Overview

This article presents seven strategies for effective supply chain forecasting, underscoring the critical role of advanced data analytics and diverse predictive techniques in enhancing accuracy and efficiency. Each strategy—ranging from machine learning and adaptive smoothing to the Delphi method—is illustrated with examples that showcase their effectiveness in improving inventory management and aligning operations with real-time market dynamics. These methodologies ultimately lead to significant cost reductions and enhanced decision-making capabilities, making them essential tools for Operations Managers seeking to optimize their supply chains.

Introduction

Supply chain forecasting has emerged as a vital element for businesses aiming to navigate the intricacies of contemporary markets. The swift advancement of technology, coupled with evolving consumer expectations, presents both opportunities and challenges in accurately predicting demand.

This article delves into seven innovative strategies that can markedly improve the accuracy of supply chain forecasting. These strategies range from:

- Harnessing advanced cloud-based ERP systems

- Integrating machine learning

- Utilizing expert insights

As companies strive to maintain a competitive edge in an increasingly fierce landscape, one question looms large: which of these strategies will be most effective in revolutionizing supply chain operations and ensuring robust inventory management?

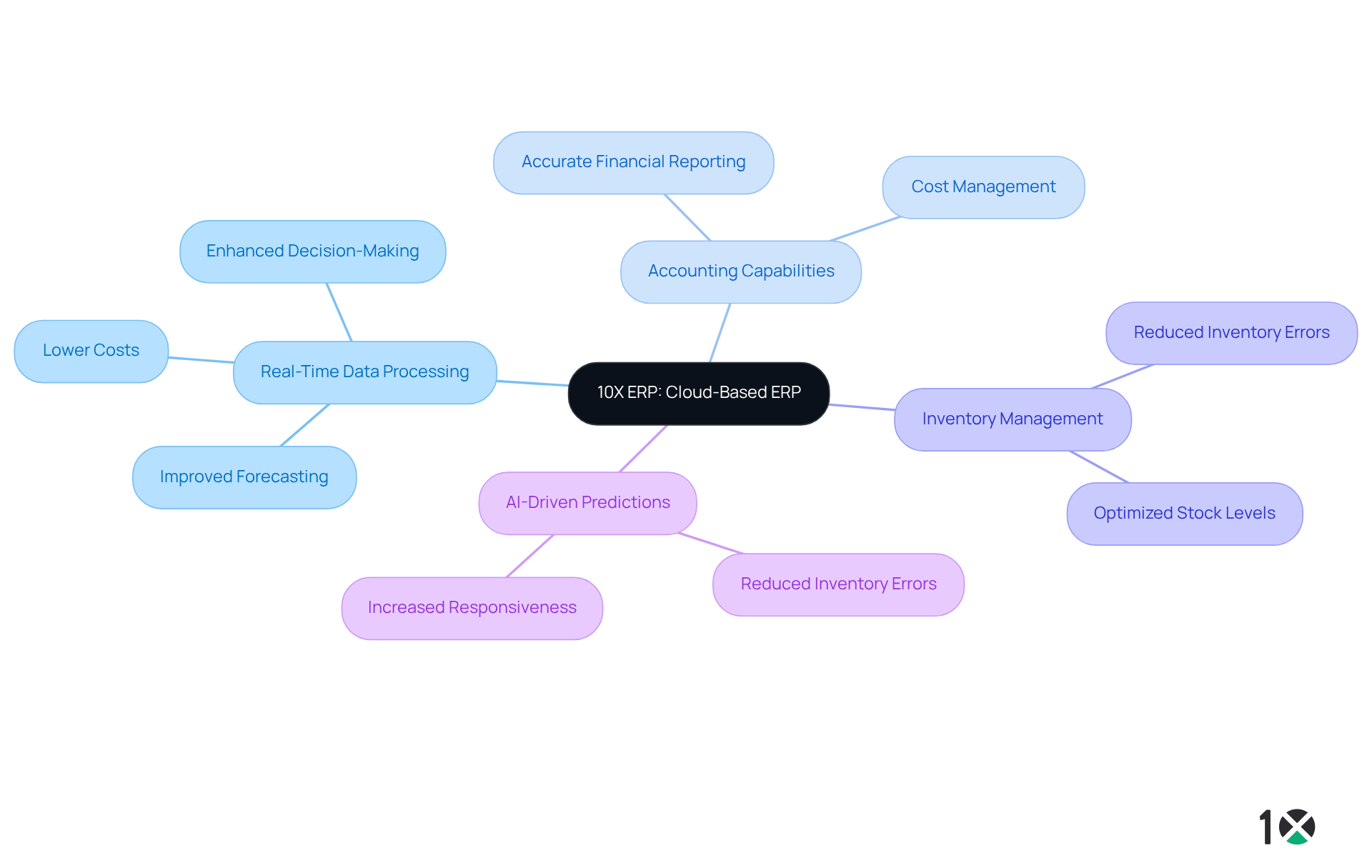

10X ERP: Cloud-Based ERP for Real-Time Supply Chain Forecasting

10X ERP stands at the forefront of innovation for expanding distributors, offering a cloud-based platform that empowers real-time supply chain forecasting. Leveraging robust accounting capabilities and dependable inventory management, companies gain access to current information that enhances their predictive models. This is crucial; accurate predictions can significantly lower costs by aligning inventory with actual demand and improving supply chain forecasting and overall supply chain management.

The platform’s intuitive interface enables stakeholders to interpret data effortlessly, fostering informed decision-making and elevating operational efficiency. Notably, companies that implement AI-driven predictions in supply chain forecasting have reported a remarkable reduction in inventory errors by up to 50%, underscoring the transformative potential of integrating advanced technologies into supply chain operations.

As we move toward 2025, the importance of cloud-based ERP systems like 10X ERP will only intensify, equipping businesses to swiftly adapt to market fluctuations and maintain a competitive edge.

