Overview

The primary advantages of implementing a Warehouse Management System (WMS) for distributors’ efficiency are significant:

- Enhanced inventory control

- Cost savings

- Improved order fulfillment

- Increased accuracy in stock management

These benefits are not merely theoretical; they are supported by evidence demonstrating how WMS automation effectively reduces manual processes. This automation accelerates decision-making and cultivates stronger relationships with both suppliers and customers. As a result, organizations experience heightened operational efficiency and greater customer satisfaction, making WMS an essential tool for any distributor aiming to optimize their operations.

Introduction

The landscape of distribution is rapidly evolving, creating a pressing need for efficiency and adaptability in warehouse management. Warehouse Management Systems (WMS) have emerged as critical tools that streamline operations, enhance inventory control, and reduce operational costs. By integrating advanced technologies, these systems provide distributors with the opportunity to optimize processes and improve customer satisfaction. However, how can businesses fully leverage the benefits of WMS to stay ahead in a competitive market?

This article explores the ten key advantages of implementing a WMS, revealing how these systems can transform distribution operations and drive long-term success.

10X ERP: Streamline Operations with Cloud-Based ERP Solutions

10X ERP presents a robust cloud-based platform that empowers suppliers to manage their operations seamlessly from any location, guaranteeing real-time data access and streamlined processes. This adaptability is essential for businesses seeking to respond swiftly to market changes.

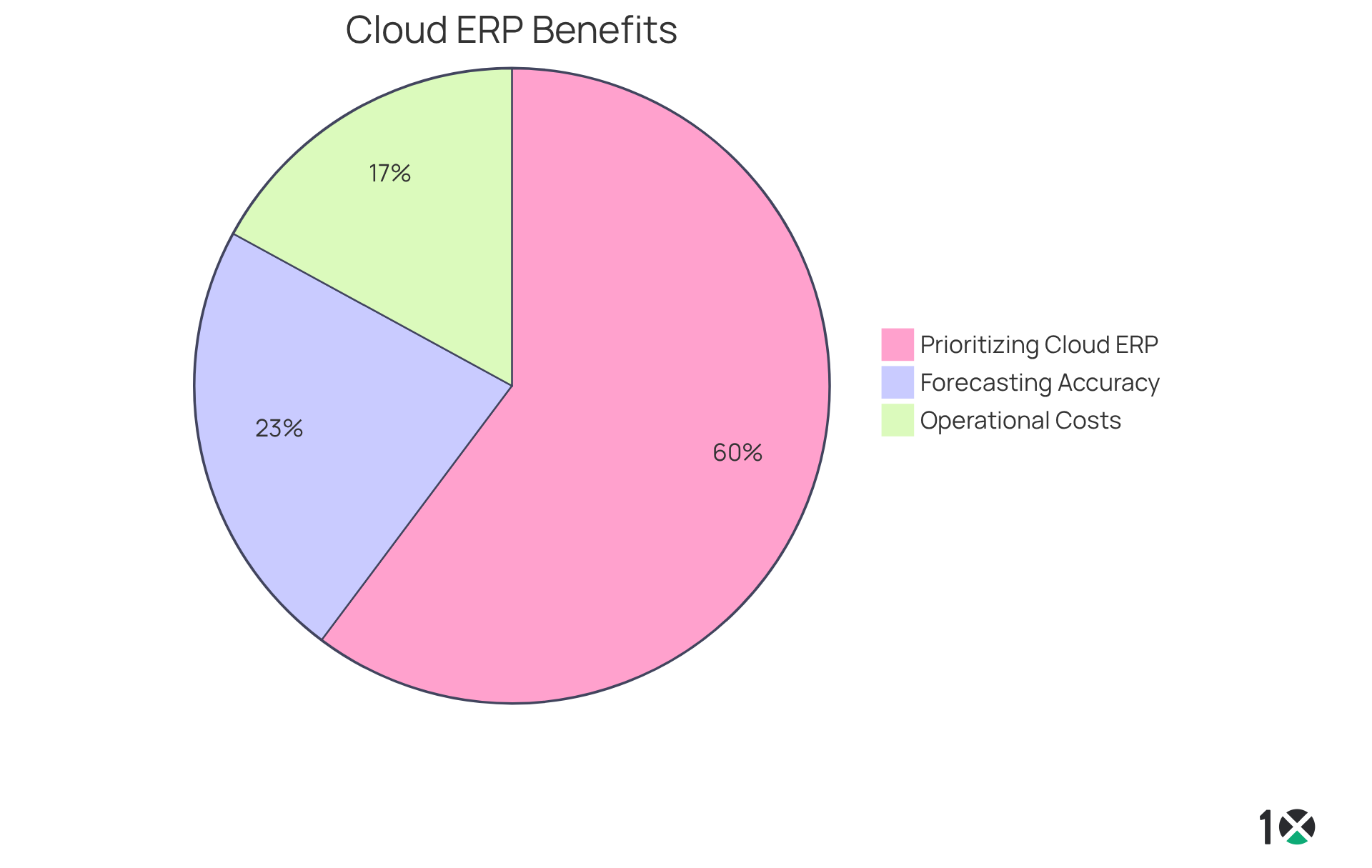

By leveraging cloud technology, 10X ERP significantly diminishes the need for extensive IT infrastructure, allowing companies to focus on their core operations while enjoying the advantages of advanced ERP functionalities. Notably, organizations that implement cloud ERP solutions experience:

- A 20% improvement in forecasting accuracy

- A 15% reduction in operational costs

This underscores the transformative potential of cloud technology in enhancing operational efficiency for suppliers. Furthermore, with 53% of organizations prioritizing cloud-based ERP systems, it is clear that this approach is becoming indispensable for businesses striving to thrive in a competitive landscape.

