Introduction

Distribution planning stands as the backbone of efficient supply chain operations, ensuring that goods flow seamlessly from production to consumers. Understanding its core concepts and functions allows businesses to gain significant advantages, such as reduced costs and enhanced customer satisfaction. As the logistics landscape evolves with technological advancements and shifting consumer expectations, organizations must adapt their distribution strategies to remain competitive and responsive.

How can your organization navigate these changes? By embracing innovative distribution planning, you can not only streamline operations but also meet the demands of today’s consumers. This proactive approach will position your business for success in an ever-changing market.

Define Distribution Planning: Core Concepts and Functions

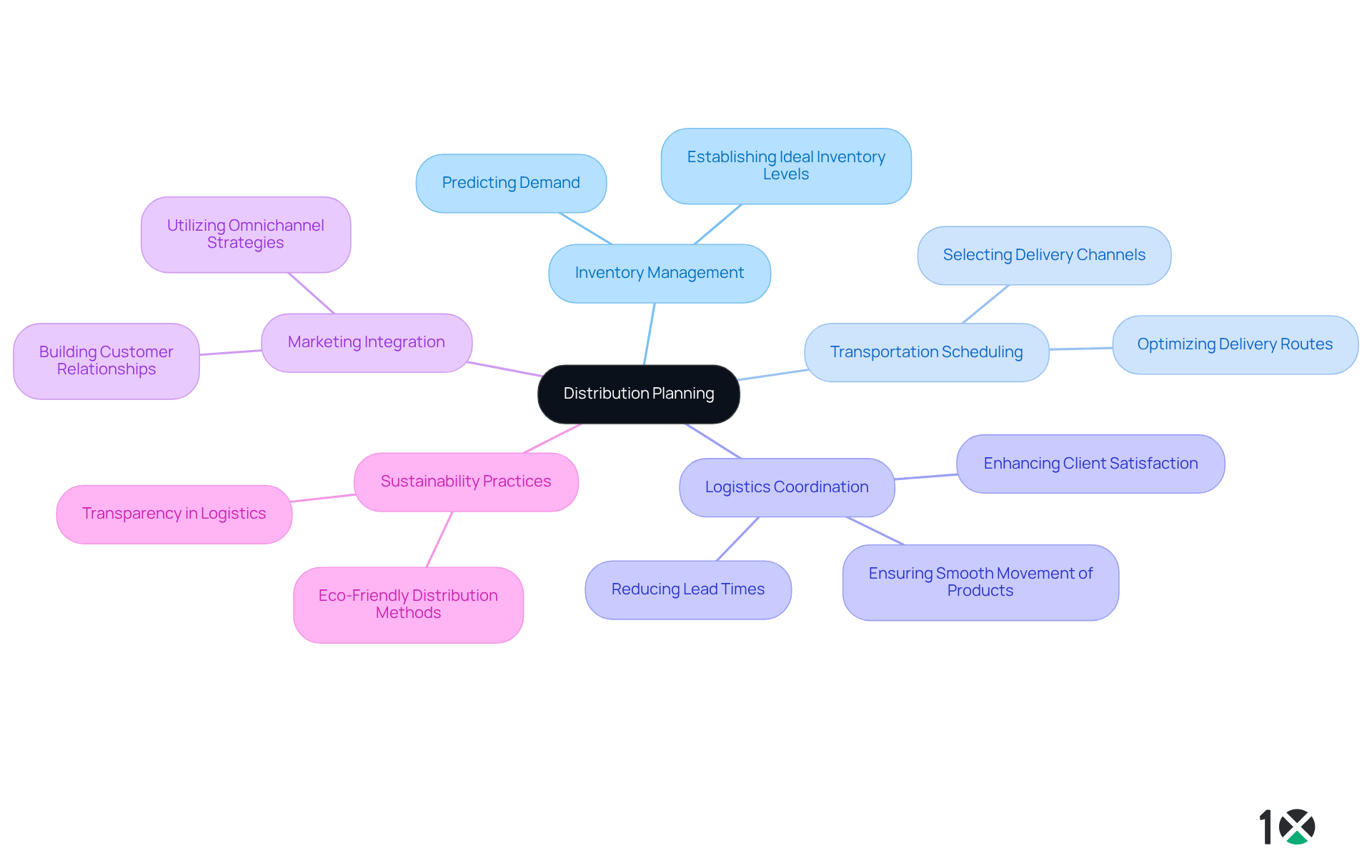

A systematic method known as distribution planning ensures the efficient delivery of goods from production locations to final recipients. It encompasses various functions, including inventory management, transportation scheduling, and distribution planning for logistics coordination. The primary objective? To satisfy client demand while minimizing costs and maximizing efficiency.