Simple Moving Average: A Fundamental Quantitative Forecasting Method

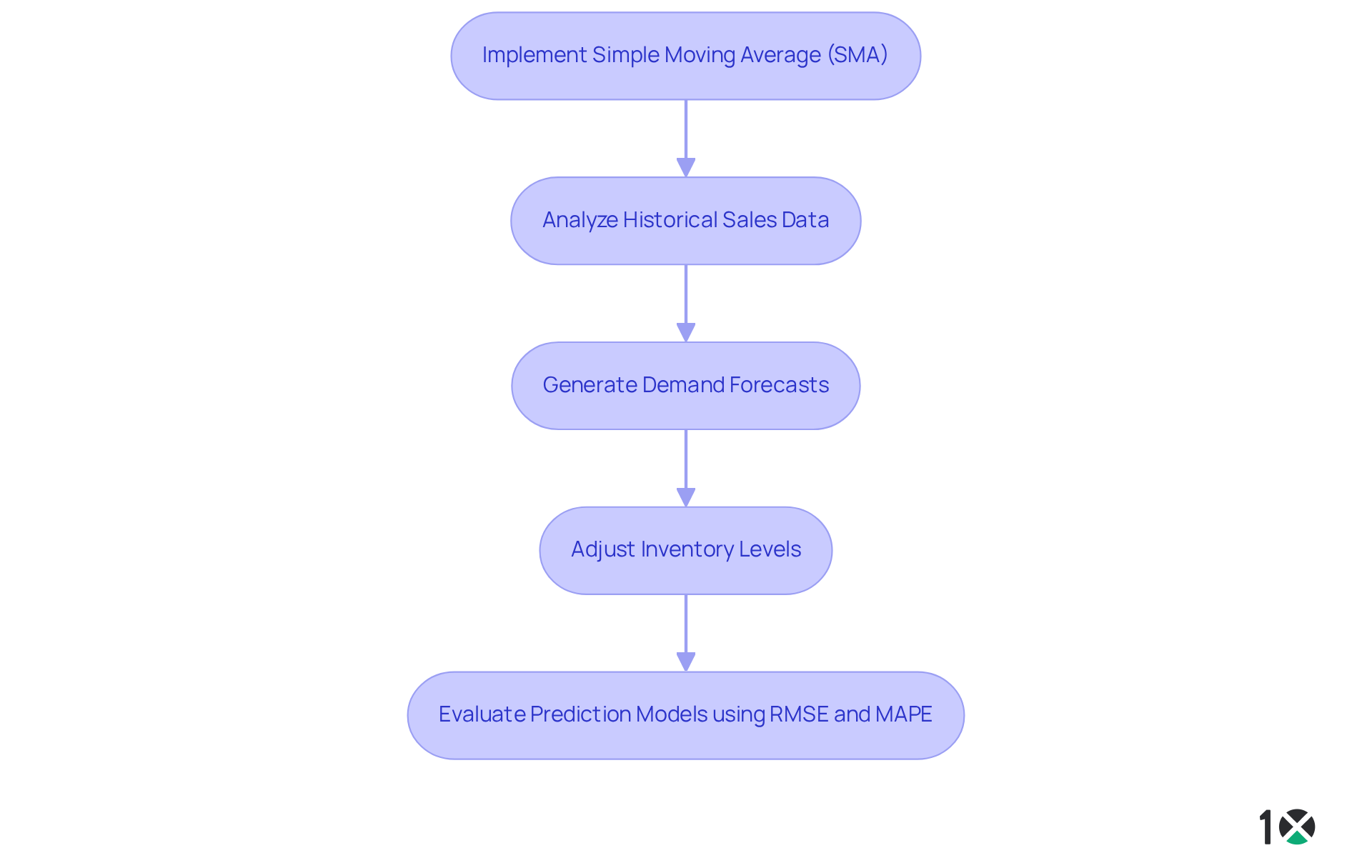

The Simple Moving Average (SMA) serves as a foundational quantitative prediction technique, calculating the average of a set of data points over a specified duration. This method proves especially advantageous for suppliers, as it smooths out short-term fluctuations and reveals longer-term demand trends. By integrating SMA into their planning processes, businesses can leverage historical sales data to make informed predictions about future demand, thus enabling more effective inventory management.

In 2025, the importance of SMA remains pronounced, particularly as suppliers strive to optimize their operations in response to evolving market conditions. Companies have successfully utilized SMA to forecast demand patterns, allowing for proactive adjustments to inventory levels. This technique is particularly valuable in stable environments where demand lacks significant seasonality or trends. To enhance the efficacy of SMA, suppliers can take advantage of 10X ERP’s cloud-based solutions, which provide real-time data processing and seamless integrations, ensuring that predictions are grounded in the most current information available.

Experts advocate for the application of SMA in inventory management, underscoring its simplicity and effectiveness. By averaging past sales data, distributors can establish a reliable baseline for future inventory needs, minimizing the risk of stockouts or overstock situations. Furthermore, 10X ERP’s functionalities facilitate the development of various predictive models employing different techniques, thereby improving prediction accuracy. As companies navigate the complexities of supply chain dynamics, supply chain forecasting through the SMA method stands out as a practical tool for enhancing prediction accuracy and operational efficiency.

To further bolster its effectiveness, suppliers should consistently evaluate their prediction models using , ensuring data-informed decisions align with their operational objectives. By leveraging the capabilities of 10X ERP, operations managers can implement SMA more adeptly, adapting to shifting market conditions and enhancing overall inventory management.

