Overview

Warehouse Management Systems (WMS) offer significant advantages for streamlined warehouse operations, including:

- Enhanced inventory accuracy

- Improved order fulfillment

- Increased operational efficiency

These benefits are underscored by evidence showing how WMS technologies, such as real-time data processing and automation, drastically reduce stock errors and fulfillment times. This improvement not only fosters better customer satisfaction but also enhances overall operational performance.

By implementing WMS, organizations can expect to see a transformation in their warehouse operations. The integration of advanced technologies facilitates a more accurate inventory management process, reducing discrepancies that can lead to costly errors. Additionally, the ability to fulfill orders more efficiently directly impacts customer satisfaction, establishing a competitive edge in the market.

In conclusion, investing in a Warehouse Management System is a strategic move for Operations Managers seeking to optimize their processes. The combination of real-time data and automation is not just a trend; it is a necessity for those aiming to thrive in today’s fast-paced business environment.

Introduction

The landscape of warehouse operations is rapidly evolving, driven by the need for efficiency and accuracy in an increasingly competitive market. Warehouse Management Systems (WMS) present numerous benefits that not only streamline processes but also significantly enhance overall operational performance. By adopting advanced WMS solutions, businesses can expect substantial improvements in inventory management, order fulfillment, and customer satisfaction.

However, with a myriad of options available, how can companies identify which WMS features will yield the most impactful results tailored to their unique challenges?

10X ERP: Real-Time Data Processing for Enhanced Inventory Management

10X ERP empowers distributors with immediate data processing, enabling ongoing oversight of stock levels. This capability is crucial for preventing stockouts and overstock situations, allowing businesses to meet customer demands efficiently while minimizing unnecessary costs. By incorporating immediate data into their stock control systems, distributors can make quick, informed choices that improve operational effectiveness and adaptability to market changes.

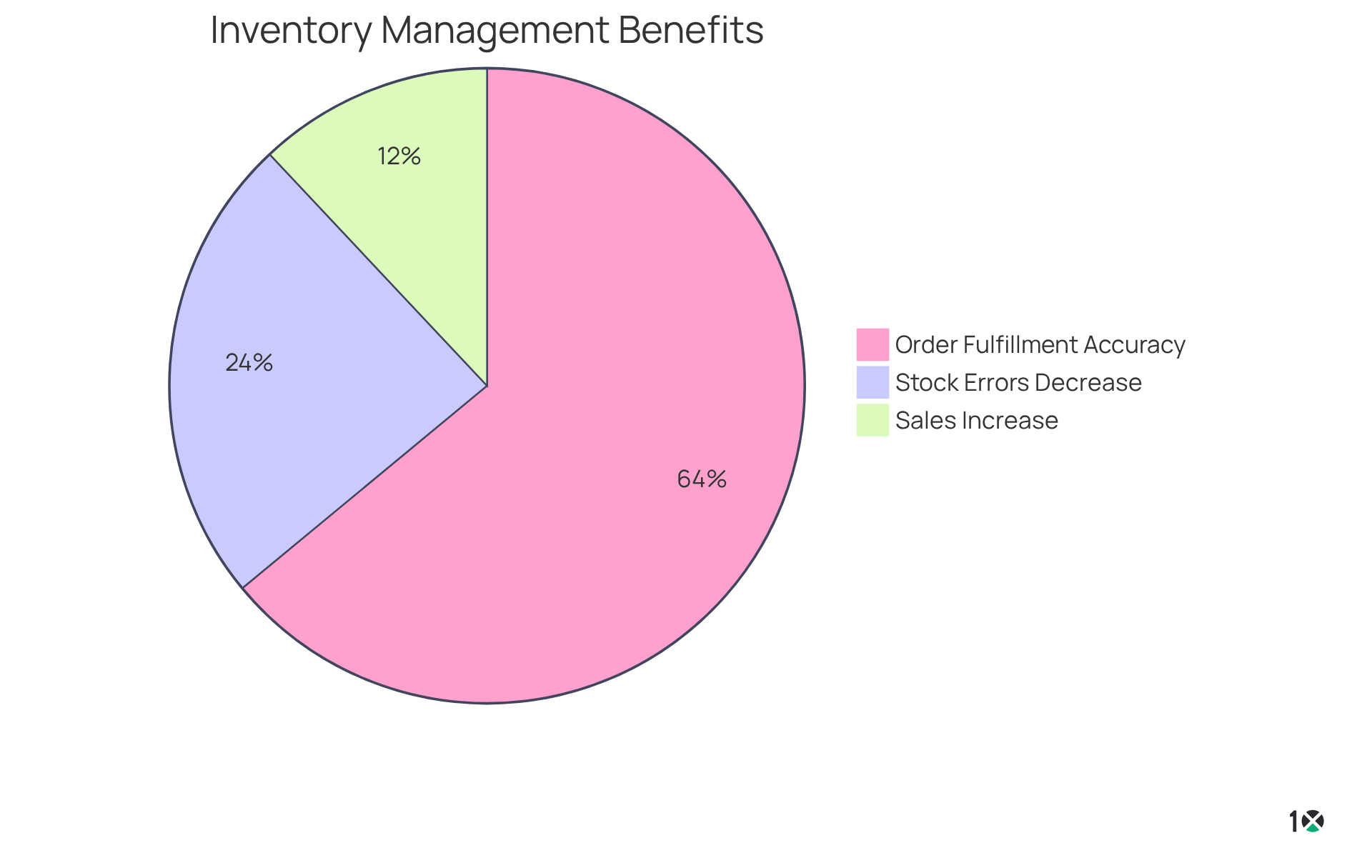

Businesses utilizing immediate stock tracking have reported notable enhancements, including:

- A 30% decrease in stock errors

- A 15% rise in sales due to improved product availability, as emphasized in the case study on ‘Advantages of Instant Data in Stock Oversight.’

Furthermore, the implementation of automated systems has been shown to enhance order fulfillment accuracy by up to 80%, ensuring that customers receive their orders promptly and accurately. This proactive approach not only strengthens customer satisfaction but also fosters loyalty, as businesses can consistently deliver on their promises.

To enhance these advantages, distributors ought to assess their existing stock management systems and contemplate that highlight the WMS benefits in line with their operational objectives.

