Overview

The article titled “7 Essential Warehousing Basics Every Operations Manager Should Know” underscores crucial principles that operations managers must grasp to enhance warehouse efficiency. It highlights the necessity of mastering key functions, including:

- Receiving

- Inventory management

- Shipping processes

Furthermore, it discusses the role of technology, such as ERP systems, in improving operational performance and tackling contemporary challenges in warehousing. By understanding these fundamentals, operations managers can significantly optimize their warehouse operations.

Introduction

Understanding the intricacies of warehousing is crucial for operations managers who aim to enhance efficiency and streamline logistics. In a landscape characterized by rapid technological evolution and rising customer demands, mastering the essential warehousing basics can significantly influence a company’s bottom line.

However, amidst the myriad of strategies and tools available, how can managers effectively navigate the complexities of modern warehousing to ensure optimal performance and compliance? This article delves into the fundamental principles every operations manager should know, offering insights that can transform warehouse operations and drive success.

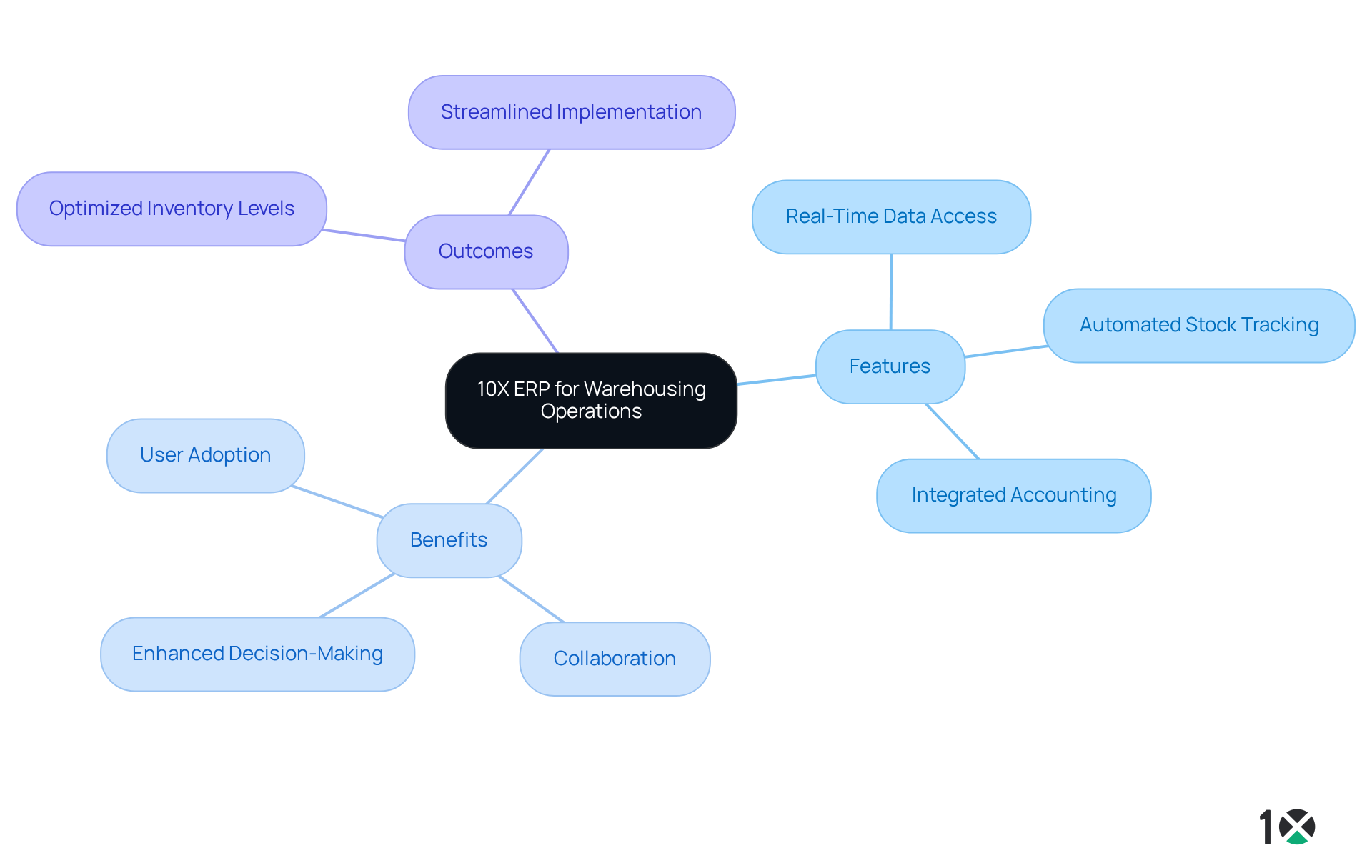

10X ERP: Streamline Your Warehousing Operations with Cloud-Based Solutions

10X ERP offers a state-of-the-art, cloud-based platform that empowers operations managers with real-time data access from any location. This capability significantly enhances decision-making and fosters collaboration among teams. For instance, automated stock tracking facilitates precise management of supplies, while integrated accounting functions simplify complex warehousing basics. The platform boasts robust accounting and stock management tools, ensuring stakeholders can make informed decisions based on real-time data processing.

Furthermore, the all-encompassing nature of the software eliminates the need to identify and purchase additional modules, thus streamlining the implementation process. Consequently, managers can focus on strategic initiatives instead of being bogged down by administrative duties. The intuitive interface further promotes user adoption, enabling staff to quickly leverage its functionalities.

With 91% of companies reporting after implementing ERP solutions, the advantages of real-time data access in warehousing basics are evident. Additionally, 10X ERP’s commitment to customer support and a lifetime partnership guarantees users receive ongoing assistance throughout their ERP journey. As cloud ERP evolves, its role in enhancing operational efficiency and responsiveness in inventory management becomes increasingly vital.

Warehouse Functions: Key Operations Every Manager Must Master

The warehousing basics include key storage functions such as receiving, putaway, picking, packing, and shipping, all of which are vital for optimizing overall operational efficiency.