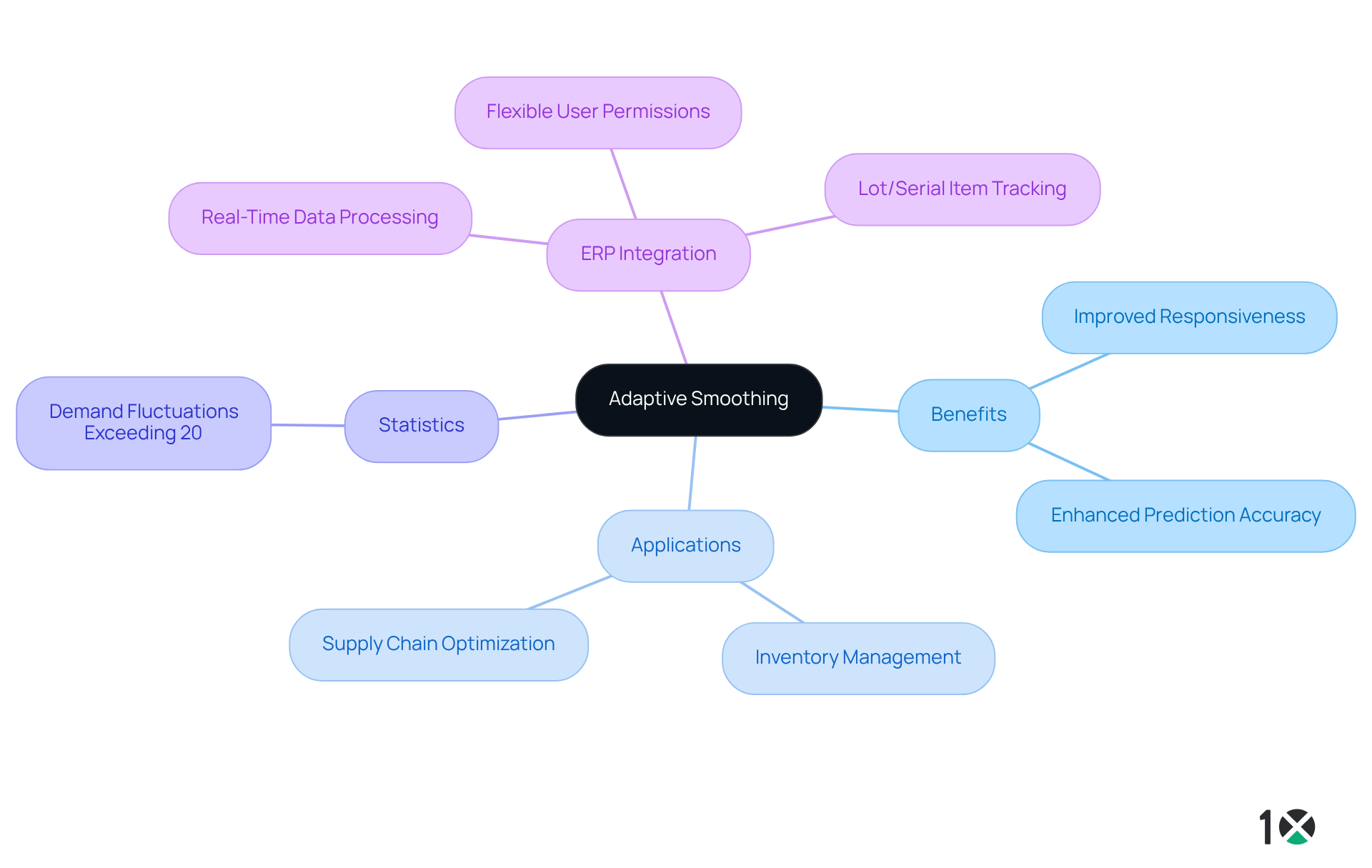

Adaptive Smoothing: Adjusting Forecasts with Recent Data Trends

Adaptive smoothing stands as a dynamic prediction technique that fine-tunes estimates based on the latest data trends, enabling businesses to swiftly adapt to fluctuations in demand. This method proves especially advantageous for distributors operating in volatile market environments, where demand can shift rapidly. By utilizing adaptive smoothing within the 10X ERP system, organizations can enhance their prediction accuracy in real-time, ensuring alignment with current market conditions and customer preferences.

Statistics reveal that demand fluctuations in distribution industries can be significant, with variations often exceeding 20% in response to market shifts. Distributors employing adaptive smoothing alongside 10X ERP’s robust accounting features—such as real-time data processing, flexible user permissions, and lot/serial item tracking—have reported improved responsiveness. This capability allows them to adjust inventory levels and optimize supply chain operations effectively. For instance, businesses utilizing this method have adeptly managed unforeseen increases in demand, showcasing the practical benefits of in predictions.

As we approach 2025, the emphasis on real-time demand prediction techniques has become crucial for companies striving to maintain competitiveness. Industry experts underscore the necessity of adjusting forecasts with recent data trends, highlighting the importance of agility in supply chain management. By implementing adaptive smoothing within the 10X ERP framework, suppliers can enhance their prediction abilities and improve supply chain forecasting, cultivating a more robust supply chain capable of enduring market fluctuations.

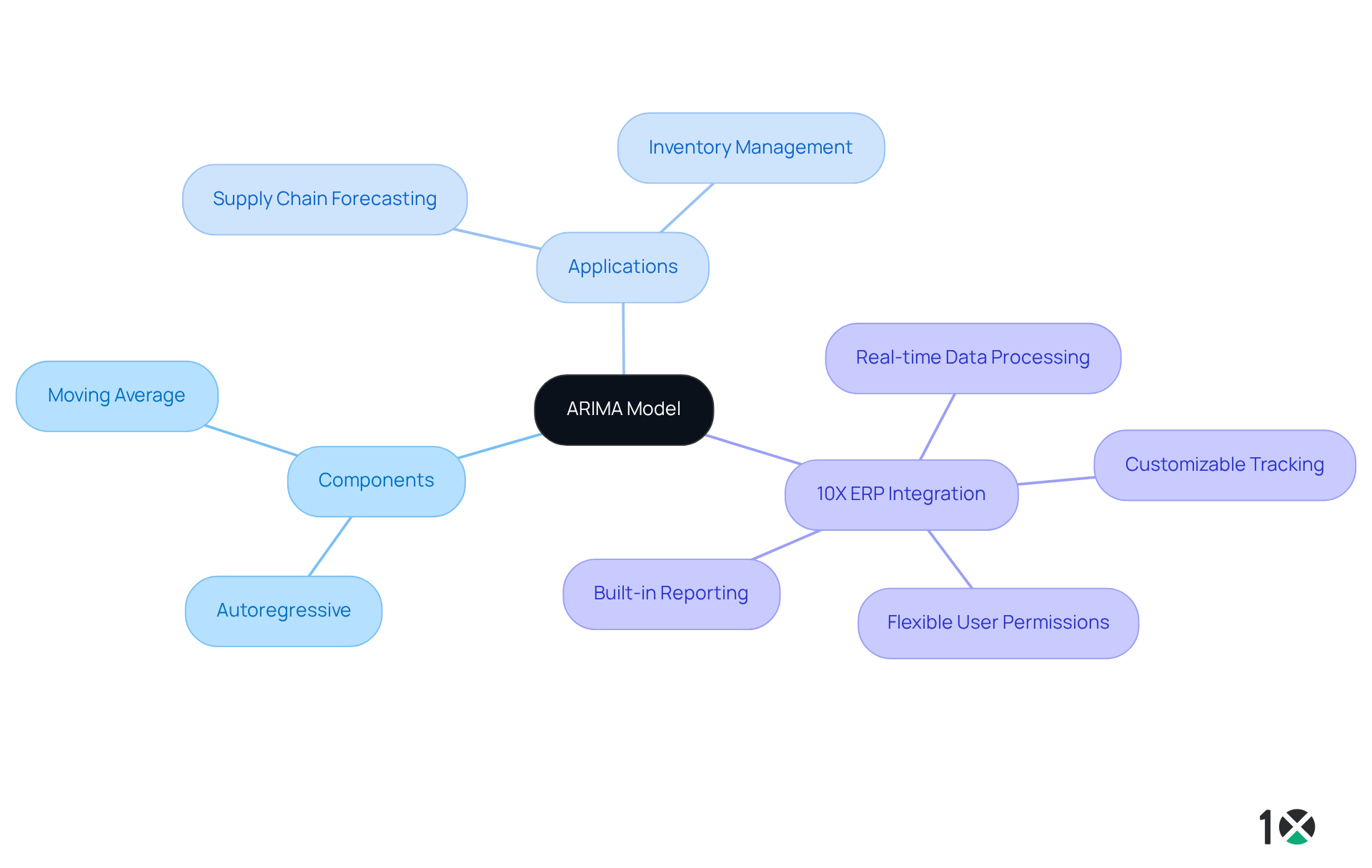

Autoregressive Integrated Moving Average (ARIMA): Capturing Complex Data Patterns

The Autoregressive Integrated Moving Average (ARIMA) model serves as a formidable statistical tool for predicting time series data. By effectively capturing complex patterns through its combination of autoregressive and moving average components, ARIMA is particularly well-suited for supply chain forecasting in intricate demand scenarios faced by suppliers. Integrating ARIMA within the 10X ERP framework significantly enhances supply chain forecasting accuracy and optimizes inventory management, leading to improved stock control and a reduction in stockouts.

