Overview

The article examines seven supply chain solutions designed to enhance distributor efficiency through various strategies and technologies. It underscores the critical role of real-time data processing, advanced analytics, and effective communication in optimizing operations, reducing costs, and improving responsiveness within a competitive market. This is exemplified by case studies of companies that have successfully leveraged these solutions. By focusing on these key areas, distributors can not only streamline their processes but also gain a significant edge in their operational capabilities.

Introduction

In the dynamic landscape of modern logistics, distributors are confronted with the urgent necessity to enhance efficiency and adaptability to thrive. This article explores seven innovative supply chain solutions tailored to empower distributors, equipping them with the tools necessary to streamline operations, reduce costs, and elevate customer satisfaction. Yet, with a plethora of options at their disposal, how can businesses discern the most effective strategies to fortify their supply chain management and maintain a competitive edge?

10X ERP: Cloud-Based ERP for Real-Time Supply Chain Management

10X ERP presents a robust cloud-based system that empowers wholesalers to manage their logistics in real-time. Featuring real-time data processing, flexible user permissions, comprehensive reporting, and seamless app integrations, businesses can obtain immediate insights into their operations. This user-centric approach guarantees that stakeholders can make informed decisions swiftly, thereby enhancing overall efficiency. The software’s all-inclusive nature simplifies the user experience by removing the need to pinpoint every required module.

Furthermore, the rapid onboarding process and ongoing product enhancements underscore our unwavering commitment to customer support. The synergy of advanced supply chain solutions, a transparent pricing structure, and a lifetime partnership model establishes 10X ERP as an essential tool for distributors striving to remain competitive in a fast-paced market.

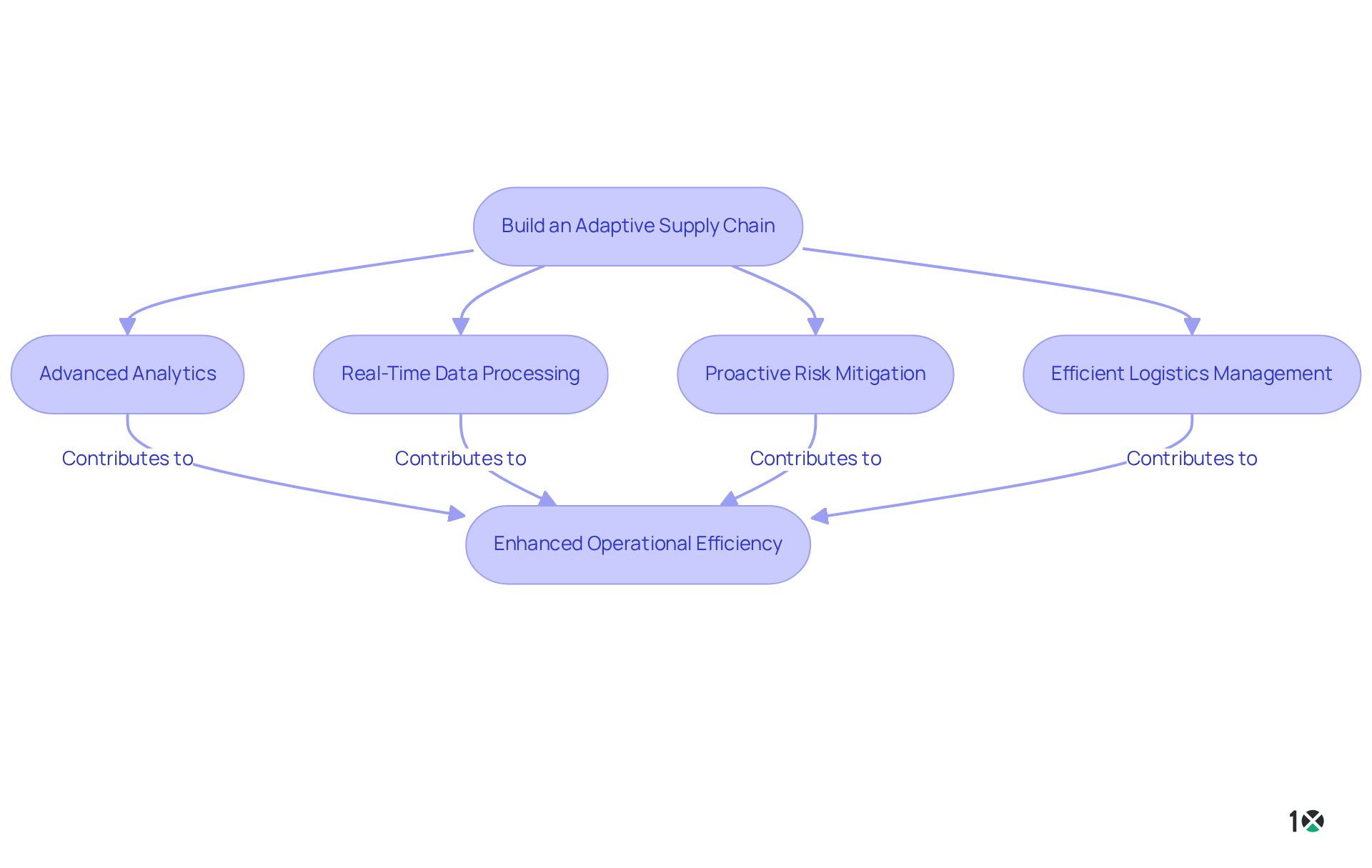

Coupa Supply Chain Solutions: Build an Adaptive and Resilient Supply Chain

10X ERP’s extensive cloud-based ERP solution empowers businesses to cultivate flexible and robust networks through the strategic application of advanced analytics and real-time data processing. By anticipating potential disruptions, organizations can implement proactive measures that not only mitigate risks but also enhance operational efficiency. This approach is vital, especially considering that 80% of organizations have faced at least one significant disruption in their logistics over the past year.

Moreover, reducing logistics expenses from 9% to 4% can potentially double a company’s profits, underscoring the financial impact of efficient management. With 10X ERP’s supply chain solutions, suppliers can ensure they maintain service levels even in challenging environments, thus remaining competitive and responsive to market demands.

The integration of seamless API connections and top-tier inventory management delivers real-time insights, enabling companies to make informed decisions that bolster resilience and adaptability in their operational processes. Additionally, 10X ERP provides a transparent pricing structure and a comprehensive software package, ensuring that businesses have all the necessary tools to succeed without hidden costs.