Efficient receiving procedures are crucial for mastering warehousing basics, as they play a vital role in accurately recording and storing goods, which directly impacts stock levels and order precision.

For instance, warehouses that employ automated picking strategies can significantly reduce average order fulfillment times, thereby enhancing customer satisfaction.

Furthermore, mastering warehousing basics is essential; it not only maintains optimal stock levels but also minimizes errors in order processing.

By implementing sophisticated ERP solutions like 10X ERP, which offers real-time data processing, customizable tracking, adaptable user permissions, and a comprehensive audit trail, managers can automate these essential functions.

This results in , decreased labor costs, and streamlined processes. Such integration of technology is recognized as a key driver of efficiency in the basics of modern warehousing.

Warehouse Types: Selecting the Right Facility for Your Operations

Choosing the appropriate type of warehousing basics is crucial for optimizing operations and meeting customer expectations. Various storage facilities, such as , fulfillment centers, and climate-controlled facilities, serve distinct operational needs. Distribution centers are particularly effective for rapid order fulfillment and high stock turnover, making them suitable for businesses with fast-moving products. Conversely, climate-controlled facilities are vital for storing perishable goods, as they maintain product integrity through regulated temperature and humidity.

To determine the most suitable storage facility type, operations managers must evaluate their specific requirements, including:

- Warehousing basics

- Stock category

- Volume

- Customer demand

For instance, companies experiencing significant return volumes, like those in e-commerce, may benefit from reverse logistics facilities designed to handle returns efficiently. Moreover, the rising trend of on-demand warehousing basics enables businesses to manage fluctuating inventory levels without long-term commitments.

Recent statistics indicate that 82% of companies plan to expand their storage operations in the next five years, underscoring the importance of selecting the right facility to support growth. Furthermore, 90% of managers believe that automation can significantly improve storage facility efficiency, highlighting the critical role of technology in both selection and management. Implementing ERP systems, such as 10X ERP, which offers real-time data processing and inventory management, can enhance the administration of various storage facilities, thereby boosting operational efficiency and responsiveness to market dynamics. By aligning the warehousing basics with business objectives, managers can markedly improve their logistics performance.