Moreover, 10X ERP’s robust accounting features—including:

- real-time data processing

- customizable tracking

- flexible user permissions

- built-in reporting

empower operations managers to access the most accurate and up-to-date information readily. This not only bolsters predictive capabilities but also supports supply chain forecasting, allowing suppliers to maintain precise management of their stock levels. By leveraging these advanced tools, businesses can position themselves for greater operational efficiency and success.

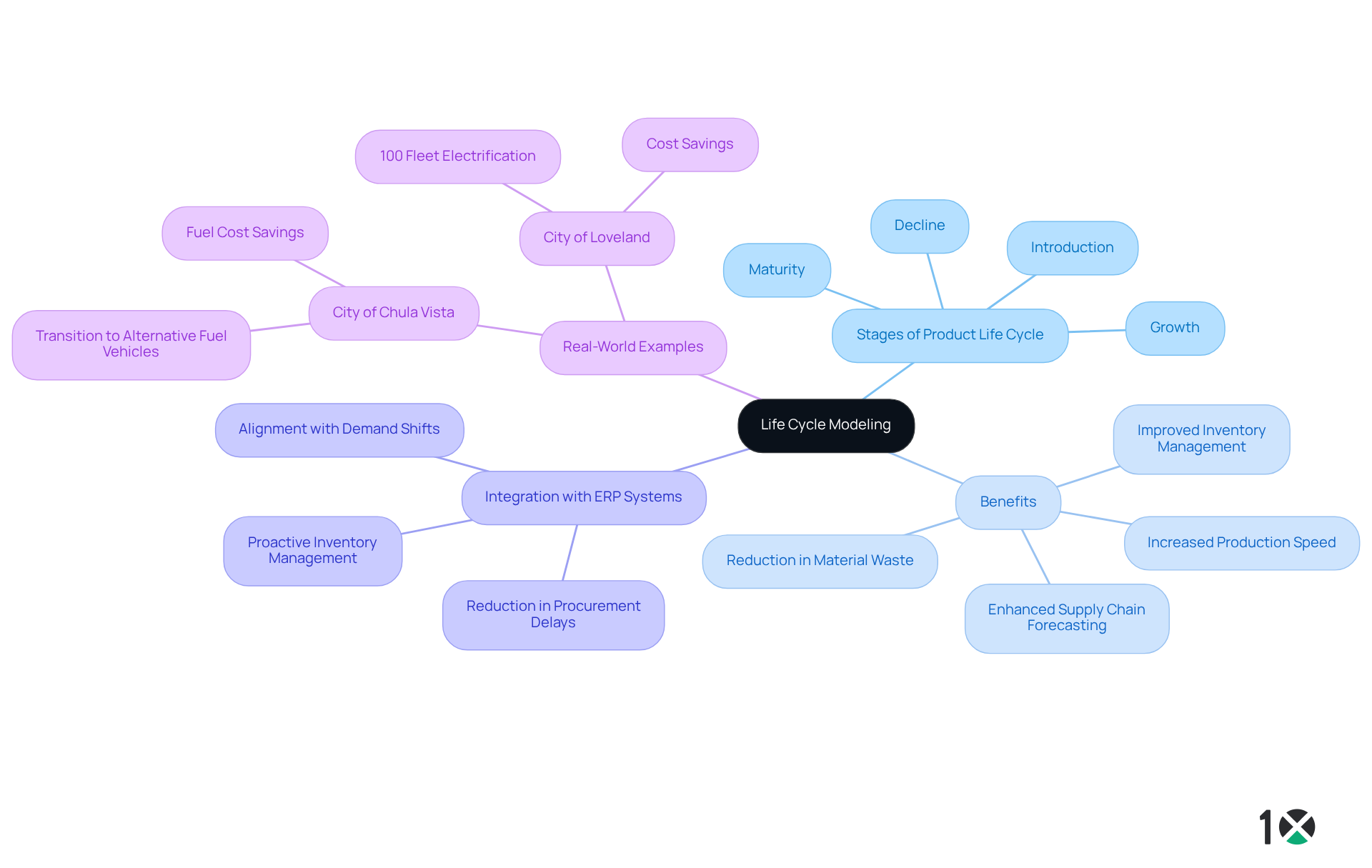

Life Cycle Modeling: Anticipating Demand Changes Through Product Life Cycles

Life cycle modeling stands as a pivotal approach that meticulously analyzes the various stages of a product’s life—from introduction to decline—enabling businesses to effectively anticipate demand fluctuations. By understanding a product’s status within its life cycle, suppliers can enhance their supply chain forecasting models, leading to improved inventory management. Notably, companies that have embraced life cycle modeling report a remarkable 25% reduction in material waste during manufacturing processes and a 15% increase in production speed, clearly demonstrating the tangible benefits of this strategy.

Integrating life cycle modeling into the 10X ERP system empowers businesses to proactively manage inventory levels through effective supply chain forecasting, ensuring they align with anticipated demand shifts. This capability is crucial in today’s fast-paced market, where a can significantly boost operational efficiency. Distributors leveraging life cycle insights can optimize their inventory management processes, effectively reducing excess stock and minimizing costs.

Real-world examples further illustrate the effectiveness of life cycle modeling. For instance, the City of Chula Vista successfully transitioned 36% of its fleet to alternative fuel vehicles, realizing significant fuel cost savings and enhanced operational efficiencies. Such outcomes underscore the critical importance of understanding how product life cycles influence supply chain forecasting, which enables businesses to respond swiftly to market changes.

As highlighted by industry experts, managing inventory through product life cycles is essential for maintaining competitiveness. By adopting sophisticated prediction methods and integrating them into robust ERP systems like 10X ERP, suppliers can enhance their operational strategies and foster sustainable growth.