This process involves distribution planning, which includes predicting demand, establishing ideal inventory levels, and selecting suitable delivery channels. Efficient logistics organization and distribution planning are crucial for ensuring a smooth movement of products, reducing lead times, and enhancing client satisfaction. For instance, companies like Amazon leverage advanced distribution planning techniques, including predictive analytics, to optimize their supply chain operations, guaranteeing timely deliveries and high service levels.

Consider this: nearly 40% of retailers report significant sales increases through omnichannel strategies, underscoring the importance of being present across multiple interaction points. As supply chain specialist M. Cox aptly observes, “The more a company regards delivery as a component of its marketing, the more enduring connections it establishes with clients.” This insight highlights the vital role of distribution planning and logistics organization in supply chain management, especially as companies strive to enhance client experiences in 2025 and beyond.

Explain the Importance of Distribution Planning in Supply Chain Management

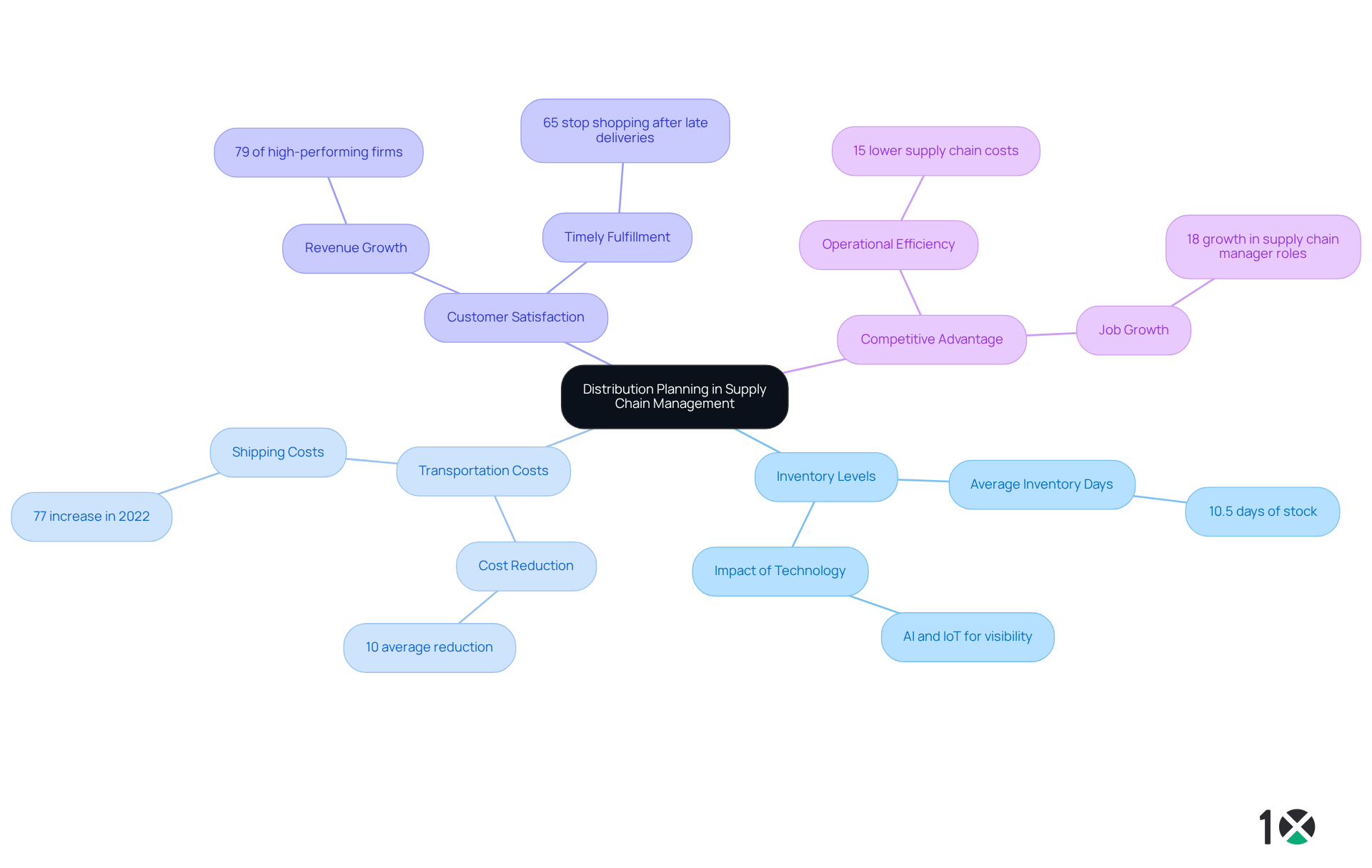

The distribution planning strategy plays a crucial role in supply chain management, significantly impacting inventory levels, transportation costs, and customer satisfaction. By optimizing the flow of goods, businesses can effectively reduce excess inventory and lower holding costs-key factors for maintaining profitability. For instance, companies that implement strategic logistics organization can achieve substantial cost reductions by optimizing routing and scheduling. A recent analysis revealed that organizations adopting advanced delivery strategies reported an average transportation cost reduction of 10%.

Moreover, effective distribution planning ensures that products are available precisely when and where clients need them, enhancing customer satisfaction and loyalty. In fact, 79% of firms with high-performing supply chains experience greater revenue growth than the industry average, underscoring the competitive advantage gained through exceptional logistics practices. Additionally, the Bureau of Labor Statistics projects an 18% increase in supply chain manager positions from 2022 to 2032, highlighting the growing demand for effective logistics organization and oversight in the sector. Firms excelling in this area not only provide outstanding service but also maintain lower operational costs, positioning themselves ahead of competitors in an increasingly demanding market.