Inventory Management: Best Practices for Efficient Stock Control

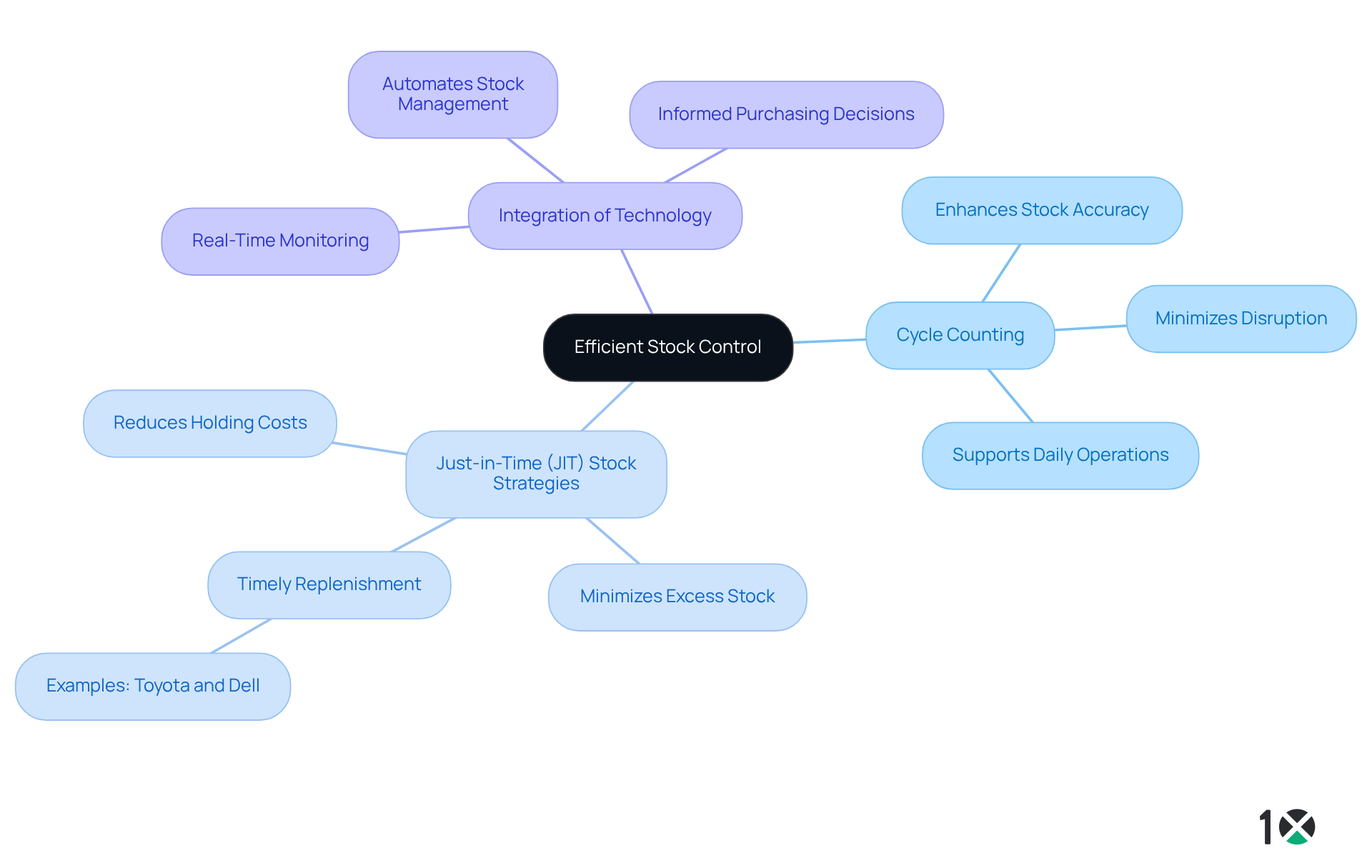

Efficient stock management, which is one of the warehousing basics, is crucial for operational success, relying on optimal methods such as:

- Cycle counting

- Just-in-time (JIT) stock strategies

- The integration of technology for real-time monitoring

Cycle counting stands out as a systematic approach that enhances stock accuracy without disrupting daily operations, allowing businesses to maintain precise stock levels. JIT stock strategies significantly reduce holding costs by ensuring that supplies are replenished only as needed, minimizing excess stock and associated expenses. Notably, companies like Toyota and Dell have successfully adopted JIT strategies, showcasing how timely replenishment can drive operational efficiency and yield cost savings.

As Peter Drucker famously stated, ‘What Gets Measured, Gets Managed,’ highlighting the significance of monitoring stock for effective management. Implementing an ERP system, such as 10X ERP, further refines these practices by automating stock monitoring. This technology equips managers with real-time insights into stock levels and locations, which is essential for making informed purchasing decisions.

