Overview

The article presents ten key benefits of cloud inventory management software specifically for distributors, underscoring significant enhancements in efficiency, cost savings, accuracy, and customer satisfaction. These advantages are substantiated by data that reveals improved real-time tracking, diminished operational expenses, and heightened service levels. Collectively, these factors contribute to superior stock management and increased responsiveness to market demands.

Introduction

Cloud inventory management software is revolutionizing the way distributors manage their stock, presenting unprecedented advantages that can transform operational efficiency. By harnessing real-time data and automation, businesses can streamline their inventory processes, enhance customer satisfaction, and significantly reduce costs. Yet, a critical question arises: how can distributors fully leverage these benefits to remain competitive in an ever-evolving marketplace? This article explores ten compelling benefits of cloud inventory management software, illuminating the path to optimized stock control and sustainable growth.

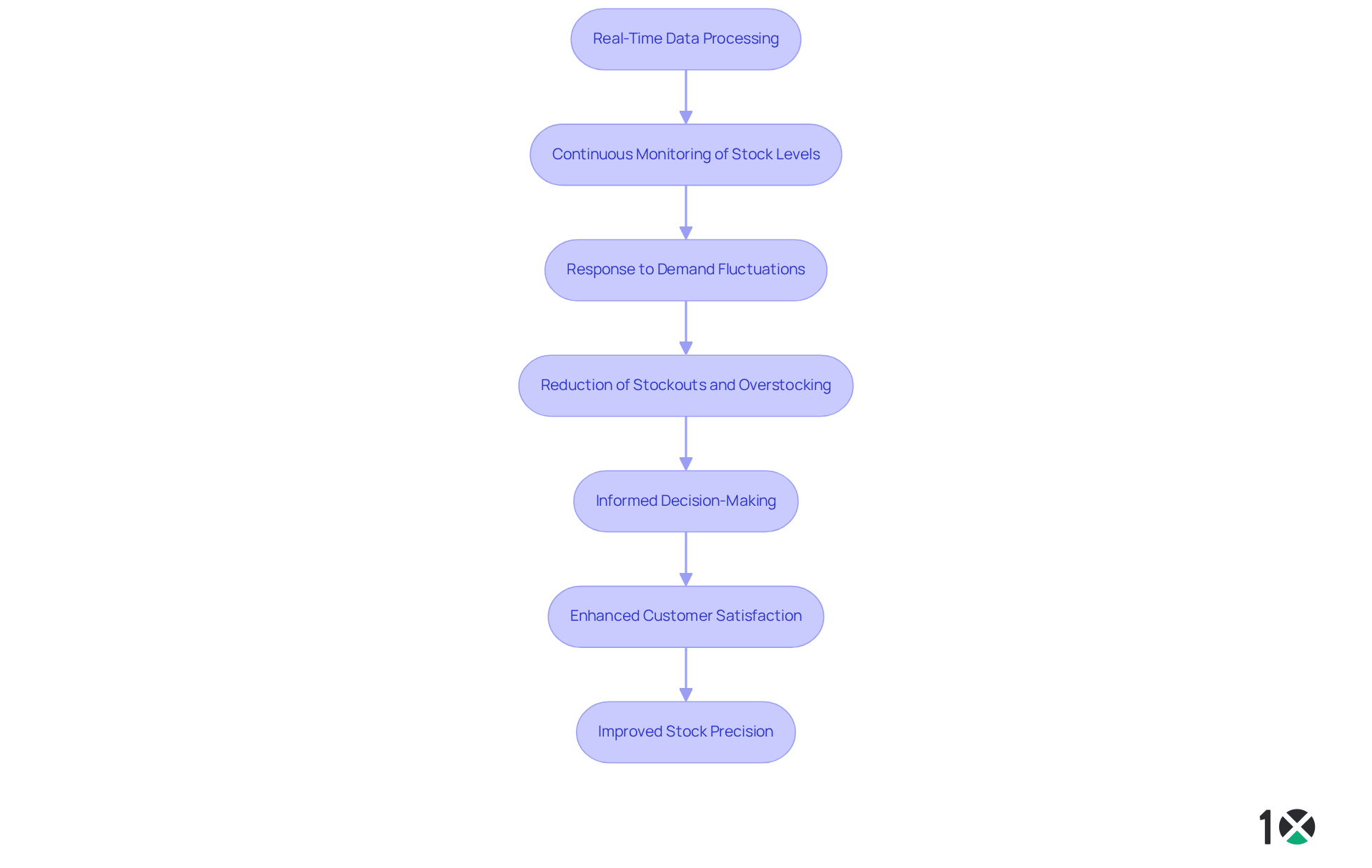

10X ERP: Real-Time Data Processing for Enhanced Inventory Control

10X ERP empowers suppliers through real-time data processing, facilitating continuous monitoring of stock levels. This capability enables businesses to respond swiftly to demand fluctuations, significantly reducing the risks of stockouts and overstocking. By leveraging cloud inventory management software, users can access real-time information from any location, which supports informed decision-making and enhances overall stock management.

For instance, when a distributor detects a sudden surge in demand for a particular product, they can promptly adjust their stock orders to align with consumer needs. This proactive strategy not only elevates service levels but also enhances customer satisfaction. Furthermore, automated stock control systems reduce human errors, improve stock levels, and increase order fulfillment accuracy. Notably, 73% of retailers report improved stock precision through forecasting tools, underscoring the transformative impact of cloud inventory management software for suppliers aiming to optimize their stock management practices.

To achieve , suppliers should consider investing in cloud inventory management software that offers precise tracking, customizable features, and seamless software integration.

Scalability: Adapt Inventory Management to Business Growth

10X ERP is designed to grow alongside your enterprise, providing scalable stock control solutions that adapt to increasing demands. With robust accounting capabilities, , customizable attributes, and lot/serial item tracking, suppliers can effortlessly adjust their stock settings, introduce new product lines, and manage multiple warehouses without extensive system overhauls. The platform’s flexible user permissions and built-in reporting empower stakeholders to make informed decisions, ensuring that businesses maintain efficiency and control as they scale.