As the global logistics management market is projected to expand significantly, investing in robust supply chain solutions like 10X ERP becomes increasingly essential for sellers aiming to enhance their operational capabilities.

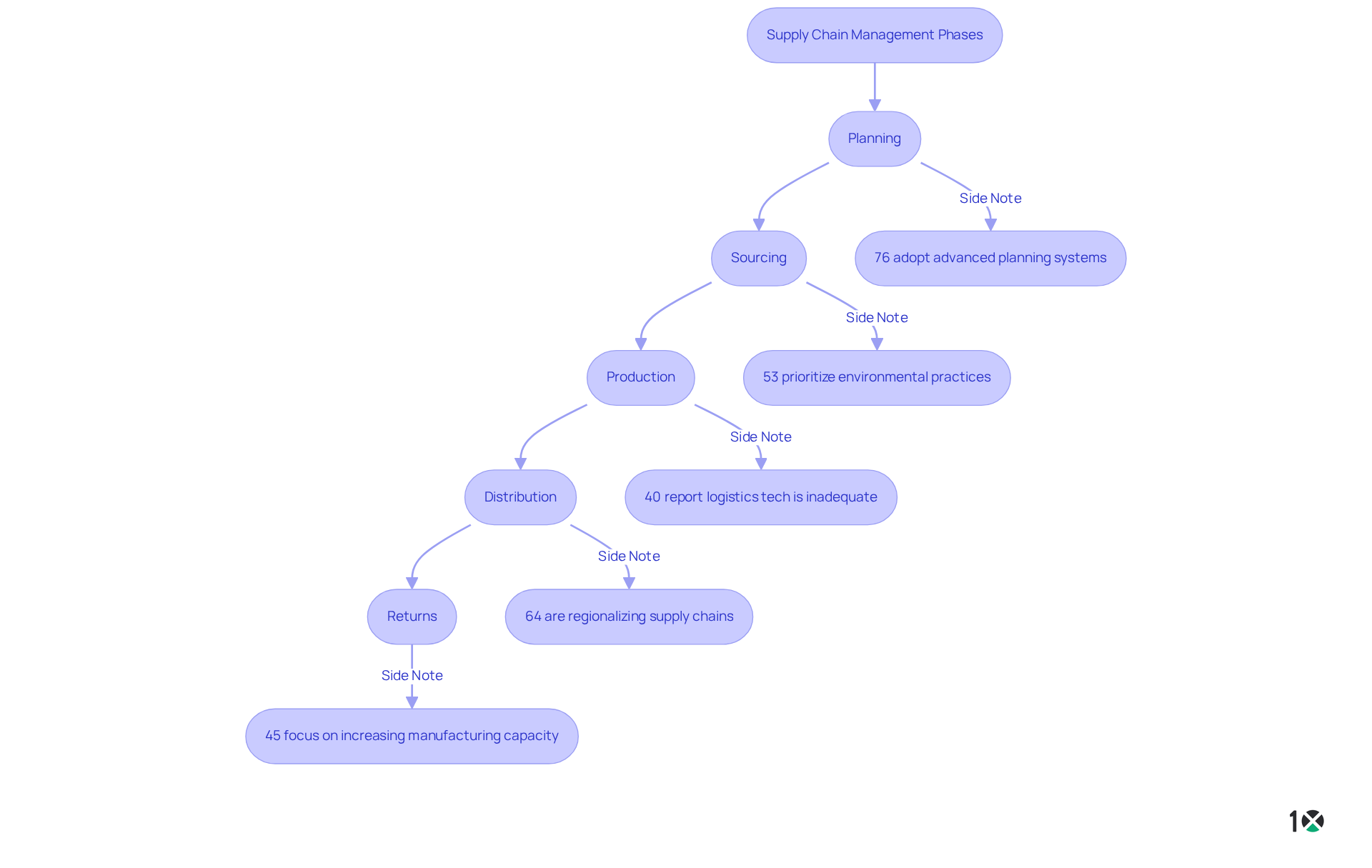

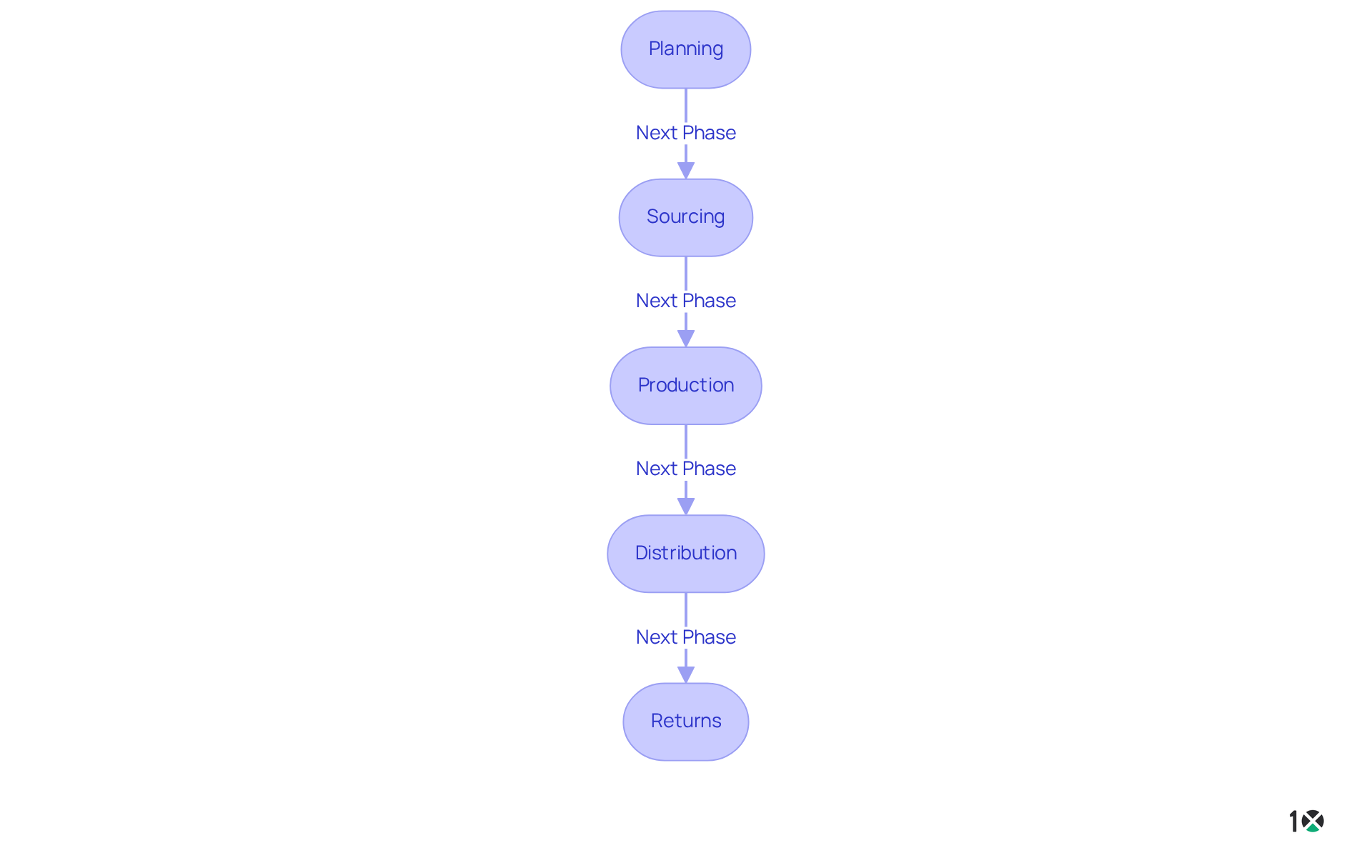

Investopedia: Understanding Supply Chain Management (SCM) Phases

Supply chain solutions consist of five essential phases: planning, sourcing, production, distribution, and returns. Mastering these phases is crucial for suppliers seeking to optimize operations, reduce costs, and enhance customer satisfaction with effective supply chain solutions. For example, 76% of organizations have adopted advanced planning systems to better align with customer demand, showcasing a proactive approach to SCM. Additionally, 53% of companies prioritize integrating environmental practices into their logistics, highlighting a growing commitment to sustainability.

Distributors face significant obstacles, such as managing distribution disruptions and efficiently handling inventory. A notable 40% of companies report that their logistics chain technology is inadequate, underscoring the need for continuous improvement and adaptation. Furthermore, as companies increasingly regionalize their logistics networks—up 20% from the previous year—understanding the complexities of each supply chain solutions phase becomes even more critical.

