Overview

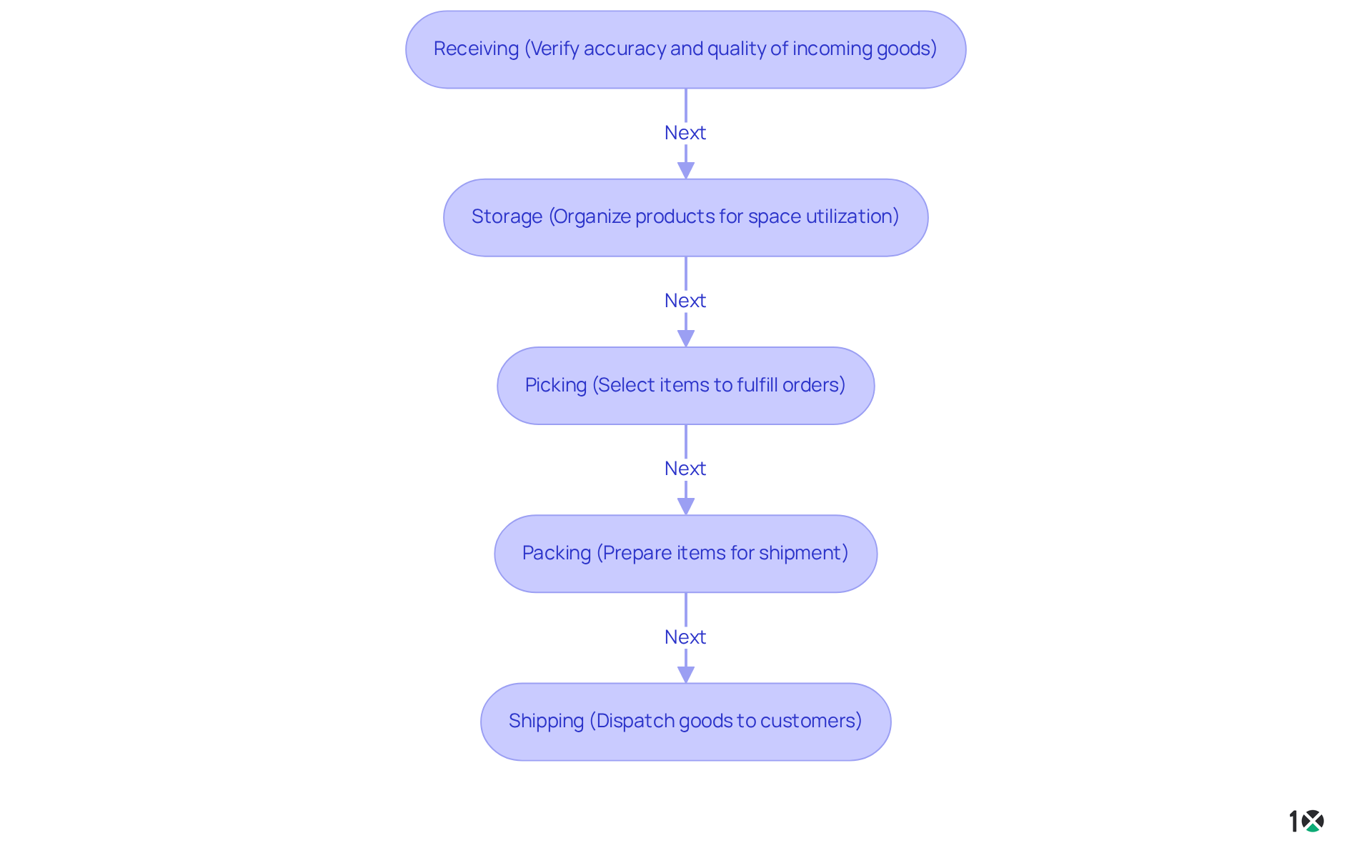

To optimize warehouse operations, it is essential to master the fundamental processes of:

- Receiving

- Storing

- Picking

- Packing

- Shipping goods

Additionally, identifying underperforming areas allows for targeted improvements that can make a significant difference. Implementing strategies such as:

- Lean warehousing

- Automation

- Technology utilization

is crucial. These approaches not only enhance efficiency and productivity but also ensure that organizations remain competitive in a rapidly evolving landscape. By focusing on these key steps, warehouse managers can drive performance and achieve operational excellence.

