Overview

This article delineates eight essential features of effective warehousing software:

- Real-time data processing

- RFID technology

- Inventory control

- Task management

- Labor tracking

- Containerization

- Seamless integrations

- Customizable attributes

These features significantly enhance operational efficiency and accuracy, ultimately leading to improved customer satisfaction. By streamlining processes and enhancing inventory management, they facilitate data-driven decision-making in warehouse operations. Understanding and implementing these features can be pivotal for Operations Managers seeking to optimize their warehousing solutions.

Introduction

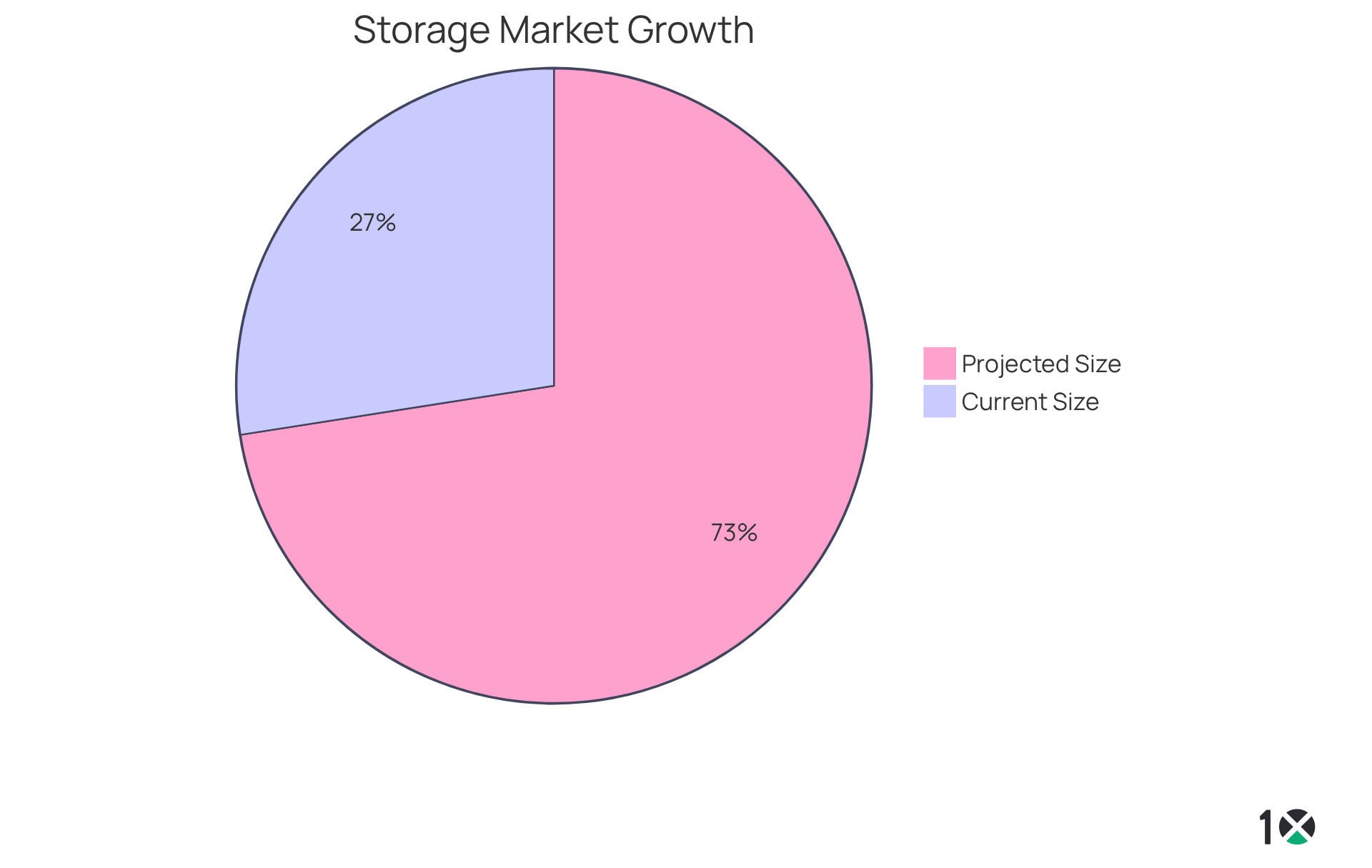

The rapid evolution of warehousing technology is reshaping the logistics landscape. The global storage system market is projected to soar to $9.11 billion by 2025, highlighting a significant opportunity for growth. This surge underscores the urgent need for businesses to adopt effective warehousing software that not only streamlines operations but also enhances inventory management.

As companies strive to remain competitive, the challenge lies in identifying the essential features that can drive efficiency and accuracy. What are the key functionalities that can transform warehouse operations and ensure businesses thrive in this dynamic environment?

10X ERP: Real-Time Data Processing for Efficient Warehouse Management

10X ERP harnesses the power of cloud technology to deliver real-time data processing, empowering storage managers to monitor stock levels, track order statuses, and manage workflows with unparalleled efficiency. This capability drastically reduces delays and errors, ensuring operations run smoothly. For instance, when stock levels dip below predetermined thresholds, automated alerts trigger reordering, effectively averting stockouts and sustaining continuous operations.

The global storage system market is projected to grow from $3.45 billion in 2025 to $9.11 billion by 2025, underscoring the urgent demand for solutions that enhance operational efficiency. Furthermore, it is anticipated that 70% of large-scale warehouses will adopt AI-driven solutions by 2024, signaling a significant shift towards advanced technology for inventory management.

Industry leaders highlight the transformative impact of warehousing software and cloud technology on inventory management. As one expert noted, “Automated processes ensure that orders are handled swiftly and precisely, decreasing the chance of mistakes and improving customer satisfaction.” This perspective resonates throughout the industry, emphasizing the essential role of warehousing software, such as cloud-based ERP systems like 10X ERP, in fostering efficiency and accuracy in warehouse operations.