Statistics reveal that firms utilizing adaptable systems experience a 50% increase in operational efficiency, underscoring the critical role of flexible resource management in achieving business objectives. This innovative cloud inventory management software ultimately fosters sustained growth and profitability.

Cost Savings: Reduce Operational Expenses with Cloud Solutions

Cloud inventory management software, such as 10X ERP, offers distributors a powerful avenue to significantly reduce operational expenses. Traditional stock management systems often necessitate considerable in hardware and software, coupled with ongoing maintenance costs that can strain budgets. In contrast, 10X ERP employs an all-inclusive subscription model, eliminating the need for expensive infrastructure and enabling businesses to allocate resources more efficiently. This model encompasses all functionality, features, modules, tools, and dashboards, ensuring users have access to everything they require without unexpected costs.

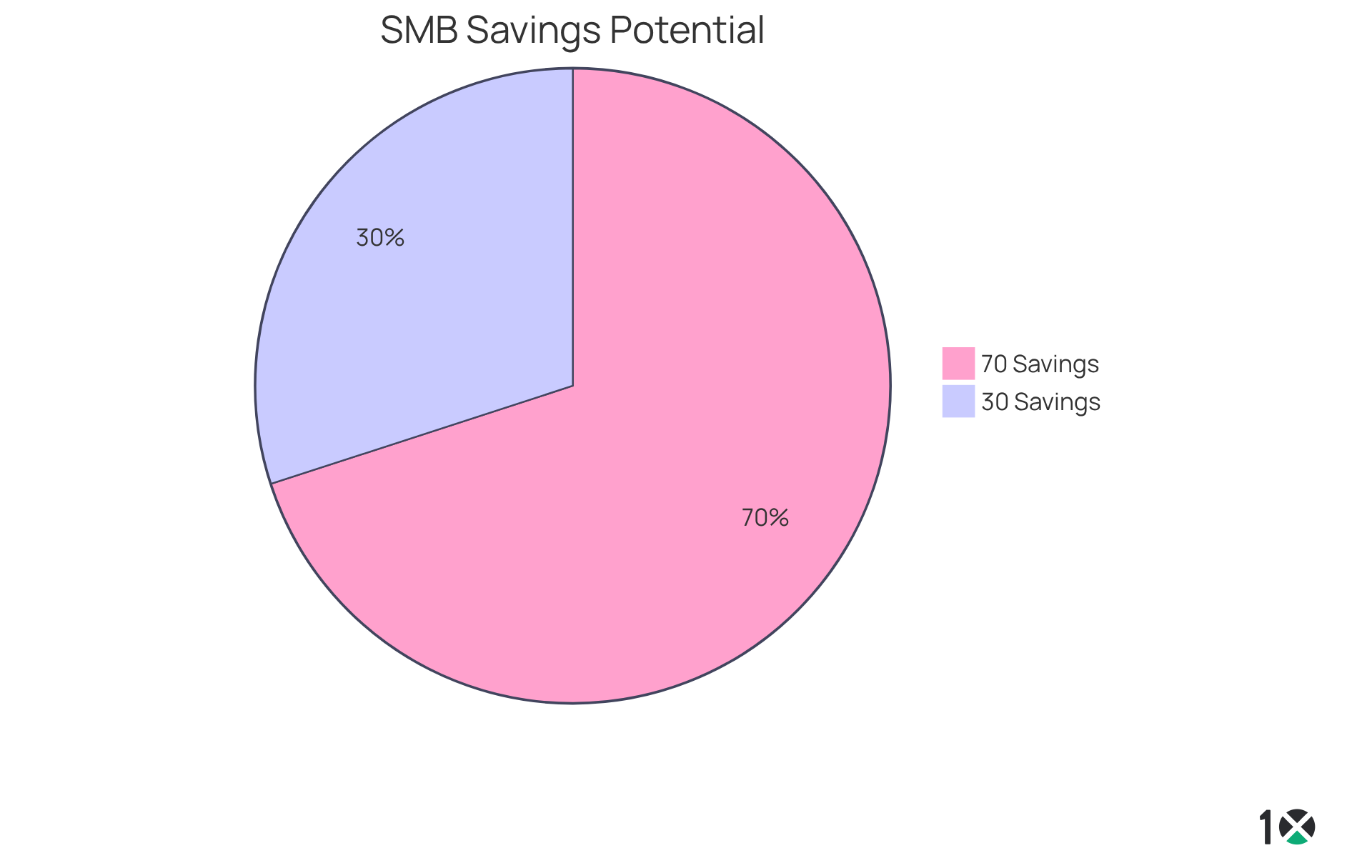

The automation of inventory processes provided by cloud inventory management software not only streamlines operations but also reduces labor costs and minimizes errors, leading to additional savings. For example, small and medium-sized businesses (SMBs) often realize 30-70% cost savings with payback periods under six months when they adopt cloud inventory management software. Financial analysts indicate that organizations can anticipate significant benefits from cloud inventory management software investments within 1-3 years, highlighting the long-term financial advantages of transitioning to cloud-based systems.

Moreover, the adaptability of 10X ERP empowers suppliers to broaden their operations without the burden of substantial capital investments. This flexibility is vital in today’s fast-paced market, where the capacity to respond swiftly to shifting demands can distinguish successful businesses from their competitors. By leveraging cloud technology, suppliers not only enhance their operational efficiency but also position themselves for sustainable growth in an increasingly digital landscape.

