Overview

To enhance fastener warehouse operations, implementing efficient inventory management systems, fostering cross-departmental communication, and adopting continuous improvement strategies are essential best practices. Techniques such as FIFO inventory management, real-time tracking, and Lean methodologies serve as foundational elements that drive increased efficiency, reduce waste, and improve collaboration within the warehouse environment. By embracing these strategies, operations managers can not only streamline processes but also create a culture of continuous improvement that propels their teams toward success.

Introduction

In the competitive landscape of fastener warehousing, operational efficiency is not merely an advantage; it is an absolute necessity. Implementing best practices in inventory management, fostering cross-departmental communication, and embracing continuous improvement strategies are crucial steps that warehouses must take to significantly enhance productivity and customer satisfaction.

Yet, the challenge persists: how can organizations effectively integrate these practices to create a streamlined operation that not only meets current demands but also anticipates future trends?

This article delves into actionable strategies designed to transform fastener warehouse operations, ensuring they remain agile and efficient in an ever-evolving market.

Streamline Inventory Management for Enhanced Efficiency

To enhance stock management in a fastener warehouse, adopting a comprehensive management system that facilitates of stock levels is essential. Implementing the First-In-First-Out (FIFO) method ensures that older stock is utilized first, significantly reducing the risk of obsolescence and waste. Furthermore, classifying fasteners based on size, type, and usage frequency improves retrieval speed and reduces picking mistakes, which is critical for maintaining operational effectiveness.

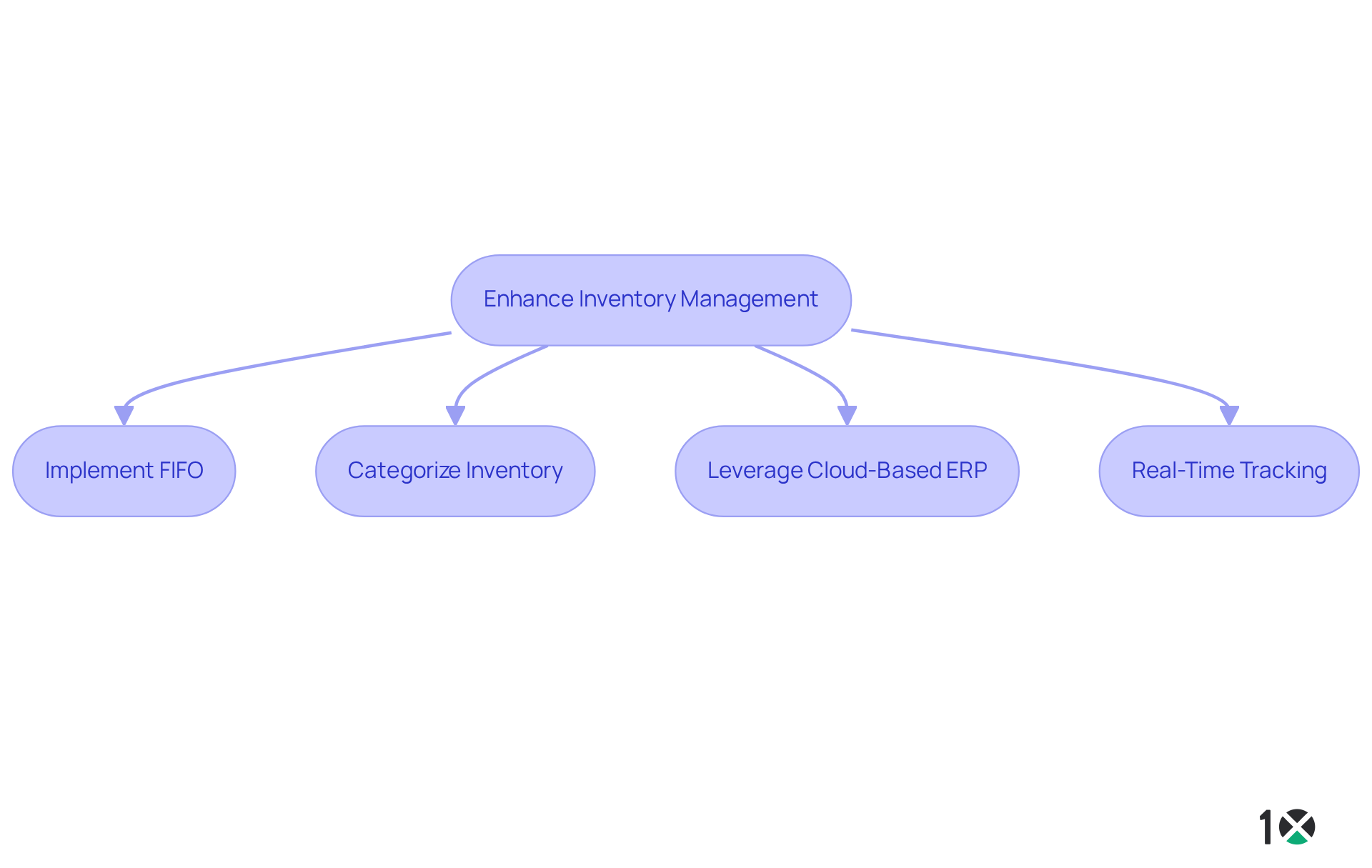

Best Practices for Inventory Management:

- Implement FIFO: Ensure older stock is used first to minimize waste.

- Categorize Inventory: Organize fasteners by size, type, and usage frequency for quicker retrieval.

- [Leverage Cloud-Based ERP](https://10xerp.com/?p=1646): Utilize solutions like 10X ERP for seamless integration with stock management processes, providing automatic updates and alerts for low supply levels.

- Real-Time Tracking: Adopt real-time tracking to reduce delays and improve customer satisfaction. Real-time monitoring has been demonstrated to cut delays by as much as 58%, further highlighting its influence on stock management.

This proactive strategy not only reduces stockouts but also optimizes storage space, resulting in improved effectiveness in warehouse operations. Moreover, well-organized stock systems can decrease fulfillment times by 23%, emphasizing the concrete advantages of efficient stock management practices.

Foster Cross-Departmental Communication to Improve Operations

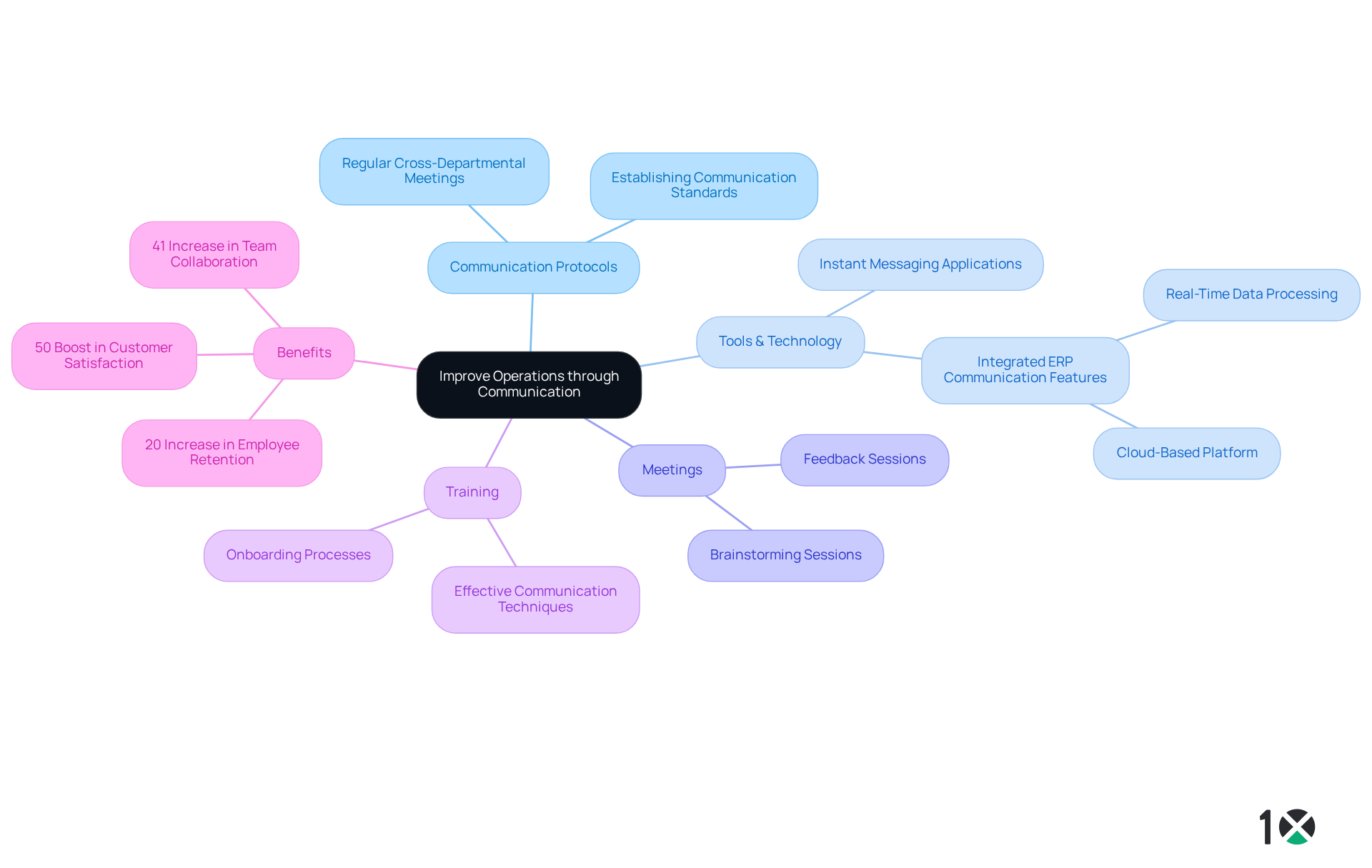

To enhance efficiency in the fastener warehouse, it is essential to establish regular communication protocols among departments such as stock management, sales, and logistics. Tools like instant messaging applications and integrated ERP communication features—such as those offered by 10X ERP—facilitate timely updates and issue resolution, significantly enhancing responsiveness. The cloud-based platform of 10X ERP provides real-time data processing, allowing teams to access critical information instantly, fostering a collaborative culture.

Regular cross-departmental meetings enable teams to discuss challenges and brainstorm solutions collectively. Training staff on not only enhances collaboration but also aligns everyone with organizational objectives and inventory needs. Research indicates that organizations with strong collaborative cultures are 20% more likely to retain employees, underscoring the value of effective communication in enhancing workplace dynamics.

Moreover, efficient communication tools can result in a 50% boost in customer satisfaction, while team collaboration can yield a 41% increase in customer satisfaction, emphasizing their vital role in success. As McKinsey states, “96% of decision-makers and 95% of employees identify communication as crucial for workplace success.” By utilizing the unique characteristics of 10X ERP, such as its support for multiple companies and seamless integrations, organizations can further improve their functional capabilities.

Implement Continuous Improvement Strategies for Operational Excellence

By implementing continuous improvement strategies such as Lean and Six Sigma, fastener warehouses can significantly enhance productivity. These frameworks systematically identify and eliminate waste, resulting in streamlined processes. Regular assessments, employing performance metrics and employee feedback, are essential for revealing areas that are primed for improvement. For example, optimizing picking routes or reducing unnecessary steps in the order fulfillment process can lead to considerable efficiency gains over time.

