Understanding the terms ERP (Enterprise Resource Planning) and MRP (Material Requirements Planning) can feel like navigating a labyrinth, especially when you consider their shared acronyms and history. While they do overlap in some areas, each system provides its own unique capabilities and levels of performance.

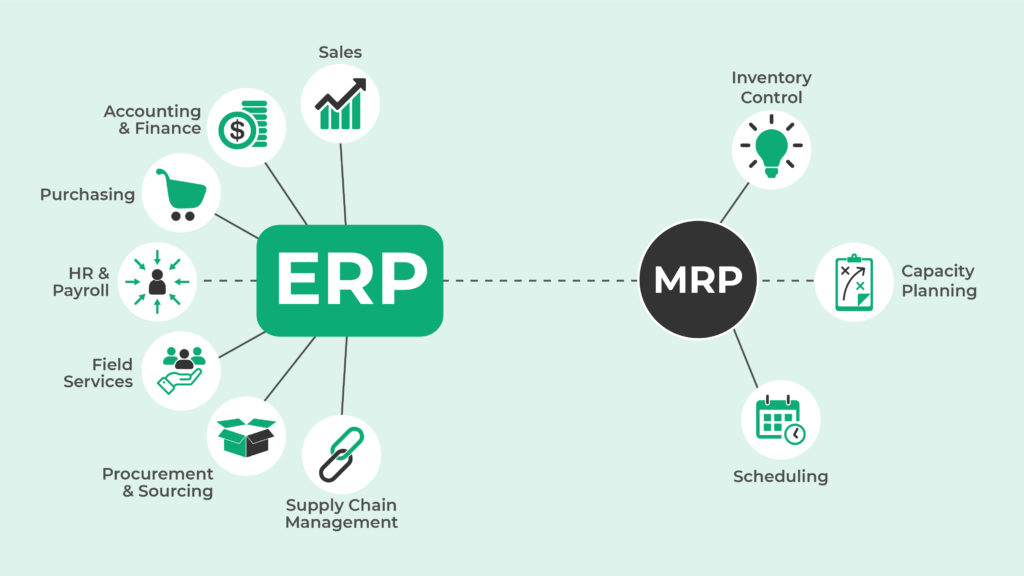

MRP software primarily enables manufacturers to manage material-related aspects of their business, including inventory control, capacity planning, and scheduling. ERP systems, however, offer a more comprehensive suite, including MRP features, along with customer/vendor relationship management, human resource planning, accounting, and more.

In this article, we delve into the differences between ERP and MRP systems and guide you on choosing the right solution for your distribution business.

UNDERSTANDING MRP SYSTEMS

MRP systems are essentially the calculators of production materials. They identify and measure the materials needed for production and when they’re needed, which helps to prevent downtime and production losses. The MRP system is a go-to tool for production planners in manufacturing, as it helps forecast and maintain the right levels of inventory or materials to ensure productivity.

The core objectives of an MRP system include:

- Ensuring the right materials are available for production

- Planning manufacturing, sales, and purchases

- Maintaining optimal inventory levels

- Ensuring products are ready for delivery.

Key features can include stock controls, production scheduling, inventory tracking and management, and supply chain management.

DEMYSTIFYING ERP SYSTEMS

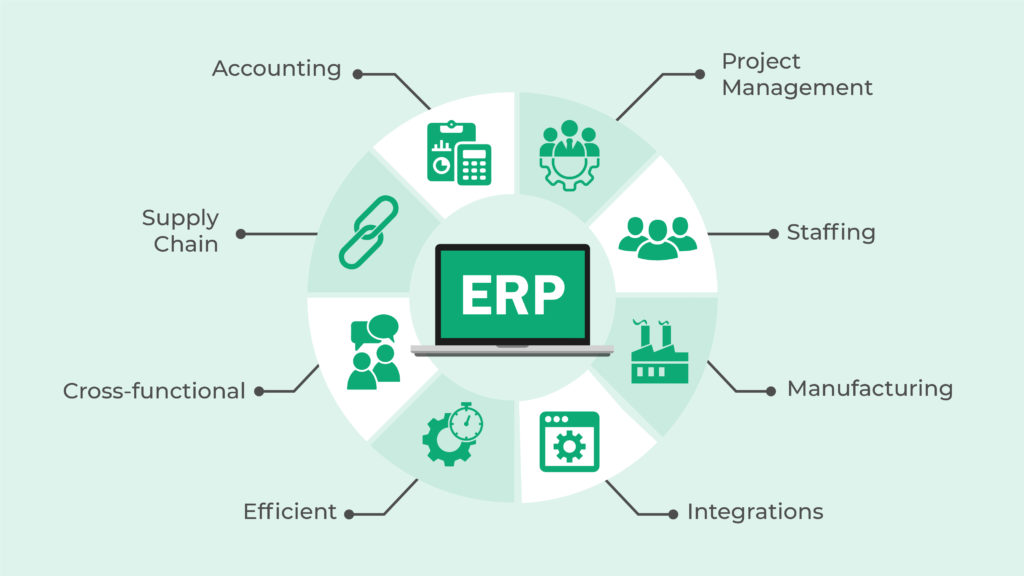

ERP systems are the multi-taskers of business operation planning and management. They provide a suite of applications that interact across various operations like supply chain management, accounting, project management, staffing, and manufacturing. As outlined by Investopedia, these systems offer an integrated system, a common database and user interface, real-time operations updates, and a cloud-based deployment.