Introduction

Mastering the intricacies of warehouse operations is paramount as businesses strive to maintain competitiveness in a rapidly evolving marketplace. Each step—from receiving and storing goods to picking, packing, and shipping—plays a pivotal role in ensuring efficiency and customer satisfaction. Yet, many organizations grapple with inefficiencies that impede their potential for optimization.

What key strategies and technologies can transform these operations and drive significant performance improvements? This exploration will uncover actionable insights that empower Operations Managers to enhance their operational effectiveness.

Understand Warehouse Operations Fundamentals

Warehouse operations encompass a range of critical activities, including receiving, storing, picking, packing, and shipping goods. Mastering these processes is vital for optimizing efficiency and ensuring smooth operations. Understanding these components not only enhances the effectiveness of warehouse operations but also positions your organization for success in a competitive landscape.

- Receiving: This initial step involves accepting incoming goods and verifying their accuracy and quality. Efficient receiving processes can significantly reduce errors and enhance inventory accuracy, laying a strong foundation for subsequent operations.

- Storage: Organizing products effectively within the facility maximizes space utilization and accessibility. Implementing advanced storage solutions can improve space consumption by up to 20%, allowing for better inventory management.

- Picking: The selection of items from storage to fulfill orders is crucial. Various picking methods, such as batch picking or zone picking, can streamline this process, leading to faster order fulfillment and increased customer satisfaction.

- Packing: Preparing items for shipment requires ensuring they are secure and correctly labeled. Automation in packing can enhance speed and accuracy, contributing to improved customer satisfaction and operational efficiency.

- Shipping: The final step involves dispatching goods to customers, necessitating coordination with logistics to ensure timely delivery. With 85% of consumers expecting next-day delivery, are more important than ever to meet customer expectations.

Comprehending these processes facilitates the recognition of areas for enhancement, allowing the application of efficient strategies for optimization. As the automation market is projected to exceed $50 billion by 2030, investing in technology and training is essential for remaining competitive in this evolving landscape. By embracing these advancements, organizations can stay ahead of the curve and ensure their operations are not only efficient but also resilient to future challenges.