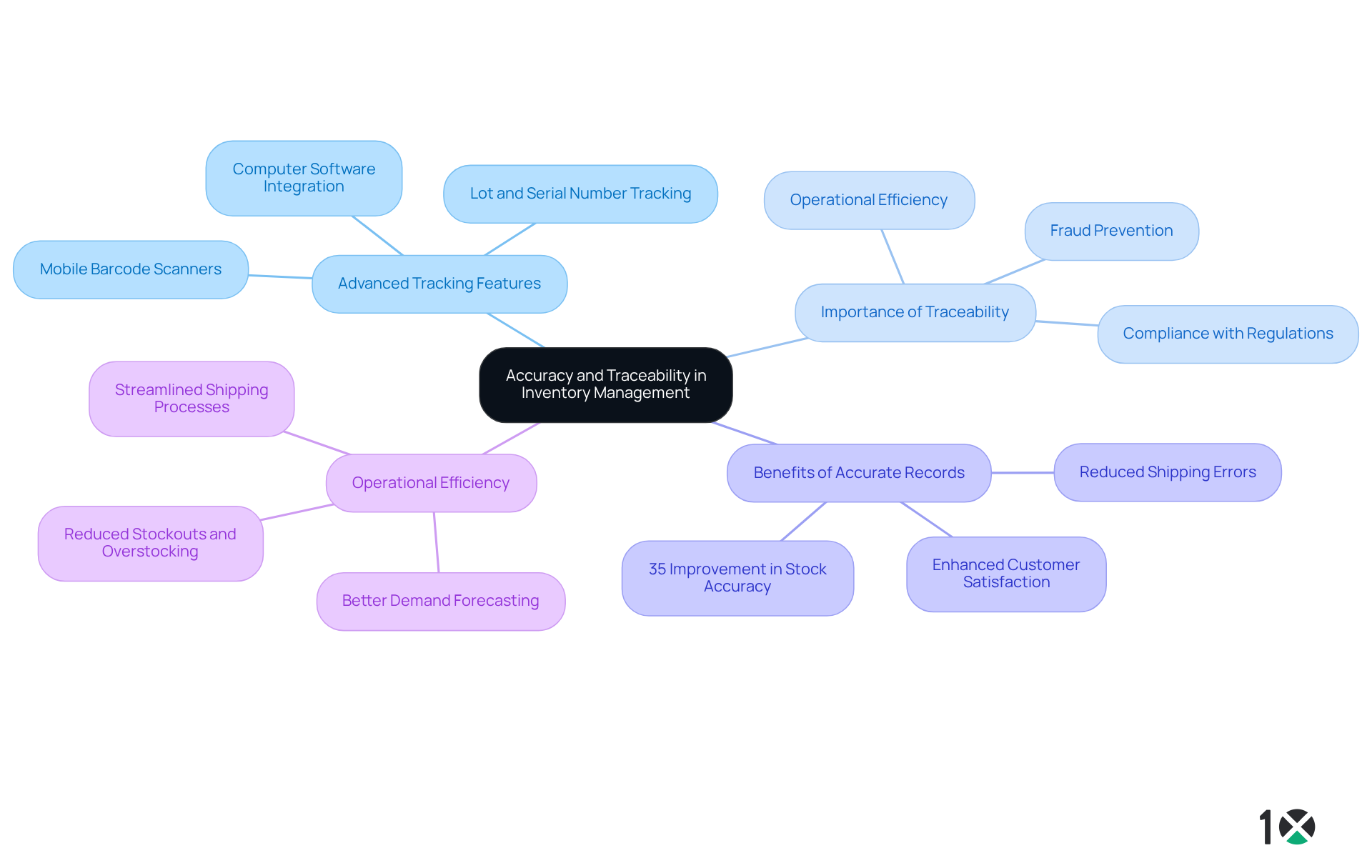

Accuracy and Traceability: Ensure Reliable Inventory Records

10X ERP significantly enhances stock precision through its advanced tracking features, particularly lot and serial number tracking. These capabilities empower distributors to uphold and effortlessly track products throughout the supply chain.

In 2025, the importance of traceability in stock management is paramount; it is essential for operational efficiency and compliance with industry regulations. Precise stock records not only mitigate costly errors, such as stock discrepancies, but also enhance responsiveness to client inquiries about product availability.

Notably, businesses utilizing serial number tracking have reported a 35% improvement in stock accuracy, showcasing the tangible benefits of implementing such systems. Experts in the supply chain domain emphasize that maintaining precise stock records is vital, as it directly influences overall operational performance and customer satisfaction.

By leveraging these advanced tracking techniques, distributors can ensure a more organized and efficient stock control process.

