Summary

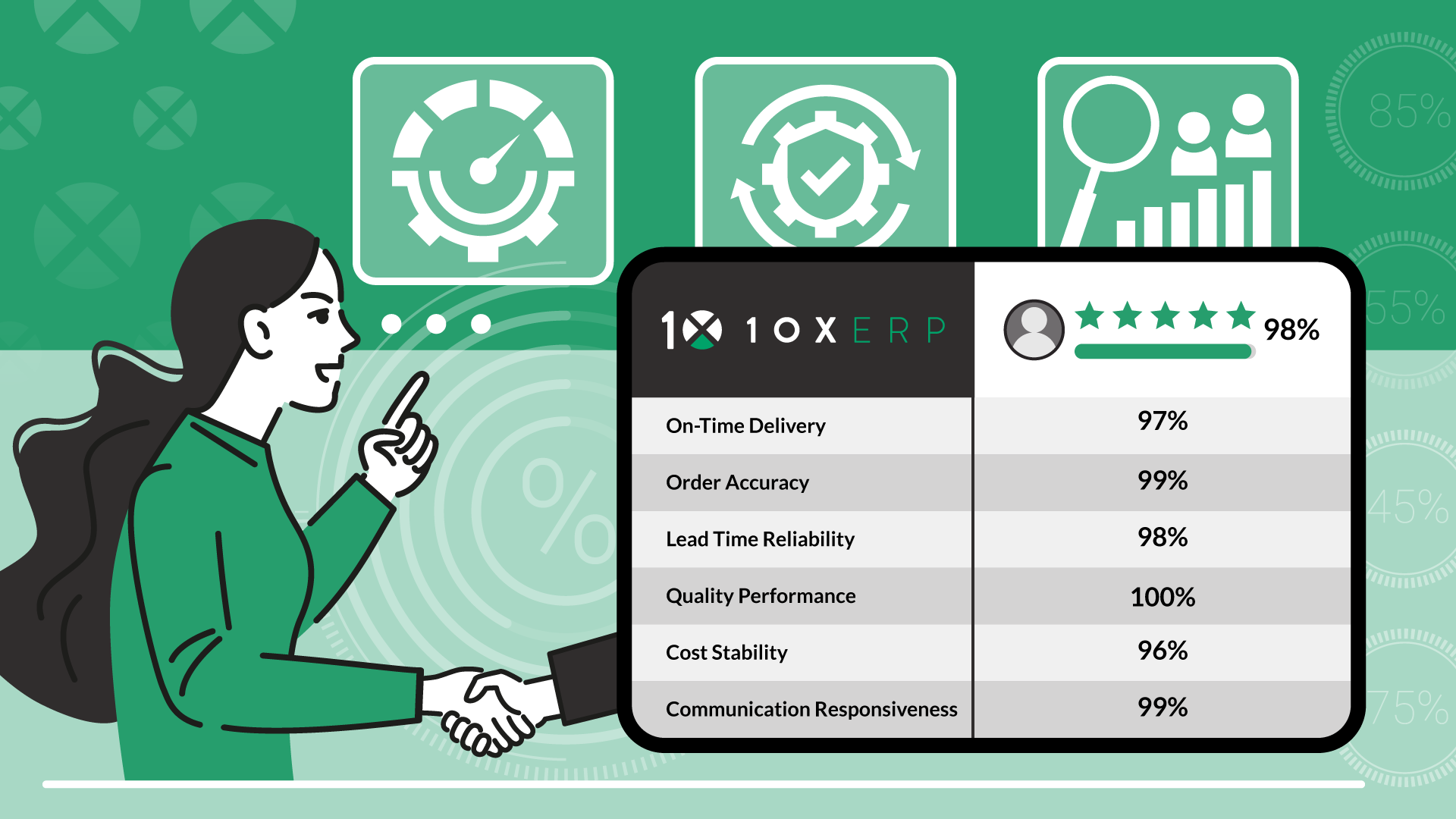

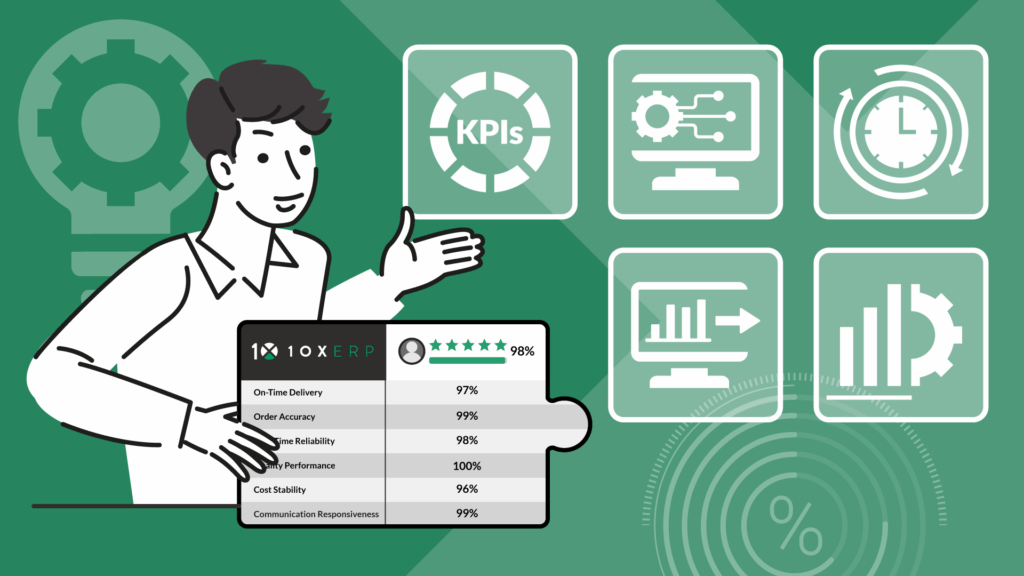

- ERP-powered vendor scorecards turn subjective supplier experiences into objective KPIs, enabling distributors to fairly compare vendors, enforce accountability, and reward high performers using real-time data.