RFID: Transform Inventory Tracking and Management

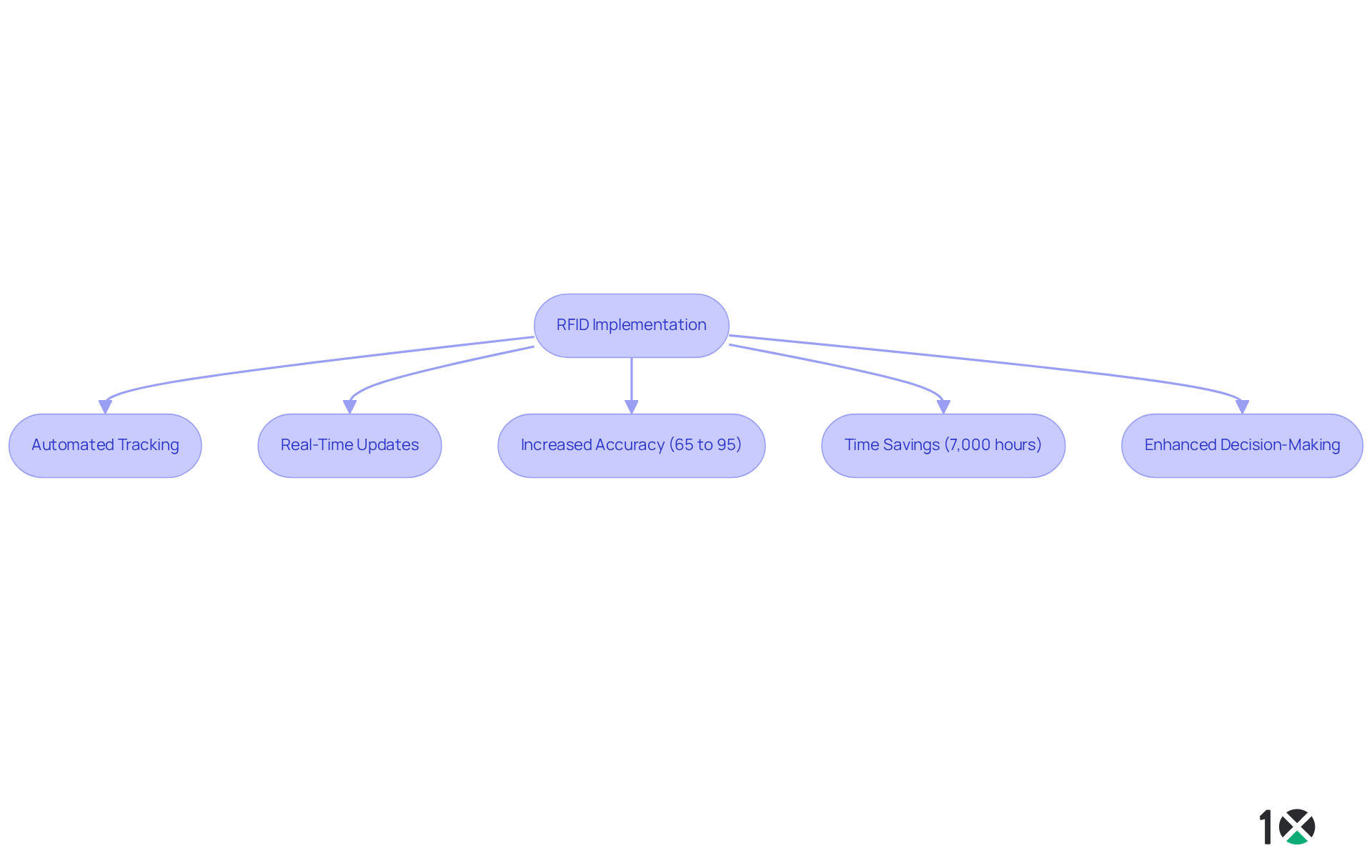

Radio Frequency Identification (RFID) technology is revolutionizing stock management by enabling automated tracking without the need for line-of-sight scanning. This advancement significantly reduces the time required for stock assessments and enhances accuracy. RFID tags can be attached to pallets or individual items, allowing for swift scanning as they move through the warehouse. This capability provides real-time updates on stock levels and locations, ensuring businesses maintain optimal stock management, particularly when integrated with 10X ERP’s cloud-based warehousing software.

Recent statistics indicate that companies employing RFID have seen accuracy in stock levels surge from an average of 65% to over 95%, leading to improved operational efficiency and increased sales. For instance, a major rug producer enhanced customer satisfaction and stock accuracy by utilizing RFID technology for faster item retrieval, demonstrating the tangible benefits of this system.

Moreover, RFID technology can eliminate up to 7,000 man-hours annually in stock management processes, streamlining operations and allowing staff to focus on more critical tasks. When combined with 10X ERP’s real-time data processing capabilities, logistics professionals assert that the automation offered by RFID not only reduces human error but also supports smarter decision-making regarding stock levels and movement. As the global RFID market continues to expand, its role in enhancing storage efficiency and accuracy becomes increasingly vital for companies aiming to thrive in competitive landscapes. Operations managers are urged to consider how integrating RFID technology with 10X ERP and warehousing software can enhance their stock management processes.

