Summary

- ERP systems facilitate sustainable practices by enhancing efficiency and reducing waste in distribution.

- Modern ERP platforms, like 10X ERP, assist in optimizing energy usage and improving supply chain management.

- Implementing ERP can lead to significant business savings and bolster the company’s reputation in the competitive market.

In today’s increasingly eco-conscious world, businesses of all sizes are under mounting pressure to adopt sustainable practices. Small to midsize distribution businesses are no exception. As businesses look to minimize waste, increase energy efficiency, and streamline their operations, many are turning to Enterprise Resource Planning (ERP) systems. But what exactly is ERP, and how can it assist in achieving these sustainability goals?

At its core, an ERP system integrates various business processes into a single, unified system. ERP systems offer a comprehensive view of business operations by consolidating functions like order processing, finance, HR, production, and inventory management. This unified view improves operational efficiency and can drive sustainability initiatives in meaningful ways.

Sustainable Distribution: The Need of the Hour

For distribution businesses, the challenges are many, from managing complex supply chains to minimizing waste and energy usage. By its very nature, distribution involves the movement of goods, often across vast distances. Such operations can have significant environmental footprints. It’s here that ERP can come as a game-changer.

Waste Reduction

In the distribution industry, waste encompasses more than just materials; it also pertains to time, effort, and valuable resources. ERP systems mitigate these wasteful practices. For instance, they allow businesses to monitor inventory in real-time, ensuring that there’s neither an excess nor a shortage – both of which can be costly in terms of wasted resources. For those businesses that operate their own fleets, ERP systems offer the advantage of route optimization, which directly translates to reduced fuel consumption and, subsequently, fewer emissions. Moreover, these systems come equipped with predictive maintenance capabilities, allowing businesses to foresee when their machinery might require attention. This not only prevents potential breakdowns that can be resource-intensive but also guarantees smoother and more efficient operations.

Energy Efficiency

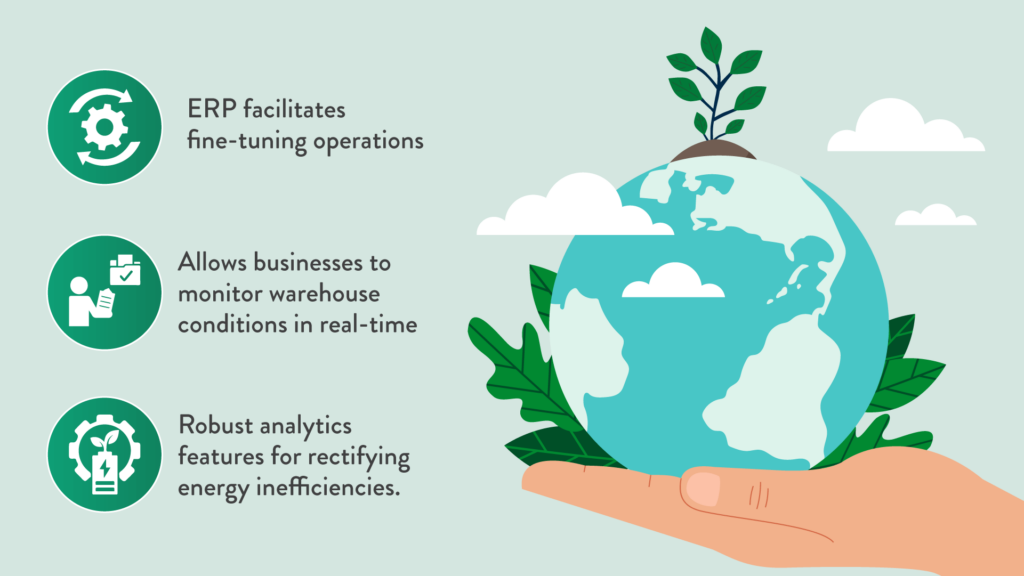

Energy expenditures comprise a substantial chunk of their overhead costs. ERP systems present solutions to curb these costs effectively. Firstly, ERP facilitates fine-tuning operations by delivering a unified perspective on all business processes, guaranteeing that machinery and facilities operate at peak efficiency. Additionally, in warehousing, the integration capabilities of contemporary ERP systems with IoT devices stand out. This fusion allows businesses to monitor warehouse conditions in real time, ensuring that utilities such as heating, lighting, and cooling systems function optimally, consequently minimizing energy wastage. Furthermore, the robust analytics features inherent in ERP systems empower businesses to harness data for decision-making, proactively pinpointing and rectifying energy inefficiencies.

Improved Supply Chain Management

A sustainable supply chain is not merely a trendy catchphrase—it’s an essential component for forward-thinking enterprises. ERP systems play an instrumental role in reshaping and refining this chain. One way they do this is through meticulous supplier evaluation. By consistently monitoring supplier performance metrics such as lead times, quality, and reliability, ERP systems enable businesses to collaborate closely with suppliers that resonate with their sustainability objectives.

Another crucial aspect where ERPs make a difference is in providing transparent traceability. In an age where both consumers and businesses are eager to understand the origins of their products, ERP systems facilitate end-to-end traceability. This not only nurtures transparency but also bolsters sustainable sourcing practices. Moreover, with the predictive prowess of ERP systems, businesses can anticipate demand with impressive accuracy. Such foresight ensures that goods are neither produced nor sourced in excess, minimizing the environmental repercussions of overproduction and subsequent waste.

The Benefits Go Beyond the Planet

While the advantages of ERP in promoting sustainability are evident, its benefits stretch beyond purely environmental concerns. Incorporating a streamlined, efficient, and sustainable distribution process driven by an ERP system can usher in substantial business cost savings from minimized waste and optimized operations. Furthermore, in today’s competitive landscape, a genuine commitment to sustainability can significantly bolster a company’s reputation, allowing it to distinguish itself in a saturated market. Additionally, an ERP system becomes indispensable as numerous regions worldwide gravitate towards implementing rigorous sustainability regulations. It serves as a safeguard, ensuring businesses adhere to these rules, thus sidestepping hefty fines and potential legal ramifications.

In Conclusion

As the world moves towards sustainable practices, it’s up to businesses to lead the charge. ERP systems like 10X ERP aren’t just tools for better business—they’re tools for a better world. ERP is setting distribution on a sustainable path by reducing waste, improving energy efficiency, and streamlining the supply chain. As a responsible business, isn’t it time you joined the journey?

Contact us if you’re eager to know more about how ERP can benefit your distribution business. Together, let’s build a sustainable future.