As Lisa Schwarz, Senior Director of Global Product Marketing, points out, “One of the primary ERP benefits is the ability to streamline business operations by automating tasks and workflows,” which aligns perfectly with the seamless user experience and rapid onboarding that 10X ERP provides.

Enhanced Inventory Control: Optimize Stock Management with WMS

Integrating a WMS warehouse system with 10X ERP significantly enhances stock management by providing real-time visibility into stock levels. This capability empowers suppliers to improve their stock turnover rates, effectively reducing surplus goods and ensuring that the right items are available when needed. For example, businesses utilizing the WMS warehouse system have reported lead time improvements of up to 39%, illustrating the substantial impact of the system on operational efficiency.

Moreover, features such as lot and serial tracking bolster precision and accountability in stock management, enabling distributors to maintain accurate control over their inventory. As e-commerce continues to drive the demand for faster fulfillment, the ability to monitor stock in real-time becomes crucial for meeting customer expectations and minimizing the risk of shortages.

Looking ahead, the global warehouse market is anticipated to reach $869.32 billion by 2025, highlighting the necessity of adopting advanced inventory management solutions like the WMS warehouse system to stay competitive. By leveraging analytics to identify best-selling products and streamline operations, suppliers can enhance their operational capabilities and ultimately elevate customer satisfaction.

![]()

Cost Savings: Reduce Operational Expenses with WMS Implementation

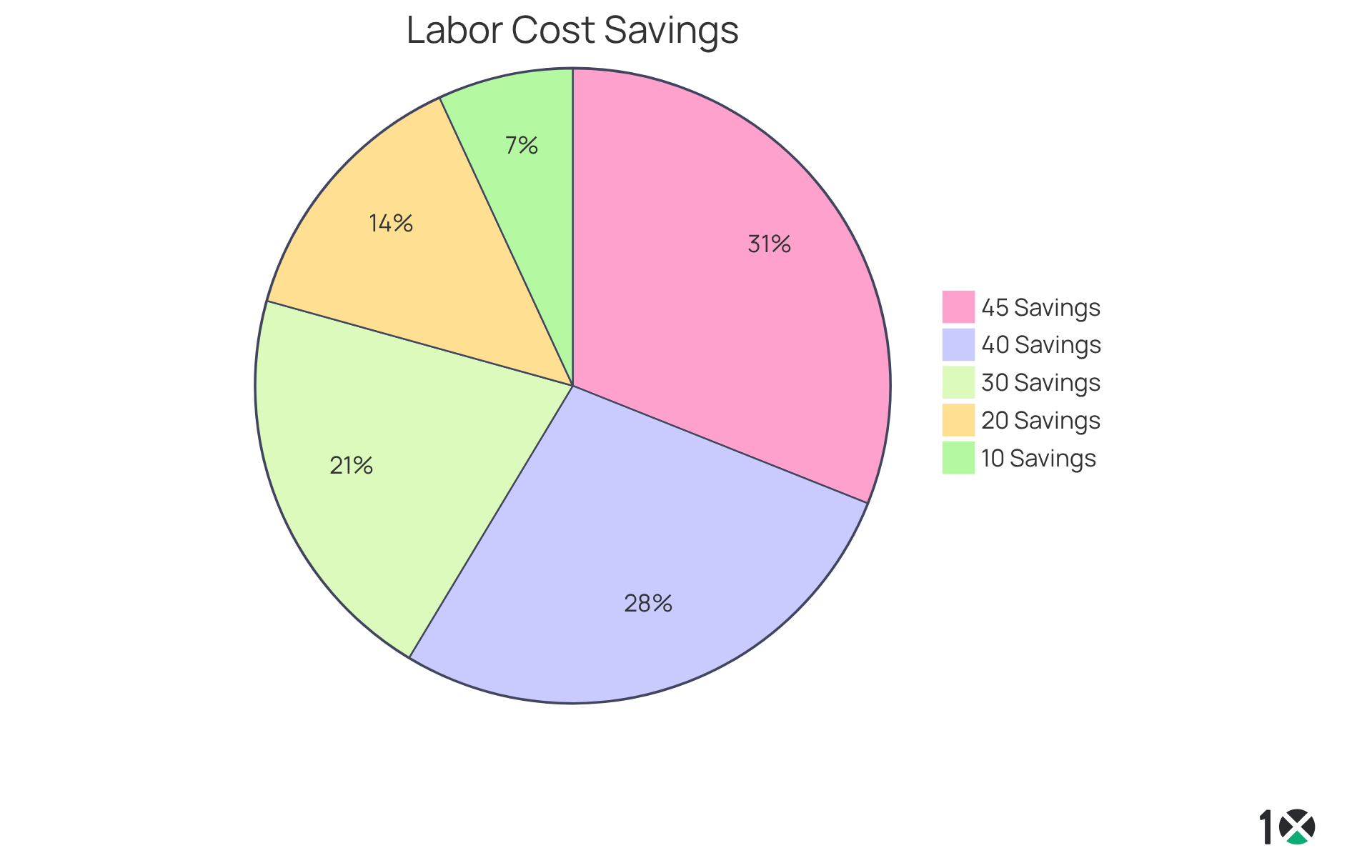

Implementing a WMS warehouse system can yield significant cost savings for suppliers by automating manual processes. This automation reduces labor expenses and minimizes errors, leading to enhanced efficiency. Companies that have adopted the WMS warehouse system report labor cost reductions ranging from 10% to 45%, demonstrating the tangible benefits of such systems. By optimizing warehouse layouts and enhancing picking efficiency, suppliers can effectively lower operational expenses while boosting profitability.