SAP Extended Warehouse Management: Streamlined Operations and Data Accuracy

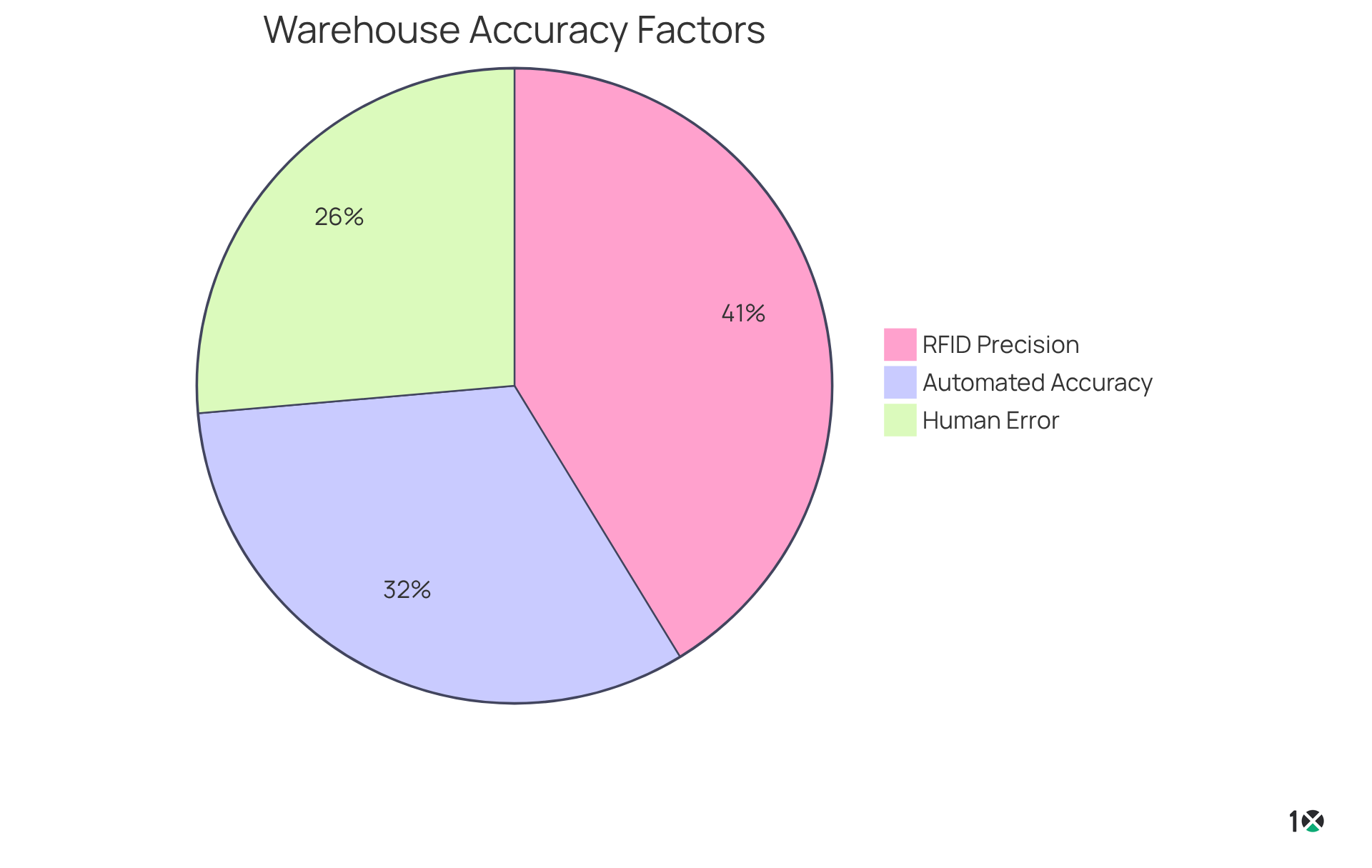

SAP Extended Warehouse Management (EWM) stands at the forefront of modern warehouse operations, delivering cutting-edge features that significantly enhance efficiency. Key functionalities, such as automated stock tracking and optimized picking routes, are essential for minimizing errors in order fulfillment. Companies utilizing RFID technology report an impressive 97% stock precision, underscoring the importance of incorporating real-time data within SAP EWM to achieve comparable outcomes. This system proves particularly advantageous for , where precision is critical.

Logistics specialists emphasize that efficient data handling is crucial; indeed, 62% of participants identify human mistakes as a primary reason for stock discrepancies. Alarmingly, nearly 43% of storage facilities worldwide continue to face issues due to human error. Furthermore, automated warehouses are 76% more likely to achieve inventory accuracy of 99% or higher. By leveraging SAP EWM, organizations can achieve WMS benefits by streamlining their processes and ensuring a higher level of data accuracy, ultimately leading to improved customer satisfaction and operational performance.