Inventory Control: Maintain Accurate Stock Levels

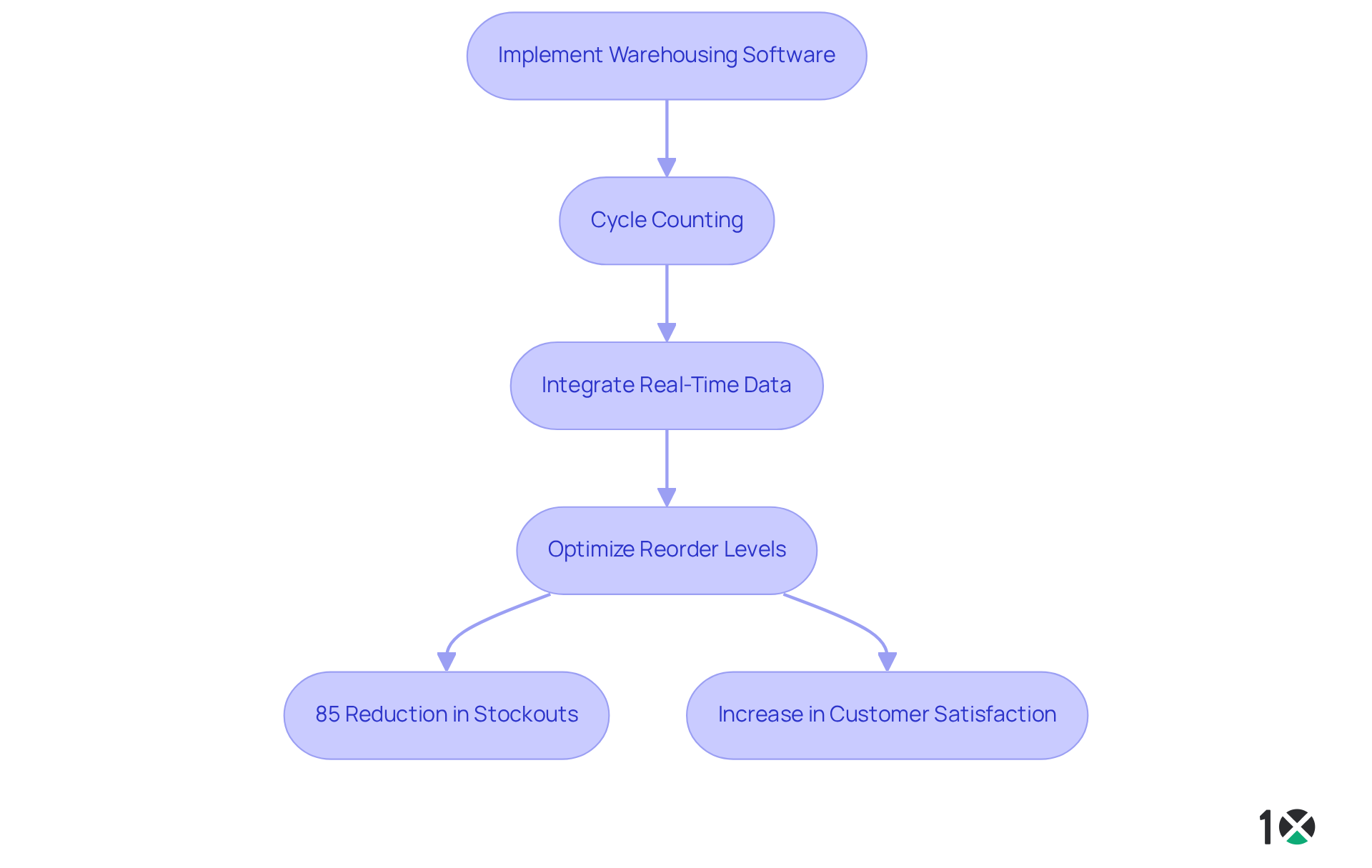

Implementing robust warehousing software is essential for warehouses aiming to maintain accurate inventory levels. Methods such as cycle counting, where segments of stock are counted in rotation, are crucial for identifying discrepancies and ensuring precision. Additionally, the integration of warehousing software with real-time data capabilities offers valuable insights into stock movement. This allows companies to optimize reorder levels and minimize surplus stock.

For instance, a clothing retailer that adopted stock management software experienced an 85% reduction in stockouts and an 18% increase in customer satisfaction scores within just six months. Furthermore, organizations employing automated stock management systems can manage 40% more volume with the same team size, significantly enhancing operational efficiency. Overall, stock precision improves to over 99% following the implementation of warehousing software, which is essential for meeting customer demands and reducing costs associated with overstocking and stockouts.

As Ritesh Kewlani, Head of Product Marketing, aptly states, “Effective inventory oversight is the backbone of eCommerce success, directly affecting profits and customer satisfaction.” Such practices not only bolster operational efficiency but also play a significant role in enhancing overall profitability.