Moreover, accurate demand forecasting capabilities enable businesses to maintain optimal inventory levels, significantly cutting costs associated with overstocking. This strategic approach not only optimizes operations but also improves overall financial performance, making the WMS warehouse system an essential investment for businesses aiming to succeed in a competitive market. With 10X ERP’s cloud-based solutions, real-time data processing enhances the WMS warehouse system’s effectiveness, allowing for better decision-making and operational flexibility.

As Michael Badwi notes, ‘Shipping accuracy can increase to 99% with a WMS warehouse system, which saves you time, money, and resources.’ Additionally, WMS contributes to environmental sustainability, aligning with the growing focus on sustainable logistics practices. The integration of these systems is not merely a technological upgrade; it is a strategic move that positions businesses for long-term success.

Improved Order Fulfillment: Boost Customer Satisfaction with WMS

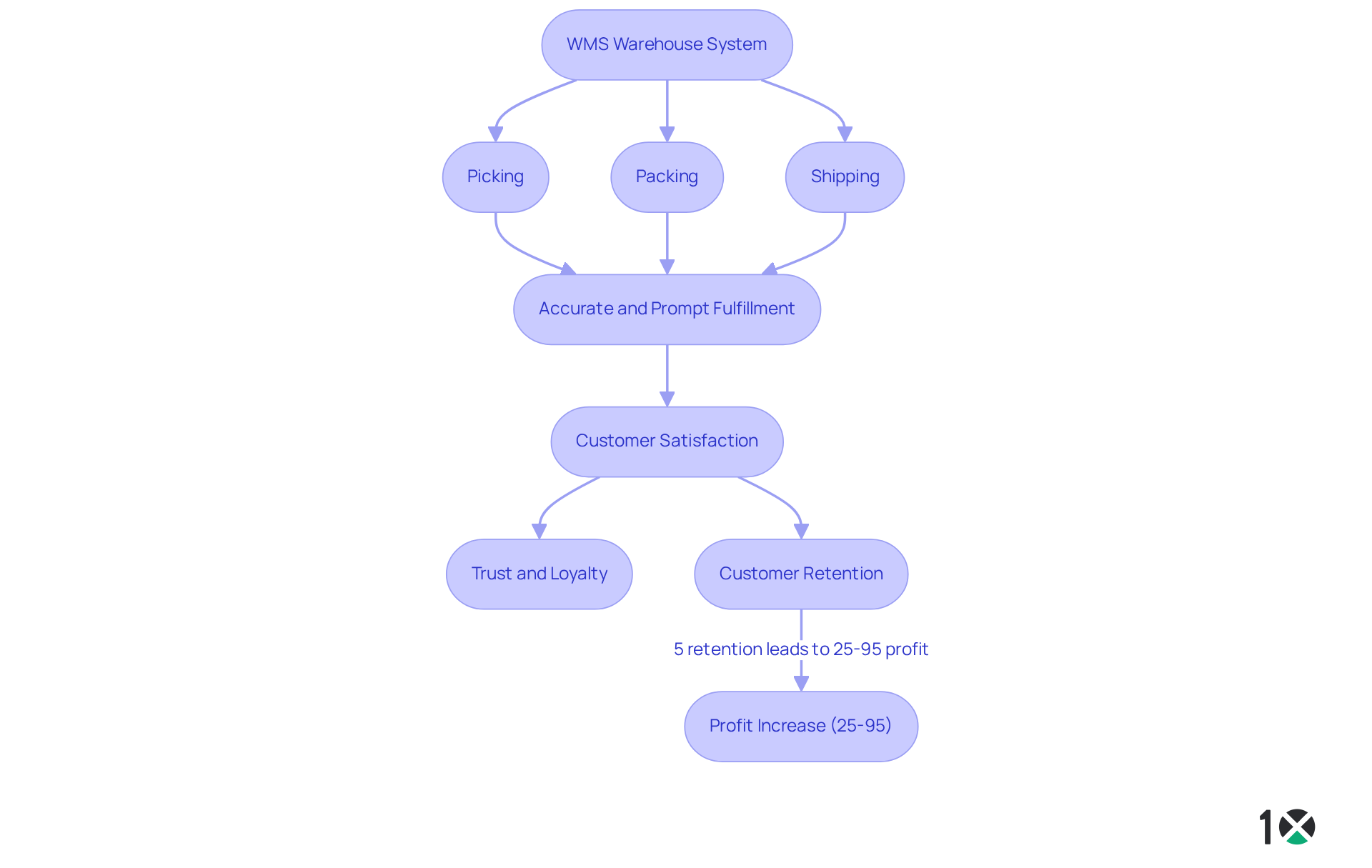

A wms warehouse system significantly enhances order fulfillment by optimizing the operations of picking, packing, and shipping. Features such as barcode scanning and automated order processing ensure that orders are fulfilled accurately and promptly. This efficiency is crucial; indeed, 80% of customers consider the customer experience as important as the products and services provided. When suppliers utilize the wms warehouse system, they not only enhance operational efficiency but also cultivate customer trust and loyalty. Prompt and precise deliveries lead to greater satisfaction rates.

For instance, companies that use a WMS warehouse system often report a marked decrease in order errors, which directly correlates with improved customer retention. In fact, a Bain & Company study indicates that a mere 5% increase in customer retention can result in a profit increase of 25% to 95%. Furthermore, as users navigate through cookie choices and data privacy settings, understanding how WMS integrates user-centric features can enhance their overall experience.

As the digital landscape evolves, the ability to consistently meet customer expectations becomes a competitive differentiator. This makes the wms warehouse system an essential tool for businesses aiming to thrive in today’s market.

Enhanced Visibility and Reporting: Make Informed Decisions with WMS

The wms warehouse system significantly enhances visibility into warehouse operations, empowering suppliers to monitor inventory levels, order statuses, and employee performance in real-time. This immediate access to data is crucial for making informed decisions regarding stock replenishment, resource allocation, and operational enhancements. Companies utilizing the wms warehouse system have reported a remarkable 20% improvement in decision-making speed, which enables quicker responses to market demands.