Cloud-Based WMS: Flexibility and Scalability for Dynamic Operations

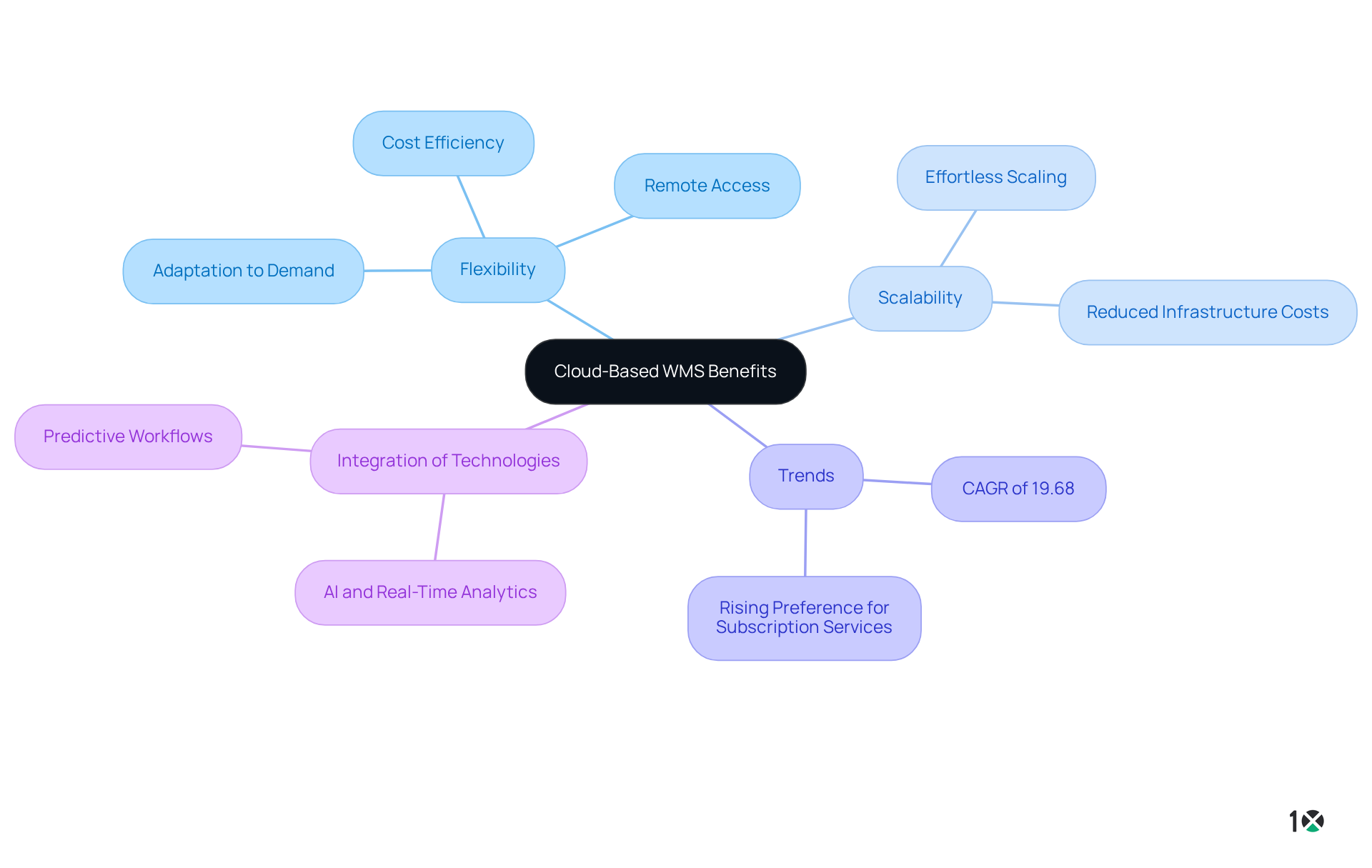

The wms benefits include remarkable flexibility and scalability, which allow businesses to swiftly adapt their operations to fluctuating demand. These systems allow for remote access to critical data, facilitating real-time decision-making and operational adjustments. For example, companies utilizing cloud WMS can effortlessly scale their operations to accommodate increased inventory and order volumes without incurring significant infrastructure costs. This adaptability is crucial in today’s fast-paced market, where businesses must respond promptly to shifting consumer demands.

Recent trends reveal that cloud-based platforms are experiencing rapid expansion, with a projected compound annual growth rate (CAGR) of 19.68% through 2030. This growth is fueled by the rising preference for that empower companies to tailor their operations according to seasonal fluctuations and market dynamics. Industry leaders assert that the capability to efficiently scale operations is a key differentiator in sustaining a competitive edge. As one expert noted, ‘Cloud computing is revolutionizing operational activities of a warehouse and supply chain operations,’ underscoring the pivotal role of cloud technology in modern logistics.

Furthermore, businesses across various sectors are increasingly adopting cloud WMS solutions to take advantage of the wms benefits that enhance their operational flexibility. For instance, e-commerce giants are leveraging these systems to navigate the complexities of rapid order fulfillment and inventory management, ensuring they meet customer expectations effectively. The integration of advanced technologies, such as artificial intelligence and real-time analytics, further enhances the capabilities of cloud WMS, enabling predictive workflows that optimize stock levels and reduce stock-outs.

In conclusion, the flexibility and scalability that WMS benefits provide are vital for businesses striving to excel in a dynamic market environment. By embracing these solutions, companies can not only streamline their operations but also position themselves for sustained growth and success.