At 10X ERP, our solution offers an integrated system, a common database and user interface, real-time operations updates, and a cloud-based deployment. ERP systems bring along a myriad of benefits, including:

- Cost savings through increased efficiency and productivity via automation

- Improved management and monitoring capabilities

- Reduction in human error and elimination of time-wasting manual processes

- Enhanced intra-departmental communication

- Improved supplier and customer management

MRP VS ERP: DRAWING THE LINE

The crucial distinctions between MRP and ERP are:

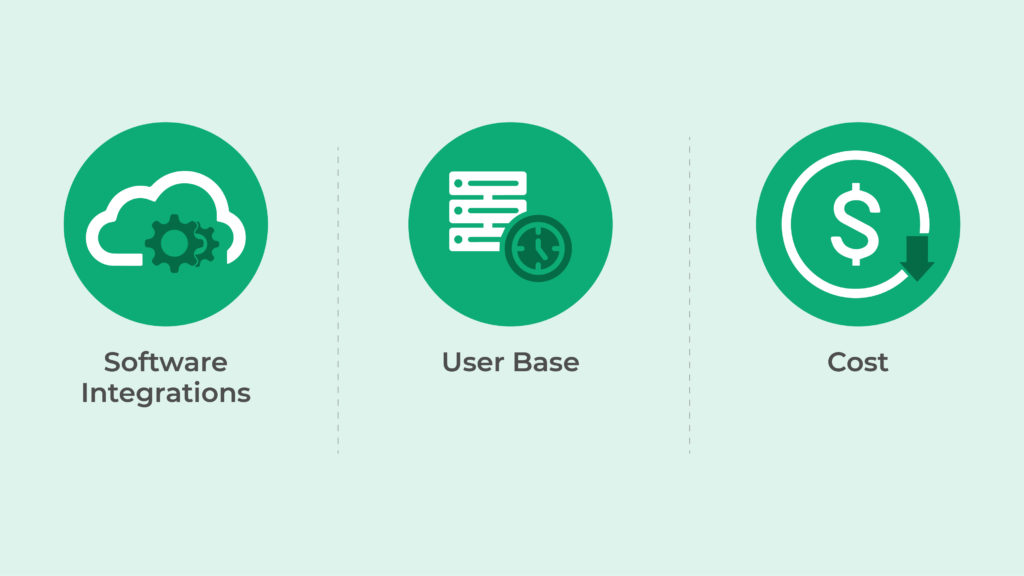

- Integration: While MRP systems function as standalone solutions with manufacturing add-ons, ERP systems provide a seamless integration experience with other software systems and modules.

- Usage: ERP software is common in organizations of all sizes that need to manage complex workflows across multiple departments. MRP systems, on the other hand, are suitable for manufacturing businesses that don’t require multiple process integrations.

- Cost: ERP systems are often pricier than MRPs due to their wider range of functionalities. They serve multiple facets of a business, not just the manufacturing operations.

THE RELATIONSHIP BETWEEN MRP AND ERP SYSTEMS

An ERP system often incorporates an MRP subsystem. Oracle’s blog post on the history and evolution of ERP explains how the MRP provides crucial data on materials and resources that the ERP uses to inform other related departments.

CHOOSING BETWEEN ERP AND MRP

Forbe’s comprehensive article on MRP vs. ERP makes it clear that selecting between an ERP and MRP system depends mainly on your business requirements. If your small to medium-sized distribution business needs help with operations or inventory management, an MRP might suffice. However, if you anticipate expansion and require an integrated and streamlined process management, an ERP solution, like 10X ERP, would be more suitable

As you weigh up your options, consider these questions:

- What operations require optimization, automation, and connection?

- What is your available budget?

- Is your company planning to scale?

CONCLUSION

While MRP and ERP systems share similarities, each offers distinct capabilities. ERPs provide a broader range of solutions, including accounting, business intelligence, sales, purchasing, and warehouse management. If your business anticipates growth or requires automation and optimization across departments, you’ll need more than an MRP.

At 10X ERP, we’re committed to empowering businesses with a user-friendly, integrated, and comprehensive ERP solution. If you’re considering implementing an ERP for your expanding business, come check us out and discover how we’re revolutionizing ERP for distributors!