Task Management: Optimize Workflow Efficiency

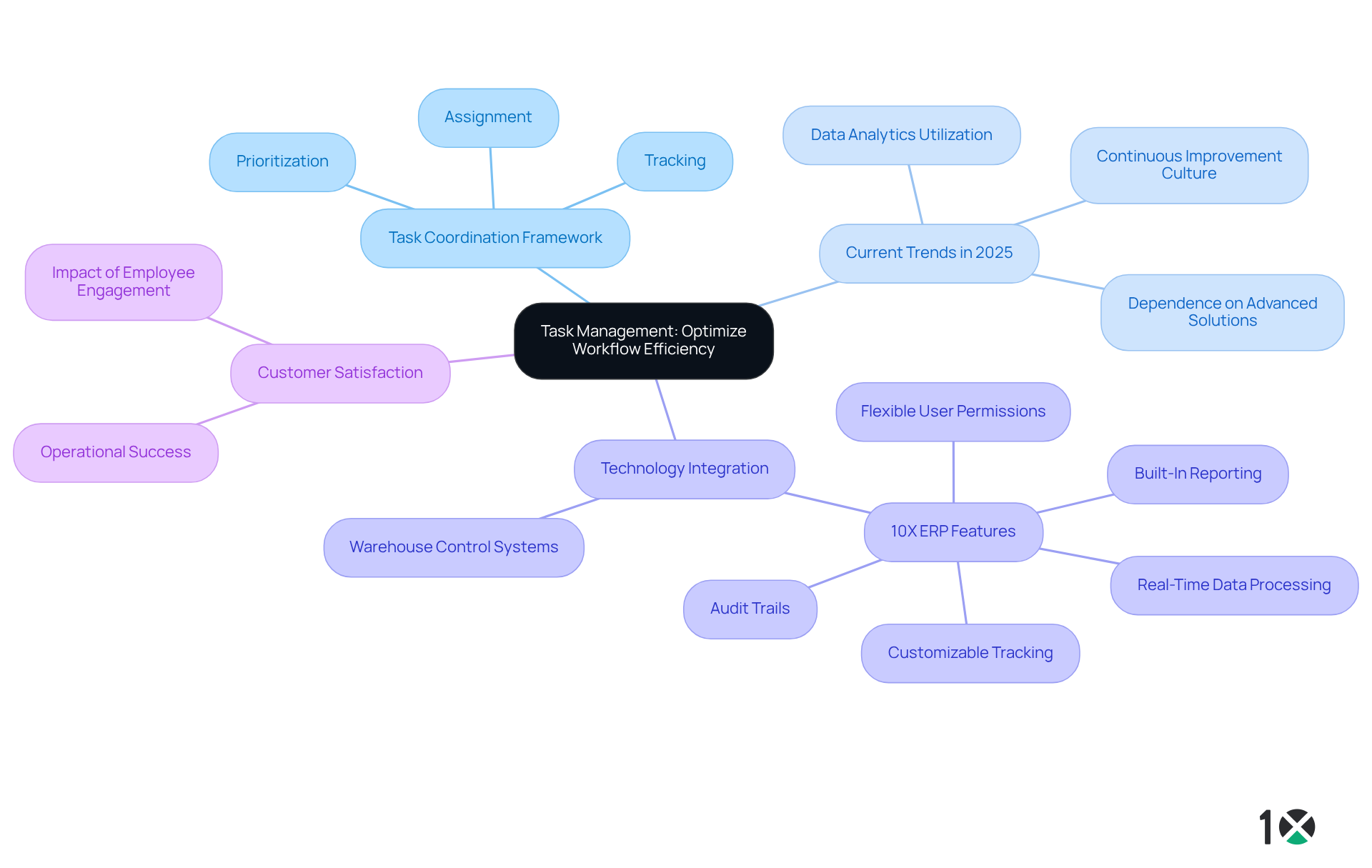

An efficient task coordination framework is essential for storage supervisors aiming to enhance workflow productivity. By facilitating the assignment, tracking, and prioritization of tasks, such software integrates seamlessly with existing warehouse control systems. This integration enables managers to allocate tasks based on employee availability and skill sets, ensuring that the right person is assigned to the right job. Consequently, order fulfillment accelerates, and employee productivity increases, allowing workers to focus on their designated tasks without unnecessary interruptions.

Current trends in 2025 indicate a rising dependence on advanced task management solutions, such as warehousing software, that utilize data analytics to boost operational efficiency. These systems not only streamline workflows but also offer insights into peak productivity periods and potential bottlenecks, enabling proactive adjustments. Operations managers stress that optimizing workflow efficiency transcends technology; it involves cultivating a culture of continuous improvement. As one manager stated, ‘Continuous improvement is better than delayed perfection,’ underscoring the need for ongoing adaptation in storage operations.

With 10X ERP’s robust accounting and inventory management features—including real-time data processing, customizable tracking, flexible user permissions, complete audit trails, and built-in reporting—storage facilities can realize substantial efficiency gains. The capability to maintain a comprehensive audit trail and generate built-in reports empowers managers to make informed decisions that drive operational success. By adopting 10X ERP, storage facilities can ultimately enhance customer satisfaction and operational success.

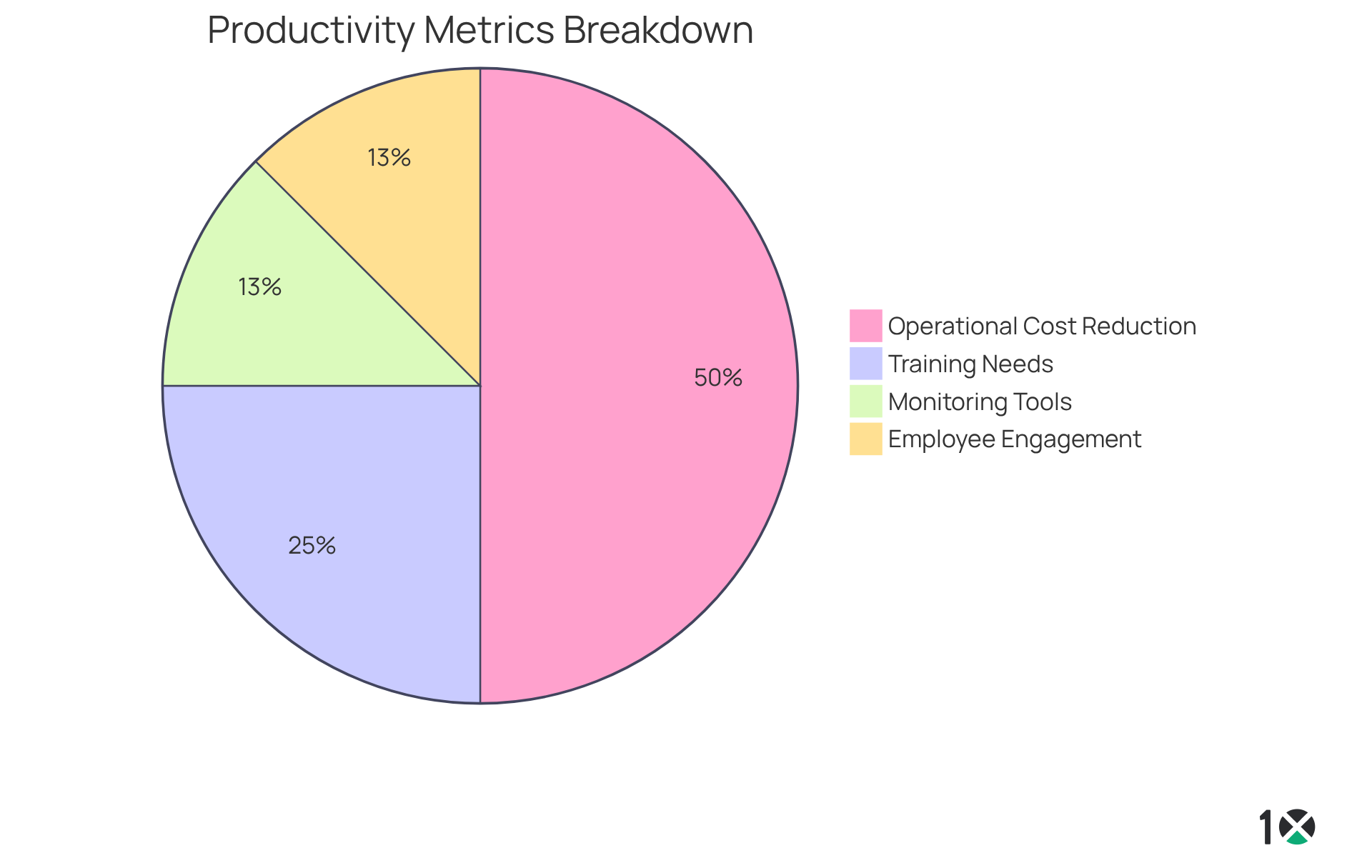

Labor Tracking: Monitor Employee Productivity

Labor monitoring tools empower managers to oversee employee performance in real-time, providing vital insights into productivity levels. By analyzing key metrics such as units picked per hour and time allocated to specific tasks, managers can effectively identify high performers and those who may benefit from additional training. This data-driven approach not only enhances workforce coordination but also fosters a culture of accountability and motivation among employees.