Trace the Evolution of Distribution Planning: Historical Context

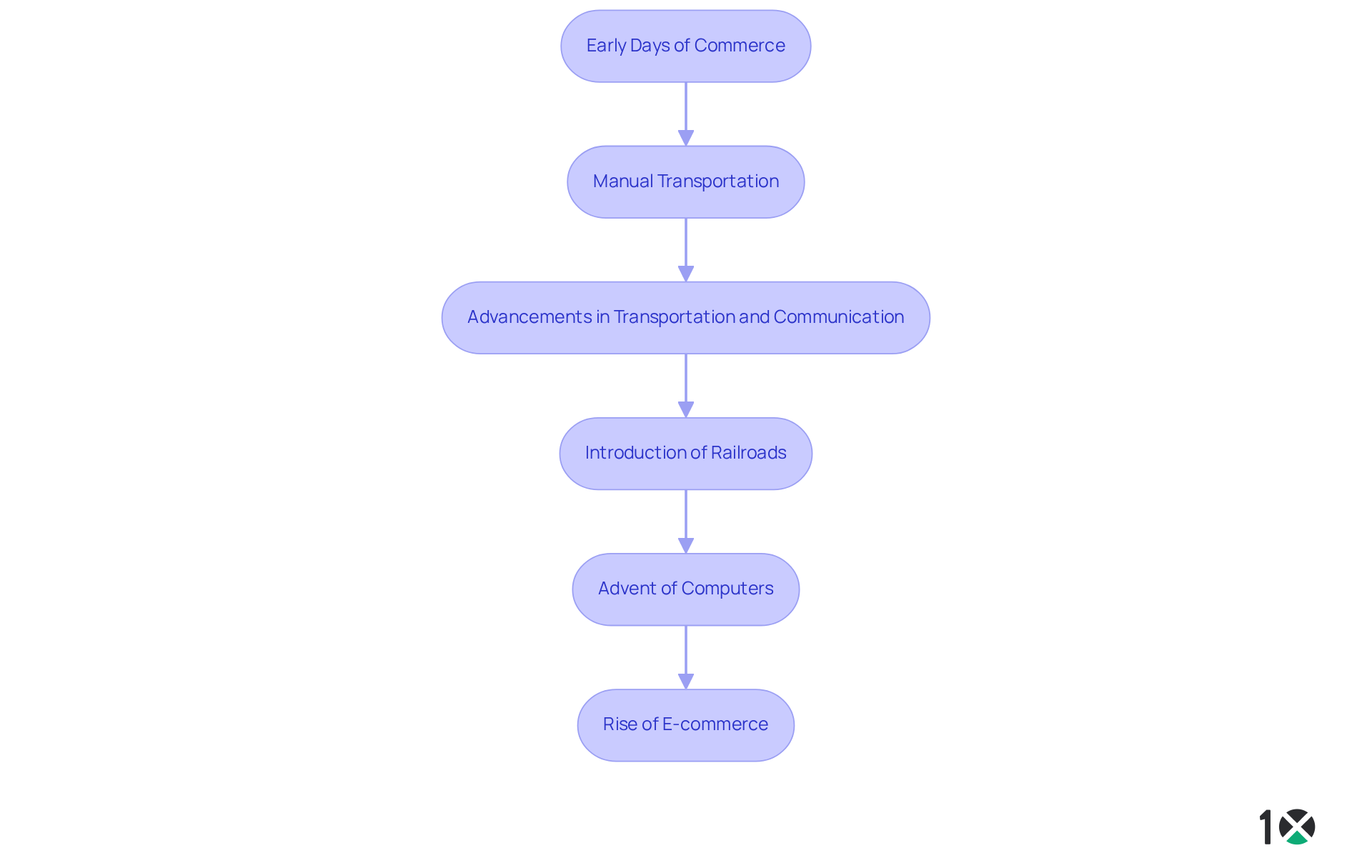

The evolution of logistics organization traces back to the early days of commerce, when goods were transported manually. As societies progressed, significant advancements in transportation and communication technologies began to reshape delivery practices. The introduction of railroads in the 19th century marked a pivotal moment, enabling faster and more efficient movement of goods across vast distances. This transformation accelerated with the advent of computers in the late 20th century, allowing businesses to leverage advanced logistics software and enhance their operational capabilities.

In the 21st century, the rise of e-commerce has dramatically reshaped the approach to distribution planning. Companies now face the necessity of adopting real-time data analysis and agile logistics strategies. Today, organizations harness advanced algorithms and machine learning to optimize their logistics networks, ensuring responsiveness to ever-changing market demands. Notably, statistics reveal that 78% of manufacturing leaders in the US believe digital solutions significantly enhance visibility and transparency across the supply chain, underscoring the critical role of technology in modern logistics practices.

Case studies illustrate the profound impact of transportation advancements on distribution planning. For instance, firms that have integrated AI into their supply chain operations report improved efficiency and reduced costs, showcasing how technology can drive innovation in delivery. As delivery practices continue to evolve, the focus on sustainability and customer-centric strategies is becoming increasingly important, reflecting a broader industry shift towards more resilient and adaptive supply chain models.

