Overview

This article delves into the essential features and significance of Warehouse Management Systems (WMS), underscoring their pivotal role in optimizing storage operations and enhancing inventory management. WMS solutions are instrumental in improving operational efficiency, accuracy, and customer satisfaction. By automating processes and providing real-time data, these systems are crucial for businesses, particularly in the rapidly expanding e-commerce sector. Understanding the impact of WMS can empower Operations Managers to tackle their challenges effectively.

Introduction

The rapid evolution of logistics has fundamentally transformed how businesses manage their inventory, rendering Warehouse Management Systems (WMS) more critical than ever. These sophisticated software solutions not only streamline storage operations but also significantly enhance accuracy and efficiency in handling goods.

With the surge in e-commerce and the increasing complexity of supply chains, companies must consider how to leverage WMS technology to remain competitive and meet rising customer expectations.

By exploring the essential features and importance of WMS, we uncover not merely a tool for organization but a strategic advantage in modern distribution and inventory management.

Define Warehouse Management System (WMS)

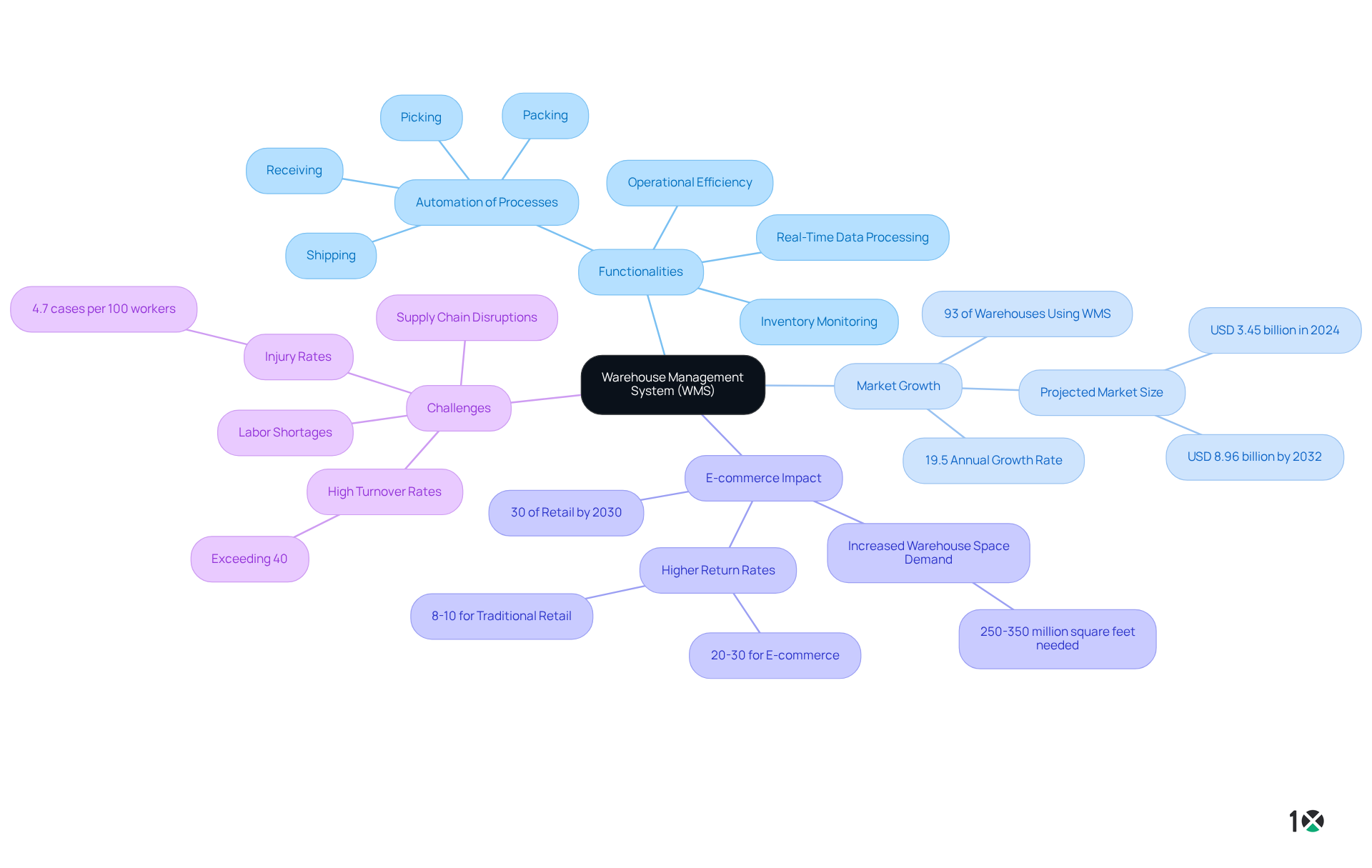

A [WMS warehouse management system](https://grandviewresearch.com/industry-analysis/warehouse-management-system-wms-market) is a sophisticated software application specifically designed to manage and optimize storage operations. It provides crucial instruments for monitoring inventory levels, managing stock locations, and supervising the flow of goods within a storage facility. By automating critical processes such as receiving, picking, packing, and shipping, a WMS significantly enhances operational efficiency and accuracy. This framework is essential for businesses that rely on effective inventory management to fulfill customer demands and optimize their supply chain processes.