Furthermore, at 10X ERP, we employ cookies and similar technologies to enhance user experience, ensuring our services are tailored to meet client needs. By embracing warehousing basics, businesses can streamline their stock management processes, allowing them to anticipate customer demands and market trends, ultimately driving growth and enhancing competitiveness. To effectively implement these strategies, consider and staying informed about industry trends, ensuring your inventory management remains agile and responsive.

Safety and Compliance: Essential Regulations for Warehouse Operations

Warehouse activities must adhere to various safety regulations, including and local health codes. Prioritizing safety not only protects employees but also enhances operational efficiency. Essential safety practices encompass:

- Regular training for employees

- Proper use of personal protective equipment (PPE)

- Maintaining clear emergency procedures

Operations managers should conduct regular safety audits to ensure compliance and that all staff are fully aware of these requirements.

Utilizing an ERP system can significantly aid in tracking compliance documentation and training schedules. This technology ensures that safety protocols are consistently followed, fostering a culture of safety within the organization. By implementing these measures, operations managers can not only meet regulatory obligations but also create a safer and more productive work environment.

Technology Integration: Leveraging Tools for Enhanced Warehouse Efficiency

Incorporating technology into the warehousing basics is essential for improving efficiency and precision. The transformation is being led by warehousing basics like Warehouse Management Systems (WMS), barcode scanners, and automated picking systems. A WMS, for instance, automates stock tracking and order fulfillment, which are essential warehousing basics that significantly enhance order precision and lower operational expenses. Companies utilizing barcode scanning have reported enhanced stock management precision, highlighting the importance of warehousing basics in minimizing errors that can lead to costly disruptions.

By adopting cloud-based solutions such as 10X ERP, managers can ensure seamless integration of these technologies, enabling real-time data processing and insights that support informed decision-making. With features such as robust accounting, customizable tracking, and powerful cross-referencing, 10X ERP empowers businesses to maintain . This proactive approach not only streamlines processes but also positions businesses to adapt swiftly to changing market demands, ultimately driving growth and customer satisfaction.

