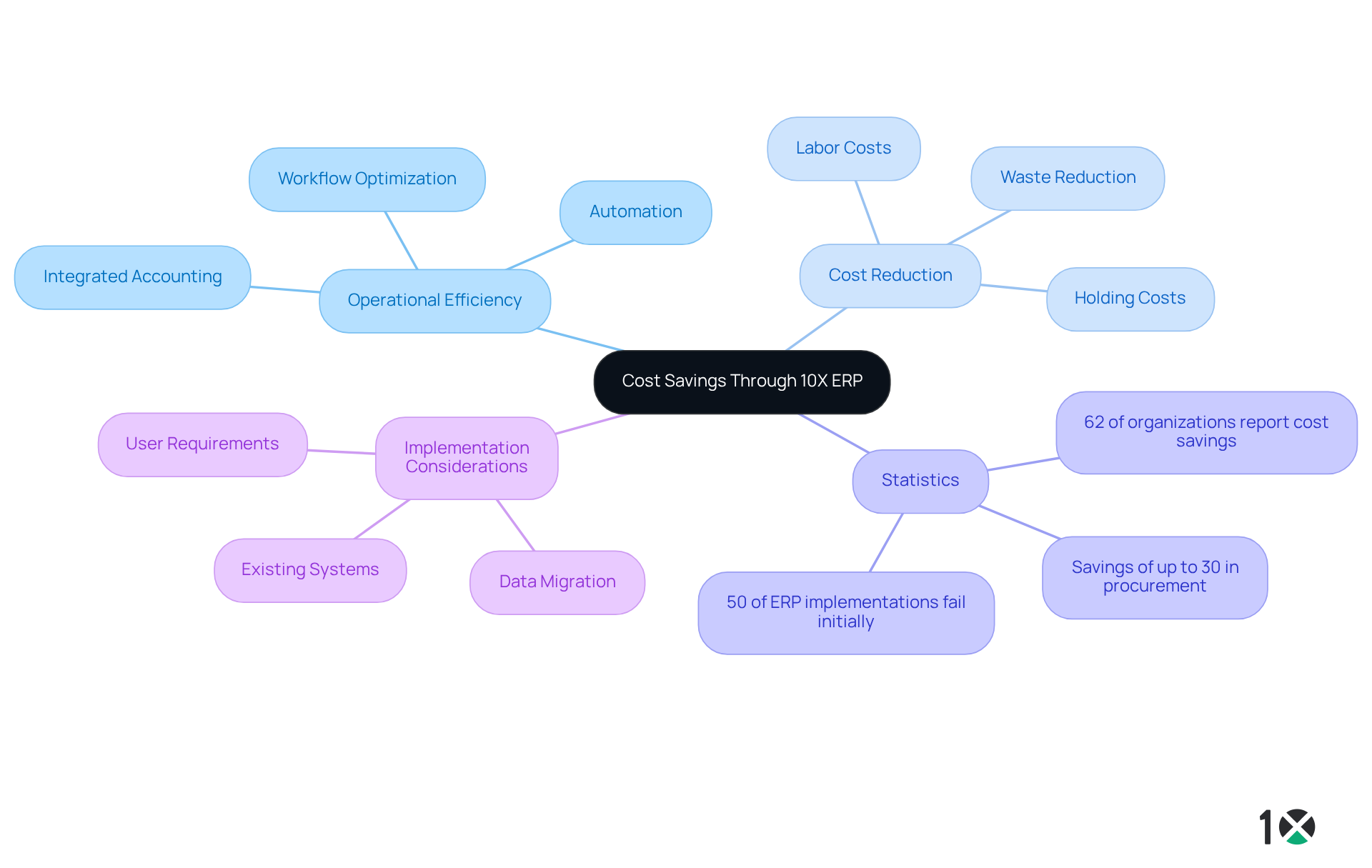

Cost Savings: Achieve Operational Efficiency and Reduce Waste

Implementing 10X ERP empowers suppliers to realize substantial cost savings by enhancing operational efficiency and reducing waste. With a transparent and predictable pricing structure that encompasses all-inclusive functionality and features, businesses can invest in the platform with confidence. By automating routine tasks and optimizing workflows, companies can significantly decrease labor costs while boosting productivity.