Furthermore, the robust reporting capabilities of the wms warehouse system allow suppliers to analyze trends and identify areas for optimization. By leveraging these insights, businesses can drive continuous improvement in their operations. A study revealed that organizations with advanced reporting features in their WMS warehouse system experienced a notable 30% increase in operational efficiency, underscoring the immense value of data-driven decision-making.

As Peter Sondergaard aptly stated, “Information is the oil of the 21st century, and analytics is the combustion engine.” This assertion emphasizes the necessity of integrating comprehensive reporting tools within the wms warehouse system to enhance informed decision-making processes. In a landscape where data is abundant, the ability to transform that data into actionable insights distinguishes successful suppliers.

Increased Accuracy: Minimize Errors in Inventory Management with WMS

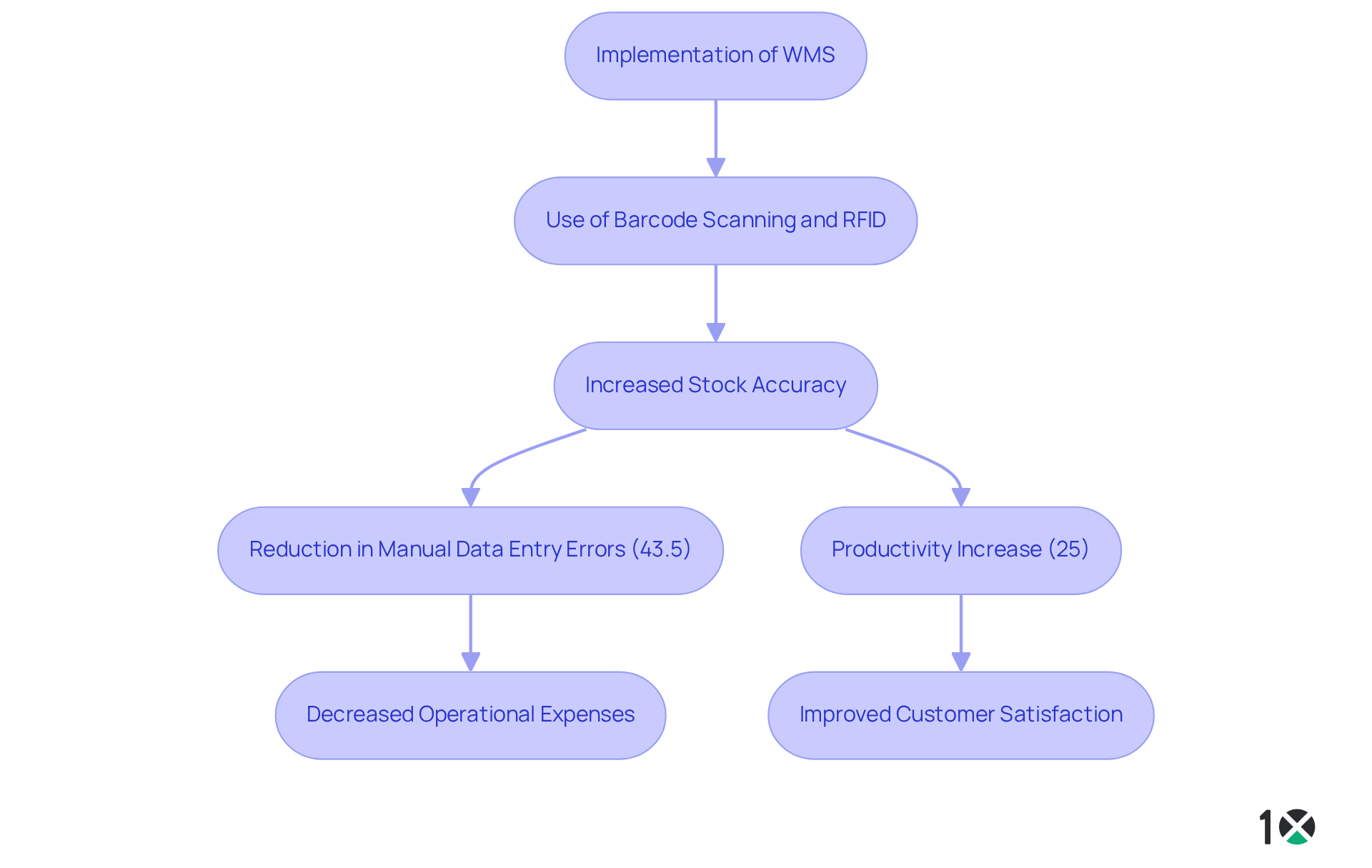

A WMS warehouse system significantly enhances stock precision through automation and real-time data updates. By leveraging barcode scanning and RFID technology, suppliers achieve accurate stock counts, thereby reducing discrepancies. Companies adopting barcode systems have reported a remarkable reduction in manual data entry errors by up to 43.5%. This statistic underscores the effectiveness of these technologies in streamlining operations. The heightened accuracy not only mitigates the risks of stockouts and overstock situations but also fosters improved customer satisfaction.

Moreover, businesses utilizing the WMS warehouse system for integrated order processing have experienced a productivity increase of 25%, demonstrating the operational efficiencies gained through the WMS warehouse system automation. The implementation of 10X ERP’s cloud-based solutions further amplifies these advantages by providing real-time data processing and seamless integrations, which are essential for efficient stock management. Employee training is crucial for successful barcode implementation, ensuring that staff are well-equipped to utilize these systems effectively.