The global storage management system market is projected to grow at an impressive annual rate of 19.5%, reflecting the increasing reliance on the WMS warehouse management system to enhance operational capabilities. For instance, 93% of storage facilities now utilize a WMS warehouse management system to orchestrate their operations, underscoring its importance in modern logistics. Furthermore, companies that implement WMS solutions, such as 10X ERP, report enhanced accuracy through real-time data processing, flexible user permissions, built-in reporting, improved customer service, and reduced operational costs. This makes the WMS warehouse management system a critical tool for businesses across the manufacturing, retail, and distribution sectors.

In the realm of e-commerce, where online sales are projected to represent 30% of all retail by 2030, the need for effective inventory management has never been more significant. The growth of e-commerce requires additional storage space and advanced management systems to handle heightened inventory turnover and intricate logistics. As such, a robust WMS not only facilitates timely product availability and delivery but also plays a crucial role in managing returns, which can range from 20-30% in e-commerce compared to 8-10% for traditional retail.

Moreover, the warehousing sector faces challenges such as high turnover rates and labor shortages, which further emphasize the need for effective WMS warehouse management system solutions. With features such as customizable tracking, seamless software integration, and built-in reporting, 10X ERP offers that are crucial for optimizing storage operations and ensuring that businesses can meet the evolving demands of the market.