By implementing best practices like enhancing visibility and refining inventory management, suppliers can streamline their processes and respond more effectively to market demands. Real-world examples, such as Unilever’s commitment to achieving net zero emissions by 2039, illustrate how leading firms are integrating sustainability into their procurement strategies. Ultimately, a thorough understanding of SCM phases empowers distributors to navigate challenges and capitalize on opportunities in a dynamic market landscape.

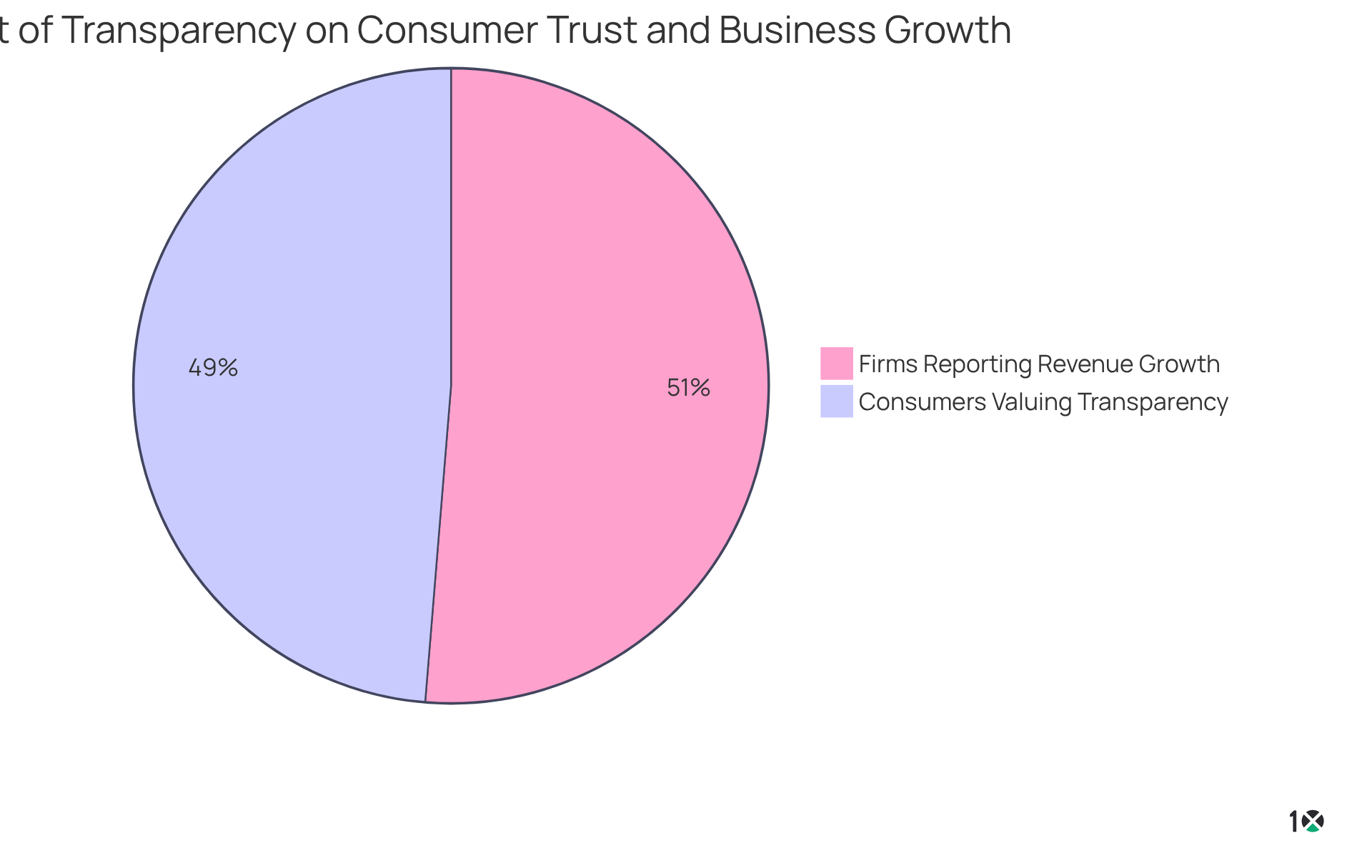

Harvard Business Review: Building a Transparent Supply Chain

Creating a transparent logistics network is essential for fostering trust among stakeholders and improving operational efficiency. Transparency not only enhances traceability but also minimizes disruptions, streamlining financing and contracting processes. Organizations that invest in logistical visibility can significantly boost consumer trust; research indicates that 75% of consumers consider transparency beneficial in cultivating trust between enterprises and customers.