GoRamp: Improved Inventory Accuracy and Order Fulfillment

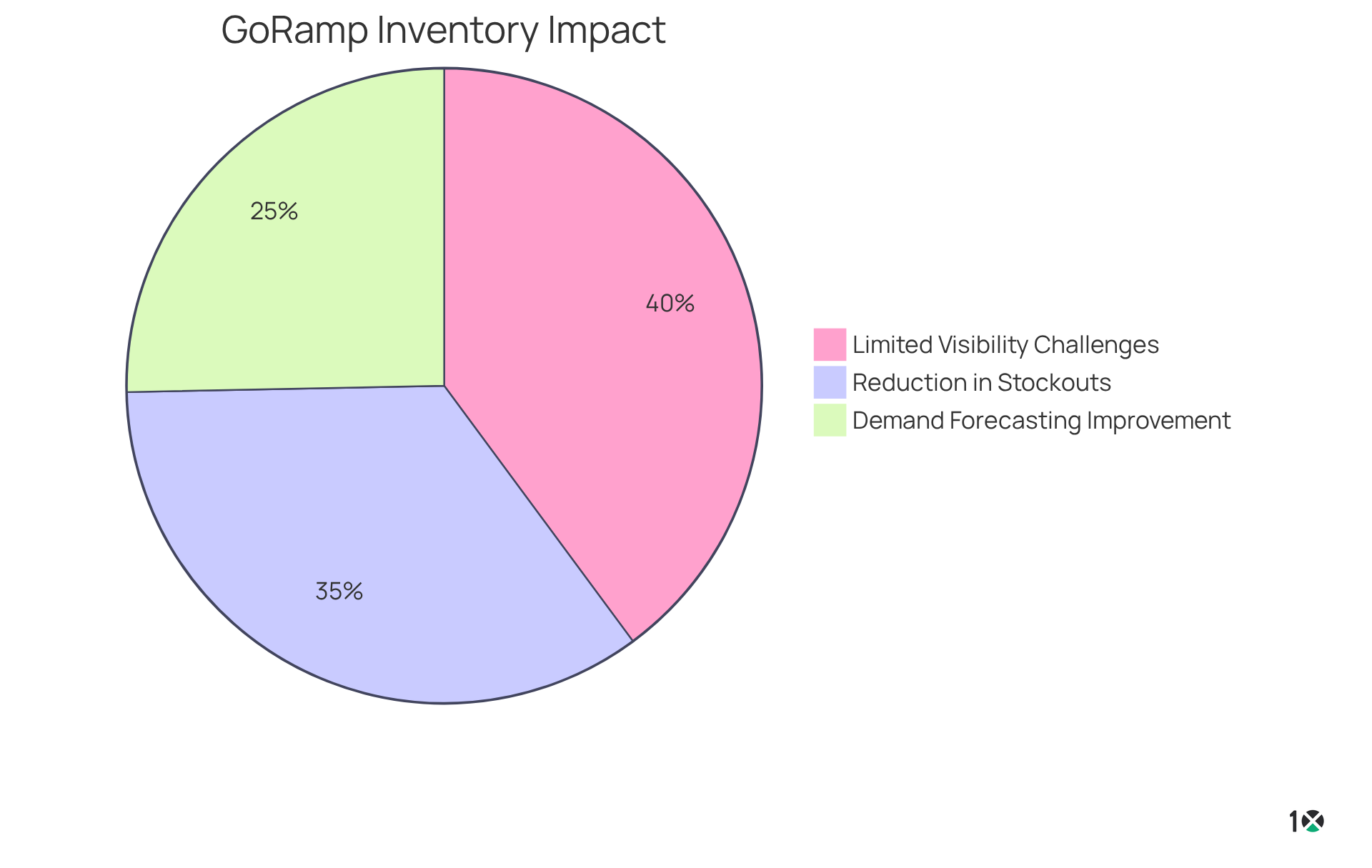

GoRamp significantly enhances stock precision through its automated tracking and coordination features. By providing real-time visibility into stock levels and order statuses, it effectively minimizes errors in order fulfillment. This capability is crucial for companies that depend on accurate stock management to meet customer expectations and maintain operational efficiency. A study from the International Journal of Logistics Management found a remarkable 55% reduction in stockouts following the implementation of automated stock management systems, directly correlating with improved customer satisfaction and retention rates.

Moreover, the real-time monitoring features have shown a 40% improvement in demand forecasting accuracy, enabling companies to optimize their stock levels and reduce carrying costs. As Ritesh Kewlani, Head of Product Marketing, aptly states, “Modern solutions are essential for meeting the demands of today’s consumers.” Consequently, organizations utilizing GoRamp’s solutions can anticipate not only a streamlined order fulfillment process but also the wms benefits that lead to significant operational enhancements.

With 63% of companies facing challenges due to , the relevance of GoRamp’s solutions becomes increasingly vital in today’s business landscape.

Accounting Integration: Enhanced Financial Oversight with WMS

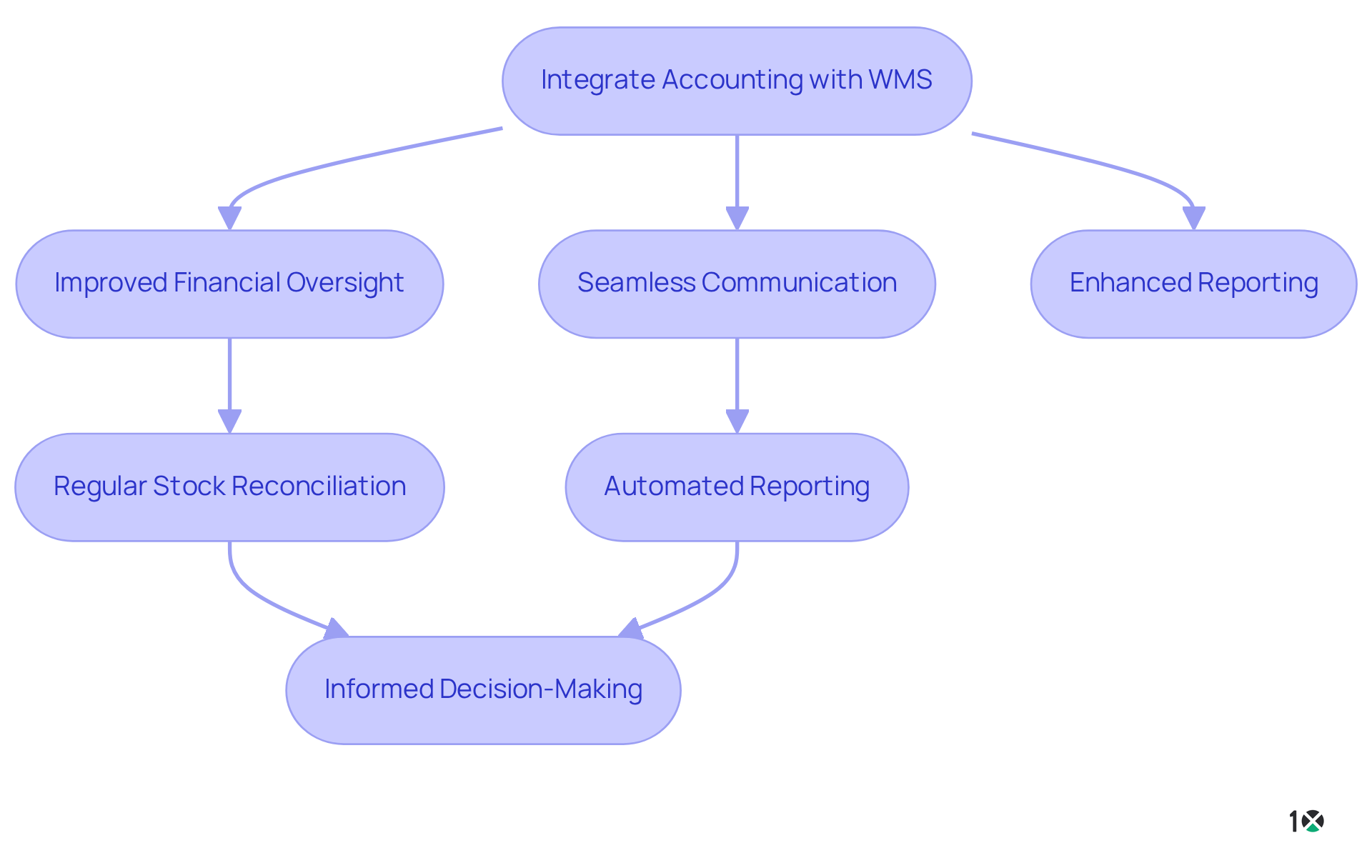

Integrating accounting systems with Warehouse Management Systems (WMS) significantly enhances financial oversight, illustrating the WMS benefits by ensuring that stock data aligns consistently with financial records. This integration fosters seamless communication and data movement, which in turn improves both stock oversight and financial reporting processes. By minimizing discrepancies and refining stock valuation, businesses can achieve superior cost control and financial accuracy, leading to more informed decision-making.