Explain the Importance of WMS in Distribution

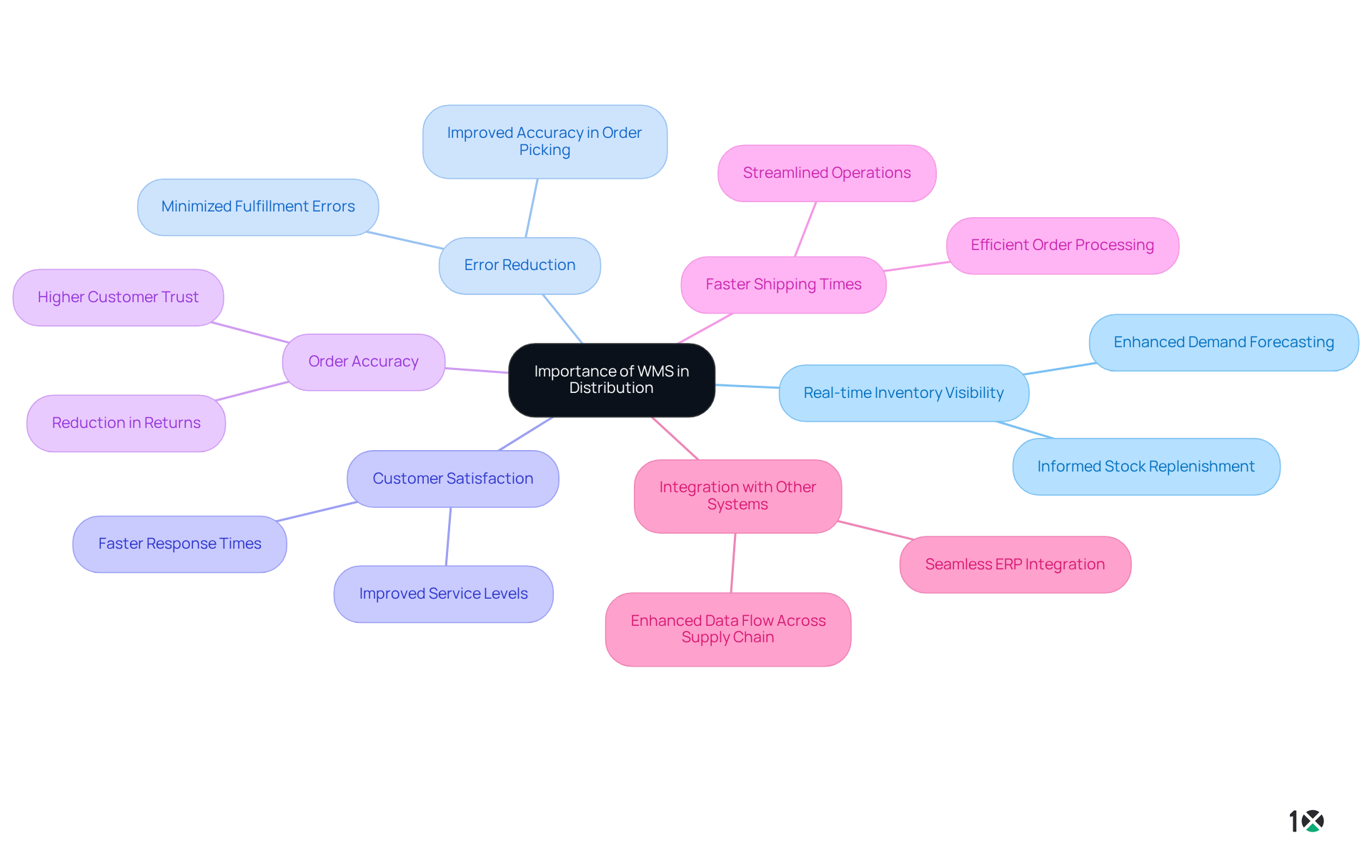

The significance of a in distribution is paramount. A WMS warehouse management system provides real-time visibility into inventory levels, which enables distributors to make informed decisions about stock replenishment and order fulfillment. By streamlining storage operations, the WMS warehouse management system effectively reduces errors, minimizes delays, and significantly enhances customer satisfaction. For distributors, this translates to improved order accuracy and faster shipping times, offering a vital competitive advantage in the marketplace. Furthermore, the ability of a WMS warehouse management system to integrate seamlessly with other systems, such as ERP and transportation management systems, facilitates a smooth flow of information across the supply chain, further optimizing operational efficiency.

Outline Key Features and Functions of WMS

Key features of a Warehouse Management System (WMS) include:

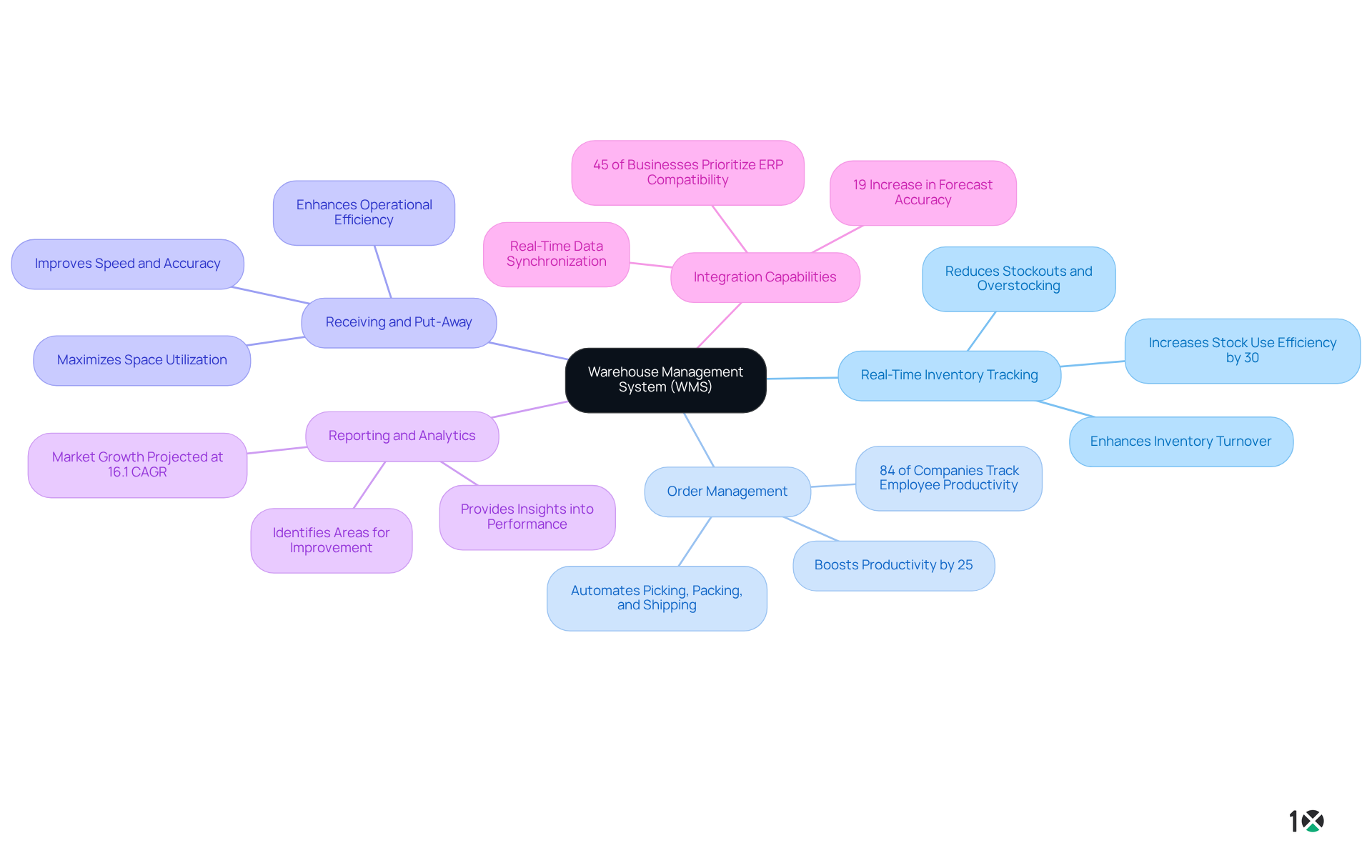

- Real-Time Inventory Tracking: This functionality allows businesses to monitor stock levels and locations in real-time, significantly reducing the risk of stockouts and overstocking. With accurate tracking, companies can enhance inventory turnover and optimize storage space, potentially increasing stock use efficiency by 30%. 10X ERP’s robust accounting features further enhance this capability by providing real-time data processing, ensuring stakeholders can make informed decisions based on current inventory status.

- Order Management: WMS streamlines the order fulfillment process by automating picking, packing, and shipping tasks. This automation can boost productivity by 25%, ensuring that orders are processed quickly and accurately—crucial for maintaining customer satisfaction. In fact, 84% of companies track various employee productivity metrics to ensure efficiency. The seamless integration capabilities of 10X ERP allow for smooth order management across different platforms, enhancing overall operational effectiveness.

- Receiving and Put-Away: This feature facilitates the efficient receiving of goods and optimal placement within the storage facility, maximizing space utilization. By improving the speed and accuracy of these processes, businesses can enhance their overall operational efficiency. A case study on receiving and put-away highlights significant improvements in efficiency through , further enhanced by 10X ERP’s customizable attributes and powerful cross-referencing capabilities.

- Reporting and Analytics: WMS offers valuable insights into storage facility performance, enabling managers to make data-driven decisions. With advanced analytics, organizations can identify areas for improvement, leading to enhanced efficiency and reduced operational costs. The warehouse management system (WMS) warehouse management system market is projected to grow at a CAGR of 16.1% from 2022 to 2030, emphasizing the importance of investing in robust WMS solutions like 10X ERP that offer built-in reporting features.

- Integration Capabilities: Smooth connectivity with other platforms, such as ERP and transportation management solutions, is essential for enhanced operational efficiency. This integration allows for real-time data synchronization, crucial for large-scale operations, potentially leading to a 19% increase in forecast accuracy. Notably, 45% of businesses prioritize a WMS warehouse management system that can accommodate their enterprise resource planning system, making 10X ERP’s innovative cloud-based solution a top choice for distributors.