By leveraging technologies such as blockchain, vendors can achieve unparalleled transparency across their logistics. This technology facilitates real-time tracking of goods, ensuring that all parties have access to accurate information, leading to better decision-making and stronger supplier relationships.

Furthermore, organizations that prioritize transparency are more likely to experience lower operational expenses and heightened customer satisfaction. This is evidenced by the statistic that 79% of firms with robust logistics report above-average revenue growth. As the logistics landscape continues to evolve, embracing transparency through innovative solutions like blockchain will be vital for suppliers aiming to thrive in a competitive market.

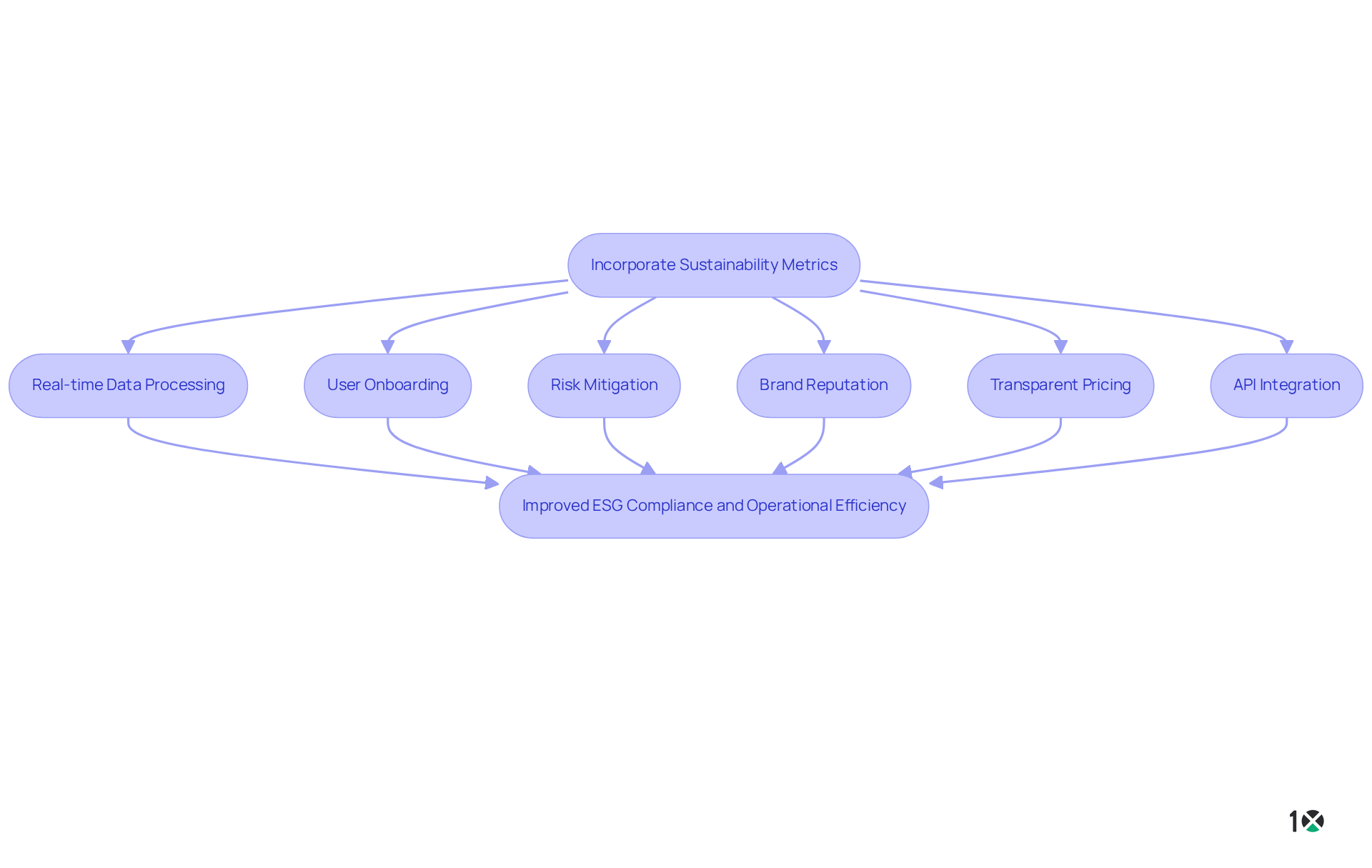

Coupa: Drive ESG Compliance in Supply Chain Operations

Incorporating sustainability metrics into logistics operations is essential for contemporary distributors aiming to enhance their ESG compliance. Solutions like 10X ERP, which offers real-time data processing, robust accounting features, and customized support, empower businesses to integrate these metrics into their procurement processes, aligning logistics with environmental and social governance standards.

The streamlined user onboarding experience of 10X ERP enables teams to swiftly adapt to the system, facilitating the immediate implementation of sustainability practices. This strategic approach not only mitigates risks associated with noncompliance but also enhances brand reputation and cultivates customer loyalty.

Additionally, the transparent pricing structure of 10X ERP clarifies the value proposition for businesses eager to adopt sustainability metrics. The API-first approach ensures seamless integration with existing systems, simplifying the incorporation of sustainability metrics into operations.

As organizations increasingly prioritize sustainability, leveraging technology like 10X ERP becomes a vital component of their supply chain solutions, helping them stay competitive in a rapidly evolving market. Firms utilizing 10X ERP to incorporate sustainability metrics have reported improved compliance and heightened operational efficiency, enabling them to navigate challenges and seize opportunities within their networks.