Financial analysts emphasize that effective integration transforms stock management into a strategic asset. This capability allows organizations to respond swiftly to market changes while maintaining robust financial health. Moreover, automated stock management systems provide enhanced reporting and analytics, crucial for superior decision-making.

Regular stock reconciliation is vital for maintaining accuracy, ensuring that discrepancies are addressed promptly. By leveraging real-time data from WMS, companies can achieve WMS benefits by significantly reducing errors and discrepancies between stock and financial records. This ultimately boosts and supports long-term growth.

As a practical recommendation, companies should implement regular reconciliation schedules to fully capitalize on the benefits of their integrated systems.

Analytics-Driven Insights: Optimizing Warehouse Performance

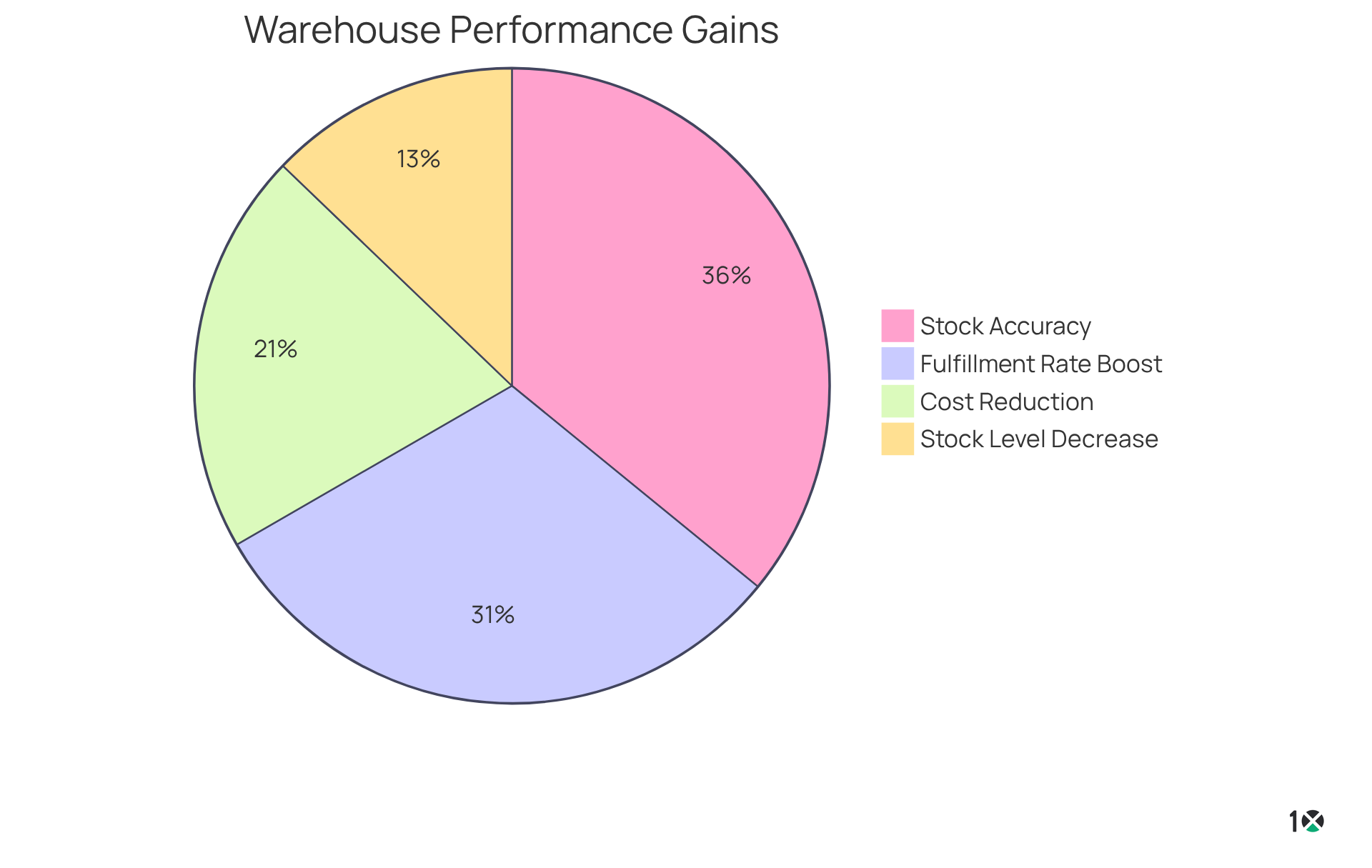

Analytics-driven insights are essential for optimizing warehouse performance. By examining data on stock turnover rates, which directly correlate with operational efficiency, businesses can identify bottlenecks and areas for improvement. For instance, organizations that leverage data analytics for stock management decisions achieve a 20% reduction in costs and a 35% increase in stock accuracy. Furthermore, those utilizing demand forecasting tools experience a 10-15% decrease in total stock levels, underscoring the benefits of data analysis in stock control.

Implementing analytics tools within Warehouse Management Systems (WMS) provides significant WMS benefits, empowering organizations to make informed decisions that enhance order fulfillment rates and labor efficiency. In fact, companies with improved stock management systems see a 30% boost in order fulfillment rates, significantly reducing delivery delays and enhancing customer satisfaction. Additionally, automated stock management tools can elevate operational efficiency by as much as 50%.

As one data analyst observed, “Harnessing analytics allows us to transform raw data into actionable insights, driving efficiency and profitability in our operations, particularly by forecasting stockouts based on lead times.” This approach not only streamlines processes but also cultivates a culture of , which is vital for thriving in today’s competitive landscape.