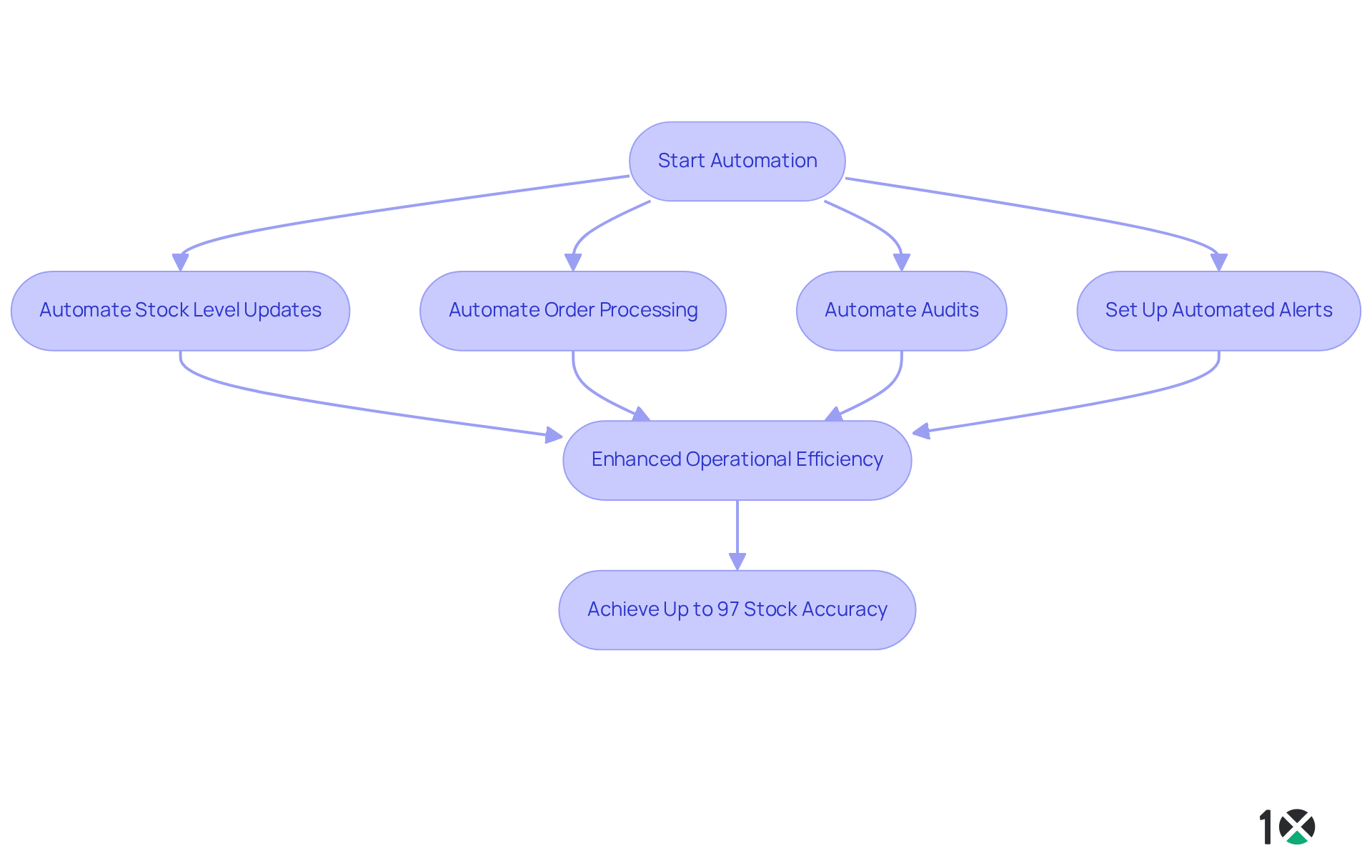

Automation: Streamline Inventory Processes and Reduce Errors

Automation within 10X ERP revolutionizes stock management by drastically minimizing human error. By automating tasks such as stock level updates, order processing, and audits, staff can shift their focus toward strategic initiatives. For instance, automated alerts promptly notify users when stock levels fall below predetermined thresholds, facilitating timely reordering. This proactive approach not only enhances but also ensures consistent stock levels, ultimately improving service delivery.

Industry leaders assert that automation can yield a 30% improvement in stock use efficiency, highlighting its potential to streamline processes and mitigate costly errors. Distributors that embrace automation have reported substantial gains in precision and efficiency, with many achieving stock accuracy rates of up to 97% through advanced technologies like RFID.

As we near 2025, integrating automation in stock management will be essential for suppliers aiming to maintain competitiveness and meet evolving customer demands.

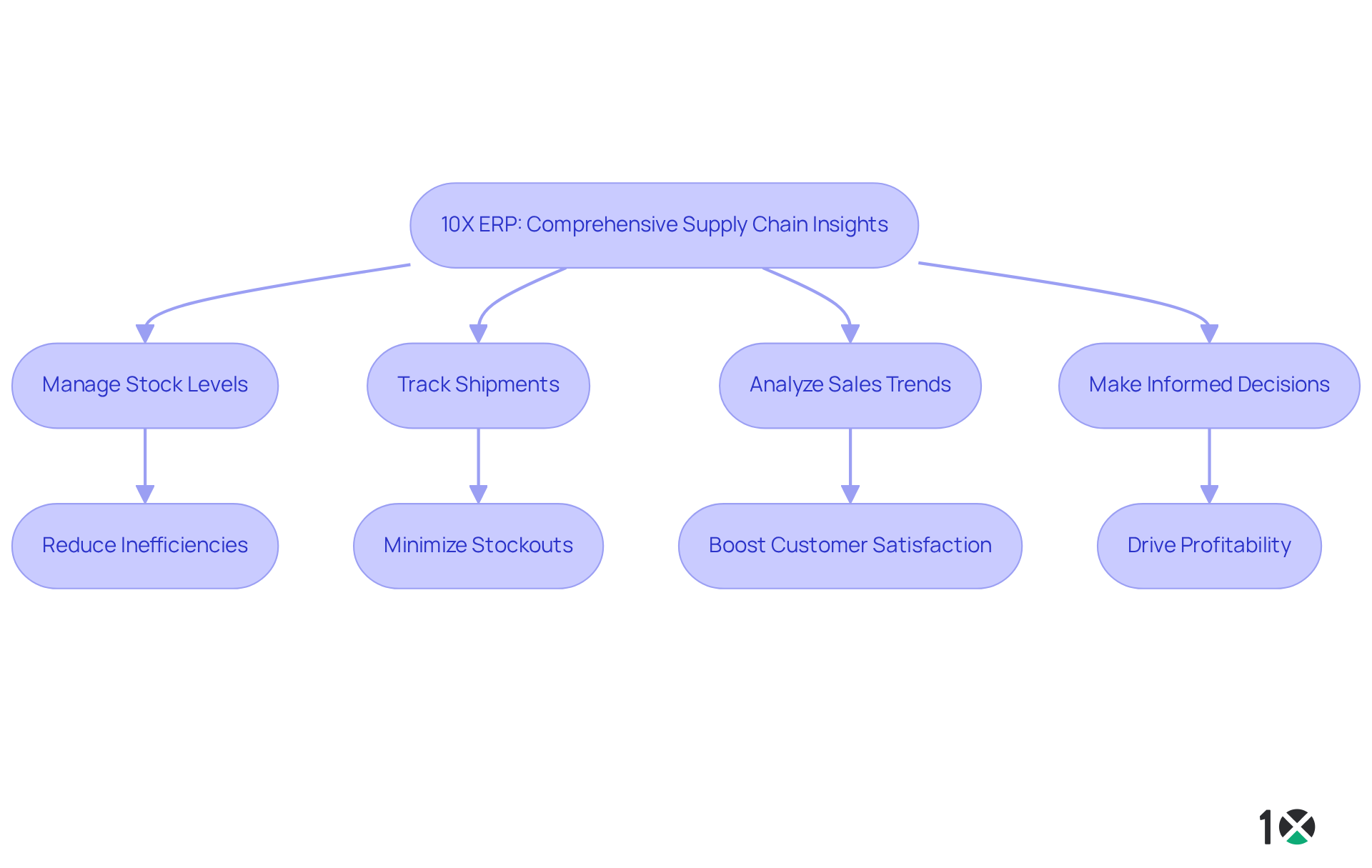

Visibility: Gain Comprehensive Insights Across the Supply Chain

10X ERP delivers unparalleled transparency throughout the supply chain, empowering distributors to effectively manage stock levels, track shipments, and analyze sales trends in real-time using cloud inventory management software. This capability is vital for making informed decisions and refining stock control strategies.