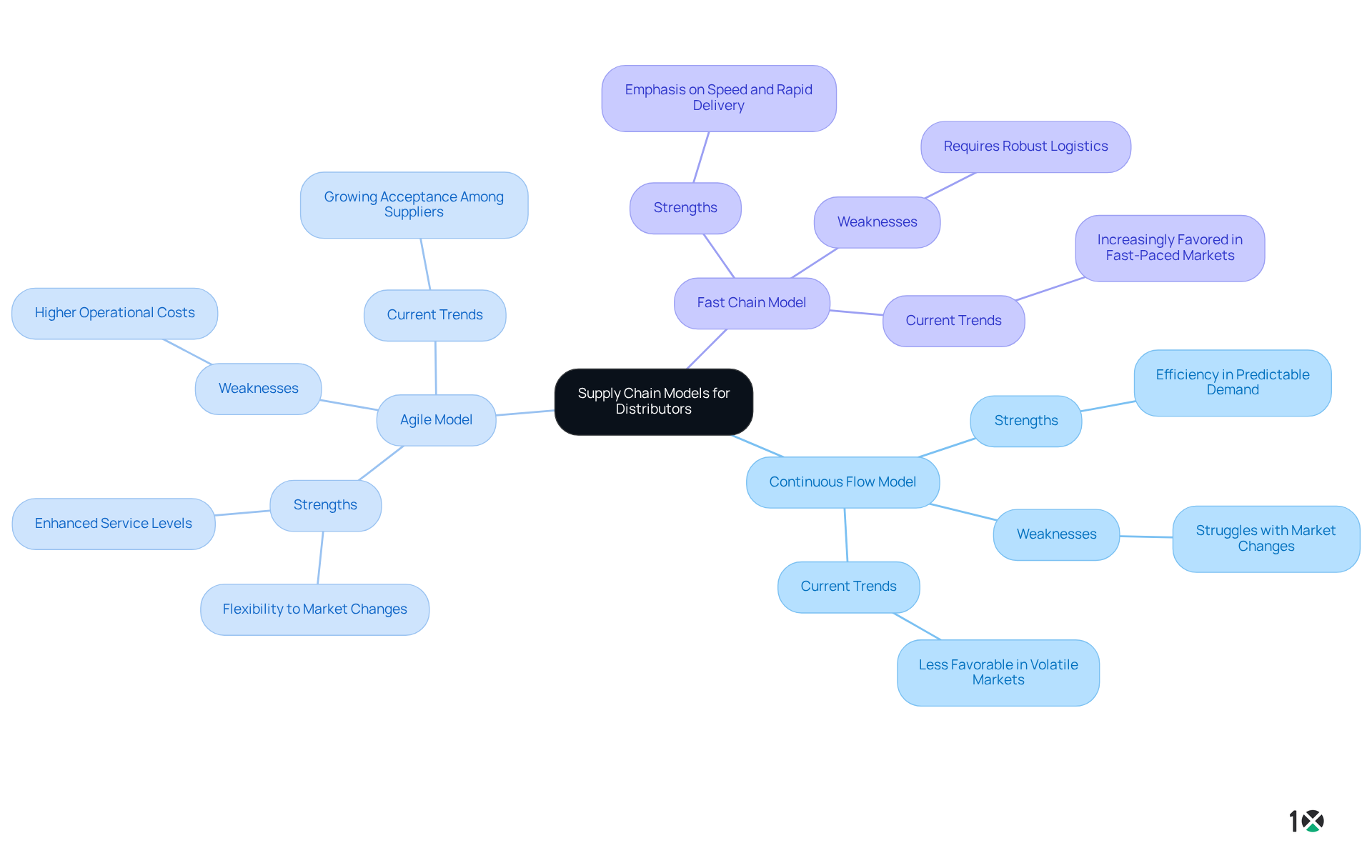

Investopedia: Exploring Different Supply Chain Models for Distributors

Distributors have the option to adopt several supply chain solutions, including the continuous flow model, agile model, and fast chain model. Each of these models showcases distinct strengths and weaknesses that can greatly influence a supplier’s responsiveness to market demands.

The continuous flow model is characterized by its efficiency in handling predictable demand, making it ideal for products with stable sales patterns. However, it may struggle to adapt to sudden market changes. In contrast, the agile model excels in flexibility, allowing suppliers to quickly pivot in response to fluctuating customer needs, though it may incur higher operational costs due to its reactive nature. The fast chain model, which emphasizes speed and rapid delivery, is increasingly favored in today’s fast-paced market, but it requires robust logistics and inventory management systems to be effective.

Current trends indicate a growing acceptance of agile and fast chain models among suppliers, driven by the demand for improved responsiveness and customer satisfaction. For instance, companies that have implemented agile strategies report enhanced service levels and reduced lead times, showcasing the model’s effectiveness in dynamic environments. Conversely, those relying solely on the continuous flow model may find themselves at a disadvantage as market volatility increases.

To enhance distribution strategies, distributors should evaluate their specific operational requirements and market conditions to develop suitable supply chain solutions. By leveraging insights from successful implementations of these models, they can tailor their approaches to maximize efficiency and effectively meet customer expectations.