Ultimately, the adoption of these technologies leads to decreased operational expenses related to stock discrepancies, positioning suppliers for enhanced success in a competitive market. As Peter Drucker wisely stated, ‘What Gets Measured, Gets Managed,’ emphasizing the importance of precise stock tracking.

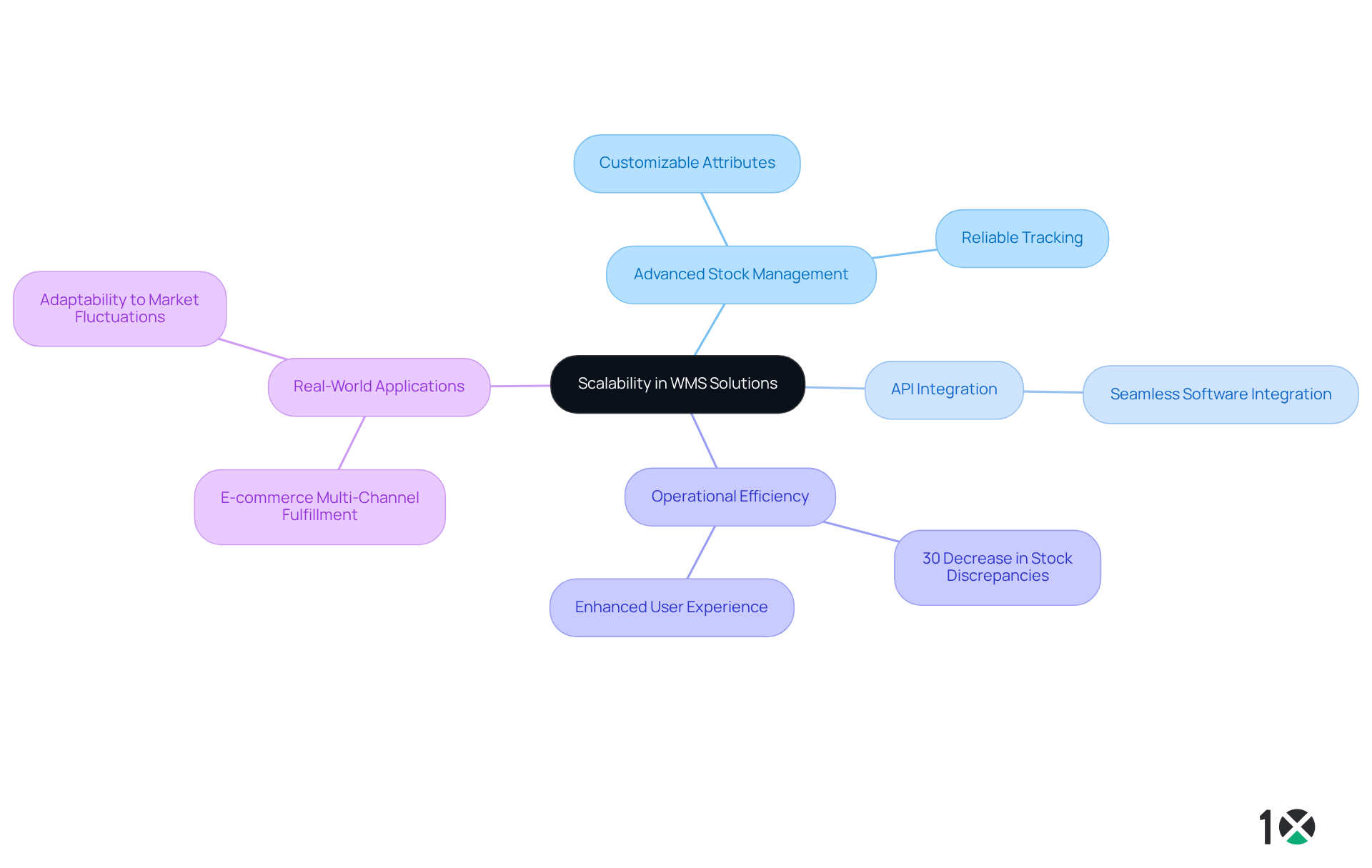

Scalability: Adapt and Grow with Flexible WMS Solutions

The wms warehouse system solutions are inherently scalable, enabling companies to adapt to evolving business demands and growth. With 10X ERP’s advanced stock management features—such as customizable attributes and reliable tracking—suppliers can adeptly manage increased stock levels and additional warehouse locations. Firms utilizing 10X ERP have reported a remarkable 30% decrease in stock discrepancies, underscoring the effectiveness of its robust stock management capabilities. Furthermore, the API-first approach of 10X ERP guarantees seamless integration with existing software, enhancing user experience and facilitating complex order fulfillment processes. This adaptability ensures that suppliers can maintain operational efficiency, regardless of their growth trajectory.

Consider real-world examples where e-commerce businesses leverage the wms warehouse system to effectively manage multi-channel fulfillment. These systems enable swift responses to market fluctuations and consumer demands, illustrating the critical role of flexibility in today’s landscape. Distributors who embrace this adaptability can significantly enhance their operational capabilities, ensuring they remain competitive in an ever-evolving market. The time to act is now—invest in solutions that not only meet your current needs but also position you for future success.