For instance, the platform’s integrated accounting features facilitate real-time tracking of expenses and revenues, enabling suppliers to identify areas ripe for cost reduction. This capability is crucial, given that 62% of organizations report that their ERP systems lead to cost savings, particularly in procurement and stock management. Furthermore, by minimizing surplus stock and improving order accuracy, suppliers can effectively reduce holding costs and waste, with ERP systems yielding savings of up to 30% in these areas.

The operational efficiencies achieved through 10X ERP, featuring Best-in-Class Cloud-Hosting and Continuous Data Backup, not only drive significant cost reductions but also enhance a supplier’s competitive edge in a rapidly evolving market. Essential implementation considerations—such as existing systems, data migration, and user requirements—must be carefully addressed to facilitate smooth adoption. However, it is vital to recognize that 50% of ERP implementations fail in their initial attempt, underscoring the importance of meticulous planning and execution. As companies increasingly prioritize the integration of their chain supply management with ERP systems, the potential for enhanced efficiency and profitability becomes even more pronounced.

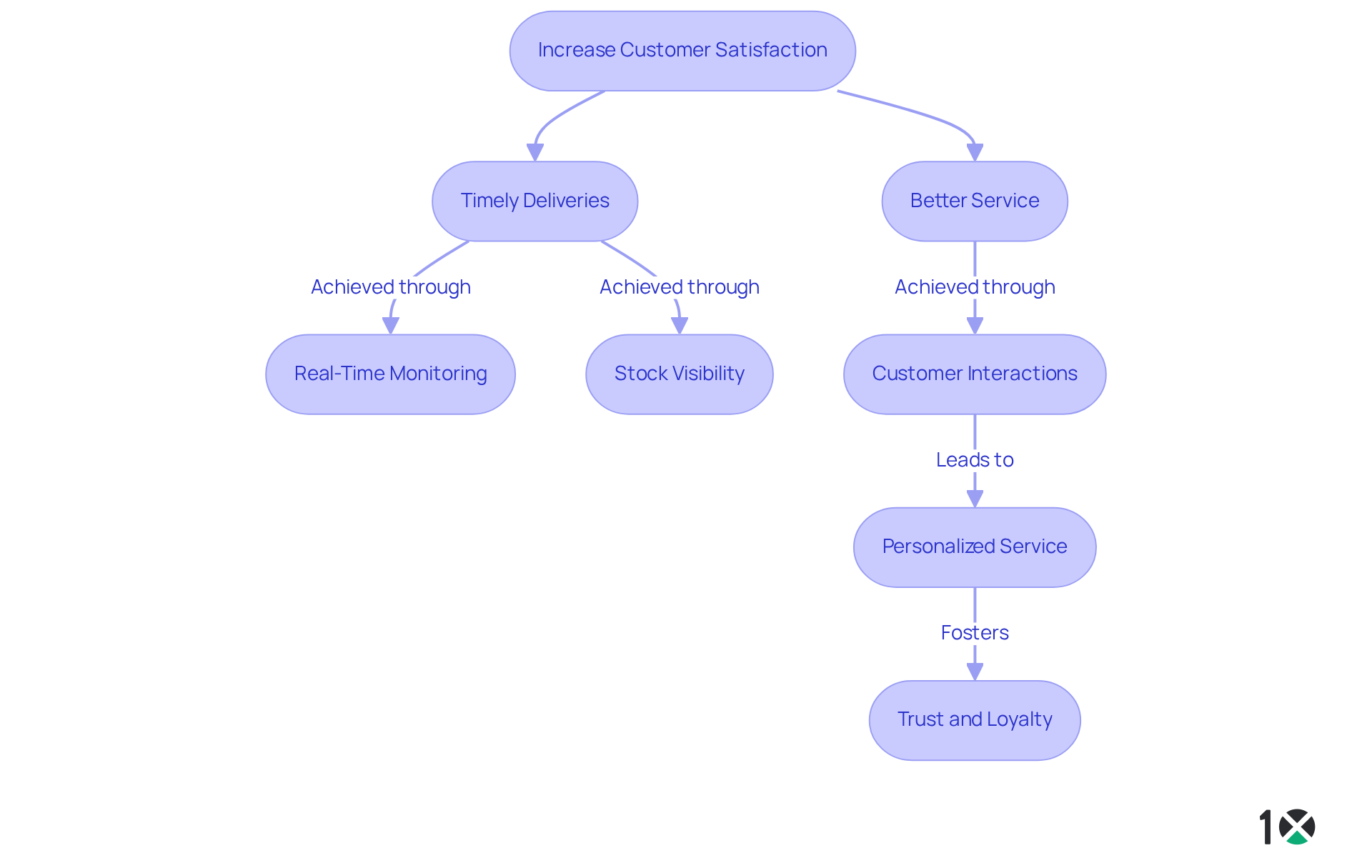

Increased Customer Satisfaction: Ensure Timely Deliveries and Better Service

10X ERP significantly enhances customer satisfaction by prioritizing timely deliveries and superior service. By leveraging real-time monitoring and comprehensive stock visibility, suppliers can effectively manage orders through chain supply management, leading to shorter lead times and improved fulfillment precision. For example, when a customer places an order, suppliers can quickly check inventory levels and provide accurate delivery estimates. This transparency not only fosters trust but also elevates the overall customer experience.

Moreover, the platform’s robust customer relationship management (CRM) features empower suppliers to track customer interactions and preferences. This capability allows for personalized service, which is vital for cultivating loyalty and encouraging repeat business. In fact, companies that implement effective CRM strategies often experience a significant boost in customer retention, as timely deliveries and attentive service become key differentiators in a competitive market.

By harnessing technology to streamline processes—including swift onboarding and seamless integrations—suppliers can consistently meet customer expectations, ultimately enhancing satisfaction and loyalty. Furthermore, with 10X ERP’s transparent pricing structure and comprehensive software features, suppliers can easily grasp the value they receive, thereby enriching their overall experience.

