Managing inventory is one of the biggest challenges a company faces, whether big or small. Getting it right means that your business has the right parts and raw goods, in the right amounts, at the right time, in one or even across multiple warehouses. This reduces production bottlenecks in the manufacturing process and optimizes order fulfillment time in distribution businesses, thus improving bottom-line performance. Getting it wrong can have devastating consequences and you may find yourself constantly dealing with stock emergencies and unhappy customers.

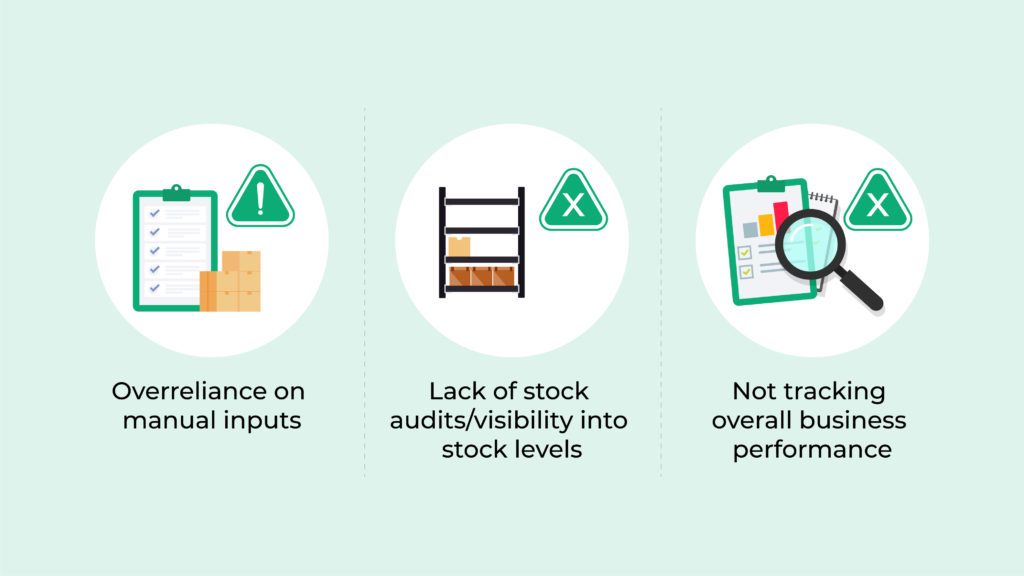

The Common Problems With Inventory Management Systems

Understanding the limitations and common problems with inventory management systems is the first step toward correcting them. Here are just a few of the reasons your inventory management system (IMS) may not be performing as intended:

Overreliance on manual inputs

Manual data entry is still surprisingly common for many businesses, despite being both time-consuming and more prone to human error. Whether you operate one warehouse or several, manually entering orders, shipping, and inventory data can cause chaos. Point-of-Sale (POS) systems can help with getting more organized but aren’t very scalable for inventory management. The same applies when you use a variety of different platforms for their primary business operations: inventory management, finances, supply chain management, and reporting. Data has to be transferred between platforms or re-entered, leading to delays and errors. To be truly effective, it’s best to use an inventory system that manages all of your information and inputs within a single, centralized platform.

Lack of stock audits/visibility into stock levels

Not having inventory insight readily available leads to multiple data errors. If exchanges and returns aren’t captured easily, incorrect counts occur, which, in turn, leads to misinformation and over, or under, stocking. A centralized inventory tracking system that integrates with RFID tags or barcode scanning tools is key to solving this issue. If you don’t control inventory sourcing and stocking levels, there will be an impact on cash flow…not to mention the fact that this could lead to missed opportunities because your business is at risk of under or overstocking. Greater visibility into stock levels significantly reduces these errors.

Not tracking overall business performance

Many inventory management systems provide real-time data on stock levels and item movement but end there. These platforms are too limited to provide the full insight and reporting required to make overarching decisions. Being able to measure stock, customer satisfaction, finances, and sales in a centralized location provides significant insight for long-term business planning. In short, it impacts your bottom line.