With access to comprehensive insights, companies can swiftly identify potential challenges and , allowing for timely adjustments to stock levels. Real-time stock management significantly reduces inefficiencies, directly linked to features such as real-time data processing, customizable user permissions, and integrated reporting.

These enhancements drive profitability by minimizing losses associated with stockouts and excess inventory. Improved visibility not only streamlines operations but also boosts customer satisfaction, as precise stock information guarantees timely order fulfillment and dependable service.

As the global supply chain management market is poised for substantial growth, integrating real-time insights into stock strategies will be essential for distributors aiming to thrive in a competitive landscape.

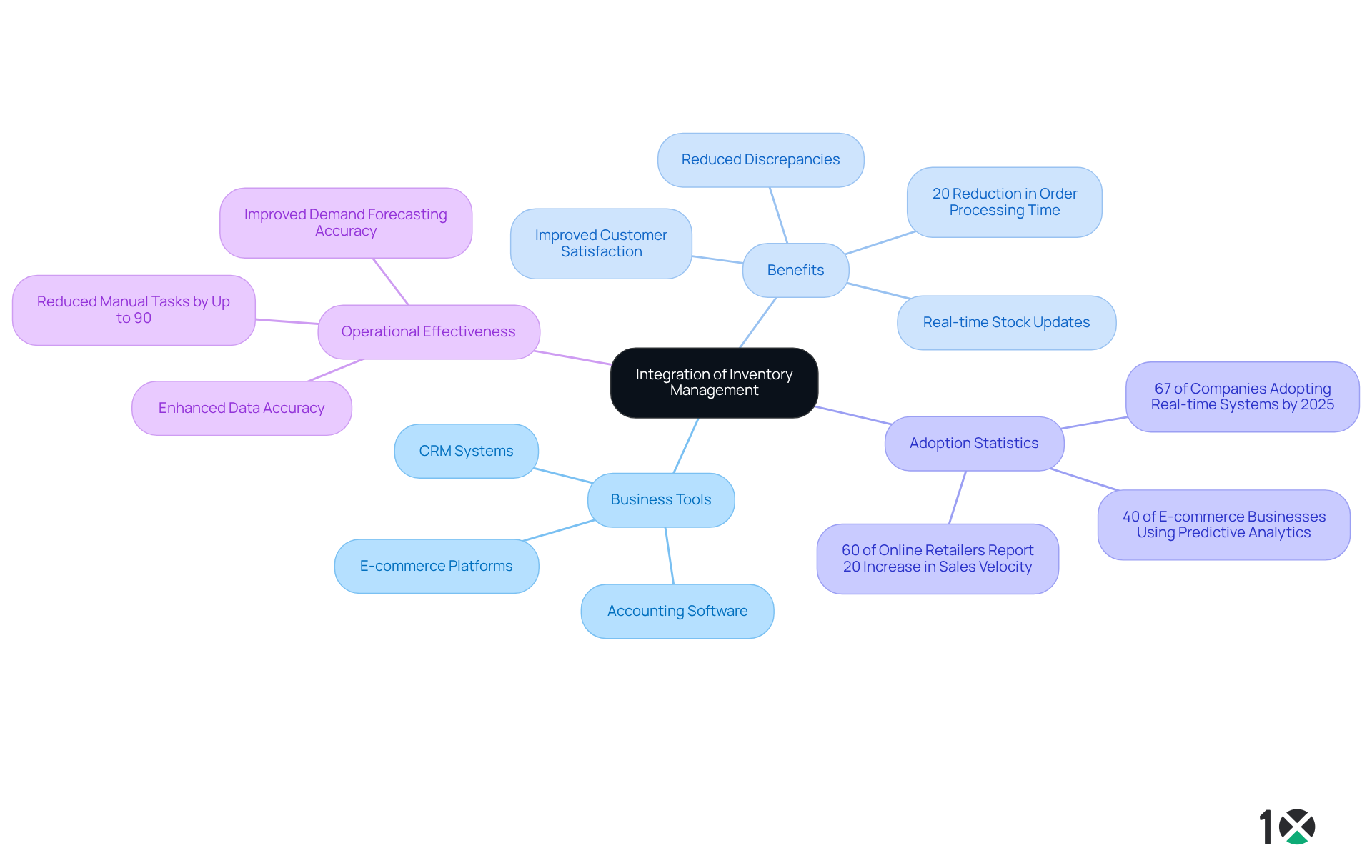

Integration: Connect Inventory Management with Other Business Tools

The API-first approach of 10X ERP facilitates seamless integration with essential business tools, including accounting software, CRM systems, and e-commerce platforms. This connectivity ensures that stock data remains synchronized across all applications, significantly reducing discrepancies and enhancing data accuracy. When a sale occurs on an e-commerce platform, stock levels are updated in real-time, effectively preventing overselling and improving customer satisfaction. Such integration cultivates a cohesive operational environment, empowering distributors to swiftly adapt to market demands.