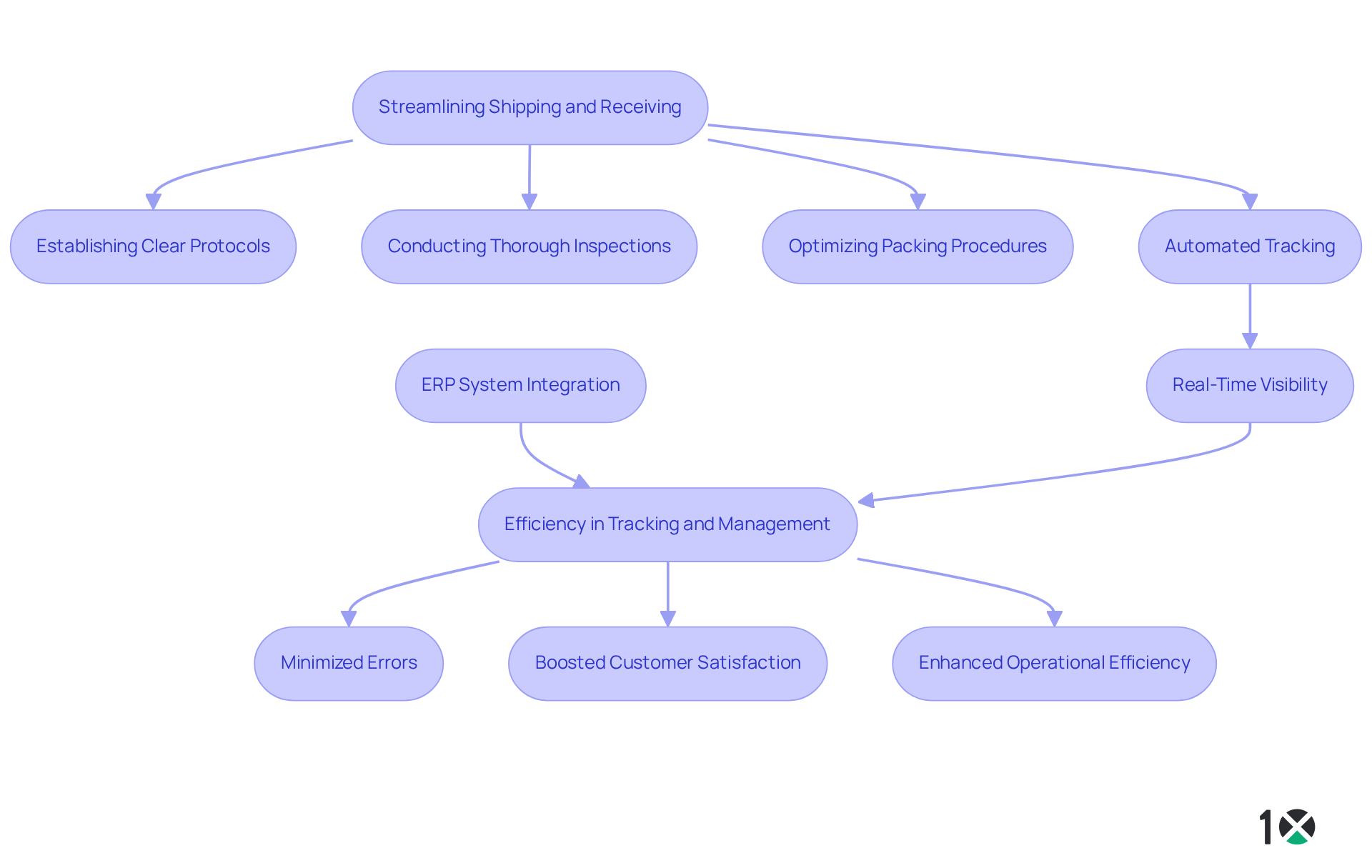

Shipping and Receiving: Streamlining Logistics for Operational Success

Streamlining shipping and receiving processes is essential for operational success. To achieve this, establishing clear protocols for receiving shipments, conducting thorough inspections, and optimizing packing procedures are foundational best practices. Notably, automated tracking significantly enhances shipping accuracy. With , companies can monitor shipments continuously, reducing delays by up to 58%. Implementing an [ERP system like 10X ERP](https://10xerp.com) can automate these processes, ensuring efficient tracking and management of all shipments. This approach not only minimizes errors but also boosts customer satisfaction by facilitating timely deliveries and accurate order fulfillment.

Looking ahead to 2025, best practices in logistics management will increasingly focus on integrating technologies such as digital twin solutions for predictive maintenance and logistics optimization. These advancements will further enhance operational efficiency. Successful examples abound, particularly among companies that have adopted real-time tracking systems, leading to substantial improvements in delivery performance and customer trust. By embracing these strategies, operations managers can position their organizations for success in an ever-evolving logistics landscape.

Continuous Improvement: Strategies for Evolving Warehouse Operations

Ongoing enhancement tactics in storage activities hinge on frequent performance evaluations, efficient staff feedback systems, and the adoption of lean management concepts. By consistently assessing processes and actively seeking feedback from staff, managers can pinpoint inefficiencies and implement changes that significantly boost efficiency. Organizations embracing lean management principles often witness reduced waste and improved workflow, fostering a more agile and responsive environment.

Utilizing 10X ERP systems further streamlines this process, as they offer robust data analytics and reporting tools that illuminate performance metrics while highlighting areas needing attention. This data-driven approach not only cultivates a culture of ongoing enhancement but also empowers employees to engage in operational excellence, ultimately elevating productivity and satisfaction within the facility.

As Shigeo Shingo remarked, “The most dangerous kind of waste is the waste we do not recognize,” underscoring the critical necessity for ongoing assessments and improvements. With 10X ERP’s commitment to and user-focused development, operations managers can leverage these insights to refine their strategies and elevate overall storage performance.