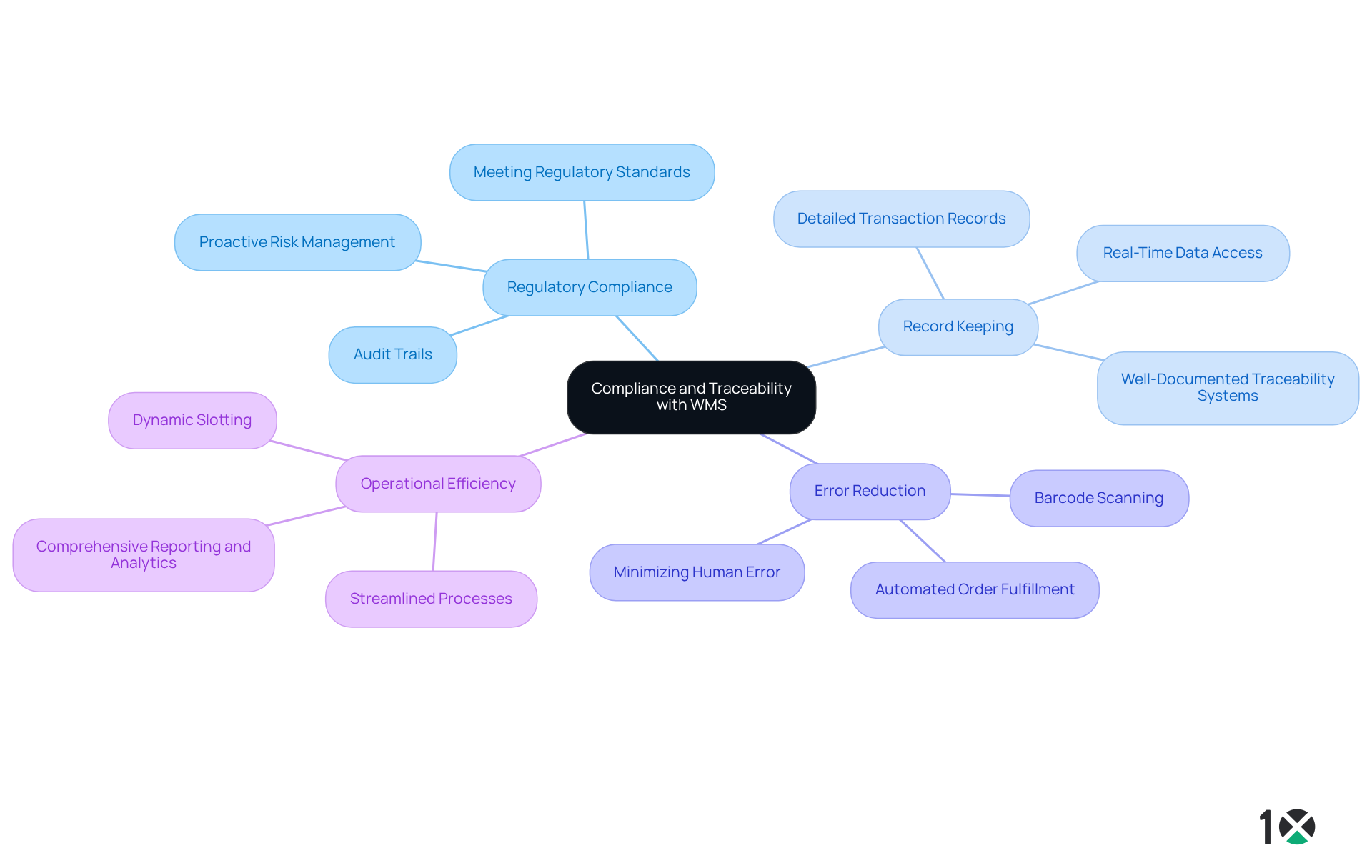

Compliance and Traceability: Ensure Regulatory Adherence with WMS

A WMS warehouse system significantly enhances compliance and traceability by meticulously recording stock movements and transactions. This comprehensive record-keeping is vital for meeting regulatory requirements across various sectors, including food and pharmaceuticals, where adherence to safety and quality standards is paramount. Companies utilizing the WMS warehouse system can swiftly provide detailed audit trails, ensuring preparedness for inspections and prompt responses to regulatory inquiries.

In practice, suppliers employing WMS have reported enhanced precision in stock management, essential for compliance. By automating processes such as order fulfillment and stock tracking, the WMS warehouse system minimizes human error and maintains current records, thereby reducing the risk of non-compliance. This proactive approach safeguards against potential penalties and fosters trust with stakeholders by demonstrating a commitment to ethical operations.

As Paul Koziarz, President and General Manager of Regulatory Compliance at CSI, notes, “Without compliance, many organizations wouldn’t have security controls in place, and there would be no consistency of standards among the protocols being used.” This underscores the necessity of the WMS warehouse system in establishing a robust compliance framework that not only meets but exceeds regulatory standards, ultimately enhancing operational efficiency and brand reputation.