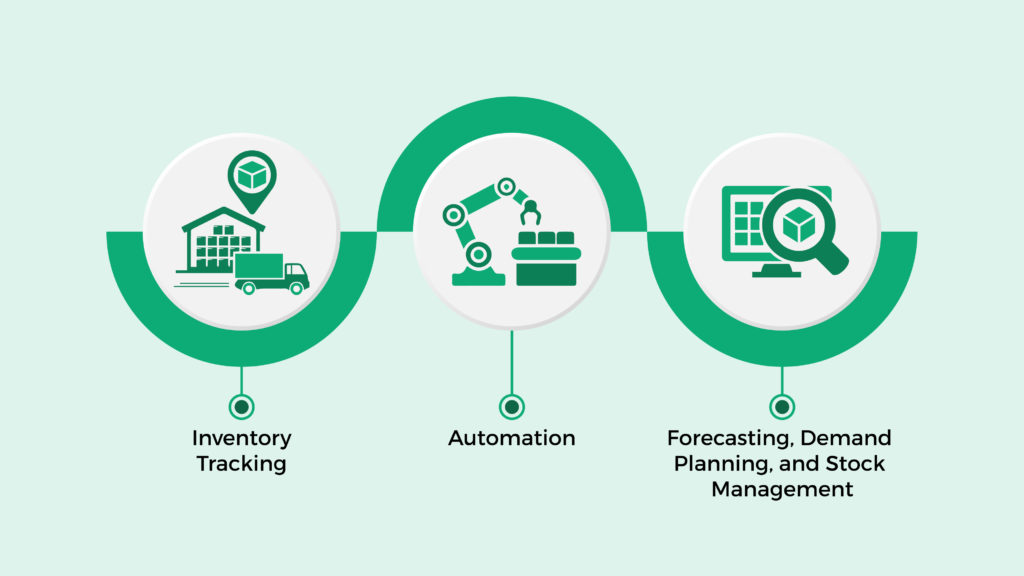

How to Improve Your Inventory Management System

Many of the common issues associated with inventory management can be solved by implementing an appropriate Enterprise Resource Planning (ERP) system that encompasses inventory management, work order tracking, warehouse management, sales, accounting, and more. Helpful features like inventory tracking, record receipts, tracking stock transfers, and cycle counts, enable more visibility within and between warehouse locations, and across the whole supply chain. Not only will you avoid the many pitfalls of using Excel to manage your inventory, but you’ll gain productivity by eliminating the time employees would have spent manually updating and balancing inventory. A good ERP system will do more than manage your inventory. It streamlines your entire organization from the top to the bottom.

When looking to improve your IMS, here are a few of the features you should look out for:

Inventory Tracking

A good IMS accurately indicates what your current stock levels are. However, if it isn’t integrated with the rest of your business, you can’t make truly informed decisions to optimize operations. An ERP will bring your inventory management system closer to the rest of your business. You gain complete insight into your inventory counts, including which order you can or can’t fulfill, and the raw materials on hand. You can confidently make decisions, knowing that the inventory levels reflected are accurate and that you have the correct inventory on hand to meet customer demand. Many good inventory management systems also have asset tracking and asset management capabilities that can be used for preventive maintenance, leading to even greater cost savings and control over every aspect of your business.

Automation

Manual processes are simply not tenable anymore. Real-time inventory updates mean that your staff spends less time poring over Excel spreadsheets and more time focusing on the tasks that drive growth and profitability. Removing manual inputs also reduces the odds of typos or other input mistakes occurring, thereby improving the accuracy of your data. You’ll have an accurate and comprehensive picture of your business at any time, including your physical inventory, sales orders, and a detailed record of stock changes.

An ERP system automatically tracks inventory used on every job, which can improve your production and inventory planning. Additionally, automation allows for better inventory optimization. This means you’ll have the right amount of stock on hand to complete jobs at the right time, helping to reduce customer dissatisfaction and dead stock levels in your company.

Forecasting, Demand Planning, and Stock Management

Look for a system that tracks sales, purchasing, and logistics together so that you have the best visibility of what inventory you need, and when. An ERP system that includes a solid IMS essentially manages and plans every aspect of your business. Many ERPs remind your purchasing manager to place an order and even automatically reorder items when stock is low. This helps avoid stock shortages and the cost of expediting stock in a hurry when you run low. Needless to say, accurately tracking inventory and stock levels means you can free up shelf space for more profitable items.

Conclusion

Inventory management software is designed to improve inventory control and management, while an ERP system does that and more. Rather than paying for separate systems to handle multiple aspects of your business, investing in a good ERP system that includes dependable inventory management reduces workloads, minimizes expenses, and optimizes many aspects of your business, from production planning to demand forecasting. In the end, increasing both profitability and scalability of your business.

Your inventory system is a key driver to growing your business, and inventory is the backbone of any wholesale distribution business. If you‘re interested in learning more about the world-class inventory management built into 10X ERP, get in touch with us today.