These features together enhance a more structured and efficient storage environment, ultimately resulting in improved service levels and lower operational costs. As the warehouse management market continues to evolve, investing in a robust WMS warehouse management system like 10X ERP is becoming increasingly vital for businesses aiming to stay competitive.

Trace the Evolution of WMS Technology

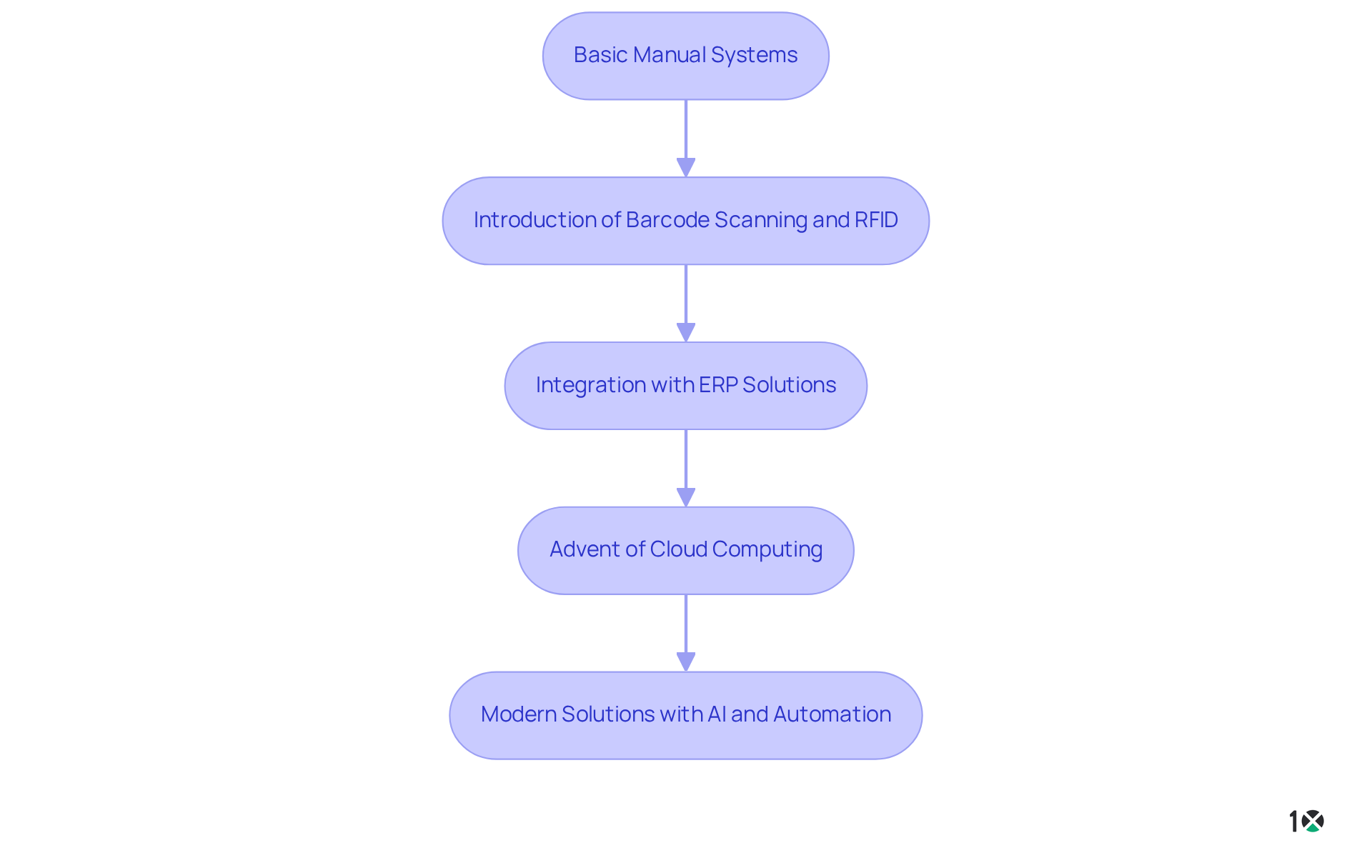

The evolution of the WMS warehouse management system has been marked by significant technological advancements. Initially, WMS solutions operated as basic, manual setups heavily reliant on paper-based processes for inventory management. Such dependence on manual methods often resulted in inefficiencies, human errors, and delays in order fulfillment. However, the introduction of barcode scanning and RFID technology in the late 20th century signified a pivotal shift, enabling real-time tracking and markedly enhancing inventory accuracy.