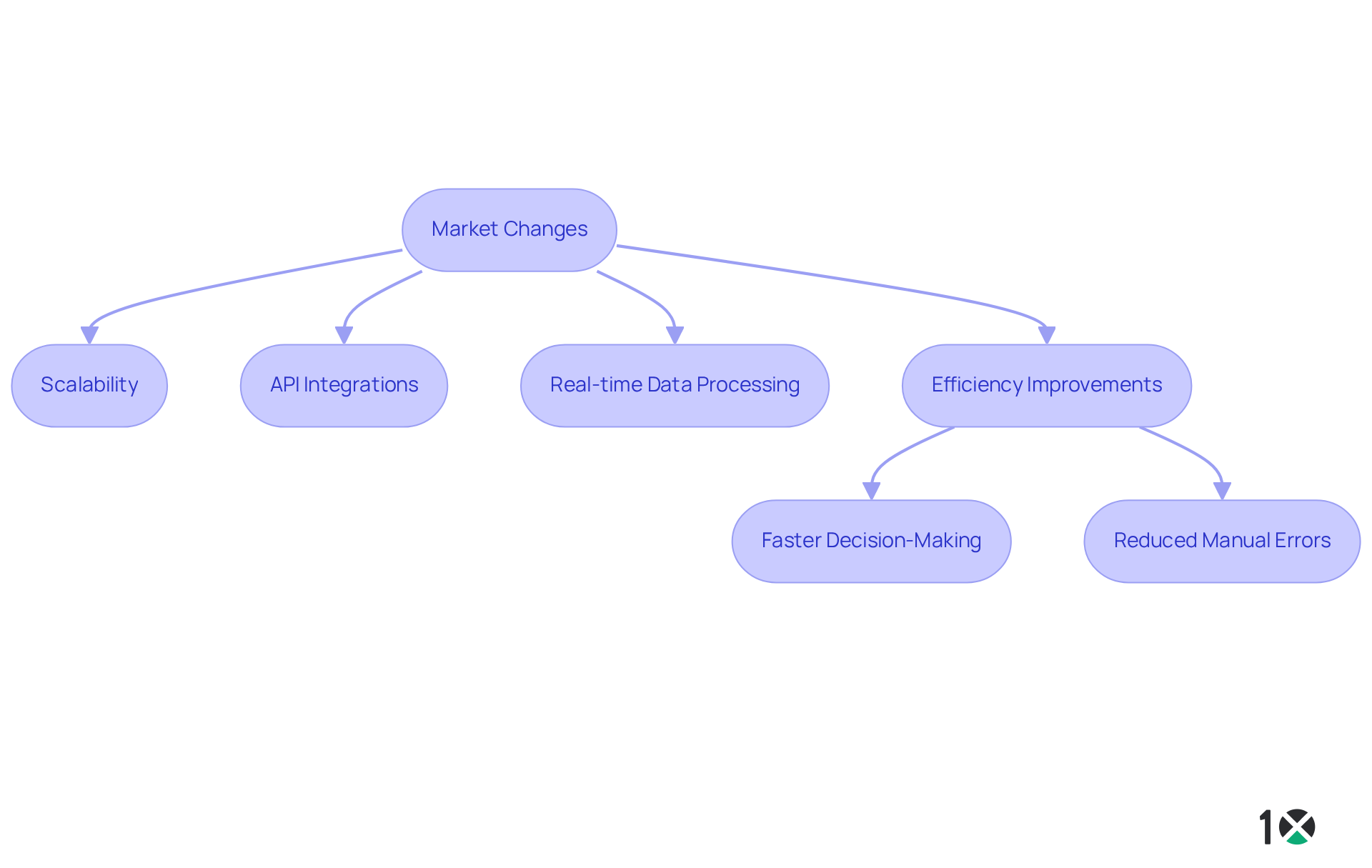

Scalability: Adapt to Market Changes Without Compromising Quality

10X ERP is meticulously crafted for scalability, empowering suppliers to swiftly adapt to market fluctuations without sacrificing quality. As businesses grow, they can effortlessly integrate additional users, features, and functionalities, ensuring the platform evolves in tandem with their operational requirements. The cloud-based architecture of 10X ERP facilitates continuous updates and enhancements in chain supply management, ensuring that suppliers benefit from the latest features and capabilities—an essential factor for maintaining high service levels while efficiently scaling operations.

For instance, when a supplier ventures into new markets, they can promptly recalibrate their inventory management and reporting functionalities to meet the surging demand. This level of adaptability is vital for sustaining exceptional service levels in chain supply management while effectively scaling operations. Notably, small businesses utilizing ERP technology experience decision-making speeds that are 36% faster than prior to adoption, underscoring the operational efficiency that 10X ERP can deliver.

Furthermore, the platform’s seamless API integrations and real-time data processing capabilities enhance chain supply management, enabling businesses to respond swiftly to market dynamics and customer expectations. As Margus Raude observes, “These systems deliver real-time data and reporting tools, enabling businesses to react swiftly to market shifts and customer demands.” Additionally, a case study involving a mid-sized distribution company that integrated its CRM, warehouse management, and ERP systems using 10X ERP revealed a 25% decrease in manual errors and an overall enhancement in efficiency, showcasing the tangible advantages of such adaptability.

To fully harness the flexibility of 10X ERP, operations managers should prioritize regular assessments of their operational needs and leverage the platform’s features, including its transparent pricing model and expedited onboarding process, to align with evolving market demands.