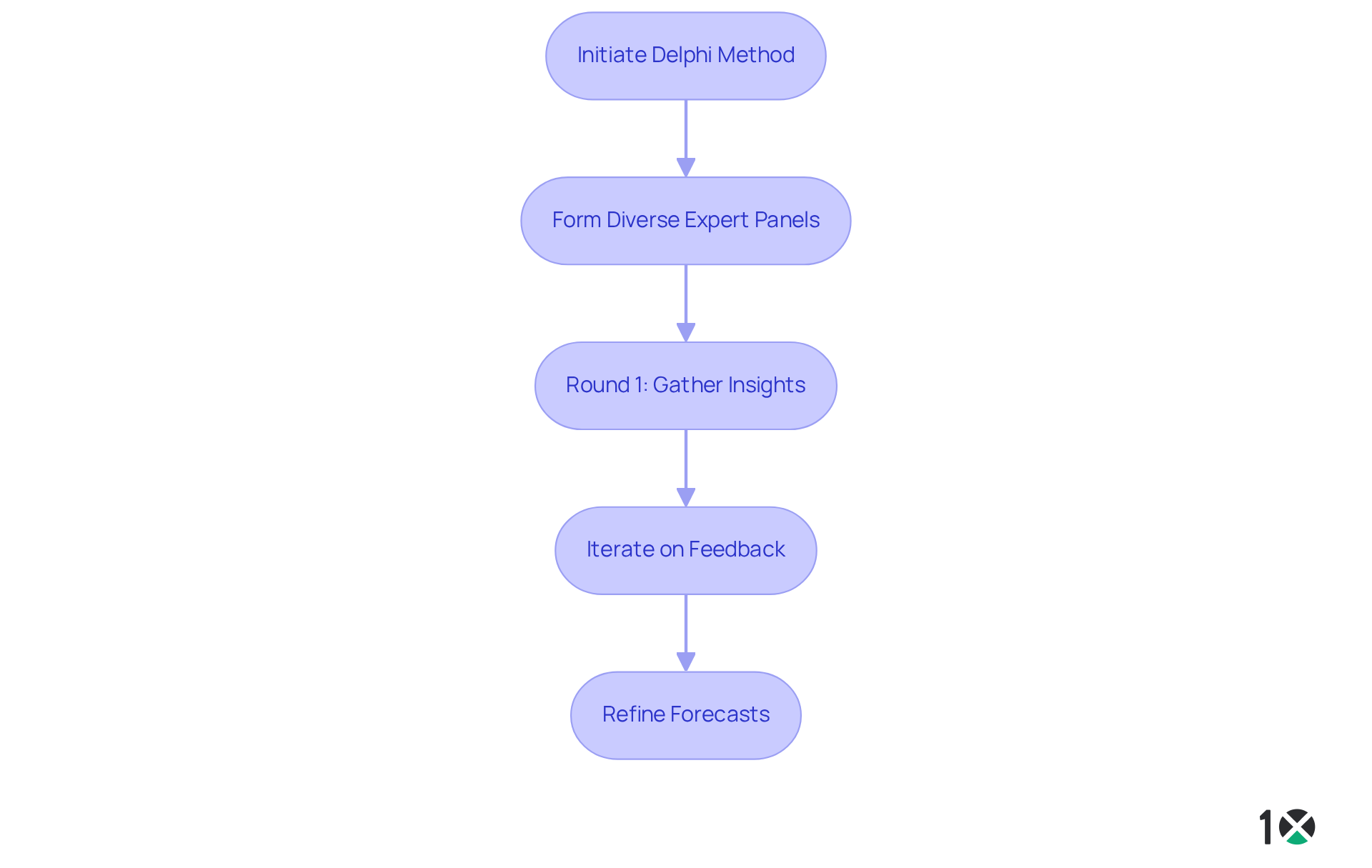

Delphi Method: Leveraging Expert Opinions for Accurate Forecasting

The Delphi method represents a qualitative prediction technique that systematically gathers insights from a panel of experts through multiple rounds of questioning. This iterative process refines predictions by leveraging collective knowledge and experience, proving particularly valuable for distributors.

By integrating the Delphi method into the 10X ERP framework, companies can significantly enhance their supply chain forecasting accuracy through real-time data processing and seamless integrations. This method not only encompasses diverse viewpoints but also aligns with contemporary trends in qualitative prediction techniques, which are increasingly favored for their flexibility in dynamic markets.

Distributors employing expert opinions in this manner, backed by 10X ERP’s comprehensive cloud-based solutions, transparent pricing structure, and unmatched support, can navigate uncertainties more effectively. They can make informed decisions that drive operational success.

To maximize the benefits of the Delphi method for supply chain forecasting, distributors should consider actionable steps, such as:

- Forming diverse expert panels

- Iterating on feedback to refine their forecasts

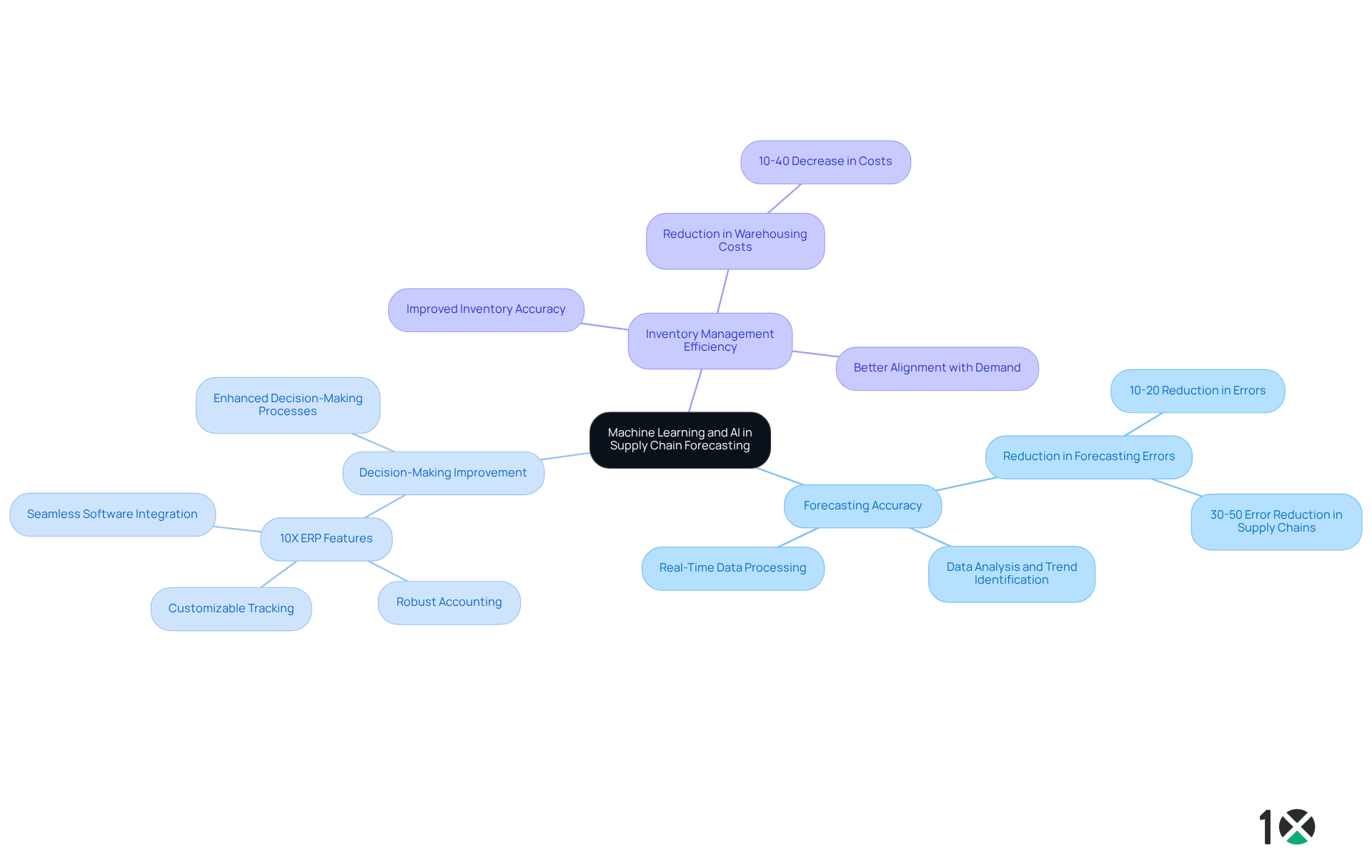

Machine Learning and AI: Enhancing Forecasting Accuracy and Efficiency

Machine learning and artificial intelligence (AI) are transforming supply chain forecasting. By analyzing extensive data and identifying trends, these technologies enhance the accuracy and efficiency of supply chain forecasting. Distributors utilizing 10X ERP can harness machine learning algorithms in conjunction with real-time data processing to continuously refine their supply chain forecasting.

With features such as robust accounting, customizable tracking, and , 10X ERP equips operations managers to adapt to new data effectively. This adaptability not only improves decision-making processes over time but also ensures that inventory management remains both efficient and precise.

As the landscape of supply chain forecasting evolves, leveraging these advanced technologies is no longer optional but essential for maintaining a competitive edge.

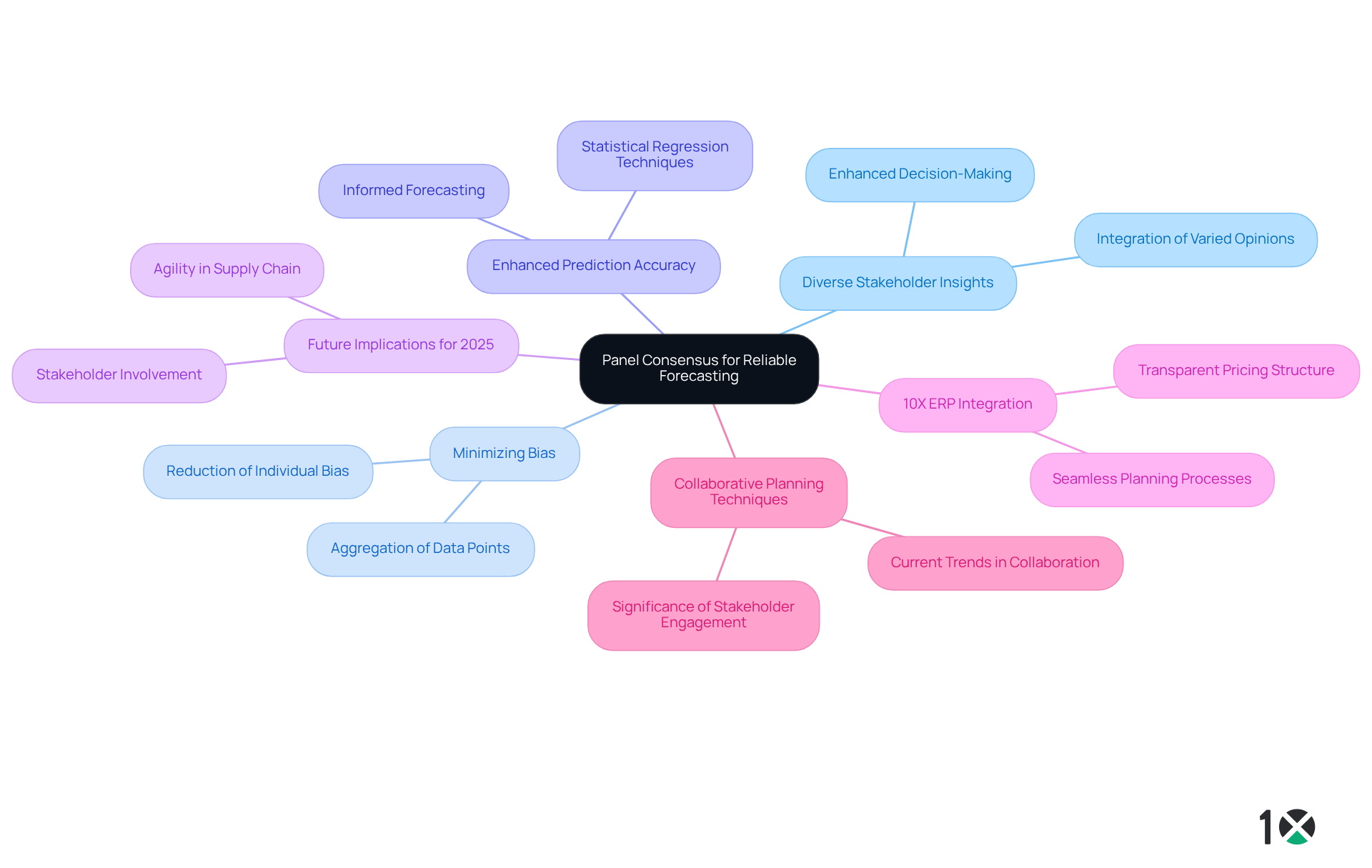

Panel Consensus: Aggregating Insights for Reliable Forecasting

Panel consensus stands as a powerful method for enhancing prediction reliability by gathering insights from a diverse group of stakeholders. This approach minimizes biases and enriches the through the aggregation of varied opinions and data points. By leveraging the features of the 10X ERP system, suppliers can seamlessly integrate diverse viewpoints into their planning processes. This not only leads to more informed decision-making but also aligns with current trends in collaborative planning techniques, emphasizing the significance of stakeholder involvement.

As we look towards 2025, the capability to gather insights efficiently will be vital for making dependable supply chain forecasting, ensuring that companies remain agile and responsive to market demands. Industry leaders consistently advocate for this collaborative method, recognizing that the shared knowledge of stakeholders can significantly enhance prediction results. Moreover, with 10X ERP’s transparent pricing structure and comprehensive features, operations managers can confidently invest in a solution that meets their unique needs while ensuring a seamless user experience.