For instance, organizations that have implemented labor performance metrics have reported an average productivity increase of 12.5%, illustrating the tangible benefits of effective monitoring. Moreover, HR professionals underscore that regular performance assessments can lead to heightened employee engagement and satisfaction, ultimately driving operational success in distribution centers.

To further elevate productivity, operations supervisors should consider integrating labor tracking systems with existing warehousing software solutions, such as 10X ERP’s comprehensive cloud-based ERP offering. With features like real-time data processing, inventory oversight, seamless integrations, clear pricing, and unparalleled support, 10X ERP can significantly enhance storage operations. A notable example is Barsan Global Logistics, which achieved a 50% reduction in storage operations through effective implementation.

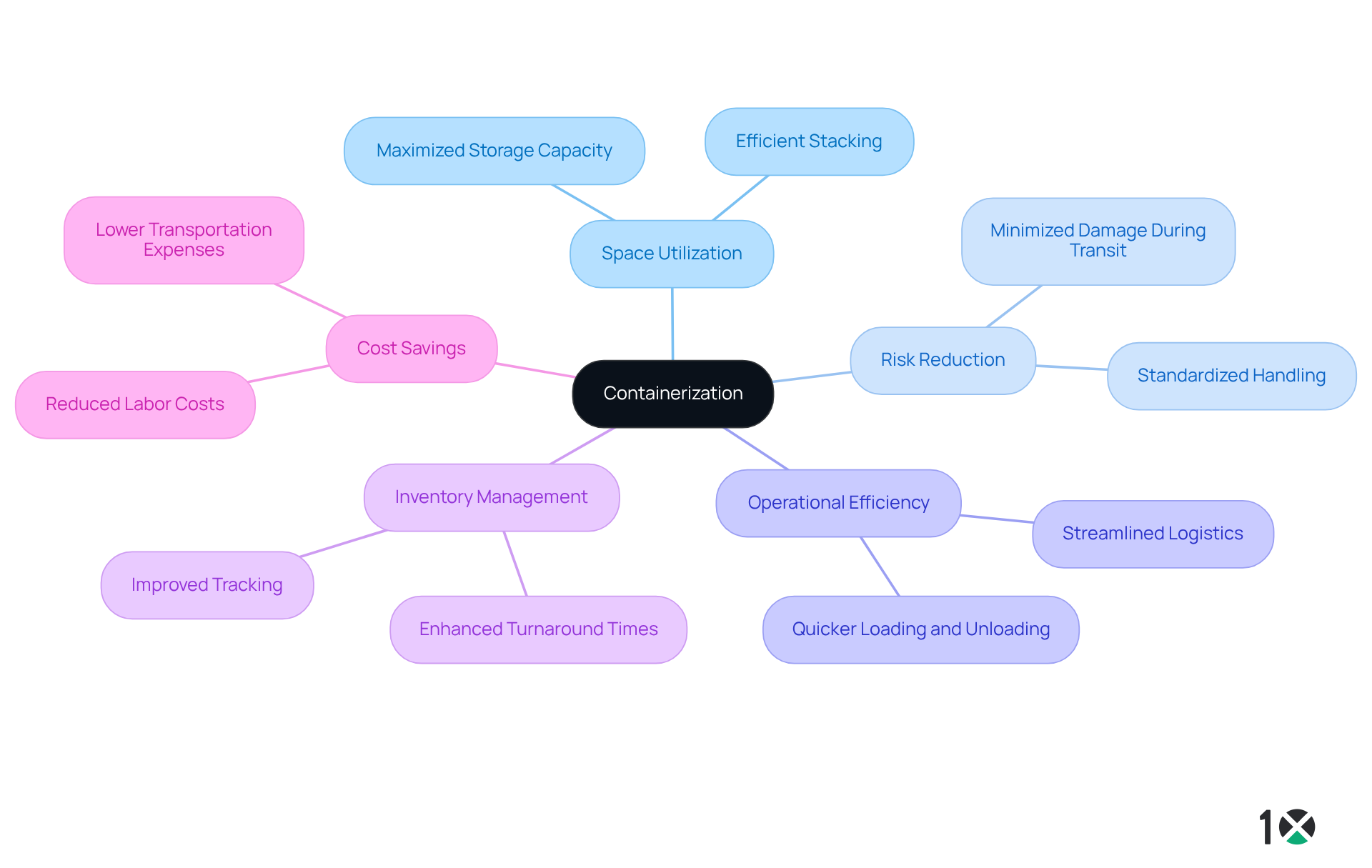

Containerization: Enhance Organization and Handling of Goods

Containerization is a pivotal practice that involves grouping goods into standardized containers, thereby simplifying the handling and transportation of items. This method not only maximizes space utilization but also significantly reduces the risk of damage during transit. By implementing containerization, storage facilities can markedly enhance their operational efficiency. Containers can be effortlessly stacked and transported using forklifts, which minimizes the time spent on loading and unloading.

The advantages of containerization are compelling. Warehousing software streamlines logistics, allowing for quicker turnaround times and improved inventory management. Operations Managers seeking effective solutions should consider the transformative impact of adopting containerization in their processes. This approach can lead to substantial cost savings and increased productivity, making it an essential strategy for modern supply chain management.

Seamless Integrations: Create a Cohesive Operational Environment

Incorporating warehousing software along with other business applications, such as ERP and CRM platforms, fosters a unified operational environment that significantly enhances efficiency. This integration enables real-time data sharing, which is essential for informed decision-making and exceptional customer service. For example, when inventory levels fluctuate, sales teams receive immediate notifications, allowing them to provide customers with accurate information regarding product availability.

