Overview

This article presents a comprehensive five-step process for implementing an effective inventory tracking system. It emphasizes the importance of:

- Assessing current practices

- Selecting the appropriate software

- Ensuring ongoing optimization

Each step is bolstered by practical recommendations, including:

- Conducting a SWOT analysis

- Choosing software such as 10X ERP for real-time data management

- Establishing performance metrics

These strategies are designed to enhance operational efficiency and reduce costs, providing Operations Managers with actionable insights to tackle their challenges.

Introduction

Establishing an effective inventory tracking system is vital for businesses aiming to enhance their stock management and operational efficiency. By employing the right tools, organizations can achieve real-time insights into their inventory levels, facilitating informed decision-making that ultimately boosts productivity and customer satisfaction. Yet, a challenge persists: how can businesses effectively navigate the complexities of implementing such a system while selecting the most suitable software and optimizing their processes? This guide delineates five essential steps to successfully implement an inventory tracking system tailored to meet the unique needs of any organization.

Understand the Basics of Inventory Tracking Systems

Inventory monitoring solutions are essential for businesses aiming to enhance stock management and streamline operations. These frameworks provide into stock levels, empowering organizations to make informed decisions that boost efficiency and customer satisfaction. Key components of an effective inventory tracking system include:

- Real-Time Data: This feature guarantees that stock levels are updated instantly as transactions occur, significantly minimizing discrepancies. With 10X ERP’s robust accounting capabilities, real-time data processing enables distributors to maintain accurate stock records. Currently, only 25% of supply chain leaders utilize real-time tracking for their shipments, highlighting a substantial opportunity for improvement in the industry.

- Stock Oversight: Effective stock oversight involves classifying goods based on various characteristics such as type, location, and status. 10X ERP offers customizable features and strong cross-referencing, which are crucial for maintaining optimal stock levels and mitigating overstocking—an issue that can tie up to 30% of capital in unsold goods. Poor stock control can lead to significant losses, with companies potentially losing as much as 11% of their annual income due to shortages and excess stock.

- Reporting and Analytics: The robust reporting tools within 10X ERP provide insights into stock trends, enabling businesses to forecast demand accurately and optimize stock levels. Organizations employing demand prediction tools have experienced a 10-15% reduction in total stock levels, improving cash flow management.

Understanding these fundamentals is key to successfully implementing an inventory tracking system that not only enhances operational efficiency but also positions your business for growth in a competitive landscape. Furthermore, the case study on 10X ERP illustrates how adopting this platform has led to improved operational efficiency and reduced stock costs for distributors, reinforcing the benefits of effective stock oversight. As Oliver Munro observes, “Real-time visibility is commonly cited as an important solution, but only a quarter of supply chain and logistics leaders are using real-time tracking for their shipments.” Familiarizing yourself with these insights will empower your organization to maximize the potential of tracking tools.

![]()