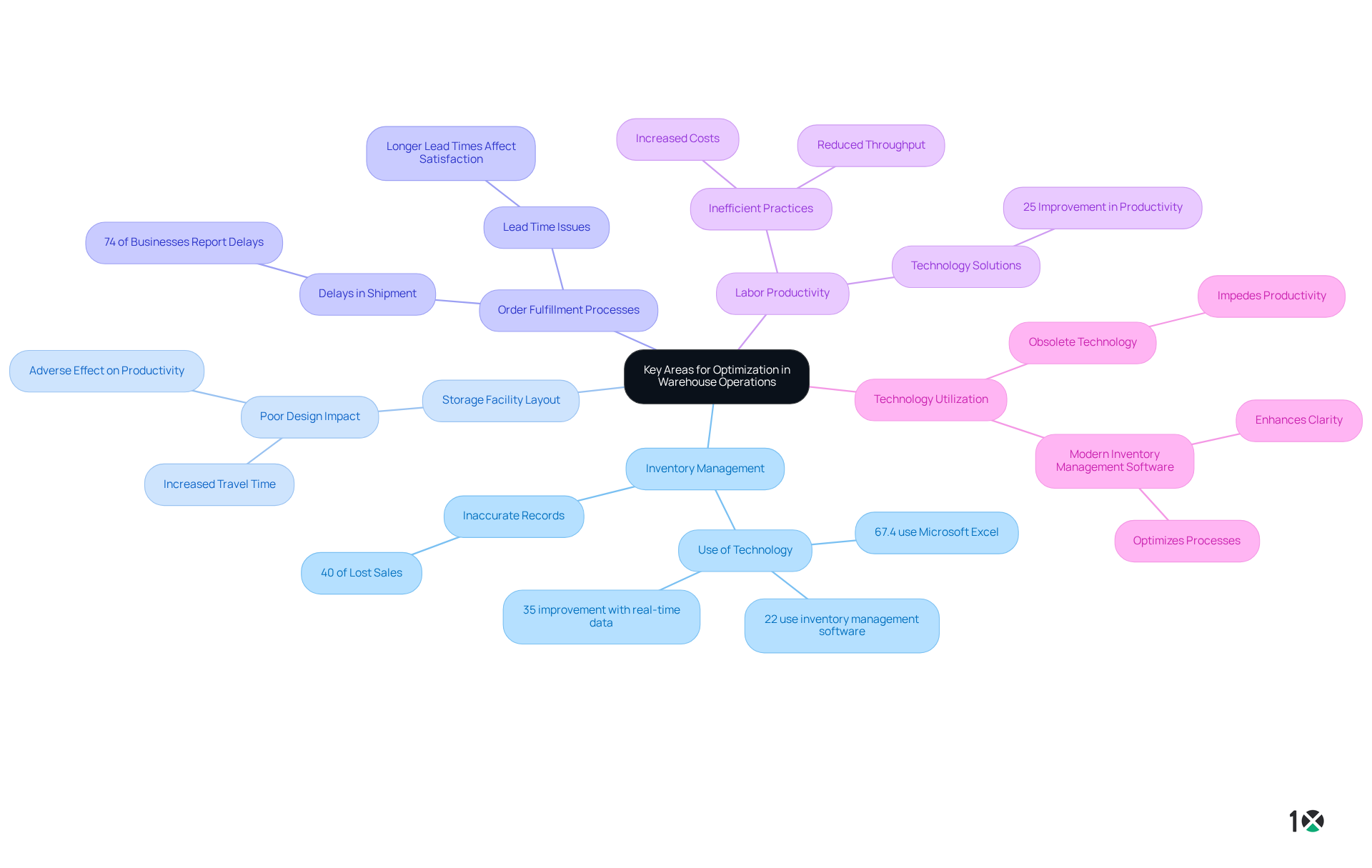

Identify Key Areas for Optimization

To effectively, identifying specific underperforming areas is crucial. Assessing key aspects can lead to significant improvements:

- Inventory Management: Evaluate the methods used for tracking and managing inventory. Inaccurate inventory records can lead to stockouts, accounting for 40% of lost sales, or overstocking, which unnecessarily ties up capital.

- Storage Facility Layout: Examine the physical configuration of the storage area. A poorly designed layout can increase travel time for picking and packing, adversely affecting overall productivity. Studies indicate that optimizing warehouse operations enhances order fulfillment processes and significantly reduces operational costs.

- Order Fulfillment Processes: Evaluate the effectiveness of order processing from receipt to shipment. Delays in any step can impact customer satisfaction, with 74% of businesses reporting delays in shipments and longer lead times.

- Labor Productivity: Assess employee performance and workflow. Inefficient labor practices can lead to increased costs and reduced throughput. Implementing technology solutions can improve labor productivity by up to 25%.

- Technology Utilization: Examine the tools and systems in place. Obsolete technology can impede productivity and precision, whereas contemporary inventory management software can improve clarity and optimize processes.

By identifying these areas, you can create a targeted strategy for enhancement in warehouse operations, ensuring that your storage activities are optimized for both efficiency and effectiveness.

Implement Strategies for Process Improvement

To effectively optimize warehouse operations, targeted strategies must be implemented. Consider the following approaches:

- Lean Warehousing: Embrace lean principles to eliminate waste and streamline processes. This includes minimizing unnecessary steps in workflows, optimizing stock levels, and standardizing processes, which can lead to cost savings of 20% to 50%. Lean warehousing aims to improve order processing times and better manage seasonal demand.

- Automation: Invest in automation technologies such as conveyor systems, automated guided vehicles (AGVs), and inventory management systems (WMS). Automated storage facilities are 76% more likely to attain inventory precision of 99% or greater, significantly improving effectiveness and precision in processes.

- Training and Development: Offer continuous training for personnel to enhance their skills and knowledge about best practices in warehouse activities. This investment in human capital fosters a and helps address challenges such as high attrition rates and rising labor costs.

- Performance Metrics: Establish key performance indicators (KPIs) to assess effectiveness and productivity. Consistently evaluating these metrics assists in recognizing trends and areas requiring focus, ensuring that processes stay aligned with business objectives.

- Continuous Improvement: Cultivate a culture of continuous improvement by encouraging employee feedback and regularly reviewing processes for potential enhancements. Implementing methodologies like 5S, which includes Sort, Set in Order, Shine, Standardize, and Sustain, can streamline workflows and optimize tasks, ensuring that all tools and materials are easily accessible.