Businesses are increasingly recognizing the importance of seamless integrations. Indeed, companies with optimized supply chains experience 15% lower supply chain costs and faster cash-to-cash cycles, highlighting the financial benefits of WMS integration. As the logistics sector evolves, the integration of AI and real-time tracking is emerging as a key trend for 2025, facilitating enhanced operational efficiency and resilience.

A notable case is Primeline, which encountered challenges in managing an expanding client portfolio across multiple facilities. By implementing a customized voice solution that integrated with their existing ERP framework, they improved resource oversight and visibility, resulting in a double-digit increase in productivity rates. This example illustrates the competitive advantage gained through effective software integration, as it not only streamlines operations but also helps businesses remain compliant with regulatory requirements.

Experts in the field emphasize that combining warehousing software with ERP solutions, such as 10X ERP, can yield significant benefits, including improved accuracy and reduced manual errors. With features like reliable inventory management, customizable tracking, and an API-first approach, 10X ERP guarantees seamless software integrations that enhance the user experience for distributors. As the demand for speed and accuracy in order fulfillment intensifies, driven by customer expectations shaped by services like Amazon, the necessity for cohesive operational environments becomes increasingly critical. Moreover, with digital transformation spending in logistics projected to reach USD 102.5 billion by 2025, leveraging technology like 10X ERP for seamless integrations is vital for boosting overall operational efficiency.

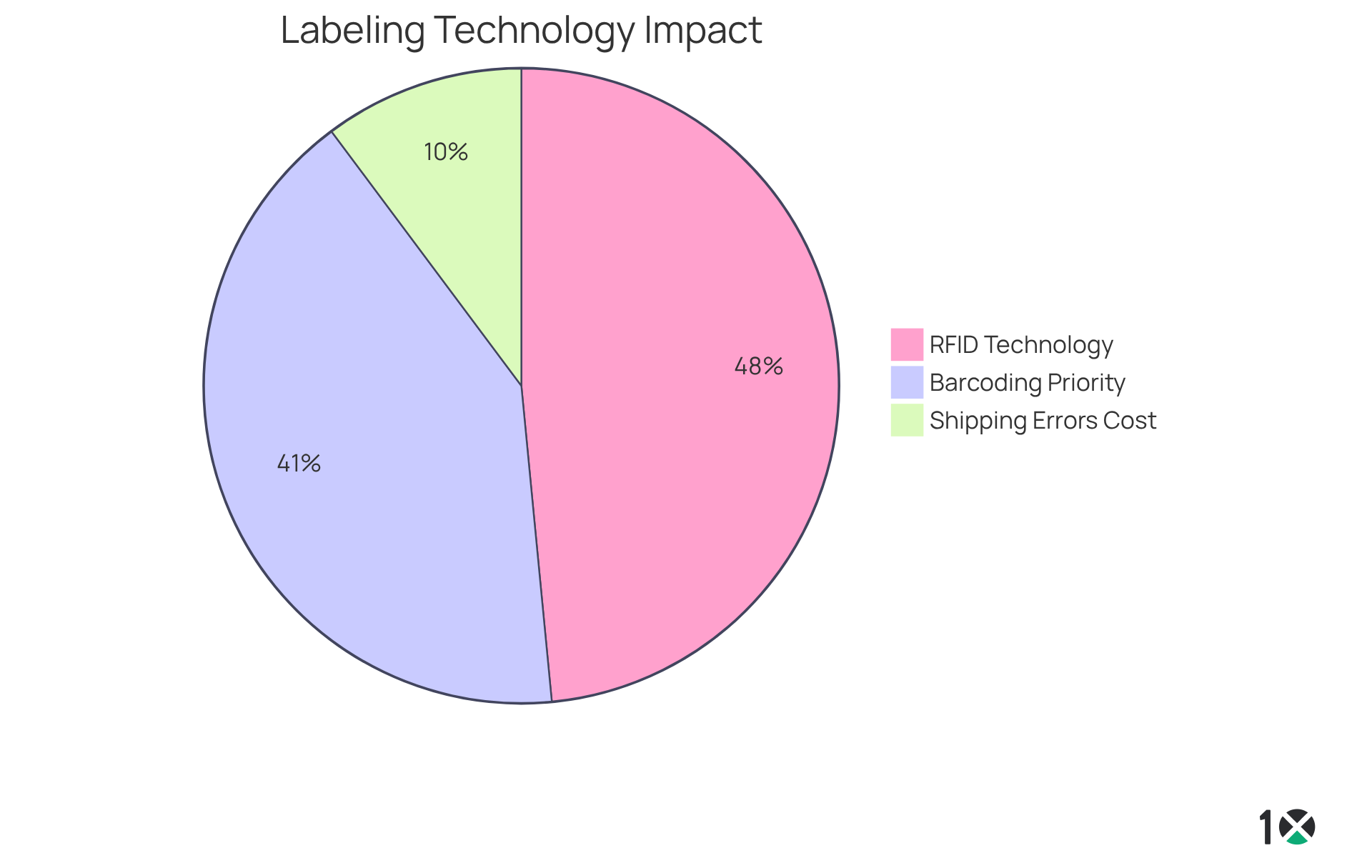

Labeling: Ensure Easy Identification and Traceability

Establishing a robust labeling framework is crucial for maintaining order within storage facilities. Labels must encompass vital information, including product names, barcodes, and storage locations. As supply chain expert Yossi Sheffi asserts, ‘A well-structured labeling framework is fundamental for ensuring traceability and operational efficiency in warehousing software.’

By leveraging advanced labeling technologies such as RFID and QR codes, storage facilities can significantly enhance traceability and streamline the picking process. This approach guarantees accurate item identification and minimizes the risk of shipping errors, which can diminish profits by as much as $20 per fulfillment due to backorders.

Furthermore, storage facilities that have adopted RFID technology report a remarkable 95% accuracy rate in stock control, underscoring the transformative impact of these innovations. Additionally, 81% of purchasers of warehousing software prioritize barcoding functionalities, illustrating the demand for solutions that bolster operational efficiency through improved traceability.

By implementing these advanced labeling systems, storage facilities can achieve heightened visibility and control over their inventory, ultimately leading to enhanced customer satisfaction and reduced operational costs.