With 67% of companies intending to adopt by 2025, the significance of precise data synchronization cannot be overstated. Organizations utilizing integrated systems have reported a 20% reduction in order processing time, underscoring the efficiency gained through API-driven connectivity. The robust accounting features of 10X ERP, including real-time data processing and built-in reporting, further enhance operational effectiveness by allowing stakeholders to make informed decisions. Real-time stock synchronization reduces errors and allows staff to focus on other priorities, further enhancing operational effectiveness.

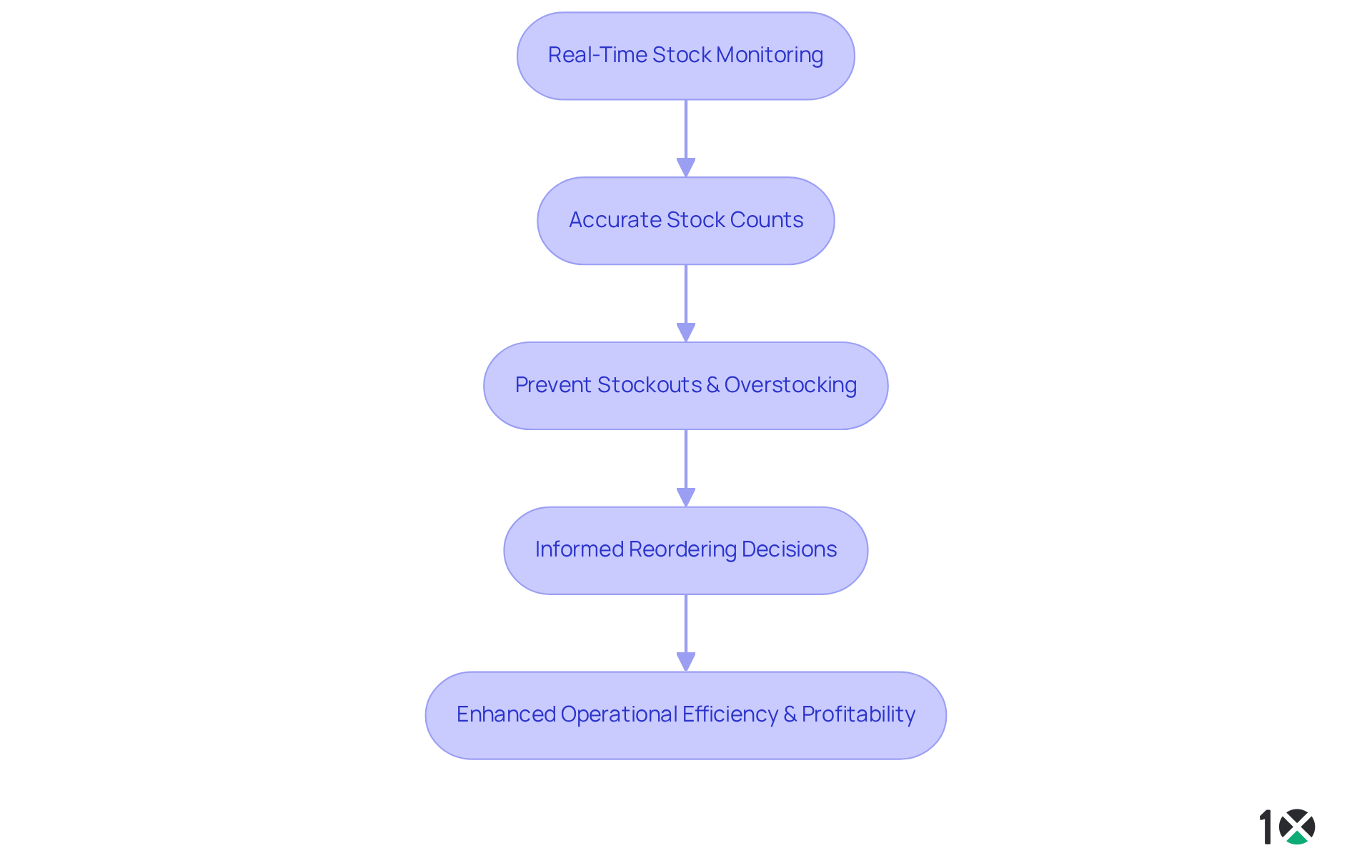

Real-Time Tracking: Maintain Accurate Stock Levels Instantly

With 10X ERP, suppliers gain the significant advantage of , which ensures precise stock counts at all times. This capability is essential for preventing stockouts and overstocking—issues that can lead to lost sales and increased carrying costs. Continuous supervision of stock levels, supported by robust accounting capabilities and flexible user permissions in cloud inventory management software, empowers companies to make informed decisions regarding reordering and stock management.

For example, if a specific item is selling faster than anticipated, suppliers can swiftly adjust their orders to maintain adequate inventory levels. By leveraging strong accounting capabilities and integrated reporting, suppliers can enhance their stock management processes with cloud inventory management software and improve overall operational efficiency, ultimately driving increased profitability.

As Amarnath Immadisetty, Sr Manager of Software Engineering, emphasizes, “This real-time stock management will enable retailers to respond to shifts in demand immediately, resulting in fewer occurrences of stockouts and overstocking.