As organizations sought to optimize their operations, the integration of the WMS warehouse management system with Enterprise Resource Planning (ERP) solutions became increasingly common. This synergy facilitated smoother workflows across various departments, promoting enhanced coordination and efficiency. The advent of cloud computing in the 21st century further revolutionized the WMS warehouse management system, making these solutions more accessible and scalable for businesses of all sizes. Cloud-based solutions, like those provided by 10X ERP, lower maintenance costs and offer real-time data visibility, empowering organizations to make swift, informed decisions. With an and interface, 10X ERP ensures users can navigate the system with ease, thereby boosting operational efficiency.

Today, the WMS warehouse management system incorporates modern solutions that harness advanced technologies such as artificial intelligence (AI), machine learning, and automation. These innovations enable predictive analytics, allowing businesses to anticipate demand and proactively optimize inventory levels. This evolution mirrors the growing complexity of supply chains and the need for sophisticated tools that can adapt to dynamic market conditions, ensuring operational efficiency and customer satisfaction. Moreover, with 10X ERP’s straightforward and transparent pricing structure, businesses can easily grasp the value they receive, further supported by an all-inclusive money-back guarantee. As Peter Drucker aptly stated, ‘What gets measured, gets managed,’ underscoring the vital role of accurate data in effective inventory management. With 10X ERP’s comprehensive cloud-based solution, distributors can enjoy seamless user experiences, transparent pricing, and unparalleled support, significantly enhancing their WMS warehouse management system capabilities.

Conclusion

The significance of a Warehouse Management System (WMS) is paramount, serving as a pivotal tool for enhancing the efficiency and accuracy of storage operations. By automating critical processes and providing real-time visibility into inventory levels, a WMS equips businesses with essential capabilities to optimize their supply chain and effectively meet customer demands.

Key insights throughout this discussion reveal the diverse features and functions of WMS, such as:

- Real-time inventory tracking

- Streamlined order management

- Seamless integration with other systems

These attributes not only improve operational efficiency but also enhance customer satisfaction through timely order fulfillment and reduced errors. The evolution of WMS technology, marked by advancements like cloud computing and AI, underscores its importance in adapting to the complexities of modern logistics.

In light of these insights, it is crucial for businesses to invest in robust WMS solutions to remain competitive in an ever-evolving market landscape. As e-commerce continues to grow and logistical challenges persist, leveraging the capabilities of a sophisticated WMS will empower organizations to enhance their operational efficiencies and drive success in their distribution efforts. Embracing these advanced systems is not merely a strategic advantage; it has become an essential requirement for thriving in today’s fast-paced supply chain environment.

Frequently Asked Questions

What is a Warehouse Management System (WMS)?

A Warehouse Management System (WMS) is a software application designed to manage and optimize storage operations, including monitoring inventory levels, managing stock locations, and supervising the flow of goods within a storage facility.

How does a WMS enhance operational efficiency?

A WMS enhances operational efficiency by automating critical processes such as receiving, picking, packing, and shipping, leading to improved accuracy and streamlined operations.

What is the projected growth rate of the global storage management system market?

The global storage management system market is projected to grow at an impressive annual rate of 19.5%.

How prevalent is the use of WMS in storage facilities?

Approximately 93% of storage facilities now utilize a WMS to orchestrate their operations, highlighting its importance in modern logistics.

What benefits do companies experience after implementing WMS solutions like 10X ERP?

Companies that implement WMS solutions report benefits such as enhanced accuracy through real-time data processing, flexible user permissions, built-in reporting, improved customer service, and reduced operational costs.

Why is effective inventory management critical in e-commerce?

Effective inventory management is critical in e-commerce due to the projected increase in online sales, requiring additional storage space and advanced management systems to handle higher inventory turnover and complex logistics.

What challenges does the warehousing sector face that necessitate WMS solutions?

The warehousing sector faces challenges such as high turnover rates and labor shortages, which emphasize the need for effective WMS solutions to optimize storage operations.

What features does 10X ERP offer for inventory management?

10X ERP offers features such as customizable tracking, seamless software integration, and built-in reporting, which are crucial for optimizing storage operations and meeting market demands.