Identify Key Characteristics of Effective Distribution Planning

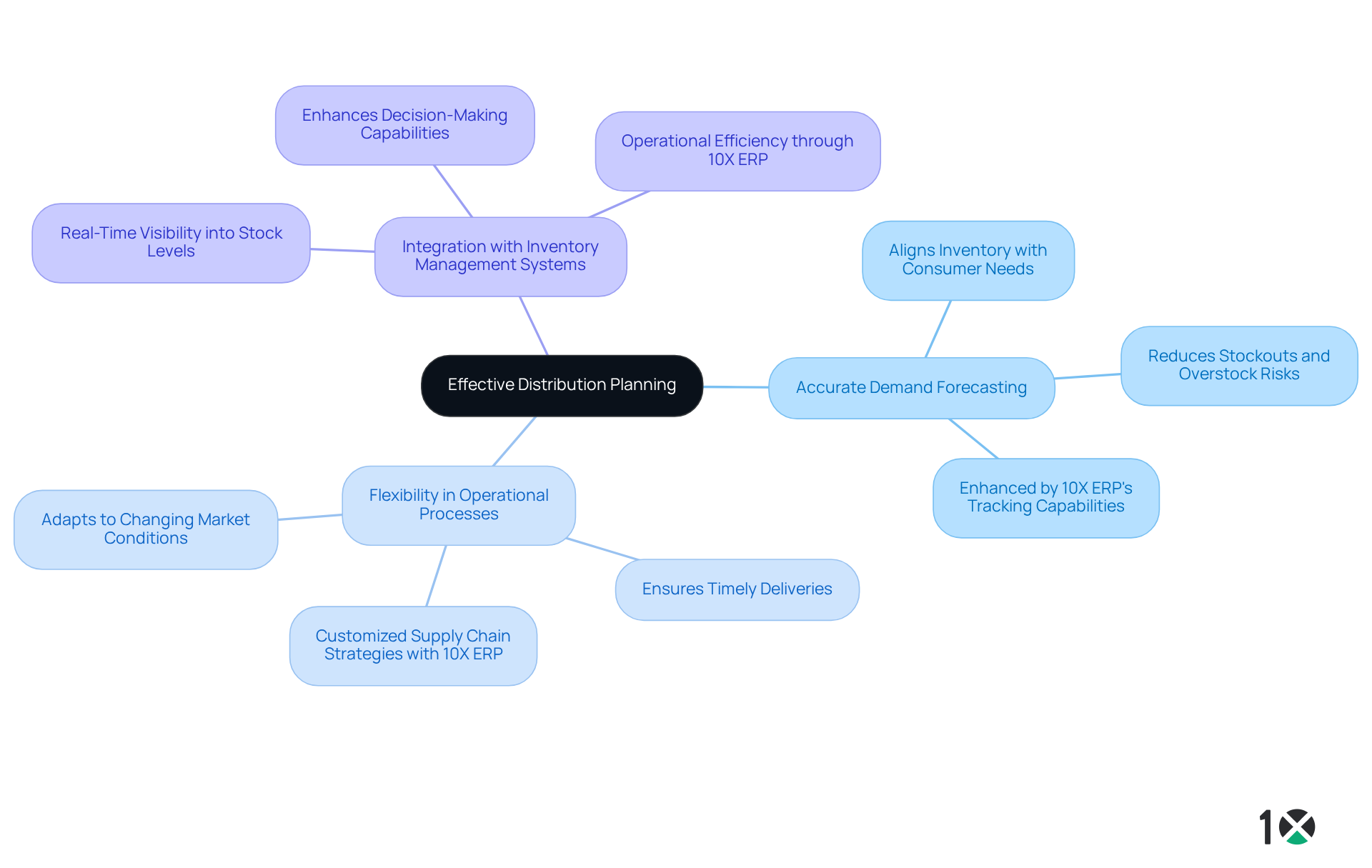

Effective distribution planning relies on several crucial components:

- Accurate demand forecasting

- Flexibility in operational processes

- Seamless integration with inventory management systems

Precise demand forecasting allows businesses to align their inventory levels with consumer needs, significantly reducing the risks of stockouts and overstock situations. With 10X ERP’s customizable tracking and powerful cross-referencing capabilities, businesses can monitor inventory levels in real-time, ensuring swift responses to changes in demand and avoiding costly inventory issues.

Adaptability in supply chain operations is essential for companies to react to changing market conditions and evolving customer preferences, ensuring timely deliveries. 10X ERP enhances this adaptability by providing tools that enable distributors to customize their supply chain strategies to tackle unique challenges, such as managing seasonal surges and ensuring punctual deliveries. Moreover, integrating supply chain processes with inventory management systems through 10X ERP offers real-time visibility into stock levels, enhancing decision-making capabilities and operational efficiency. By employing sophisticated forecasting techniques and maintaining robust logistics networks, distributors using 10X ERP can effectively respond to market changes and optimize their distribution planning.

Conclusion

Distribution planning stands as a cornerstone of effective supply chain management, ensuring goods transition smoothly from production to the end consumer. By focusing on efficiency, cost-effectiveness, and customer satisfaction, organizations can significantly boost their operational performance and carve out a competitive advantage in the marketplace.

This article has delved into key aspects of distribution planning, highlighting core functions like inventory management and transportation scheduling. The historical evolution of logistics practices reveals how technological advancements and shifts in consumer behavior have influenced modern distribution strategies. Moreover, characteristics of effective distribution planning – such as precise demand forecasting and adaptability – are essential for navigating market dynamics and optimizing supply chain operations.