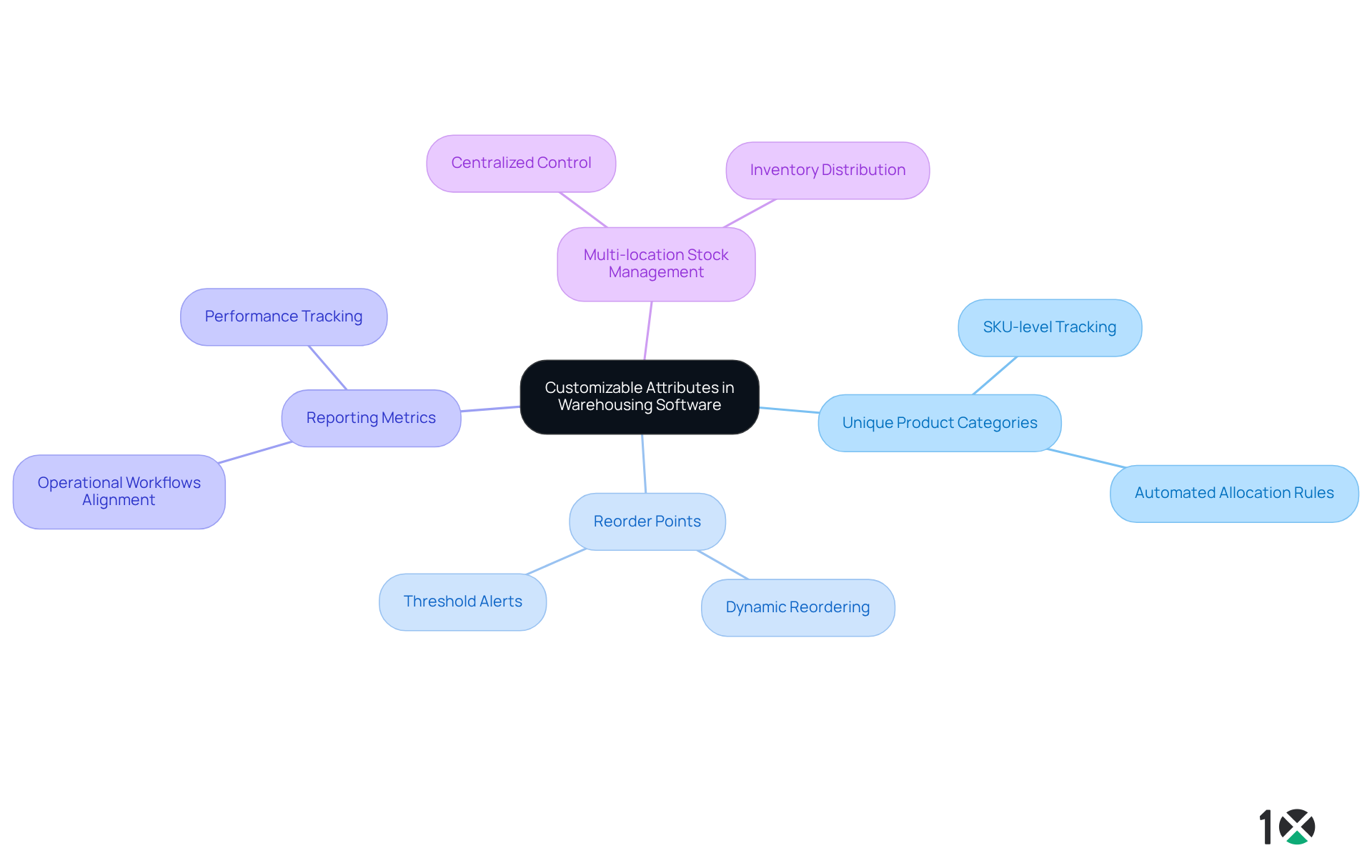

Customizable Attributes: Tailor Software to Operational Needs

Customizable features in warehousing software are essential for companies aiming to optimize their operations. 10X ERP offers robust functionalities that empower storage facilities to:

- Define unique product categories

- Establish specific reorder points

- Create tailored reporting metrics aligned with their operational workflows

This flexibility, including SKU-level lot and serial tracking, automated allocation rules, and the capability to manage stock across multiple warehouse locations, enhances user satisfaction and significantly boosts overall efficiency. As the demand for personalized solutions escalates, companies are increasingly investing in warehousing software that adapts to their specific needs, ensuring alignment with evolving operational requirements. Those who have effectively customized their software report enhanced stock turnover and reduced storage costs, showcasing the tangible benefits of personalization. Organizations prioritizing customization will be strategically positioned to tackle the challenges of modern logistics and distribution.