By applying these strategies, warehouse operations can achieve substantial advancements in effectiveness and output, ultimately resulting in improved performance.

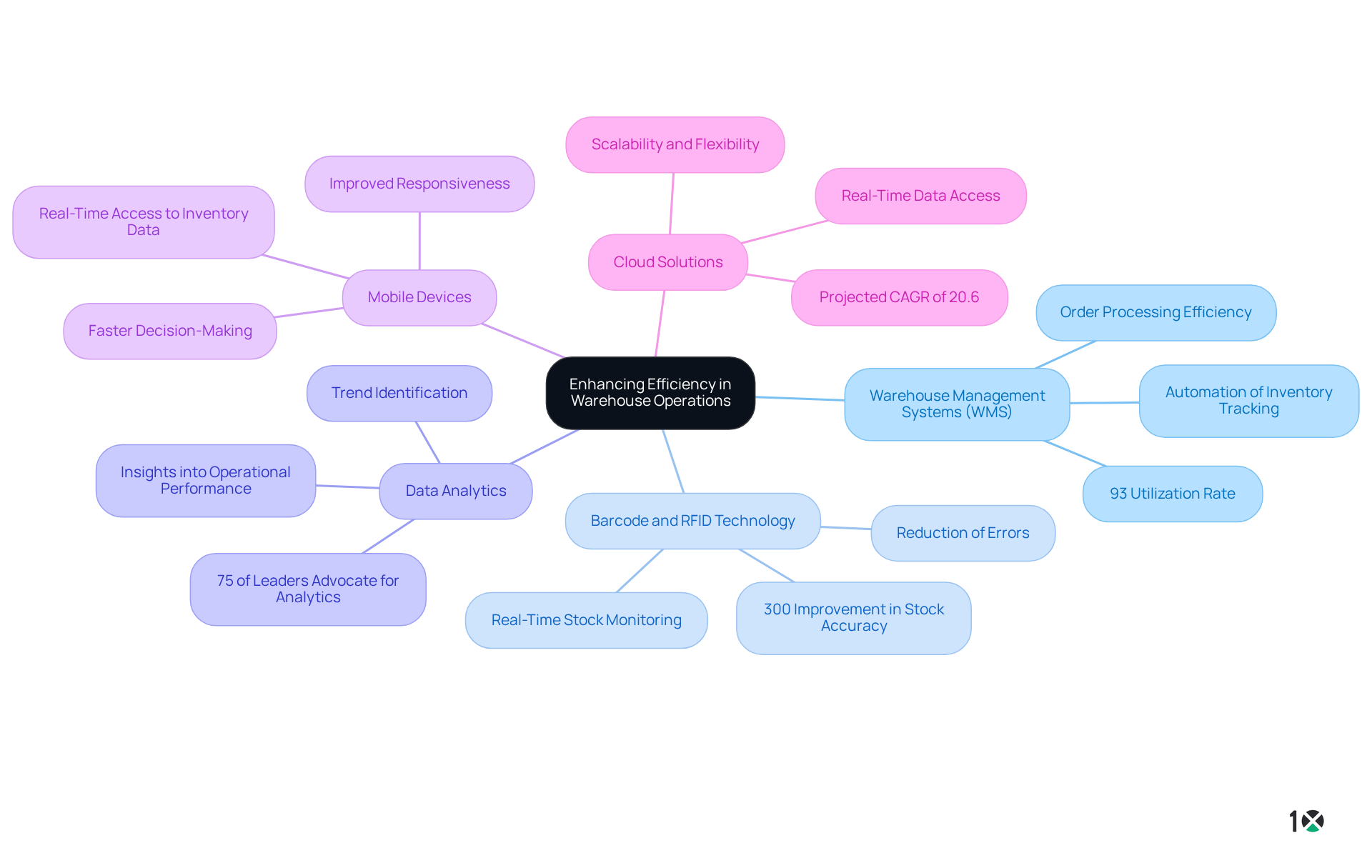

Utilize Technology and Tools for Enhanced Efficiency

To enhance productivity in warehouse operations, implementing technology is essential. Consider the following tools and technologies:

- Warehouse Management Systems (WMS): The adoption of a WMS automates inventory tracking, order processing, and reporting, leading to improved accuracy and efficiency. With over 93% of warehouses utilizing WMS, this system has become a cornerstone for .