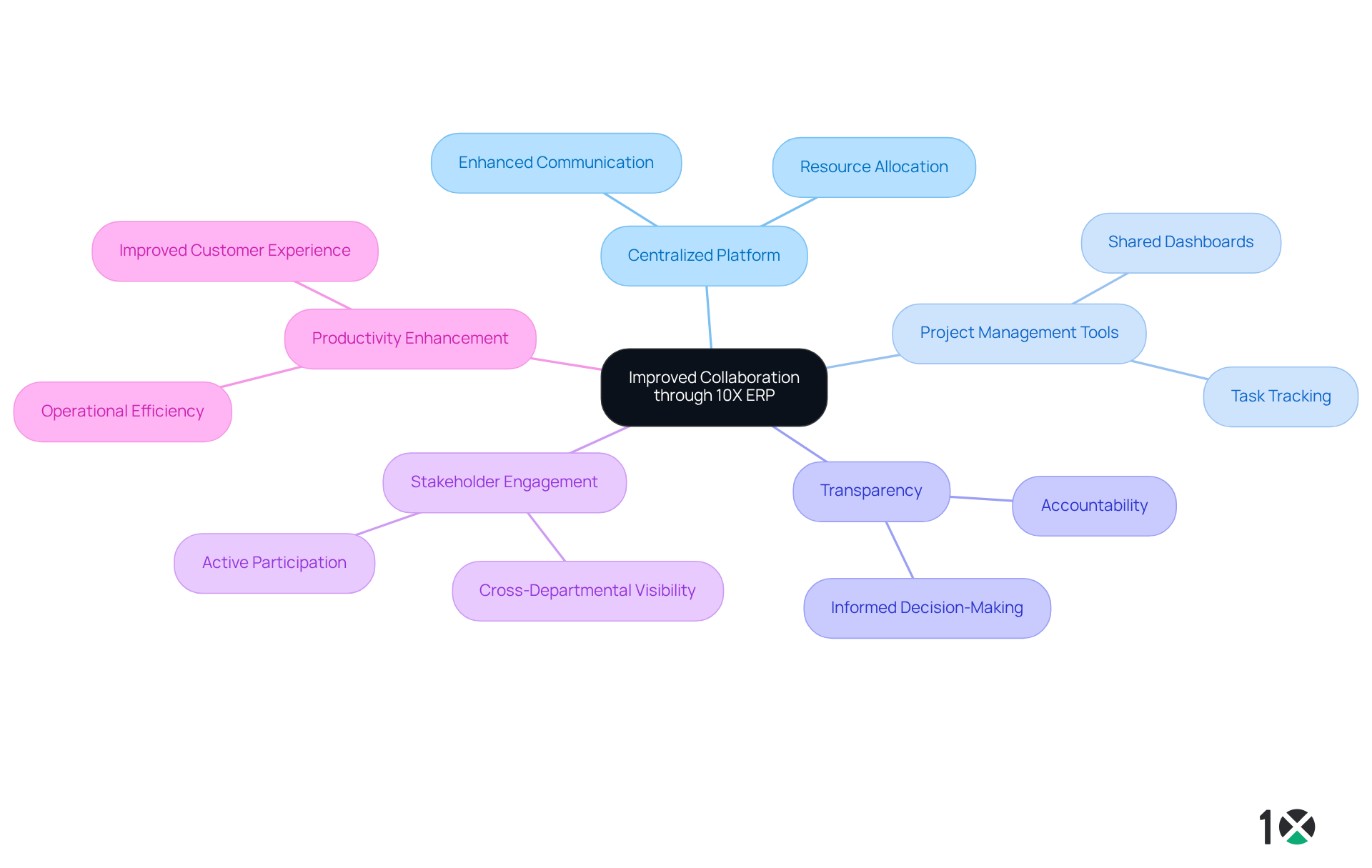

Improved Collaboration: Enhance Communication and Resource Allocation

10X ERP significantly enhances collaboration among teams by providing a centralized platform for communication and resource allocation. Integrated project management and task tracking tools allow suppliers to streamline teamwork, ensuring alignment on goals and objectives. Shared dashboards and reporting tools grant teams immediate access to critical information, facilitating informed decision-making and effective resource allocation. This transparency fosters a culture of collaboration and accountability, essential for operational efficiency.

Moreover, the integration of data across departments ensures that all stakeholders remain informed and can actively participate in the decision-making process. This interconnectedness not only improves communication but also drives productivity; 66% of organizations report enhanced operational efficiency following ERP implementation. By leveraging these centralized communication tools, along with adaptable user permissions and roles, suppliers can refine their processes and cultivate a more unified working environment. To further enhance collaboration, suppliers should evaluate their current communication tools and explore how 10X ERP can integrate and elevate their existing systems.