Argos Software: Cost Reduction Through Automation

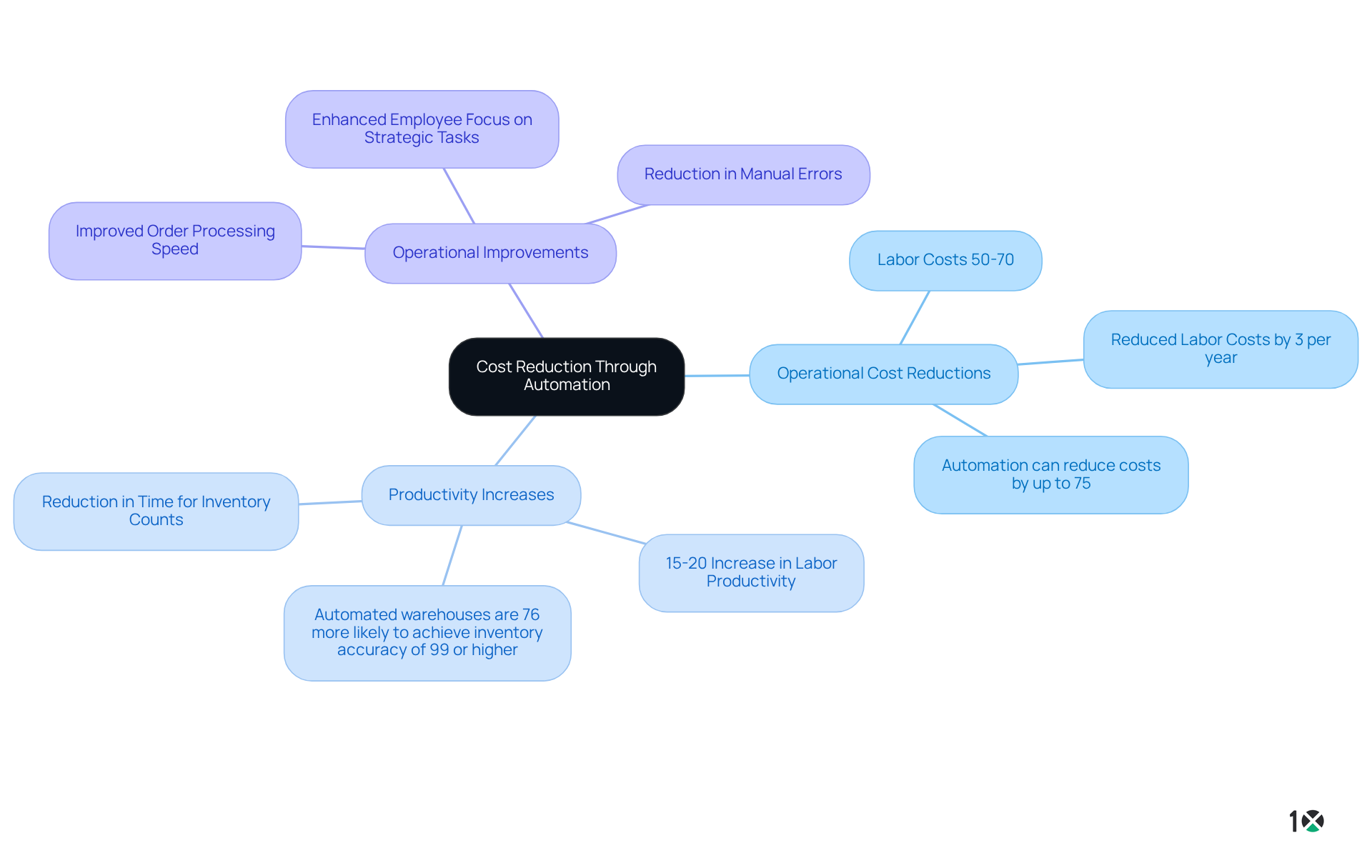

10X ERP harnesses the power of automation to optimize warehouse operations, which demonstrates the WMS benefits through significant reductions in operational costs. By automating repetitive tasks such as stock monitoring and order processing, businesses can substantially lower labor costs, which typically account for 50% to 70% of a company’s warehousing budget. This strategic shift not only enhances and contributes to WMS benefits but also empowers employees to focus on higher-value tasks, ultimately driving profitability.

For instance, businesses that swiftly implement automation report labor productivity increases of 15-20%. Furthermore, automated storage facilities are 76% more likely to achieve stock precision of 99% or greater. The integration of technologies like RFID provides real-time insights into stock levels, significantly improving accuracy and reducing the time needed for stock counts from days to mere hours. As AbeTech states, ‘By automating routine and repetitive tasks such as inventory management, RFID allows employees to concentrate on more strategic work that contributes greater value to the organization.’

Consequently, companies can realize substantial cost reductions and operational improvements, both of which are significant WMS benefits, positioning themselves advantageously in an ever-evolving market.

Caisoft: Boosting Workforce Productivity with WMS

Caisoft’s WMS solutions are strategically designed to leverage WMS benefits that enhance workforce productivity through real-time tracking of employee activities and task completion rates. By optimizing labor allocation and streamlining workflows, Caisoft empowers enterprises to elevate their operational efficiency, showcasing the WMS benefits. This not only boosts employee satisfaction but also contributes significantly to overall organizational success.

Studies reveal that effective labor optimization can yield a remarkable 20% increase in productivity. HR professionals underscore that real-time tracking cultivates accountability and transparency—key components for enhancing employee performance. Industry experts assert that the WMS benefits of integrating WMS technology are essential for contemporary warehouse operations, as they enable businesses to adapt to evolving demands while maximizing workforce potential.

Moreover, fostering a positive work culture, as emphasized by Tony Hsieh, is crucial for nurturing employee happiness, which directly correlates with productivity. Teamwork, as highlighted by Chadwick Heard, also plays a pivotal role in warehouse operations, with collaborative efforts further enhancing efficiency. Additionally, proactive inventory oversight, including systems that provide alerts for low stock, is vital for optimizing labor allocation and ensuring seamless operations.