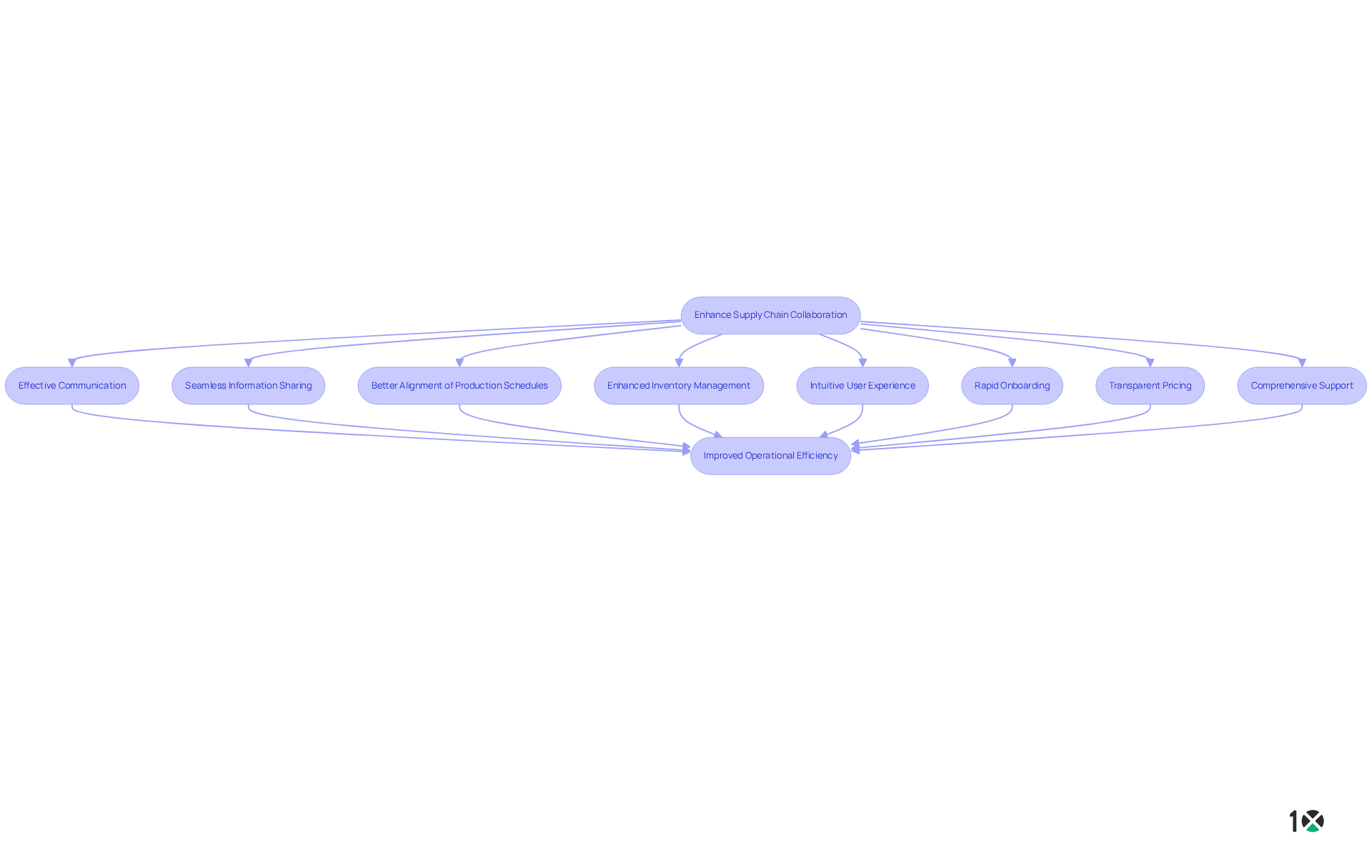

Coupa: Enhance Supply Chain Collaboration for Operational Success

Effective communication is vital for improving collaboration in logistics, a cornerstone of operational success. 10X ERP’s platform facilitates seamless information sharing among supply chain partners by providing effective supply chain solutions, enabling better alignment of production schedules and inventory management. With its intuitive user experience, rapid onboarding, and transparent pricing structure, 10X ERP empowers suppliers to enhance responsiveness and shorten lead times, ultimately boosting customer satisfaction.

Furthermore, the comprehensive support and customer service provided by 10X ERP ensure that suppliers can navigate complexities more effectively. As Charles Yeung observes, having a clear perspective of products within the logistics network minimizes disruptions and enhances inventory management.

By implementing these communication strategies and leveraging 10X ERP’s extensive supply chain solutions, suppliers can significantly improve their overall operational efficiency.