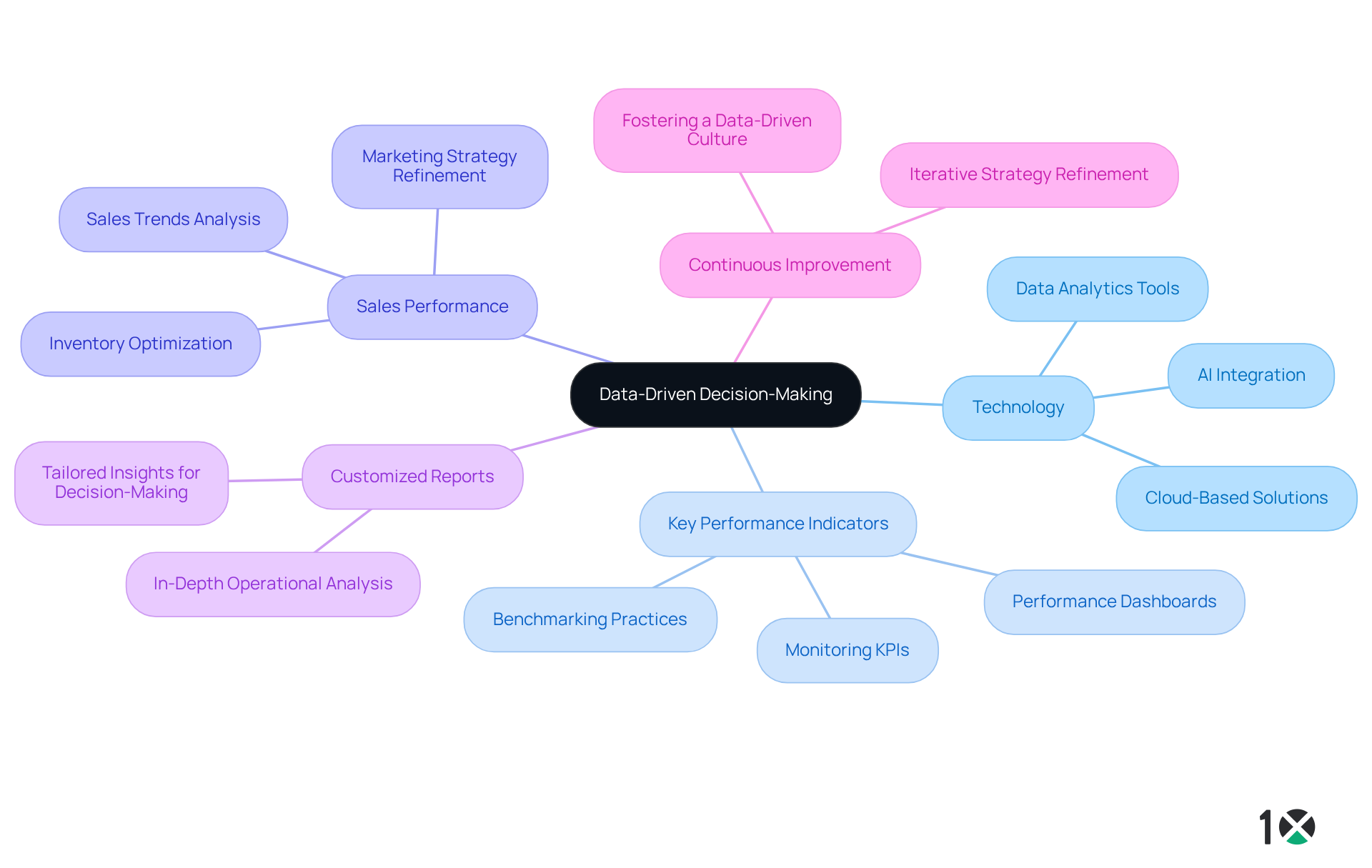

Data-Driven Insights: Leverage Technology for Informed Decision-Making

10X ERP equips suppliers with powerful data analytics tools that facilitate informed decision-making through technology. By examining key performance indicators (KPIs) and operational metrics, businesses can identify trends and target areas for improvement.

For instance, suppliers can monitor sales performance across various product categories, enabling them to refine marketing strategies and optimize inventory levels. This data-driven approach ensures that decisions are founded on precise information rather than mere intuition, leading to more effective strategies and enhanced outcomes.