- Barcode and RFID Technology: The use of barcode scanners and RFID tags allows for real-time stock monitoring, significantly reducing errors and enhancing visibility. For instance, RFID technology can enhance stock accuracy by as much as 300%, showcasing its transformative impact on supply management.

- Data Analytics: Employing data analytics tools provides insights into operational performance, aiding in the identification of trends and informed decision-making. Notably, a substantial 75% of industry leaders advocate for comprehensive analytics to enhance storage processes.

- Mobile Devices: Equipping staff with mobile devices grants real-time access to inventory data and order information, which facilitates faster decision-making and improves overall responsiveness.

- Cloud Solutions: The adoption of cloud-based platforms like 10X ERP offers scalability and flexibility, enabling real-time data access and collaboration across teams. The cloud sector in inventory management is projected to expand at a CAGR of 20.6% from 2025 to 2030, underscoring its rising significance in contemporary operations.

Incorporating these technologies into warehouse operations can significantly improve efficiency and streamline procedures, enabling companies to adapt to the evolving market demands. To discover how 10X ERP can specifically address your warehouse operations challenges and enhance your processes, let’s connect. Fill out our simple contact form to get started.

Conclusion

Mastering warehouse operations is essential for organizations that aim to thrive in a competitive environment. Understanding the fundamental processes—receiving, storing, picking, packing, and shipping—enables businesses to lay the groundwork for enhanced efficiency and operational success. Emphasizing these components streamlines workflows and positions companies to respond effectively to evolving market demands.

This article highlights key areas for optimization, including:

- Inventory management

- Storage layout

- Order fulfillment

- Labor productivity

- Technology utilization

Each of these elements plays a critical role in identifying inefficiencies and implementing targeted strategies. By adopting lean warehousing principles, investing in automation, and fostering a culture of continuous improvement, organizations can achieve significant cost savings and enhanced performance. Furthermore, leveraging advanced technologies such as Warehouse Management Systems, barcode and RFID technology, and data analytics can transform operations, yielding improved accuracy and responsiveness.

In conclusion, optimizing warehouse operations is not merely a tactical move; it is a strategic imperative that drives substantial improvements in efficiency and customer satisfaction. By embracing best practices and innovative technologies, organizations can navigate the complexities of modern warehousing and position themselves for sustained success. Taking proactive steps today will ensure that warehouse operations are not only efficient but also resilient against future challenges, ultimately enhancing overall business performance.

Frequently Asked Questions

What are the main activities involved in warehouse operations?

The main activities involved in warehouse operations include receiving, storing, picking, packing, and shipping goods.

Why is mastering warehouse operations important?

Mastering warehouse operations is vital for optimizing efficiency and ensuring smooth operations, which positions an organization for success in a competitive landscape.

What does the receiving process entail?

The receiving process involves accepting incoming goods and verifying their accuracy and quality, which helps reduce errors and enhance inventory accuracy.

How can effective storage solutions benefit warehouse operations?

Effective storage solutions can maximize space utilization and accessibility, potentially improving space consumption by up to 20% and aiding in better inventory management.

What are some methods of picking items in a warehouse?

Various picking methods include batch picking and zone picking, which can streamline the selection of items to fulfill orders, leading to faster order fulfillment and increased customer satisfaction.

What is involved in the packing process?

The packing process involves preparing items for shipment, ensuring they are secure and correctly labeled. Automation in packing can enhance speed and accuracy.

What is the significance of the shipping process in warehouse operations?

The shipping process is crucial for dispatching goods to customers and requires coordination with logistics to ensure timely delivery, especially since 85% of consumers expect next-day delivery.

How can understanding warehouse operations lead to improvements?

Comprehending warehouse processes allows for the recognition of areas for enhancement, enabling the application of efficient strategies for optimization.

What is the projected growth of the automation market in warehouse operations?

The automation market is projected to exceed $50 billion by 2030, highlighting the importance of investing in technology and training to remain competitive.

Why is it important for organizations to embrace advancements in warehouse operations?

Embracing advancements in technology and training allows organizations to stay ahead of the curve and ensure their operations are efficient and resilient to future challenges.