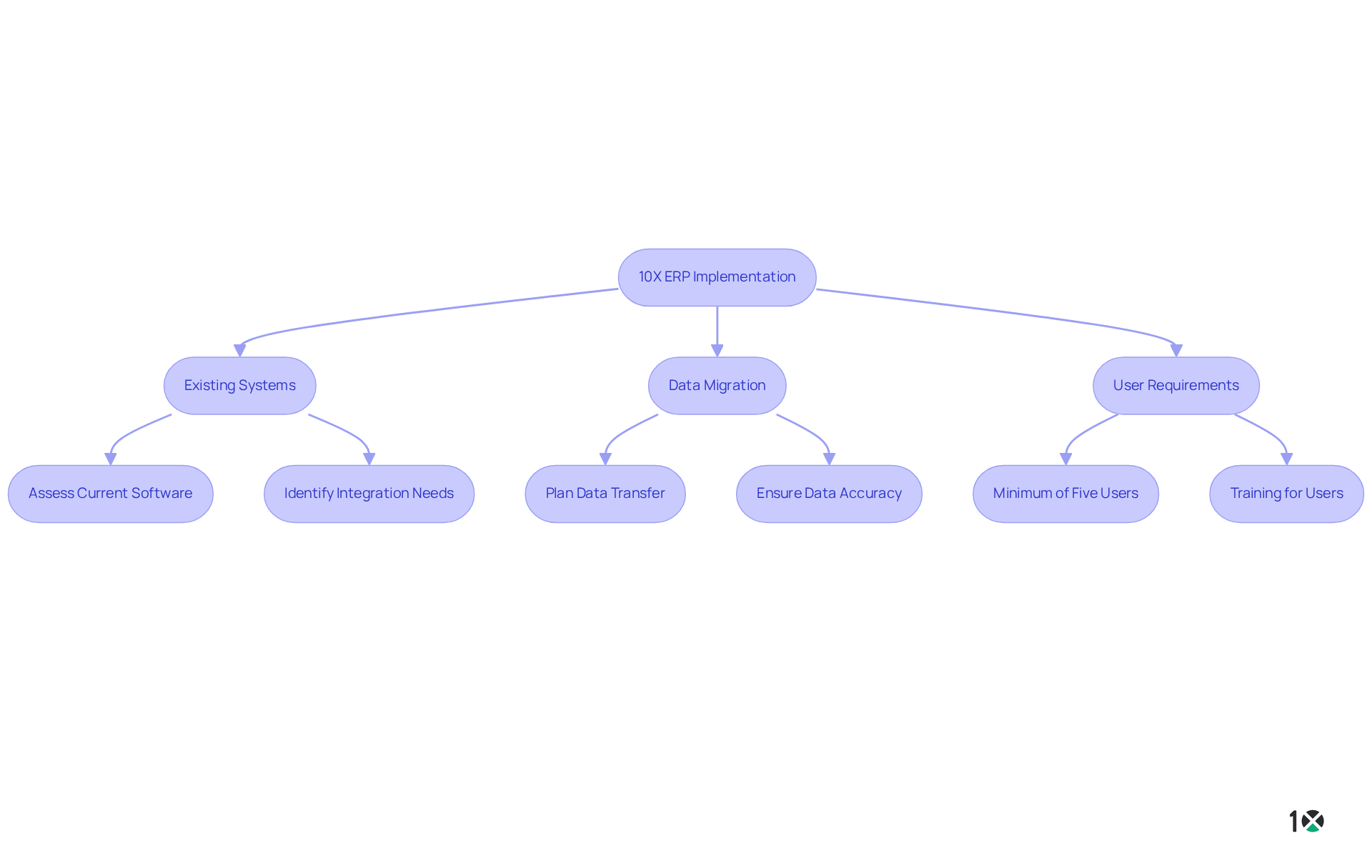

Coupa: Improve Effective Service Delivery in Supply Chains

Efficient service provision is crucial for successful logistics management. 10X ERP’s comprehensive supply chain solutions empower suppliers to optimize their operations, ensuring timely and complete product delivery. With a transparent and predictable pricing structure—featuring a lump sum that encompasses all functionalities, features, modules, tools, and dashboards—businesses can effectively plan their budgets. This all-inclusive pricing eliminates hidden costs, providing clarity and confidence in financial planning.

Considerations for implementation include:

- Existing systems

- Data migration

- User requirements (minimum of five users)

These considerations are designed to facilitate a smooth adoption process. Furthermore, 10X ERP offers best-in-class cloud hosting, real-time data processing, continuous data backup, and regular product updates, significantly enhancing operational efficiency.

By optimizing logistics and improving communication with suppliers, 10X ERP offers supply chain solutions that enable businesses to minimize delays and elevate overall service levels. This leads to higher customer satisfaction and loyalty, making it an essential tool for Operations Managers seeking effective solutions to their challenges.

Investopedia: Mastering the Five Phases of Supply Chain Management

Achieving operational excellence in Supply Chain Management hinges on mastering its five critical phases: planning, sourcing, production, distribution, and returns, as well as utilizing effective supply chain solutions. Each phase demands meticulous attention and optimization to ensure efficient and effective product delivery. For instance, Walmart exemplifies operational excellence through its advanced supply chain management system, utilizing technology and data analytics to optimize inventory and reduce costs. This approach not only enhances efficiency but also maintains competitive pricing for customers.

In the planning phase, organizations must define clear goals and analyze current processes to identify improvement opportunities. As Michael Porter noted, ‘Continuity of strategic direction and continuous improvement are mutually reinforcing.’ This principle is essential for suppliers aiming to enhance their supply chain solutions and streamline operations. Leveraging a comprehensive cloud-based ERP solution like 10X ERP, which includes all necessary features without the need for additional modules, can facilitate this process by providing supply chain solutions that enable real-time data processing and insights to drive informed decision-making.

The sourcing phase involves selecting suppliers who align with operational excellence goals. Companies like Amazon have set benchmarks in this area by employing advanced technologies to enhance supplier relationships and ensure timely deliveries. 10X ERP supports this phase with its seamless integrations and transparent pricing, enabling suppliers to effectively manage vendor relationships as part of their supply chain solutions.

During production, the focus shifts to minimizing waste and maximizing value. The Toyota Production System (TPS) serves as a model here, emphasizing continuous improvement and just-in-time production to enhance operational efficiency. The features of 10X ERP, including top-tier inventory management, enable suppliers to adopt effective supply chain solutions, ensuring that production processes are optimized for efficiency.

Distribution requires a keen understanding of logistics and customer needs. Successful companies like Starbucks have implemented Lean Thinking to streamline their supply chains, significantly reducing service times and improving customer satisfaction. By focusing on eliminating waste, Starbucks has enhanced its operational efficiency and customer experience. With 10X ERP’s lightning-fast performance and unlimited data capacity, suppliers can achieve similar results in their supply chain solutions during distribution processes.

Finally, the returns phase is often overlooked but is crucial for maintaining customer loyalty. Organizations must develop efficient processes to handle returns, ensuring that customer experiences remain positive even when issues arise. 10X ERP’s dedication to ongoing product enhancements and unmatched assistance, featuring a comprehensive onboarding procedure, can aid suppliers in effectively managing their supply chain solutions.

However, suppliers encounter challenges in optimizing these phases, including resistance to change and the need for effective communication. As W. Edwards Deming stated, ‘Change is inevitable. Everybody resists change.’ Tackling these challenges with a dedication to ongoing enhancement, supported by a strong ERP system such as 10X ERP, can lead to improved logistics performance and effective supply chain solutions, ultimately resulting in operational excellence.