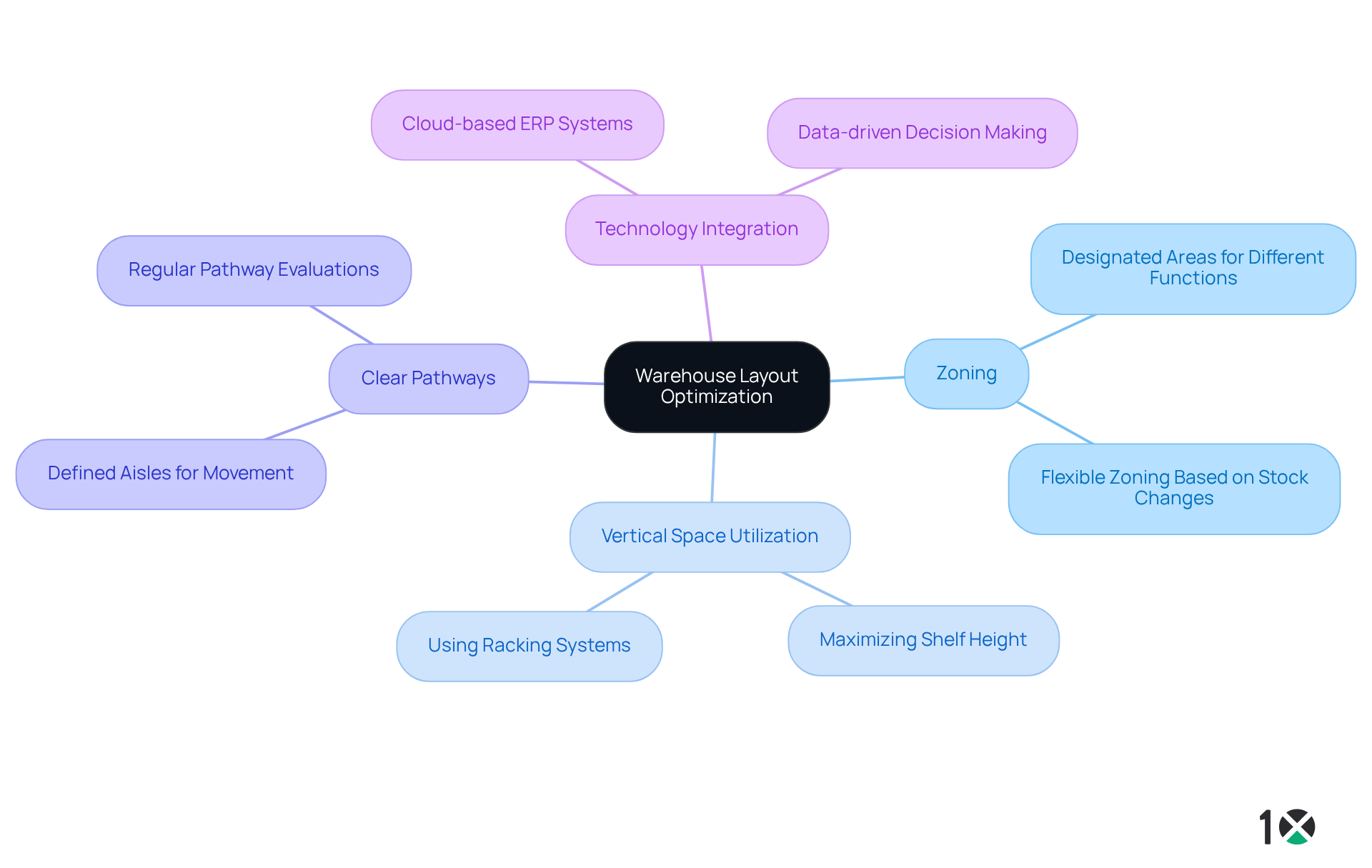

Warehouse Layout Optimization: Designing for Maximum Efficiency

Understanding warehousing basics is essential for optimizing storage layout, minimizing travel time, and enhancing workflow. By strategically designing the warehousing basics, you can significantly improve efficiency. Key considerations in warehousing basics include:

- Zoning for different functions

- Utilizing vertical space

- Ensuring clear pathways for movement

Consistently evaluating and modifying the arrangement based on stock changes and operational requirements is crucial. This proactive approach not only streamlines processes but also adapts to evolving needs. Implementing a cloud-based ERP system like 10X ERP can further assist in visualizing layout changes and analyzing their impact on efficiency.

With its and seamless integration with existing software, 10X ERP empowers operations managers to make data-driven decisions. By leveraging this technology, you can enhance your storage processes effectively, driving operational excellence.

Challenges in Modern Warehousing: Navigating Common Operational Hurdles

Contemporary storage facilities are grappling with significant challenges, including labor shortages, inventory inaccuracies, and escalating operational expenses. With labor accounting for 50% to 70% of a storage facility’s total operating budget, emerges as a critical priority. To effectively navigate these hurdles, operations managers must implement proactive strategies. Investing in employee training programs equips staff with the necessary skills to adapt to new technologies. Moreover, leveraging advanced technology for real-time stock monitoring can substantially enhance precision; automated warehouses are 76% more likely to achieve stock accuracy of 99% or higher.