The importance of distribution planning cannot be overstated. As businesses face an increasingly complex landscape, prioritizing robust distribution strategies is vital for meeting customer expectations and enhancing profitability. By embracing innovative technologies and proven practices in distribution planning, organizations can not only respond adeptly to current demands but also anticipate future challenges, securing long-term success in a competitive environment.

Frequently Asked Questions

What is distribution planning?

Distribution planning is a systematic method that ensures the efficient delivery of goods from production locations to final recipients. It involves various functions such as inventory management, transportation scheduling, and logistics coordination.

What are the primary objectives of distribution planning?

The primary objectives of distribution planning are to satisfy client demand while minimizing costs and maximizing efficiency.

What functions are included in the distribution planning process?

The distribution planning process includes predicting demand, establishing ideal inventory levels, and selecting suitable delivery channels.

Why is efficient logistics organization important?

Efficient logistics organization is crucial for ensuring smooth movement of products, reducing lead times, and enhancing client satisfaction.

How do companies like Amazon utilize distribution planning?

Companies like Amazon use advanced distribution planning techniques, including predictive analytics, to optimize their supply chain operations, ensuring timely deliveries and high service levels.

What impact do omnichannel strategies have on retailers?

Nearly 40% of retailers report significant sales increases through omnichannel strategies, highlighting the importance of being present across multiple interaction points.

How does distribution planning relate to marketing?

As supply chain specialist M. Cox notes, viewing delivery as a component of marketing helps companies establish more enduring connections with clients, emphasizing the vital role of distribution planning in enhancing client experiences.