ShipBob: Enhancing Customer Service Through Accurate Fulfillment

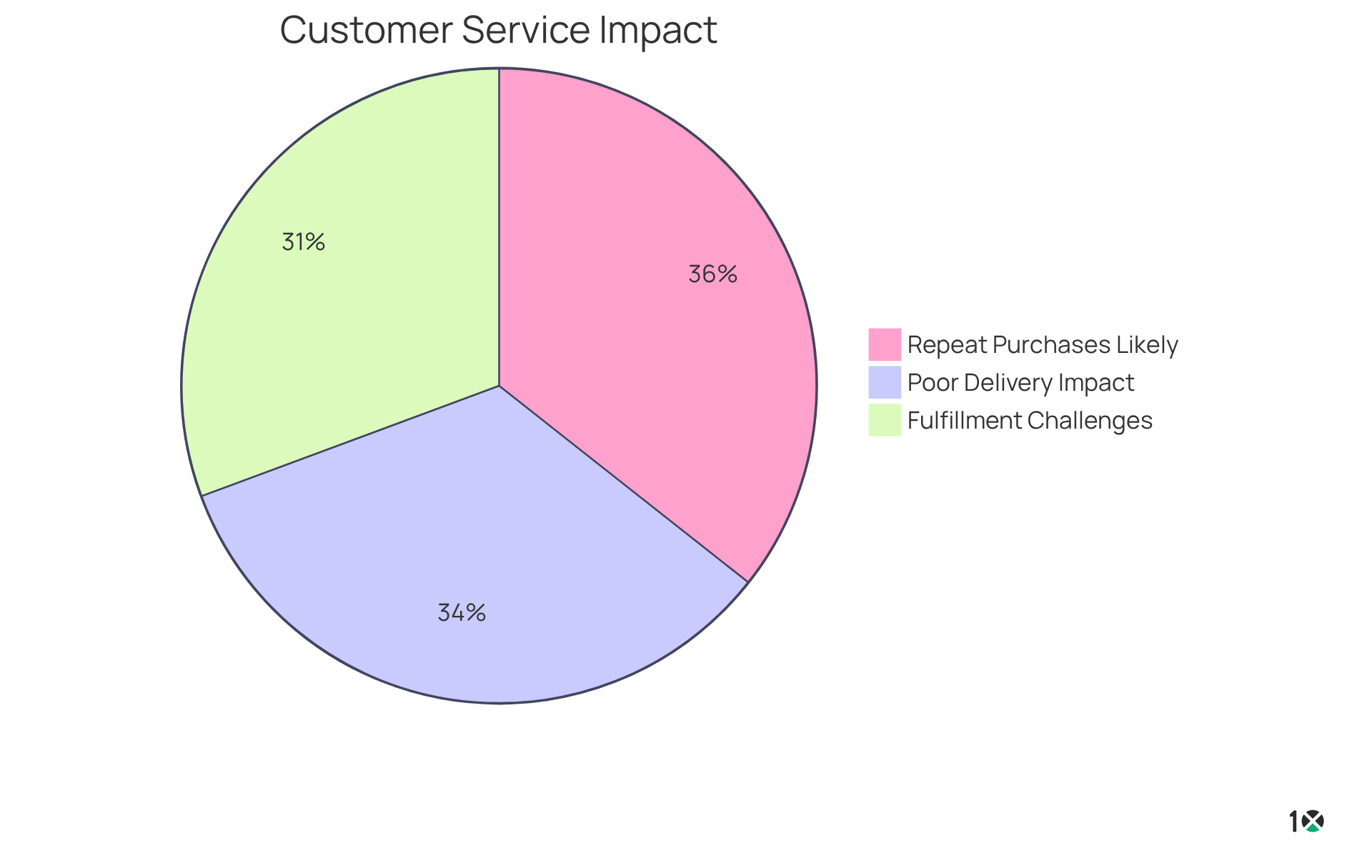

ShipBob significantly enhances customer service by ensuring precise order fulfillment through its advanced warehouse management system (WMS), showcasing the WMS benefits. This precision is not merely a benefit; it is essential for companies aiming to deliver the right products to clients quickly. Consider this: studies indicate that 88% of consumers are less likely to shop with a retailer after a poor delivery experience. Thus, reliability in is crucial.

Furthermore, accurate fulfillment directly correlates with customer satisfaction and loyalty. In fact, 93% of customers are likely to make repeat purchases with companies that provide excellent service. In today’s competitive e-commerce environment, where 80% of companies struggle with fulfillment efficiency, the WMS benefits include:

- Streamlining operations

- Nurturing long-term customer relationships

This makes it an essential asset for successful e-commerce activities, prompting businesses to invest in solutions that enhance their operational effectiveness.