- By capturing metrics like on-time delivery, order accuracy, lead-time reliability, quality, and cost stability directly in ERP, distributors eliminate manual tracking and gain clear benchmarks for performance and negotiations.

- With automated scorecards from 10X ERP, distributors can drive continuous improvement, strengthen vendor relationships, reduce risk, and build a more reliable, scalable supply chain.

Strong vendor relationships are the backbone of successful distribution. But those relationships don’t just rely on personal connections—they depend on performance, consistency, and measurable results. Distributors know that not all suppliers are created equal: some deliver on time and in full, while others create costly delays, quality issues, or communication breakdowns.

The challenge is turning those day-to-day experiences into measurable insights you can act on. That’s where vendor scorecards, powered by ERP data, come in. By leveraging real-time performance metrics captured in your ERP, distributors can benchmark suppliers objectively, improve negotiations, and strengthen their supply chain.

Why Vendor Scorecards Matter

When it comes to evaluating suppliers, gut feelings and anecdotal feedback aren’t enough. Without hard data, it’s difficult to:

- Compare suppliers fairly.

- Hold vendors accountable to service-level agreements.

- Identify underperformers that cost you time and money.

- Reward high-performing partners with more business.

Vendor scorecards create a clear, data-driven framework for supplier evaluation. They turn subjective experiences into measurable KPIs, enabling better decisions and stronger partnerships.

The Power of ERP-Driven Metrics

Many distributors track supplier performance in spreadsheets or ad-hoc reports, but these methods are time-consuming and error-prone. A modern ERP system like 10X ERP eliminates that challenge by automatically capturing the data you need to evaluate vendors.

From the moment a purchase order is issued to the time goods are received and invoices are processed, ERP records every touchpoint. This creates a goldmine of performance data that can be transformed into scorecards with little extra effort.

Key metrics ERP data can power include:

- On-Time Delivery Rate: How often suppliers meet promised delivery dates.

- Order Accuracy: Frequency of correct quantities, specifications, and documentation.

- Lead Time Reliability: Variability between quoted lead times and actual delivery.

- Quality Performance: Return rates, defect counts, or quality inspection failures.

- Cost Stability: Frequency of price changes, surcharges, or hidden fees.

- Communication Responsiveness: Time to acknowledge or resolve inquiries.

Benchmarking Supplier Performance

Once metrics are captured, ERP-driven scorecards make benchmarking simple. Suppliers can be compared side by side, highlighting who delivers consistent value and who may need corrective action.

For example, two suppliers may offer similar pricing, but one consistently ships on time while the other causes frequent delays. With clear benchmarks in hand, you have the evidence to shift more business to the reliable partner—or to approach the underperformer with data-backed feedback.

Driving Accountability and Improvement

Scorecards are not just about measurement—they’re about action. With regular reporting, distributors can share performance data with suppliers to encourage improvement. Instead of vague complaints (“your shipments are always late”), you can provide specific metrics (“your on-time delivery rate averaged 72% this quarter versus our standard of 95%”).

This fosters constructive conversations and gives suppliers a chance to improve. Over time, vendors that consistently underperform can be phased out, while high performers can be rewarded with preferred supplier status or expanded contracts.

Streamlining Negotiations and Compliance

Vendor scorecards also provide leverage in negotiations. Armed with objective data, you can renegotiate pricing, lead times, or terms with confidence. Scorecards also help with compliance—whether it’s meeting customer SLAs, industry standards, or internal policies.

For large distributors, automated ERP-driven scorecards ensure that vendor management scales smoothly, even as the supplier base grows. No more manual tracking or selective memory—performance is always clear and consistent.

Practical Tips for Getting Started

Implementing vendor scorecards doesn’t have to be complicated. Here are a few best practices for distributors:

- Define clear KPIs: Choose 4–6 key metrics that align with your business goals.

- Automate data capture: Use ERP as the central source of truth to avoid manual reporting.

- Regular cadence: Review vendor scorecards monthly or quarterly, not just annually.

- Engage suppliers: Share results with vendors to drive accountability and collaboration.

- Act on insights: Use performance trends to guide sourcing, negotiation, and supplier development.

Conclusion

In distribution, vendor performance directly impacts customer satisfaction, profitability, and growth. By leveraging ERP data to create vendor scorecards, you can benchmark suppliers with ease, drive accountability, and make better sourcing decisions.

10X ERP empowers distributors to move beyond gut instinct into data-driven vendor management. With automated scorecards, you’ll have the insights needed to strengthen relationships, eliminate weak links, and build a supply chain that fuels long-term success.