Assess Current Inventory Management Practices

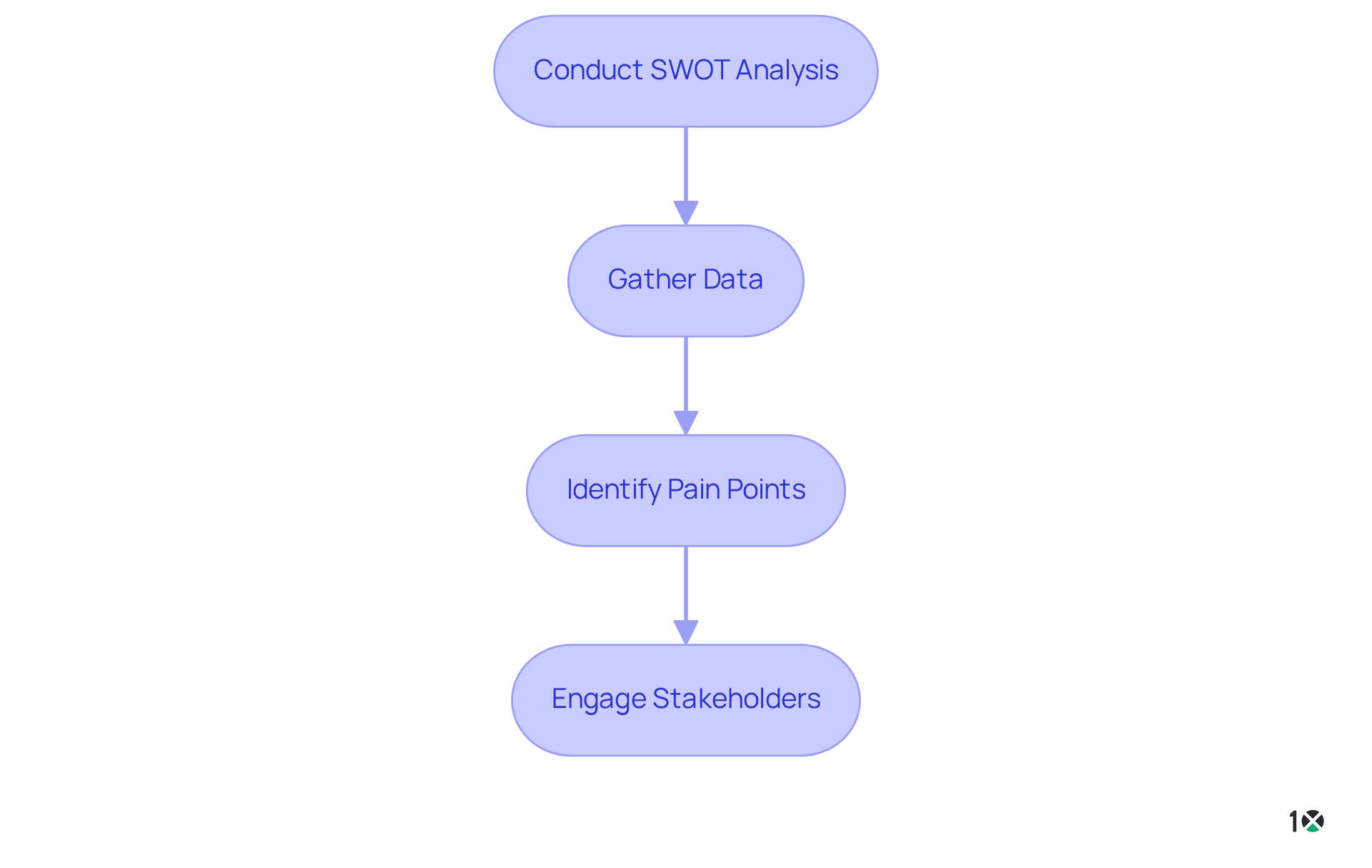

To successfully introduce a new stock monitoring system, begin with a careful evaluation of your existing stock handling practices. Consider the following steps:

- Conduct a SWOT Analysis: Assess the strengths, weaknesses, opportunities, and threats associated with your current stock management. This analysis reveals critical insights into areas for improvement and potential growth.

- Gather Data: Collect comprehensive data on stock levels, turnover rates, and order fulfillment times. Understanding these metrics is crucial for recognizing patterns that may affect efficiency.

- Identify Pain Points: Pinpoint specific issues such as stockouts, overstocking, or inaccuracies in stock records. Addressing these pain points is essential for enhancing operational efficiency and customer satisfaction. Inadequate stock visibility can lead to significant issues, including delayed shipments and higher cancellation rates. A solution like 10X ERP can help tackle these challenges through features such as SKU-level lot/serial tracking and automated allocation rules that ensure optimal stock management.

- Engage Stakeholders: Involve team members who handle stock daily. Their insights provide valuable perspectives on challenges and needs that may not be immediately apparent from data alone.

This thorough evaluation will clarify what your new inventory tracking system must address, ensuring alignment with your operational objectives and overall efficiency improvement. With 10X ERP’s innovative cloud-based features, you can achieve and operational flexibility, significantly enhancing your stock management effectiveness.

Choose the Right Inventory Tracking Software

Choosing the right inventory tracking software requires careful consideration of several key factors:

- Define Your Requirements: Start by outlining the essential features you need, such as barcode scanning, real-time tracking, and reporting capabilities. Remember the wisdom of Peter Drucker, who said, ‘What Gets Measured, Gets Managed.’ This emphasizes the importance of effectively monitoring your stock using an inventory tracking system.

- Research Options: Seek out software solutions tailored specifically for distributors. Consider 10X ERP, which offers a robust inventory tracking system featuring real-time data processing, customizable attributes, and a user-friendly interface designed to streamline operations and boost productivity. With built-in reporting and a , 10X ERP enables stakeholders to make informed decisions. Its transparent pricing model ensures you gain extensive functionality without unexpected costs.

- Evaluate Integration: Confirm that the software can integrate seamlessly with your existing ERP infrastructure to prevent data silos. 10X ERP offers unlimited integrations through modern APIs, ensuring a cohesive operational framework that optimizes efficiency.

- Consider Scalability: Select a solution capable of growing alongside your business, accommodating increased stock and complexity over time. 10X ERP is designed for growth, ensuring that as your distribution needs evolve, your stock control solution adapts accordingly. An efficient inventory tracking system can reduce total holding costs by 10% by minimizing shortages and excesses, making scalability a crucial factor.

- Request Demos: Connect with vendors to experience the software firsthand and evaluate its user-friendliness. Engaging with the software provides valuable insights into its fit for your operational needs. With 10X ERP’s rapid onboarding process, you can quickly leverage its features, and the clear pricing structure helps you understand the value it adds to your operations.