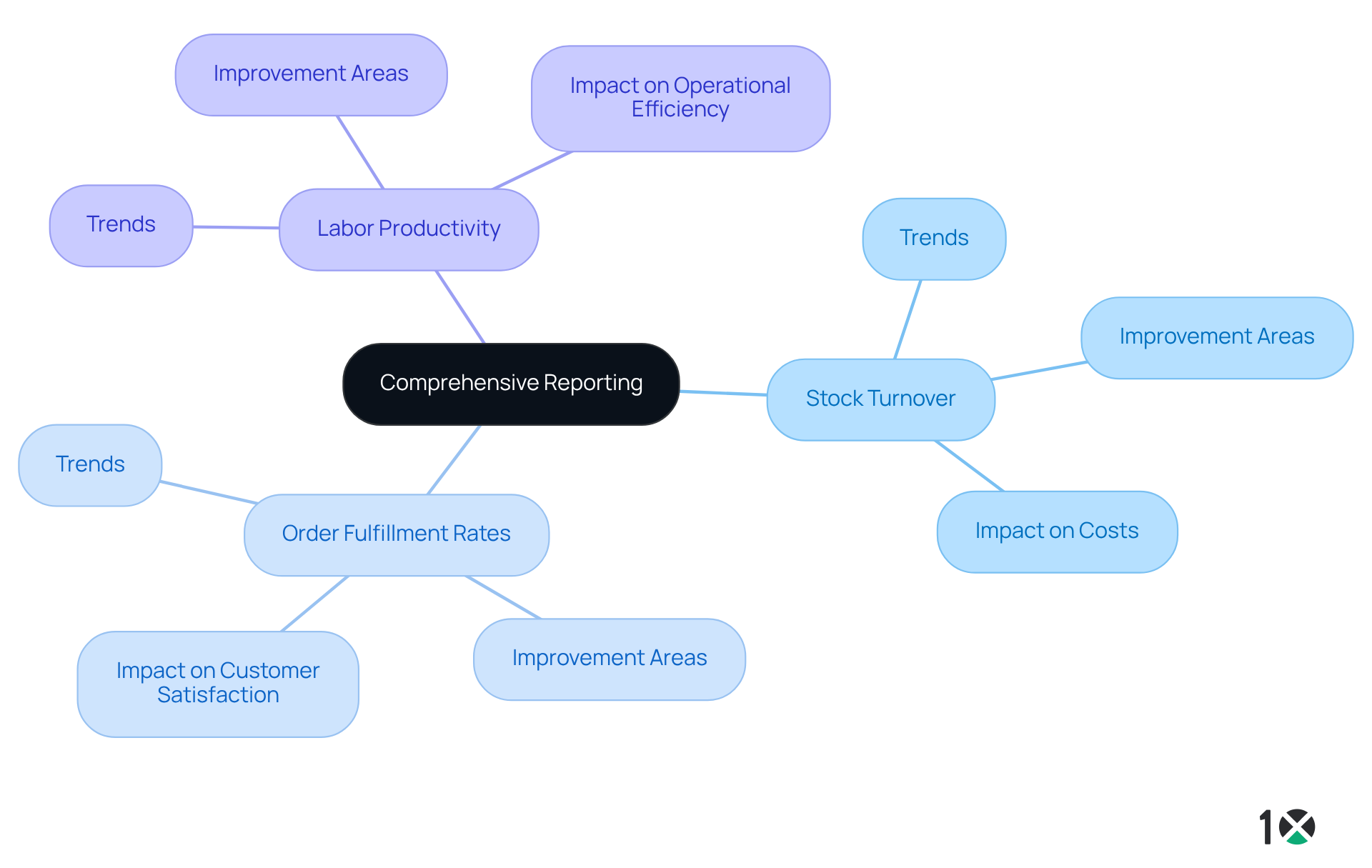

Comprehensive Reporting: Gain Insights for Continuous Improvement

Comprehensive reporting tools empower storage facility managers to gain essential insights into operational performance. By analyzing key metrics such as:

- Stock turnover

- Order fulfillment rates

- Labor productivity

Managers can identify trends and areas primed for improvement. This data-driven approach fosters informed decision-making, enabling storage facilities to implement targeted strategies that enhance efficiency and reduce costs over time. For example, predictive analytics can optimize inventory management, decreasing stockouts and overstock situations by 25-40%. Furthermore, predictive maintenance can minimize unplanned downtime by up to 70%, significantly contributing to operational efficiency.

As the storage landscape evolves, the adoption of advanced reporting tools, including warehousing software and Management Systems (WMS), which are expected to be utilized by over 90% of facilities by 2025, will be crucial for ongoing improvement. Data analysts assert that leveraging warehousing software not only streamlines processes but also fosters a culture of accountability and performance enhancement within warehouse operations.

To maximize the effectiveness of these tools, operations managers should consistently review and update their KPI reports, ensuring they remain relevant and actionable.

Conclusion

The significance of effective warehousing software cannot be overstated, especially as the industry evolves toward enhanced efficiency and accuracy. By leveraging essential features such as real-time data processing, RFID technology, and seamless integrations, warehouses can streamline operations and boost productivity. Furthermore, the integration of customizable attributes and comprehensive reporting tools empowers businesses to adapt to changing demands while maintaining optimal inventory levels.

Throughout this article, we have explored how various functionalities contribute to improved warehouse management. From task management systems that optimize workflows to labor tracking tools that elevate employee performance, each feature plays a vital role in achieving operational excellence. Additionally, practices like containerization and advanced labeling enhance organization and traceability, ensuring that goods are handled efficiently and accurately.

As the warehousing landscape continues to transform, embracing these innovative software solutions will be crucial for organizations striving to remain competitive. Investing in effective warehousing software not only drives operational efficiency but also fosters a culture of continuous improvement. By prioritizing technology and data-driven decision-making, businesses can better meet customer expectations and navigate the complexities of modern supply chains.

Frequently Asked Questions

What is 10X ERP and how does it benefit warehouse management?

10X ERP is a cloud-based software that provides real-time data processing for warehouse management. It allows storage managers to monitor stock levels, track order statuses, and manage workflows efficiently, reducing delays and errors in operations.

How does 10X ERP handle stock levels and reordering?

10X ERP triggers automated alerts when stock levels fall below predetermined thresholds, prompting reordering to prevent stockouts and ensure continuous operations.

What is the projected growth of the global storage system market?

The global storage system market is projected to grow from $3.45 billion in 2025 to $9.11 billion by 2025, indicating a rising demand for solutions that enhance operational efficiency.

What role does AI play in warehouse management?

It is anticipated that 70% of large-scale warehouses will adopt AI-driven solutions by 2024, highlighting a significant shift towards advanced technology for inventory management.

How does RFID technology improve inventory tracking and management?

RFID technology allows for automated tracking without line-of-sight scanning, significantly reducing the time for stock assessments and enhancing accuracy by providing real-time updates on stock levels and locations.

What improvements have companies experienced by using RFID technology?

Companies using RFID have seen stock level accuracy increase from an average of 65% to over 95%, leading to improved operational efficiency and increased sales.

How much time can RFID technology save in stock management?

RFID technology can eliminate up to 7,000 man-hours annually in stock management processes, allowing staff to focus on more critical tasks.

What methods can warehouses use to maintain accurate inventory levels?

Warehouses can implement cycle counting and integrate warehousing software with real-time data capabilities to identify discrepancies and optimize reorder levels.

What impact did stock management software have on a clothing retailer?

A clothing retailer that adopted stock management software experienced an 85% reduction in stockouts and an 18% increase in customer satisfaction scores within six months.

How does effective inventory oversight affect eCommerce success?

Effective inventory oversight is crucial for eCommerce success as it directly affects profits and customer satisfaction, enhancing operational efficiency and overall profitability.