Implementing ERP systems like 10X ERP can be pivotal in tackling these challenges. This comprehensive cloud-based solution offers a seamless user experience, real-time data processing, and transparent pricing—essential elements for effective inventory management. The system’s automation tools and data analytics capabilities not only enhance operational efficiency but also reduce costs. For example, companies adopting sophisticated automation technologies can lower labor costs by an average of 3% annually while improving order fulfillment accuracy. Furthermore, organizations such as DHL have successfully integrated robotics into their processes, achieving case unloading rates of up to 700 cases per hour without human intervention, significantly boosting productivity and minimizing reliance on manual labor.

In summary, by focusing on workforce development, embracing technology, and refining workflows, managers can effectively confront the pressing challenges of contemporary warehousing basics. With 55% of warehouse managers identifying labor scarcity as a top concern, addressing these issues is more critical than ever. With 10X ERP’s unparalleled support and transparent pricing, operations managers can confidently invest in solutions that drive efficiency and growth.

Conclusion

Understanding the fundamentals of warehousing is vital for operations managers aiming to enhance efficiency and responsiveness in their logistics operations. By mastering essential warehousing basics, managers can streamline processes, optimize inventory management, and ensure compliance with safety regulations. The integration of technology, particularly cloud-based ERP solutions like 10X ERP, emerges as a transformative force that empowers managers to make data-driven decisions, ultimately fostering a culture of continuous improvement.

Key insights from the article highlight the importance of various warehousing functions, such as:

- Receiving

- Inventory management

- Shipping

Selecting the right type of warehouse facility tailored to specific operational needs is crucial for meeting customer demands. Emphasizing best practices in inventory control and safety not only mitigates risks but also enhances overall productivity. Furthermore, the challenges faced in modern warehousing, including:

- Labor shortages

- Inventory inaccuracies

can be effectively addressed through strategic workforce development and advanced technology integration.

As the warehousing landscape continues to evolve, operations managers must remain proactive in adopting innovative solutions and refining their strategies. Embracing continuous improvement and leveraging cloud-based technologies will enhance operational efficiency and position organizations for long-term success in a competitive market. By prioritizing these essential warehousing basics, managers can significantly elevate their logistics performance and drive sustainable growth.

Frequently Asked Questions

What is 10X ERP and how does it benefit warehousing operations?

10X ERP is a cloud-based platform that provides operations managers with real-time data access from any location, enhancing decision-making and team collaboration. It includes automated stock tracking and integrated accounting functions, streamlining warehousing processes and allowing managers to focus on strategic initiatives.

How does 10X ERP improve inventory management?

10X ERP optimizes inventory levels by offering real-time data processing and robust stock management tools. Statistics show that 91% of companies experience improved inventory levels after implementing ERP solutions.

What are the key functions of warehousing that managers must master?

Key warehousing functions include receiving, putaway, picking, packing, and shipping. Mastering these functions is essential for optimizing operational efficiency and maintaining accurate stock levels.

How can automation impact warehousing operations?

Automation, such as automated picking strategies, can significantly reduce order fulfillment times and enhance customer satisfaction. It also leads to improved accuracy, decreased labor costs, and streamlined processes.

What types of warehousing facilities are available, and how do they differ?

Various types of warehousing facilities include distribution centers, fulfillment centers, and climate-controlled facilities. Distribution centers are ideal for rapid order fulfillment, while climate-controlled facilities are necessary for storing perishable goods. Each type serves distinct operational needs.

What factors should managers consider when selecting a warehousing facility?

Managers should evaluate their specific requirements, including warehousing basics, stock category, volume, and customer demand, to determine the most suitable storage facility type.

What is the trend regarding storage operations among companies?

Recent statistics indicate that 82% of companies plan to expand their storage operations in the next five years, highlighting the importance of selecting the right facility for growth.

How does technology play a role in warehousing management?

Technology, particularly automation and ERP systems like 10X ERP, is critical for improving storage facility efficiency and enhancing operational responsiveness to market dynamics.

What ongoing support does 10X ERP provide to its users?

10X ERP offers a commitment to customer support and a lifetime partnership, ensuring users receive ongoing assistance throughout their ERP journey.