Moreover, the capability to generate customized reports allows suppliers to analyze their operations in greater depth, fostering a culture of continuous improvement. By harnessing technology in this way, suppliers can elevate their operational insights, ultimately propelling performance and efficiency.

Risk Mitigation: Identify Disruptions and Ensure Business Continuity

10X ERP is pivotal in risk mitigation, equipping suppliers with advanced tools to identify potential disruptions and ensure business continuity. Through real-time data processing and monitoring, complemented by alert systems, suppliers can swiftly address issues like stock shortages or disruptions in chain supply management. For example, when a supplier encounters delays, the platform promptly notifies the retailer, enabling proactive measures—such as securing alternative sources or adjusting stock strategies—to minimize operational impact.

The platform’s robust accounting features—including flexible user permissions, a comprehensive audit trail, and built-in reporting—empower suppliers to analyze historical disruptions. This capability allows them to devise informed strategies to avert similar challenges in the future. Moreover, the adaptable tracking and lot/serial item tracking features ensure that suppliers have precise visibility of their inventory at all times, enhancing operational flexibility.

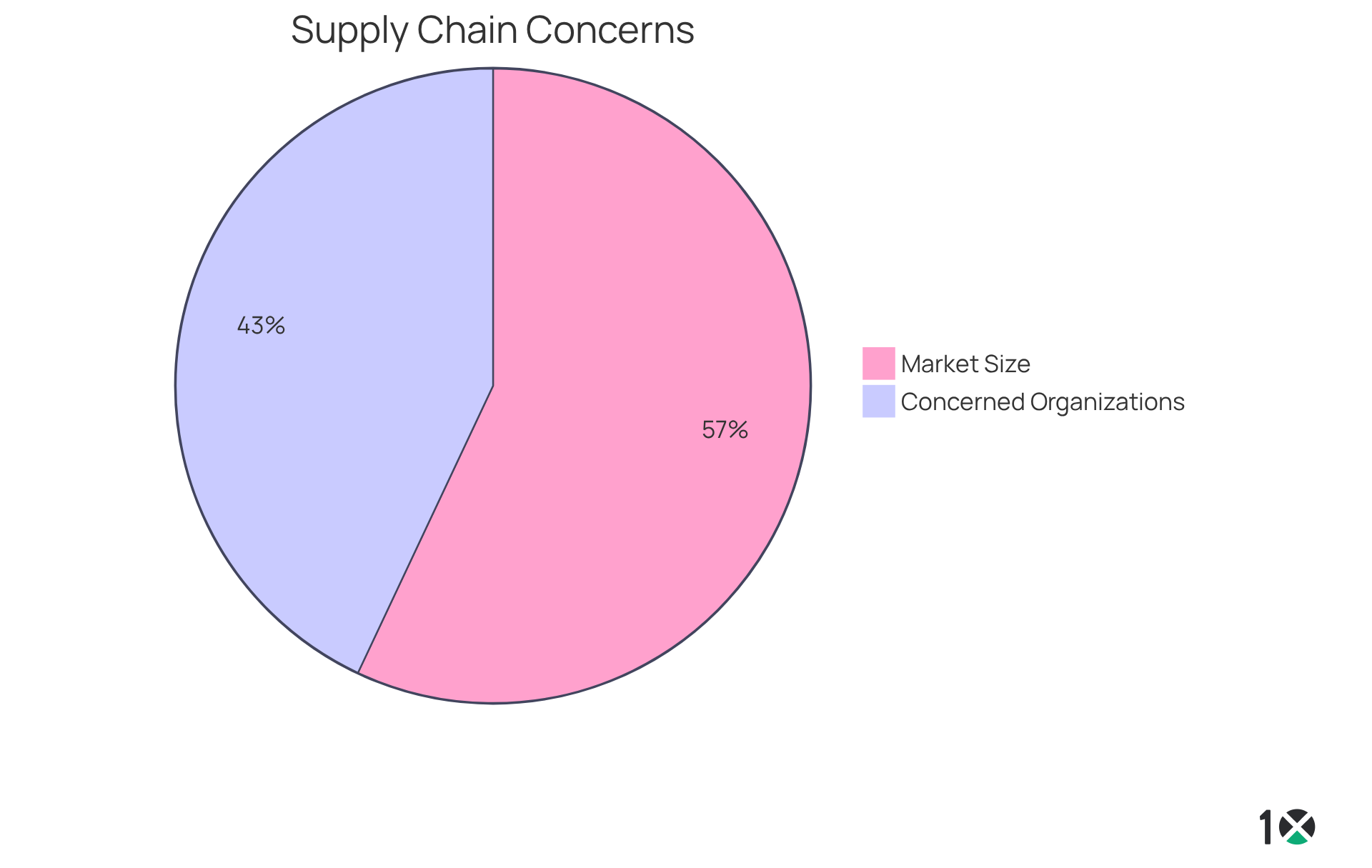

This proactive approach not only boosts immediate responsiveness but also contributes to long-term operational stability, enabling suppliers to effectively navigate challenges and maintain seamless operations. Notably, 43% of organizations express significant concern regarding supply chain risks to their growth, underscoring the critical necessity for effective chain supply management and risk management solutions like 10X ERP. Furthermore, 65% of senior finance leaders concur that the volume and complexity of corporate risks have evolved dramatically, emphasizing the indispensable role of tools that facilitate real-time monitoring and reporting. With the global risk management market projected to reach $23.57 billion by 2028, investing in robust ERP solutions is essential for distributors aiming to thrive in an increasingly complex landscape.

Conclusion

The significance of effective supply chain management in enhancing distributor efficiency is paramount. By utilizing advanced tools like 10X ERP, distributors can optimize operations, enhance inventory management, and cultivate stronger supplier relationships. This comprehensive strategy not only guarantees timely deliveries and elevates customer satisfaction but also yields substantial cost savings through enhanced operational efficiency.