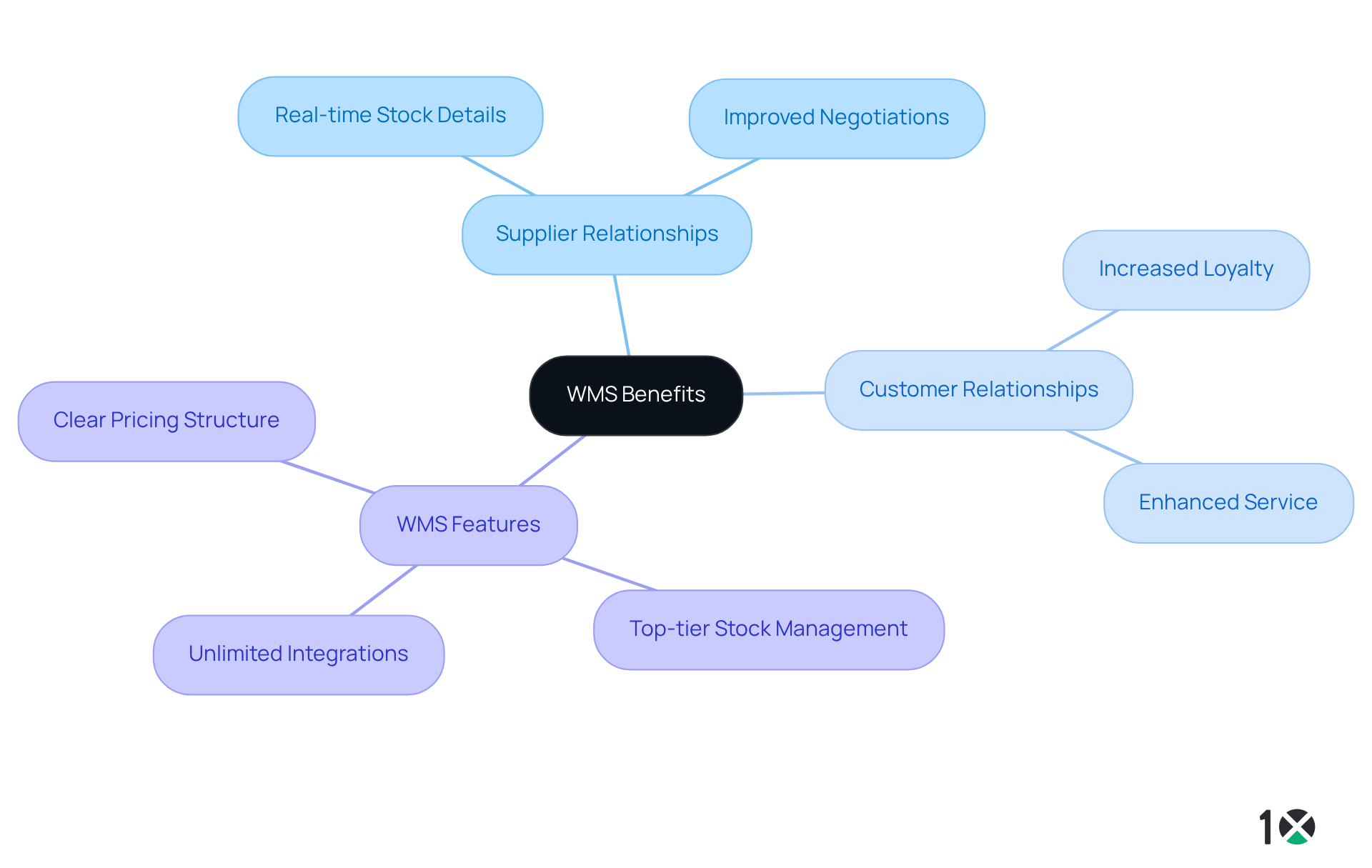

Improved Supplier and Customer Relationships: Strengthen Partnerships with WMS

Implementing a WMS warehouse system significantly enhances relationships with both suppliers and customers. By providing precise, real-time details regarding stock levels and order statuses, suppliers can interact more efficiently with their partners. This clarity fosters trust and teamwork, enabling partners to negotiate improved conditions with suppliers. Furthermore, reliable service bolstered by WMS capabilities enhances customer loyalty, as businesses can consistently meet or exceed expectations.

With 10X ERP’s comprehensive features, including top-tier stock management, unlimited integrations, and a clear pricing structure, users enjoy a seamless experience that guarantees quick onboarding and operational efficiency. Companies that adopted the WMS warehouse system reported an impressive 87% improvement in order accuracy, which directly correlates with increased customer satisfaction and retention. In a competitive landscape, where every customer interaction counts, the ability to provide timely and precise information can be a game-changer, solidifying long-term partnerships and driving business growth.