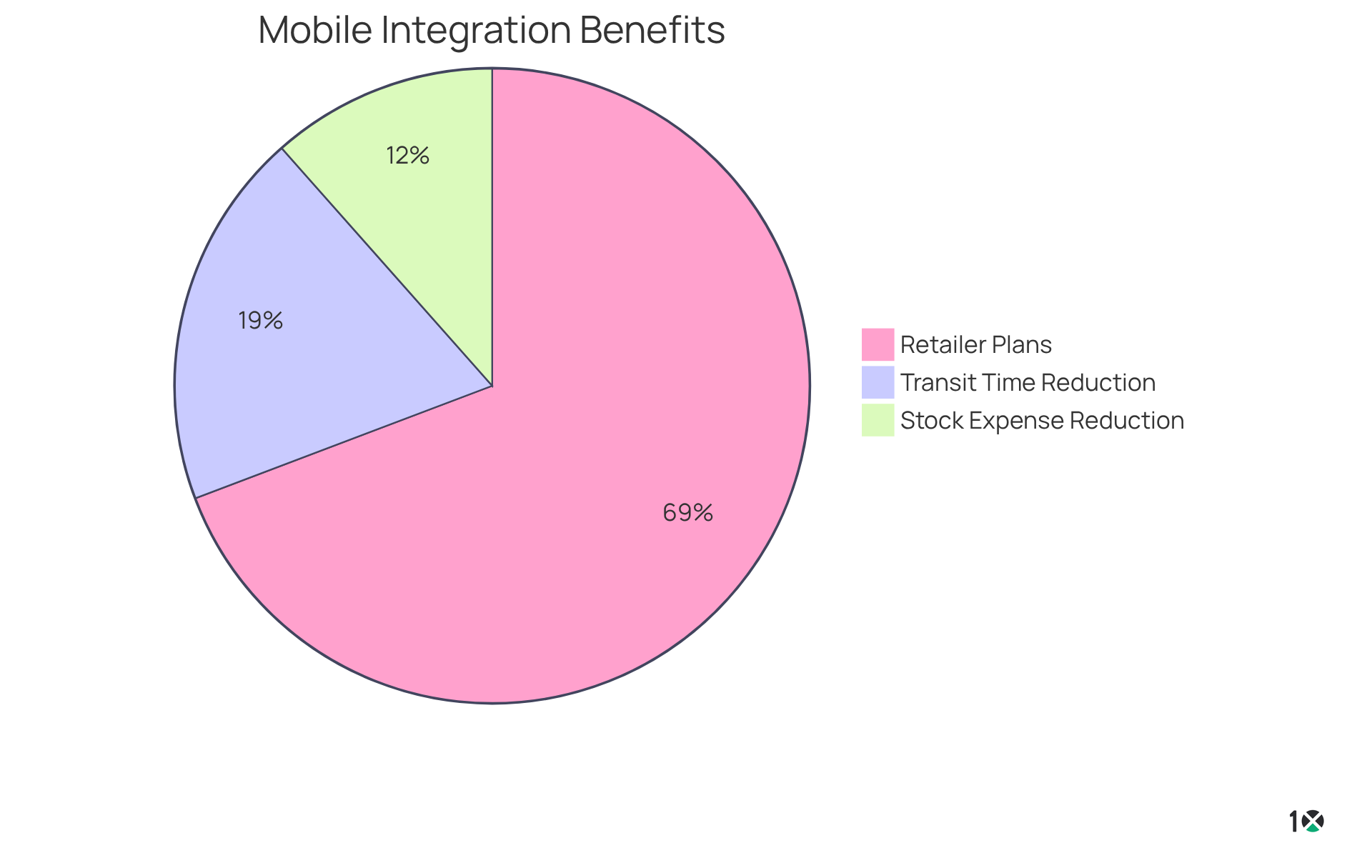

Mobile Integration: Real-Time Tracking for Enhanced Warehouse Efficiency

Mobile integration within warehouse management systems significantly enhances real-time monitoring of stock and order statuses. By equipping staff with mobile devices, businesses can foster improved communication and streamline operations. This capability not only enhances efficiency but also enables quick reactions to stock fluctuations, ultimately resulting in superior performance in warehouse operations.

For instance, instantaneous tracking has been demonstrated to decrease stockouts and overstocks, possibly reducing total stock expenses by as much as 12%, as emphasized by industry studies. Furthermore, companies utilizing mobile WMS solutions report a 20% reduction in transit times, highlighting the WMS benefits of adopting such technologies. As logistics experts stress, the capability to track inventory levels and order statuses instantly is essential for ensuring operational efficiency and fulfilling customer expectations for timely deliveries.

Additionally, with 72% of retailers planning to transform their supply chain operations using real-time visibility, the importance of mobile integration in warehouse management systems is more evident than ever. This trend underscores the necessity for Operations Managers to consider to enhance their operational capabilities and take advantage of the WMS benefits to meet evolving market demands.

Conclusion

The advantages of Warehouse Management Systems (WMS) are pivotal in transforming warehouse operations, enabling businesses to achieve unprecedented levels of efficiency and accuracy. By implementing advanced technologies like real-time data processing, automated tracking, and cloud-based solutions, organizations can streamline their processes, reduce costs, and enhance customer satisfaction. The integration of WMS not only optimizes inventory management but also fosters a culture of continuous improvement, essential for staying competitive in the evolving market landscape.

Throughout this article, key insights have highlighted the multifaceted benefits of WMS, including enhanced inventory accuracy, improved order fulfillment, and the ability to make data-driven decisions. The implementation of automated systems drastically reduces stock errors, while the flexibility offered by cloud-based solutions allows for swift adaptation to market demands. The evidence is clear: WMS is integral to modern logistics. Furthermore, the role of analytics in optimizing performance and the importance of integrating financial oversight further underscore the transformative potential of these systems.

In light of these compelling benefits, businesses are encouraged to assess their current warehouse management practices and consider the adoption of WMS solutions that align with their operational goals. Embracing these technologies not only leads to immediate improvements in efficiency but also positions companies for sustainable growth and success in a competitive environment. The future of warehouse operations lies in the strategic implementation of WMS, making it essential for organizations to invest in these systems to thrive in an increasingly complex supply chain landscape.

Frequently Asked Questions

What is 10X ERP and how does it benefit inventory management?

10X ERP enables distributors to process data in real-time, allowing for continuous monitoring of stock levels. This capability helps prevent stockouts and overstock situations, ensuring that businesses can meet customer demands efficiently while minimizing costs.

What improvements have businesses seen by using immediate stock tracking?

Businesses utilizing immediate stock tracking have reported a 30% decrease in stock errors and a 15% increase in sales due to improved product availability.

How does automated order fulfillment impact customer satisfaction?

The implementation of automated systems can enhance order fulfillment accuracy by up to 80%, ensuring that customers receive their orders accurately and on time, which strengthens customer satisfaction and loyalty.

What is SAP Extended Warehouse Management (EWM) and its key features?

SAP Extended Warehouse Management (EWM) is a modern warehouse operations system that enhances efficiency through features like automated stock tracking and optimized picking routes, which minimize errors in order fulfillment.

How does RFID technology contribute to inventory accuracy in SAP EWM?

Companies using RFID technology report an impressive 97% stock precision, highlighting the importance of real-time data in achieving high inventory accuracy.

What challenges do storage facilities face due to human error?

Nearly 43% of storage facilities worldwide face issues related to human error, which is identified by 62% of logistics specialists as a primary cause of stock discrepancies.

What advantages do cloud-based Warehouse Management Systems (WMS) offer?

Cloud-based WMS provide flexibility and scalability, allowing businesses to adapt operations to fluctuating demand and access critical data remotely for real-time decision-making.

What is the projected growth rate for cloud-based WMS platforms?

Cloud-based platforms are experiencing a projected compound annual growth rate (CAGR) of 19.68% through 2030, driven by the demand for scalable subscription services.

How are businesses leveraging cloud WMS to meet customer expectations?

Businesses, particularly in e-commerce, are using cloud WMS to manage rapid order fulfillment and inventory, ensuring they can effectively meet customer expectations.

What role does advanced technology play in enhancing cloud WMS capabilities?

The integration of advanced technologies like artificial intelligence and real-time analytics in cloud WMS enables predictive workflows that optimize stock levels and reduce stock-outs.