Throughout this discussion, the key advantages of implementing a robust supply chain management system have been underscored. The capacity to process real-time data facilitates agile decision-making, while improved inventory management techniques result in optimized stock levels and reduced costs. Furthermore, precise demand forecasting and effective risk mitigation strategies empower distributors to navigate market fluctuations and sustain business continuity.

Ultimately, adopting the principles of supply chain management and integrating innovative solutions like 10X ERP is crucial for distributors striving to excel in a competitive environment. By emphasizing efficiency, collaboration, and data-driven insights, businesses can not only bolster their operational capabilities but also secure a sustainable growth trajectory. The time to invest in these transformative strategies is now; the future of distribution relies on the ability to adapt and thrive in an ever-evolving market.

Frequently Asked Questions

What is 10X ERP?

10X ERP is a modern, cloud-based platform that empowers suppliers by offering real-time data processing, enabling immediate access to critical information from any device.

How does 10X ERP improve decision-making for suppliers?

By providing real-time insights, 10X ERP allows suppliers to swiftly adjust to market fluctuations, manage stock effectively, and optimize order fulfillment, significantly enhancing their decision-making capabilities.

What are the benefits of real-time data processing in 10X ERP?

Real-time data processing reduces errors linked to manual data entry, improves reporting and forecasting accuracy, and helps suppliers identify and respond to sudden changes in demand efficiently.

How does 10X ERP assist with inventory management?

10X ERP provides tools for monitoring stock levels, managing reorder points, and assessing turnover rates, allowing suppliers to make informed, data-driven decisions that optimize stock levels and reduce costs.

In what ways can suppliers benefit from enhanced supplier relationships through 10X ERP?

10X ERP enhances supplier relationships by providing integrated communication tools, enabling streamlined negotiations, and fostering transparency through real-time inventory information, which builds trust and reliability.

How does 10X ERP support effective chain supply management?

By integrating real-time data processing with stock management, 10X ERP allows suppliers to respond quickly to shifts in demand, improving operational efficiency and contributing to increased profitability.

What features of 10X ERP help ensure data security and control?

10X ERP includes customizable user permissions and roles, which ensure that stakeholders can access necessary information while maintaining security and control over sensitive data.

Why is it important for suppliers to monitor performance metrics in 10X ERP?

Monitoring supplier performance metrics enables wholesalers to identify areas for improvement, collaborate on solutions, and strengthen relationships, ultimately enhancing overall chain supply management efficiency.