By meticulously evaluating your options and considering these elements, you can select a software solution that meets your specific management needs, ultimately leading to enhanced efficiency and effectiveness in your operations.

![]()

Implement the Inventory Tracking System

Implementing your new inventory tracking system requires a series of critical steps that ensure a successful transition:

- Develop an Implementation Plan: Begin by outlining the timeline, key milestones, and responsibilities associated with the implementation process. This structured approach not only keeps the project on track but also ensures accountability among team members.

- Data Migration: Next, migrate current stock information into the new platform with precision and thoroughness. Validating data before migration is vital to maintaining , as this step is crucial for successful implementation.

- User Training: Conduct comprehensive training sessions for staff to familiarize them with the new software and its features. Leverage in-app video guides created by the developers to enhance the training experience, allowing users to access helpful resources without leaving the application. These guides are invaluable as they assist users at various stages of the implementation process.

- Pilot Testing: Implement a pilot test with a small group of users to identify any issues prior to full-scale deployment. This proactive approach allows for the identification of potential challenges and provides an opportunity to refine processes based on real user feedback.

- Go Live: Finally, launch the platform across the organization, ensuring robust support for users as they transition to the new processes. Continuous monitoring and feedback collection during this phase are essential to address any challenges that may arise promptly.

If you have any questions or require further assistance, please do not hesitate to reach out through our contact form. Following these steps will facilitate a smooth implementation of the inventory tracking system and foster user buy-in.

![]()

Monitor and Optimize Your Inventory Tracking System

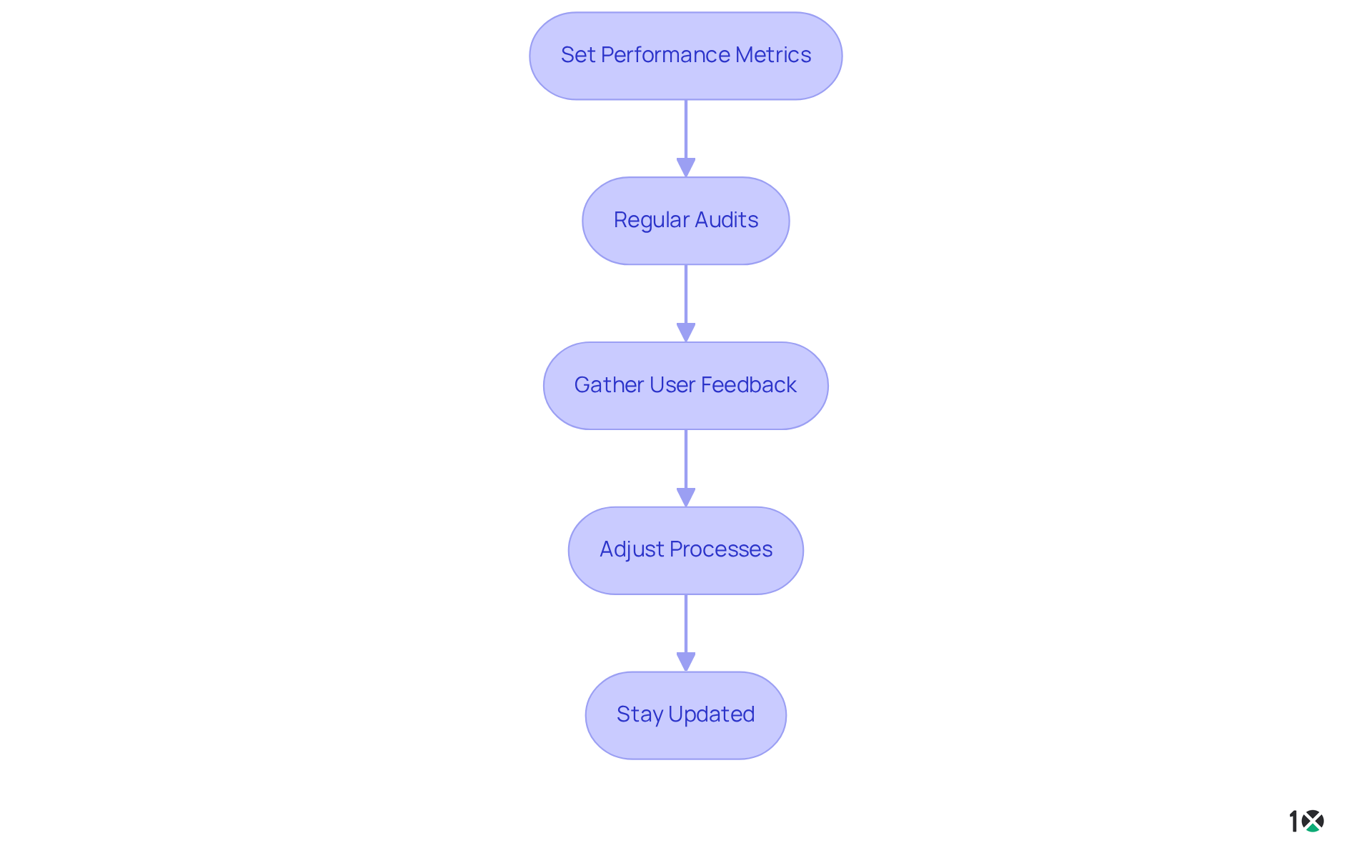

Once your inventory tracking system is set up, continuous monitoring and optimization are essential for its success.