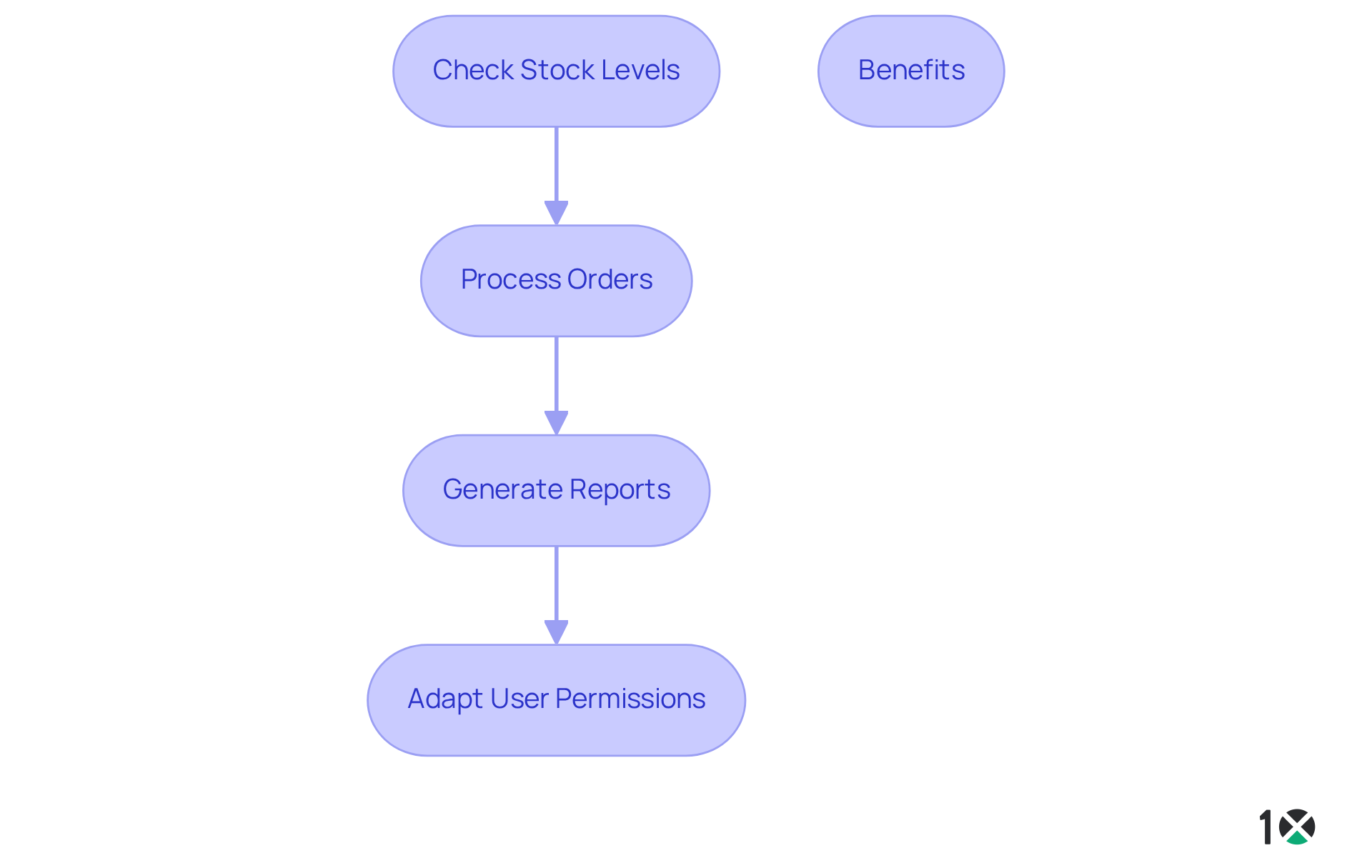

Remote Access: Manage Inventory Anytime, Anywhere

10X ERP’s cloud inventory management software empowers distributors to effortlessly manage their stock anytime and anywhere. This is essential for businesses operating across multiple sites. It allows users to check stock levels, process orders, and generate reports from any internet-enabled device. Such capabilities significantly enhance operational efficiency, enabling teams to respond swiftly to customer inquiries and adapt to market fluctuations.

Moreover, the platform features adaptable user permissions, allowing stakeholders to tailor access according to their roles, alongside a comprehensive audit trail that ensures accountability and transparency in resource management. Businesses utilizing cloud inventory management software have reported substantial improvements. For instance, Target Corporation achieved a 40% reduction in out-of-stocks and a 20% increase in stock turns after implementing cloud inventory management software.

As the demand for real-time data access continues to grow, the ability to oversee stock remotely is becoming a critical component of effective distribution strategies for 2025 and beyond.

Customer Satisfaction: Improve Service Levels with Efficient Inventory Management