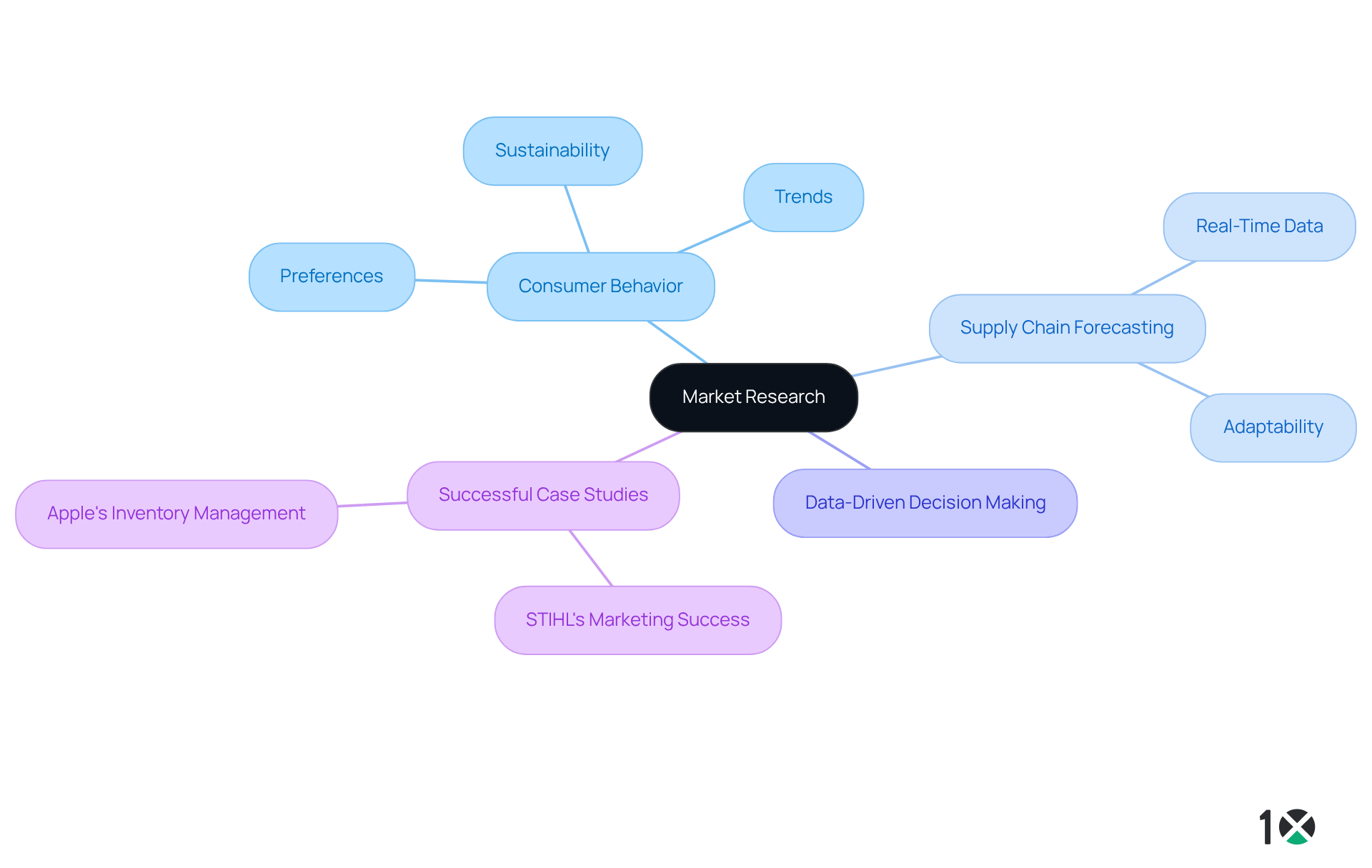

Market Research: Understanding Consumer Behavior for Better Forecasting

Market research is indispensable for understanding consumer behavior, preferences, and emerging trends. By conducting thorough market research, suppliers can uncover valuable insights that refine their supply chain forecasting models. For instance, 29% of global companies are already utilizing digital twin applications to enhance their supply chain strategies, highlighting the shift towards data-driven decision-making. Integrating these insights into the [10X ERP system](https://10xerp.com) enables businesses to align their inventory strategies with actual consumer demand, leading to improved sales and increased customer satisfaction.

To comprehend consumer behavior in 2025, a focus on real-time data and adaptability is crucial. As supply chain experts assert, supply chain forecasting is only as effective as the execution that follows. This underscores the necessity for suppliers to leverage to anticipate shifts in consumer preferences, especially in an environment where the demand for sustainable products is on the rise.

Successful suppliers, such as STIHL, exemplify the impact of market research in generating demand insights. Their partnership with InMarket’s GeoLink platform allowed them to effectively engage audiences during pivotal shopping moments, achieving an impressive 18.17% click-through rate—31.37 times higher than industry benchmarks. This case illustrates how integrating consumer intelligence into inventory management can yield significant competitive advantages. By prioritizing market research, distributors can enhance their prediction accuracy through supply chain forecasting and also foster stronger relationships with their customers.