- Set Performance Metrics: Establish key performance indicators (KPIs) such as stock turnover rates, order accuracy, and stockout frequency. These metrics provide and help identify areas for improvement. A high stock turnover rate indicates efficient stock management, while a low rate may signal overstocking issues.

- Regular Audits: Conduct periodic reviews of stock records to ensure precision and reveal discrepancies. Regular audits not only help maintain data integrity but also enhance operational efficiency. For instance, a case study on Putaway Time Efficiency showed that shorter putaway durations result in faster order fulfillment and enhanced stock accuracy.

- Gather User Feedback: Actively solicit input from users to identify challenges and areas for enhancement. Grasping user experiences can reveal inefficiencies and guide essential modifications to the framework. Integrating user feedback systems can result in actionable insights that enhance overall stock control practices, particularly when employing features from 10X ERP.

- Adjust Processes: Be ready to refine workflows and processes based on performance data and user feedback. Adaptability in responding to new knowledge is vital for sustaining an efficient stock control framework. As noted by Peter Drucker, “What Gets Measured, Gets Managed,” emphasizing the importance of data-driven adjustments. Leveraging the real-time data processing capabilities of 10X ERP can significantly aid in this process.

- Stay Updated: Keep informed about software updates and industry trends to leverage new features and best practices. Keeping up with advancements in stock management technology, such as those provided by 10X ERP, can greatly improve operational capabilities and customer satisfaction.

By actively monitoring and optimizing your inventory tracking system, you can ensure that it consistently meets your business needs and enhances operational efficiency.

Conclusion

Implementing an effective inventory tracking system is crucial for businesses seeking to enhance operational efficiency and customer satisfaction. Understanding the fundamentals of inventory management, assessing current practices, selecting the right software, executing a structured implementation plan, and continuously monitoring and optimizing the system are essential steps that organizations can take to significantly improve their stock control processes.

Key arguments discussed include:

- The importance of real-time data for maintaining accurate stock levels

- The necessity of thorough assessments to identify pain points

- The critical role of user training in ensuring a smooth transition

The insights gained from performance metrics and user feedback are vital for refining inventory practices and adapting to changing business needs.

Ultimately, the successful implementation of an inventory tracking system not only streamlines operations but also positions a business for growth in a competitive landscape. Embracing best practices in inventory management can lead to substantial cost savings and improved service levels. Therefore, it is essential for organizations to prioritize these efforts. By taking the necessary steps to enhance inventory tracking, businesses can unlock their full potential and drive sustainable success.

Frequently Asked Questions

What are inventory tracking systems and why are they important?

Inventory tracking systems are solutions that help businesses enhance stock management and streamline operations by providing real-time insights into stock levels. This allows organizations to make informed decisions that boost efficiency and customer satisfaction.

What are the key components of an effective inventory tracking system?

Key components include real-time data updates, stock oversight through classification of goods, and reporting and analytics tools to forecast demand and optimize stock levels.

How does real-time data benefit inventory management?

Real-time data ensures that stock levels are updated instantly with each transaction, minimizing discrepancies and enabling accurate stock records. This is crucial for maintaining efficient inventory management.

What issues can poor stock oversight lead to?

Poor stock oversight can result in overstocking, which can tie up to 30% of capital in unsold goods, and shortages that may lead to significant losses, with companies potentially losing up to 11% of their annual income.

How can reporting and analytics improve inventory management?

Reporting and analytics tools provide insights into stock trends, helping businesses to accurately forecast demand and optimize stock levels. Companies using demand prediction tools have seen a 10-15% reduction in total stock levels, improving cash flow management.

What steps should be taken to assess current inventory management practices?

Steps include conducting a SWOT analysis, gathering data on stock metrics, identifying pain points, and engaging stakeholders who manage stock daily.

What specific issues should be identified during the assessment of inventory management practices?

Specific issues to identify include stockouts, overstocking, and inaccuracies in stock records, as these can affect operational efficiency and customer satisfaction.

How does 10X ERP assist in improving inventory management?

10X ERP offers features such as real-time data processing, SKU-level lot/serial tracking, and automated allocation rules, which help tackle challenges in stock management and enhance operational efficiency.