Moreover, fostering a workplace culture that encourages employee suggestions not only promotes engagement but also drives innovation, ultimately leading to operational excellence. Industry studies indicate that organizations adopting these methodologies frequently witness substantial improvements in both productivity and quality. This reinforces the in the fastener warehouse distribution sector, highlighting the necessity for operations managers to embrace these powerful tools.

Conclusion

Effective fastener warehouse operations hinge on the implementation of best practices that enhance efficiency and productivity. By focusing on streamlined inventory management, fostering cross-departmental communication, and embracing continuous improvement strategies, warehouses can significantly elevate their operational capabilities. These practices not only reduce waste and improve stock management but also enhance collaboration and drive innovation among teams.

Key strategies include:

- The adoption of FIFO for inventory control

- The use of cloud-based ERP systems for real-time tracking

- The promotion of a collaborative culture through effective communication tools

Moreover, methodologies like Lean and Six Sigma play a crucial role in identifying waste and optimizing processes, ultimately leading to improved productivity and quality in fastener distribution.

In an ever-evolving industry, prioritizing these best practices is essential for maintaining a competitive edge. Organizations are encouraged to implement these strategies not merely for immediate gains but as part of a long-term commitment to operational excellence. By investing in efficient inventory management, fostering communication, and continuously seeking improvement, warehouses can position themselves for sustained success in the dynamic landscape of fastener operations.

Frequently Asked Questions

What is the importance of a comprehensive management system in inventory management?

A comprehensive management system is essential for real-time tracking of stock levels, which enhances stock management in a fastener warehouse.

What inventory method is recommended to minimize waste?

The First-In-First-Out (FIFO) method is recommended to ensure that older stock is utilized first, significantly reducing the risk of obsolescence and waste.

How should fasteners be organized for better efficiency?

Fasteners should be categorized based on size, type, and usage frequency to improve retrieval speed and reduce picking mistakes.

What technology can be leveraged for inventory management?

Cloud-based ERP solutions, such as 10X ERP, can be utilized for seamless integration with stock management processes, providing automatic updates and alerts for low supply levels.

What are the benefits of real-time tracking in inventory management?

Real-time tracking reduces delays and improves customer satisfaction, with studies showing it can cut delays by as much as 58%.

How does effective inventory management impact warehouse operations?

Effective inventory management reduces stockouts, optimizes storage space, and can decrease fulfillment times by 23%, leading to improved effectiveness in warehouse operations.