Summary

- Lot and expiration tracking is critical in regulated industries, and modern ERP systems like 10X ERP ensure full traceability, real-time visibility, and audit readiness.

- Automated expiration management with ERP helps businesses reduce waste, prioritize older inventory (FEFO), and prevent expired products from being shipped.

- By centralizing compliance, recall readiness, and inventory rotation, 10X ERP transforms regulatory requirements into a strategic advantage for industrial, fluid power, and other sensitive industries industries.

In industries where product safety, traceability, and compliance are non-negotiable, managing lot-controlled and expiring inventory is more than good practice, it’s essential. Whether you’re distributing hoses, seals, plastics, or material governed by regulatory standards, a well-executed inventory strategy can protect both your business and your customers.

Unfortunately, many companies still rely on manual systems or spreadsheets to track lot numbers and expiration dates, increasing the risk of human error, non-compliance, and costly waste. With a modern ERP like 10X ERP, these risks can be significantly reduced by automating lot tracking, expiry management, and recall readiness across your entire supply chain.

The Critical Role of Lot Tracking

Lot tracking assigns a unique identifier to a specific batch of products, linking them to key data like production date, expiration, origin, and quality checks. In regulated industries, lot numbers serve as a central reference point for quality assurance, customer service, and compliance reporting.

When this information is siloed or disconnected from operational systems, the consequences can be serious. Product recalls become chaotic. Expired items slip through the cracks. Proving compliance during audits becomes a manual and time-consuming process.

10X ERP is designed to manage lot-level inventory with precision. Every transaction involving a lot, whether it’s receiving, picking, shipping, or return, is recorded in real time and tied back to the original batch, ensuring full traceability throughout the product lifecycle.

Expiration Management Beyond the Label

Expiration dates are critical thresholds that determine product viability and regulatory status. In the food, pharmaceutical, and other perishable or sensitive goods industries, expired inventory can’t simply be written off. It must be properly quarantined, documented, and fully traceable.

Effective ERP-driven expiry management means more than tracking dates. It’s about automation and proactive planning. With 10X ERP, you can set system alerts when items are approaching expiration, adjust picking rules to prioritize older inventory, and configure rules to prevent expired products from being shipped.

These capabilities allow businesses to make smarter purchasing decisions, reduce spoilage, and maintain a higher standard of service for their customers. Over time, this builds not only compliance but trust.

Compliance Requirements You Can’t Afford to Miss

Industrial suppliers face a growing web of regulations from agencies like the EPA, DOT, and international regulatory bodies. Requirements for traceability, lot recall readiness, and proper inventory rotation are not optional. They are table stakes for doing business.

A modern ERP like 10X ERP centralizes compliance-related data and provides complete visibility into where a product came from, where it’s been, and where it is now. This level of traceability is essential not only for audits and inspections but also for internal quality control and supplier accountability.

When a recall or customer inquiry occurs, the ability to instantly pull up affected lots, identify customers, and execute replacements can prevent reputational damage and legal exposure. It also enables your team to respond with speed and confidence, rather than scrambling to piece together information from multiple sources.

First-Expiry-First-Out (FEFO) in Action

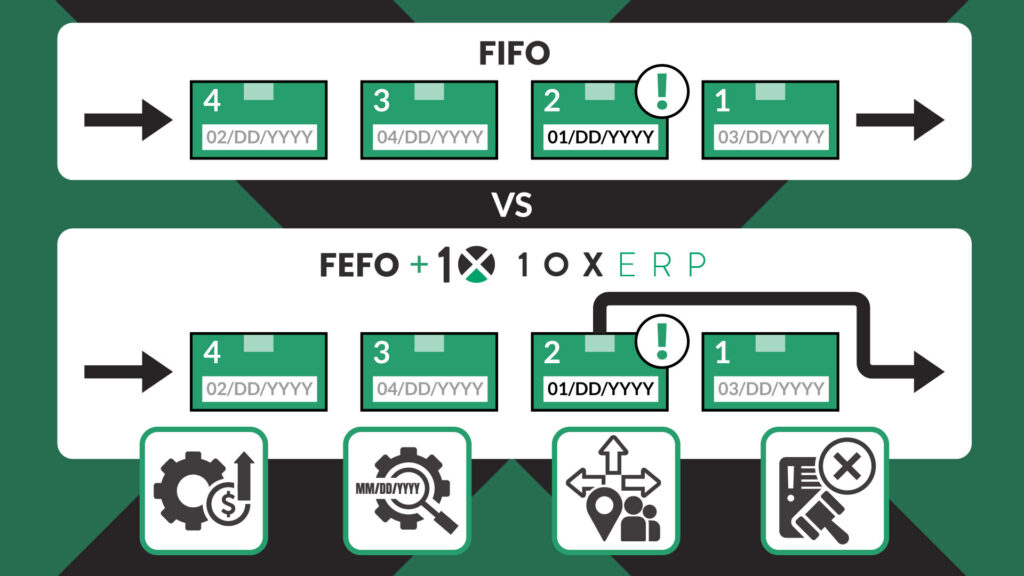

Traditional inventory strategies like FIFO (First-In-First-Out) can fall short when dealing with perishable or regulated items. That’s why many ERP systems, including 10X ERP, offer support for FEFO (First-Expiry-First-Out) ensuring the oldest expiring stock is used first, regardless of when it was received.

Implementing FEFO through your ERP system allows for smarter fulfillment. Rather than relying on warehouse staff to manually check dates, the system guides picking decisions based on expiration logic, reducing the chance of waste or compliance violations. And because it’s system-driven, it’s scalable across locations and teams without requiring custom processes or workarounds.

A Future-Proof Approach to Traceability

As supply chain transparency and product safety continue to move to the forefront, lot and expiration tracking will only grow in importance. Companies that invest in modern, integrated tools now will be better prepared to meet future regulations, customer expectations, and operational complexity.

At 10X ERP, we understand the demands of regulated industries. Our platform is built to provide real-time lot tracking, expiration monitoring, audit trails, and actionable insights—all from a single source of truth. Whether you’re navigating a complex recall or simply aiming to improve stock rotation, our tools are designed to help you move quickly, confidently, and compliantly.

Conclusion

Managing lot-controlled and expiring inventory isn’t just about staying organized—it’s about protecting your customers, your brand, and your bottom line. With the right ERP system, what once felt like a regulatory burden becomes a strategic advantage.

Ready to modernize your inventory compliance process? Contact us to learn how 10X ERP helps regulated businesses streamline lot tracking, expiration management, and more.