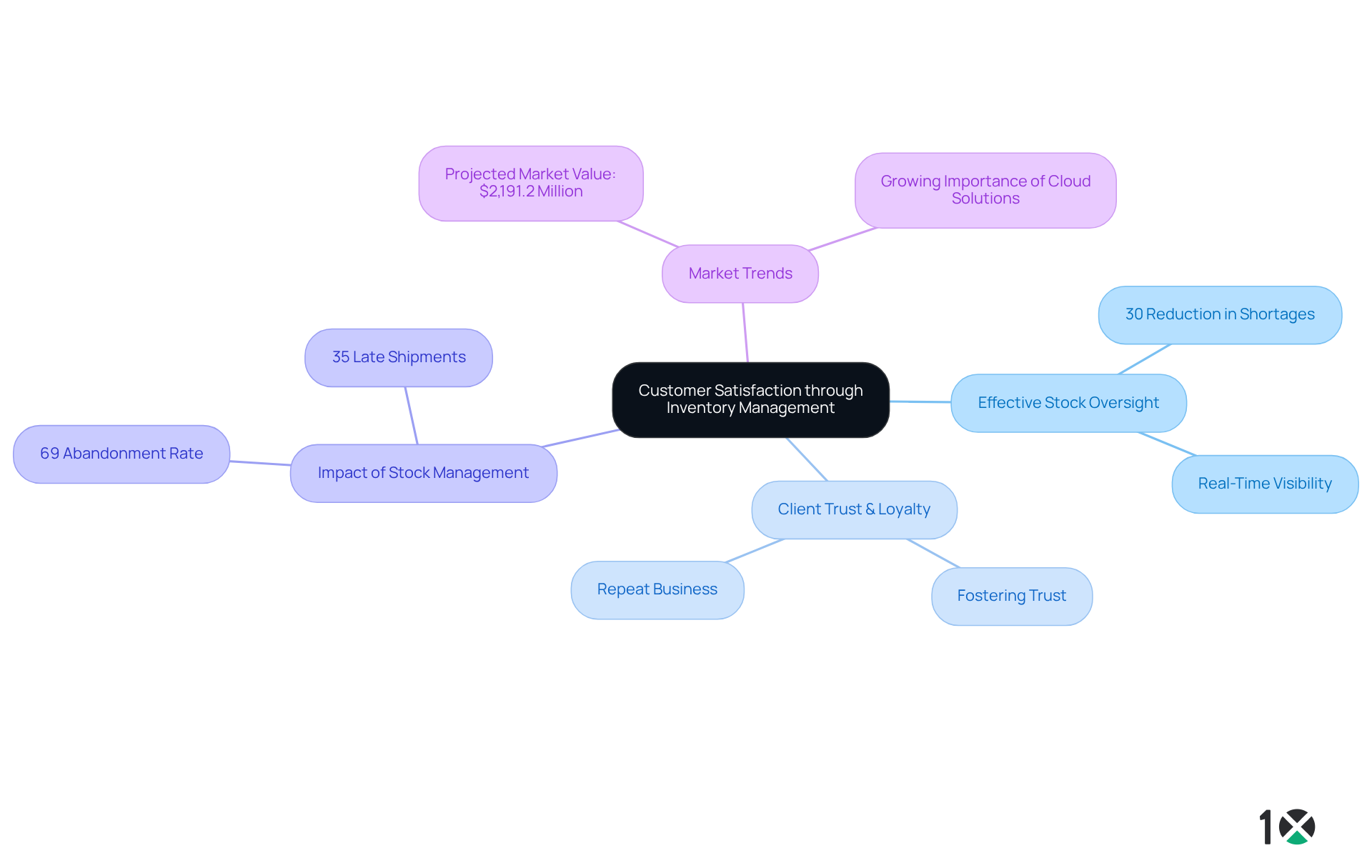

Effective stock oversight through 10X ERP significantly enhances client satisfaction by ensuring accurate stock quantities and streamlining order processing. Distributors equipped with real-time visibility can guarantee product availability, fostering trust and loyalty among clients. This reliability not only drives repeat business but also encourages positive referrals, which are essential for growth in a competitive market. Consider this: 69% of online buyers will abandon their purchase if their preferred item is unavailable, underscoring the financial implications of stock management on client retention.

Moreover, the ability to swiftly respond to inquiries about product availability and order status enriches the overall experience, securing long-term success. As service professionals emphasize, maintaining accurate stock levels is crucial for enhancing service delivery, as it directly impacts client loyalty. In fact, 35% of businesses have shipped an order late because they unintentionally sold a product that was out of stock.

Distributors utilizing cloud inventory management software, such as that offered by 10X ERP, have reported remarkable improvements in service levels, with automated stock handling systems reducing shortages by 30%. This illustrates that is a pivotal factor in achieving operational excellence and customer satisfaction. Additionally, the cloud inventory management software market is projected to reach a valuation of $2,191.2 million by the end of 2024, highlighting the growing importance of investing in such systems.

Conclusion

Cloud inventory management software, exemplified by 10X ERP, provides distributors with a transformative approach to inventory control that enhances efficiency, accuracy, and customer satisfaction. By leveraging real-time data processing, businesses can swiftly respond to market demands, ensuring optimal stock levels while minimizing the risks associated with stockouts and overstocking. This adaptability not only supports growth but also positions companies for long-term success in an increasingly competitive landscape.

The article highlights several key benefits, including:

- Scalability

- Cost savings

- Automation

- Improved visibility across the supply chain

With features such as real-time tracking and seamless integration with existing business tools, distributors can maintain accurate stock records, streamline operations, and reduce operational expenses. The emphasis on automation further underscores the potential for minimizing human error and enhancing overall operational efficiency, leading to significant financial advantages.

As the market for cloud inventory management continues to expand, the importance of adopting such systems cannot be overstated. Distributors are encouraged to invest in these innovative solutions, not only to improve their inventory management practices but also to enhance customer satisfaction and loyalty. By doing so, businesses will be better equipped to navigate the complexities of modern distribution, ensuring they remain competitive and responsive to ever-changing market dynamics.

Frequently Asked Questions

What is 10X ERP and how does it enhance inventory control?

10X ERP is a cloud inventory management software that empowers suppliers through real-time data processing, enabling continuous monitoring of stock levels. This allows businesses to respond quickly to demand fluctuations, reducing the risks of stockouts and overstocking.

How does real-time data processing benefit businesses?

Real-time data processing allows businesses to access up-to-date information from any location, facilitating informed decision-making and improved stock management. For example, distributors can adjust stock orders promptly in response to sudden demand surges, enhancing service levels and customer satisfaction.

What impact does automated stock control have on inventory management?

Automated stock control systems reduce human errors, improve stock levels, and increase order fulfillment accuracy. Statistics show that 73% of retailers report improved stock precision through forecasting tools, highlighting the benefits of cloud inventory management software.

What features should suppliers look for in cloud inventory management software?

Suppliers should consider software that offers precise tracking, customizable features, and seamless integration to achieve effective real-time stock oversight.

How does 10X ERP support business scalability?

10X ERP is designed to grow with businesses, providing scalable stock control solutions that adapt to increasing demands. It allows suppliers to adjust stock settings, introduce new product lines, and manage multiple warehouses without extensive system changes.

What are the operational efficiency benefits of using adaptable systems?

Firms that utilize adaptable systems experience a 50% increase in operational efficiency, which is crucial for achieving business objectives and maintaining control as they scale.

How does 10X ERP help reduce operational expenses?

10X ERP reduces operational expenses by employing an all-inclusive subscription model, eliminating the need for expensive hardware and software investments. This model allows businesses to allocate resources more efficiently and avoid unexpected costs.

What cost savings can small and medium-sized businesses expect from adopting cloud inventory management software?

Small and medium-sized businesses can realize 30-70% cost savings with payback periods under six months after adopting cloud inventory management software. Significant benefits can be anticipated within 1-3 years of investment.

How does the adaptability of 10X ERP contribute to business growth?

The adaptability of 10X ERP allows suppliers to broaden their operations without substantial capital investments, enabling them to respond quickly to shifting market demands and enhancing their operational efficiency for sustainable growth.