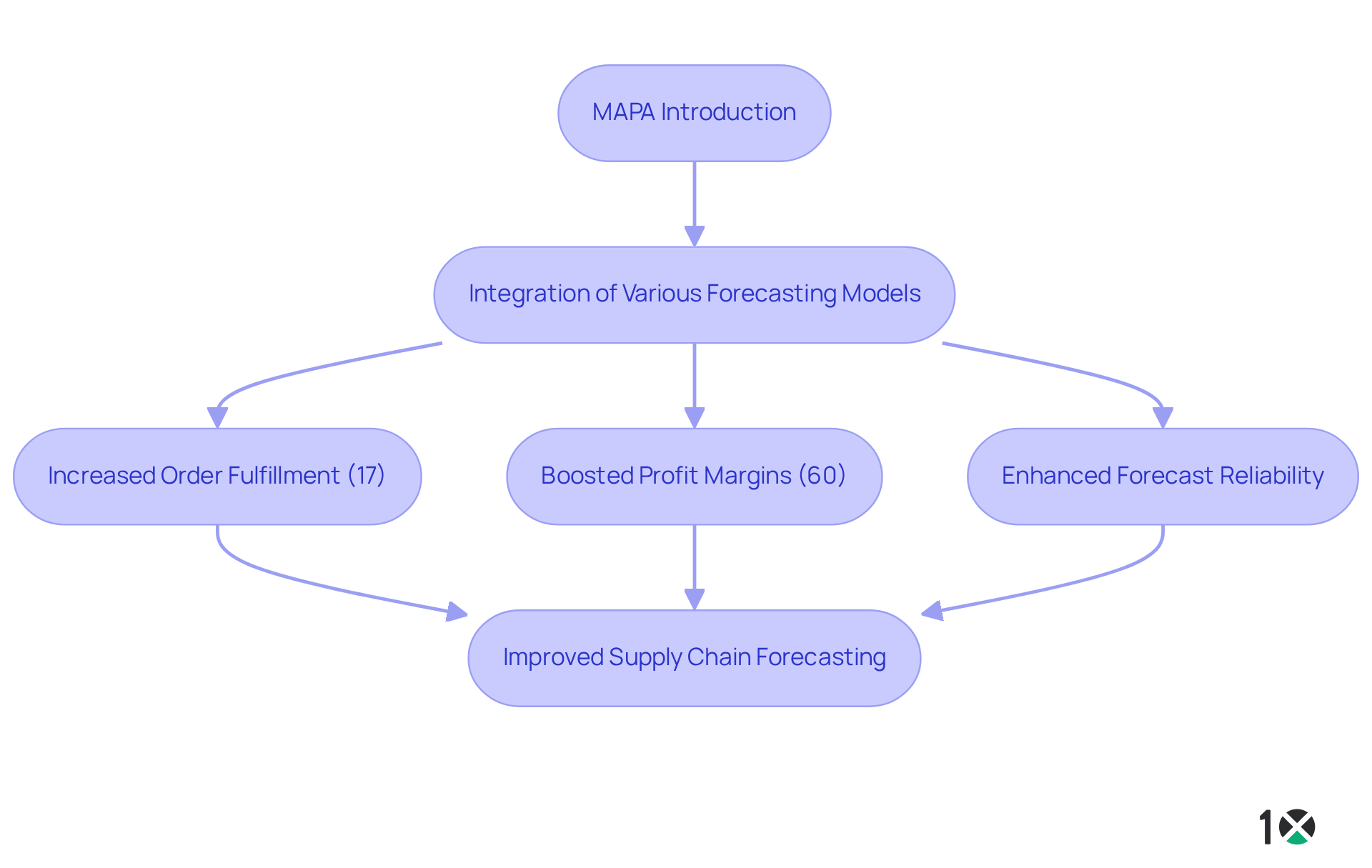

Multiple Aggregation Prediction Algorithm (MAPA): Combining Techniques for Improved Accuracy

The Multiple Aggregation Prediction Algorithm (MAPA) emerges as a sophisticated prediction method that significantly enhances accuracy by integrating forecasts from various models. This innovative approach effectively addresses the limitations inherent in individual prediction techniques, resulting in a more robust and reliable output. Distributors leveraging 10X ERP can seamlessly execute MAPA, greatly improving their predictive capabilities and ensuring agility in response to market fluctuations. With 10X ERP’s dependable inventory management features—including customizable tracking and lot/serial item tracking—businesses can maintain precise oversight of their inventory, further amplifying the effectiveness of MAPA.

Recent trends indicate that merging prediction methods, particularly through MAPA, can yield substantial improvements in accuracy. For instance, organizations that have adopted MAPA reported a remarkable 17% increase in order fulfillment and a 60% boost in profit margins, attributed to more precise demand predictions. Experts underscore that the integration of statistical and machine learning methods within MAPA not only enhances forecast reliability but also aligns closely with real-time market dynamics, supported by 10X ERP’s API-first approach and real-time data processing capabilities.

As we advance through 2025, the significance of MAPA in supply chain forecasting is undeniable. Its ability to amalgamate various prediction techniques positions it as an essential resource for distributors aiming to enhance their supply chain forecasting operations. By incorporating external data, such as weather patterns and economic indicators, MAPA further refines its predictions, enabling businesses to anticipate customer needs with greater accuracy. This strategic approach to forecasting, coupled with the provided by 10X ERP, is crucial for maintaining a competitive edge in today’s fast-paced distribution landscape.

Conclusion

Effective supply chain forecasting is crucial for businesses striving to excel in a rapidly evolving market. By implementing diverse strategic approaches—such as leveraging advanced technologies like cloud-based ERP systems, utilizing quantitative methods including the Simple Moving Average and ARIMA, and incorporating qualitative techniques such as the Delphi method—companies can markedly improve their forecasting accuracy and responsiveness. These strategies collectively empower organizations to synchronize inventory with actual demand, minimize costs, and enhance overall operational efficiency.

Throughout this article, we have explored key insights into how each forecasting method contributes to superior supply chain management. From the foundational principles of life cycle modeling to the sophisticated integration of machine learning and AI, the various techniques discussed present unique advantages. Notably, the application of real-time data processing via platforms like 10X ERP has emerged as a transformative element, enabling businesses to make informed decisions and adapt swiftly to market fluctuations.

As the landscape of supply chain forecasting continues to evolve, the integration of these strategies grows increasingly imperative. Companies are urged to adopt these innovative forecasting techniques not only to meet current demands but also to anticipate future trends. By prioritizing effective supply chain forecasting, businesses can strategically position themselves for sustainable growth and maintain a competitive edge in the marketplace.

Frequently Asked Questions

What is 10X ERP and its main purpose?

10X ERP is a cloud-based platform designed for expanding distributors, focusing on real-time supply chain forecasting. It enhances predictive models through robust accounting capabilities and dependable inventory management.

How does 10X ERP improve supply chain forecasting?

10X ERP provides real-time data processing, allowing companies to make accurate predictions that align inventory with actual demand, thereby lowering costs and improving overall supply chain management.

What benefits do companies experience when using AI-driven predictions in supply chain forecasting?

Companies that implement AI-driven predictions report a reduction in inventory errors by up to 50%, demonstrating the transformative potential of integrating advanced technologies into supply chain operations.

What is the Simple Moving Average (SMA) and its significance?

The Simple Moving Average (SMA) is a fundamental quantitative forecasting method that calculates the average of a set of data points over a specified duration. It helps suppliers smooth out short-term fluctuations and identify longer-term demand trends.

How can suppliers utilize SMA for inventory management?

By integrating SMA into their planning processes, businesses can leverage historical sales data to make informed predictions about future demand, enabling more effective inventory management and minimizing stockouts or overstock situations.

What role does 10X ERP play in enhancing the SMA method?

10X ERP’s cloud-based solutions provide real-time data processing and seamless integrations, ensuring that predictions using SMA are based on the most current information available.

What is adaptive smoothing and its advantages?

Adaptive smoothing is a dynamic prediction technique that adjusts estimates based on the latest data trends, allowing businesses to quickly adapt to fluctuations in demand, particularly in volatile market environments.

How does adaptive smoothing work with 10X ERP?

By utilizing adaptive smoothing within the 10X ERP system, organizations can enhance their prediction accuracy in real-time, ensuring their forecasts align with current market conditions and customer preferences.

Why is real-time demand prediction important for companies?

As we approach 2025, the ability to predict demand in real-time has become crucial for companies to maintain competitiveness, especially in industries where demand can fluctuate significantly.

What performance indicators should suppliers evaluate for their prediction models?

Suppliers should consistently evaluate their prediction models using performance indicators such as RMSE (Root Mean Square Error) and MAPE (Mean Absolute Percentage Error) to ensure their data-informed decisions align with operational objectives.