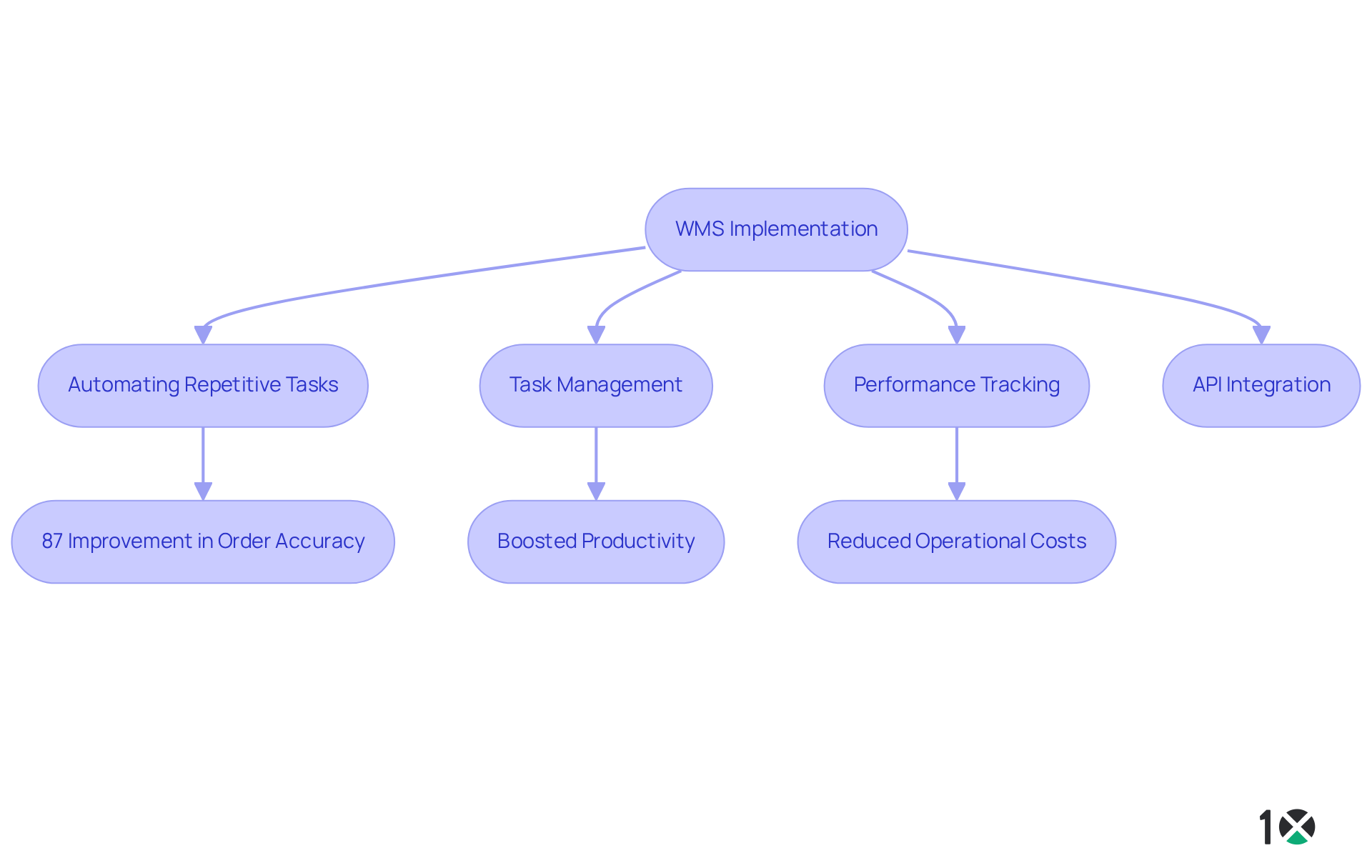

Labor Efficiency: Optimize Workforce Productivity with WMS

A wms warehouse system significantly enhances labor efficiency by automating repetitive tasks and providing employees with essential tools for effective job performance. With 10X ERP’s dependable inventory management capabilities—featuring simplified item types, customizable attributes, robust cross-referencing, and lot/serial item tracking—suppliers can monitor inventory with accuracy, guaranteeing they know precisely where their stock is at any moment. Task management features and performance tracking capabilities enable suppliers to allocate resources more strategically and identify areas for improvement.

For instance, companies that have implemented the wms warehouse system report a remarkable 87% improvement in order accuracy, showcasing the impact of the system on operational effectiveness. By streamlining workflows and minimizing manual labor, distributors not only boost productivity but also achieve substantial reductions in operational costs. As Maryam Oseni from GoRamp notes, ‘The wms warehouse system is not just a tool; it is a core part of your business strategy in the logistics landscape.’ This strategic integration of the wms warehouse system transforms warehouses into dynamic environments, maximizing workforce productivity and ensuring that businesses remain competitive in a rapidly evolving market.

Furthermore, the effectiveness of WMS is heavily reliant on the quality of data used, ensuring that the system can deliver accurate insights. 10X ERP’s API-first approach allows seamless integration with virtually any other software your business utilizes, enhancing labor allocation and productivity.

Conclusion

The integration of a Warehouse Management System (WMS) is revolutionizing the efficiency of distribution operations, providing significant advantages that are essential for modern businesses. By streamlining inventory control, enhancing order fulfillment, and improving visibility, WMS empowers distributors to operate with precision and agility. The adoption of such systems not only optimizes stock management but also leads to substantial cost savings and improved customer satisfaction, creating a competitive edge in a rapidly evolving market.

Key insights from the article highlight the transformative benefits of WMS, including:

- Increased accuracy in inventory management

- Enhanced labor efficiency

- The ability to scale operations seamlessly

Companies leveraging WMS report significant improvements in operational metrics, such as reduced errors and faster decision-making capabilities. These advancements underscore the necessity of adopting advanced technologies like WMS to meet the demands of today’s logistics and distribution landscape.

Ultimately, the call to action is clear: businesses must embrace WMS and cloud-based ERP solutions to not only streamline their operations but also to position themselves for future growth and success. The landscape of distribution is changing, and those who invest in these technologies will not only enhance their operational capabilities but also foster stronger relationships with customers and suppliers, ensuring long-term sustainability and profitability.

Frequently Asked Questions

What is 10X ERP and what are its main benefits?

10X ERP is a cloud-based platform that helps suppliers manage their operations from any location, providing real-time data access and streamlined processes. Its benefits include a 20% improvement in forecasting accuracy and a 15% reduction in operational costs, enhancing operational efficiency for businesses.

How does cloud technology impact the need for IT infrastructure?

By leveraging cloud technology, 10X ERP significantly reduces the need for extensive IT infrastructure, allowing companies to concentrate on their core operations while benefiting from advanced ERP functionalities.

What role does a WMS warehouse system play in inventory management?

A WMS warehouse system integrated with 10X ERP enhances stock management by providing real-time visibility into stock levels, improving stock turnover rates, and ensuring the availability of the right items when needed.

How much can lead times improve with a WMS warehouse system?

Businesses utilizing the WMS warehouse system have reported lead time improvements of up to 39%, demonstrating its impact on operational efficiency.

What are the cost-saving benefits of implementing a WMS warehouse system?

Implementing a WMS warehouse system can lead to labor cost reductions between 10% to 45% by automating manual processes, optimizing warehouse layouts, and enhancing picking efficiency.

How does a WMS warehouse system contribute to sustainability?

The WMS warehouse system contributes to environmental sustainability by promoting efficient logistics practices, aligning with the growing focus on sustainable operations.

What is the anticipated growth of the global warehouse market?

The global warehouse market is expected to reach $869.32 billion by 2025, highlighting the importance of adopting advanced inventory management solutions like the WMS warehouse system.

What does Lisa Schwarz say about the benefits of ERP?

Lisa Schwarz, Senior Director of Global Product Marketing, emphasizes that one of the primary benefits of ERP is the ability to streamline business operations by automating tasks and workflows, which aligns with the user experience offered by 10X ERP.