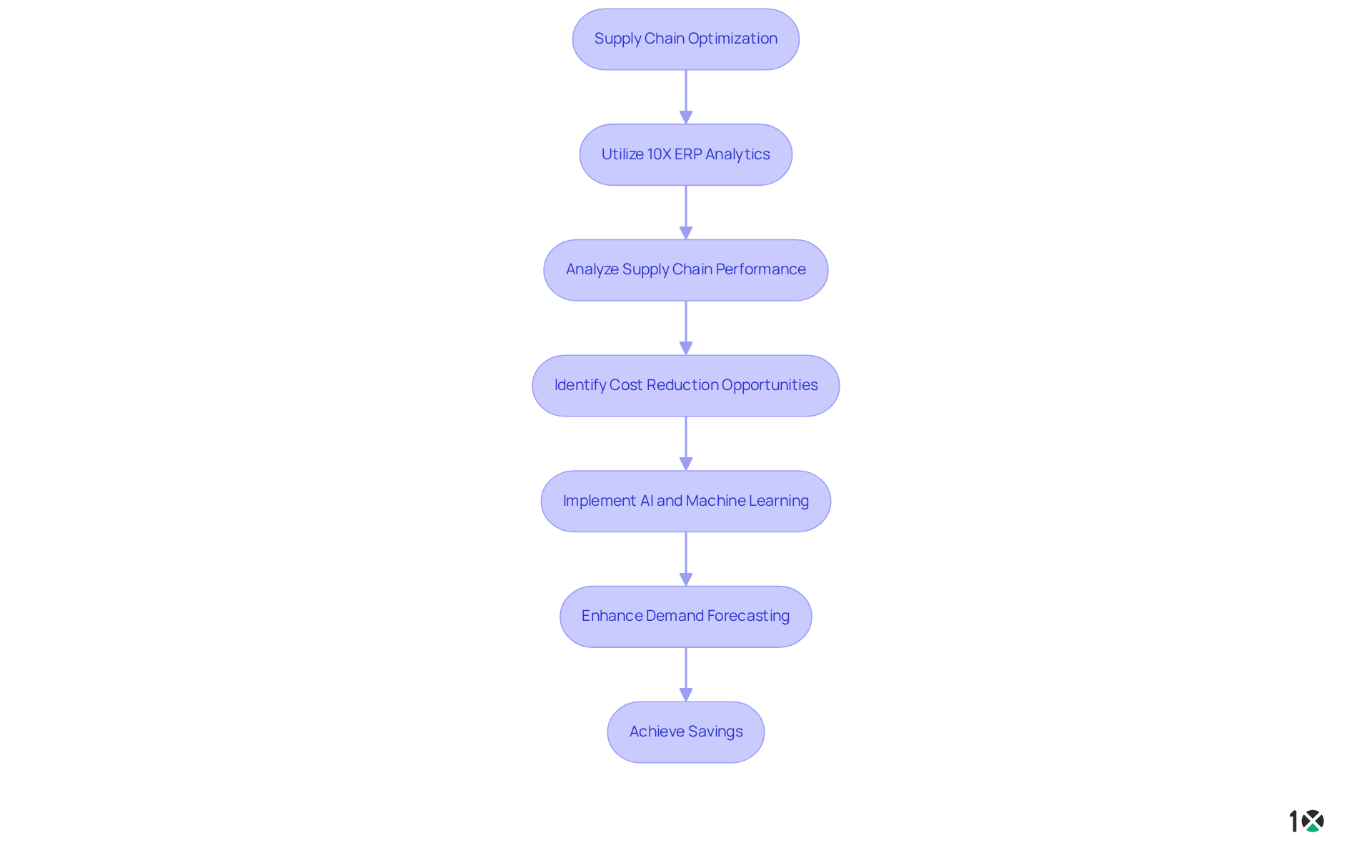

Coupa: Achieve Actionable Savings Through Supply Chain Optimization

Attaining practical savings through logistics optimization is essential for wholesalers aiming to enhance efficiency and profitability. 10X ERP’s cloud-based solution provides advanced analytics tools that empower businesses to scrutinize supply chain solutions performance and pinpoint opportunities for cost reduction. For instance, real-time data processing enables suppliers to uphold optimal inventory levels, thereby minimizing excess stock and associated carrying costs. By harnessing data-driven insights, organizations can streamline operations, reduce waste, and elevate overall performance.

Current trends highlight the integration of technologies such as AI and machine learning, which support predictive analytics for demand forecasting and inventory optimization. Real-world examples, such as a distributor that implemented 10X ERP’s advanced inventory management system, illustrate how precise demand forecasting can enhance customer satisfaction and yield substantial cost savings. In a competitive distribution landscape, it is crucial to prioritize supply chain solutions through data-driven strategies to achieve sustainable savings and retain a competitive advantage.

Conclusion

Investing in effective supply chain solutions is crucial for distributors aiming to elevate their operational efficiency and sustain a competitive advantage. By leveraging advanced technologies such as 10X ERP and implementing proactive strategies, businesses can adeptly navigate the complexities of modern logistics, streamline processes, and respond swiftly to market demands. The integration of real-time data analytics, transparency, and sustainability metrics not only simplifies operations but also cultivates trust among stakeholders, ultimately enhancing customer satisfaction.

Key insights throughout the article underscore the importance of mastering the phases of supply chain management—planning, sourcing, production, distribution, and returns. Each phase is vital in optimizing logistics and necessitates a tailored approach to address unique challenges. Furthermore, understanding various supply chain models, including agile and fast chain, empowers distributors to adapt their strategies in response to evolving market dynamics. The focus on collaboration and communication further highlights the necessity for a cohesive approach to improve overall service delivery.

In a rapidly evolving marketplace, the importance of adopting robust supply chain solutions cannot be overstated. Distributors are urged to assess their current practices, embrace innovative technologies, and prioritize sustainability to unlock actionable savings and achieve operational excellence. By doing so, they not only enhance efficiency but also position themselves for long-term success in an increasingly competitive landscape.

Frequently Asked Questions

What is 10X ERP?

10X ERP is a cloud-based enterprise resource planning (ERP) system designed to help wholesalers manage their logistics in real-time, featuring real-time data processing, flexible user permissions, comprehensive reporting, and seamless app integrations.

How does 10X ERP enhance decision-making for businesses?

The real-time insights provided by 10X ERP allow stakeholders to make informed decisions quickly, thereby enhancing overall efficiency in operations.

What are the key features of 10X ERP?

Key features of 10X ERP include real-time data processing, flexible user permissions, comprehensive reporting, seamless app integrations, and a user-centric approach that simplifies the user experience.

What benefits does 10X ERP offer regarding onboarding and customer support?

10X ERP offers a rapid onboarding process and ongoing product enhancements, demonstrating a strong commitment to customer support.

How does 10X ERP help businesses manage supply chain disruptions?

10X ERP enables businesses to anticipate potential disruptions and implement proactive measures, which enhances operational efficiency and mitigates risks.

What financial benefits can companies achieve by using 10X ERP?

By reducing logistics expenses from 9% to 4%, companies can potentially double their profits, highlighting the financial impact of efficient supply chain management.

What phases are involved in supply chain management (SCM)?

The five essential phases of supply chain management are planning, sourcing, production, distribution, and returns.

Why is mastering SCM phases important for suppliers?

Mastering SCM phases is crucial for optimizing operations, reducing costs, and enhancing customer satisfaction.

What challenges do distributors face in supply chain management?

Distributors face challenges such as managing distribution disruptions, handling inventory efficiently, and dealing with inadequate logistics chain technology.

How can companies improve their supply chain management practices?

Companies can improve SCM by enhancing visibility, refining inventory management, and integrating environmental practices into their logistics.

What is the significance of sustainability in supply chain management?

A growing commitment to sustainability is evident as 53% of companies prioritize integrating environmental practices into their logistics, showcasing the importance of sustainable procurement strategies.