Overview

Hydraulic hose distributors can significantly enhance their operational efficiency by thoroughly understanding the manufacturing process.

- Selecting appropriate materials is crucial.

- Implementing effective inventory management strategies is essential.

- Leveraging technology plays a pivotal role in this enhancement.

Knowledge of production techniques and materials not only improves product quality but also ensures that:

- Efficient stock management

- Technology adoption

These factors streamline operations, which in turn boosts customer satisfaction, creating a cycle of continuous improvement and success.

Introduction

In the rapidly evolving landscape of hydraulic hose distribution, grasping the intricacies of the manufacturing process and material selection is paramount. Distributors can reap substantial benefits by implementing effective inventory management strategies and harnessing cutting-edge technology to streamline operations. Yet, the pressing question persists: how can distributors not only adapt to these changes but also excel in a competitive market? This article explores four essential strategies designed to enhance efficiency and propel success for hydraulic hose distributors in 2025 and beyond.

Understand the Hydraulic Hose Manufacturing Process

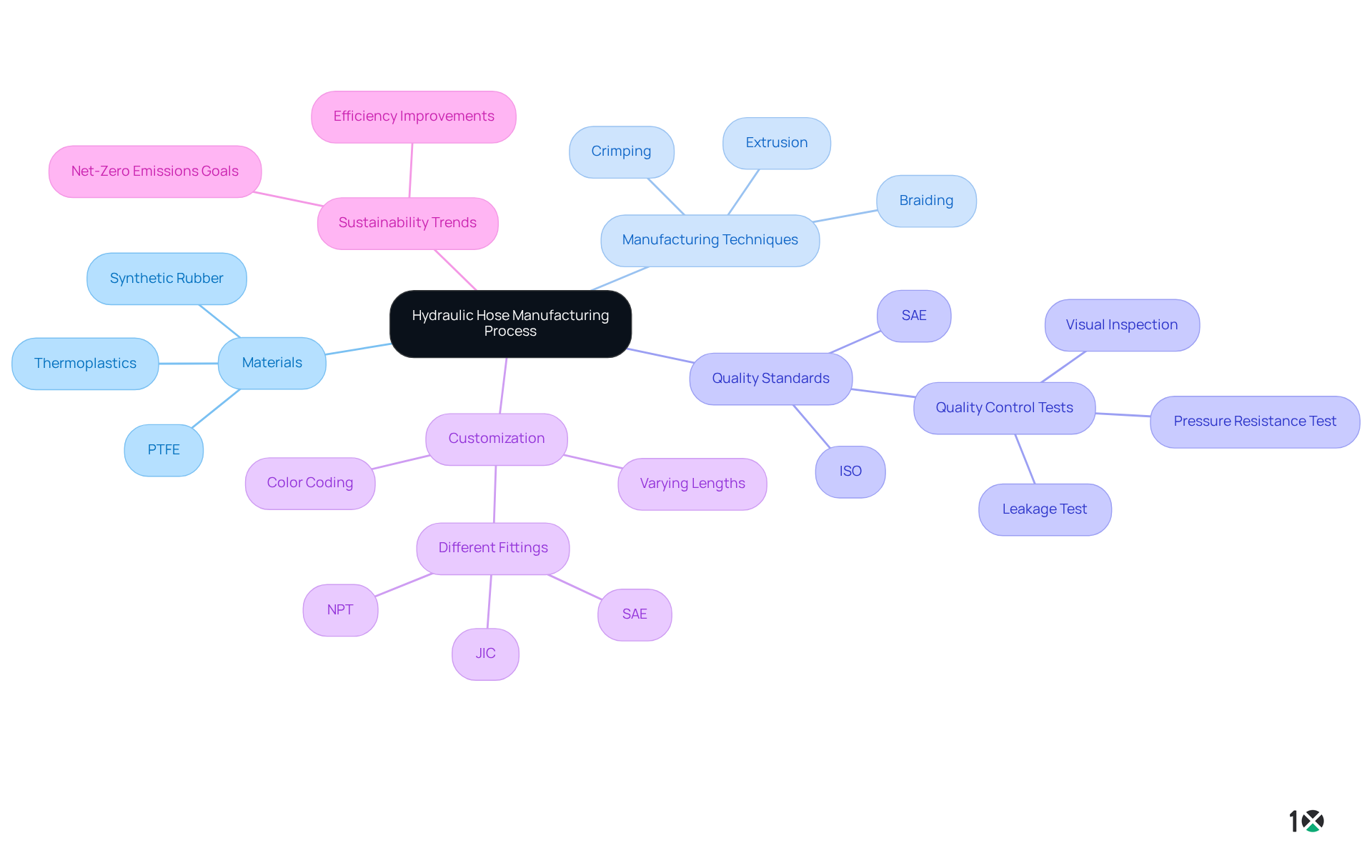

To enhance efficiency, hydraulic hose distributors must have a comprehensive understanding of the hydraulic hose production process. This includes knowledge of materials such as synthetic rubber and thermoplastics, as well as various manufacturing techniques like extrusion and braiding. Familiarity with these procedures enables suppliers to evaluate the quality of the piping they procure, ensuring compliance with client specifications. Grasping manufacturing standards, including SAE and ISO, is vital for maintaining compliance and ensuring quality assurance in product offerings.

For example, recognizing that the reinforcement layer of hydraulic tubing is fortified with multiple layers of steel wire spirals empowers hydraulic hose distributors to select products capable of withstanding high pressures and harsh conditions. This informed approach not only boosts client satisfaction but also minimizes return rates, ultimately enhancing operational efficiency. Recent trends reveal that companies adopting sustainable practices are witnessing efficiency improvements of up to 25%, highlighting the significance of this knowledge in today’s competitive landscape.

Moreover, customization options for hydraulic tubing, such as varying lengths and fittings, are essential for meeting specific client requirements. By integrating insights from industry leaders regarding the importance of quality control in hydraulic tubing manufacturing, the critical nature of understanding these processes is further reinforced.

Select Appropriate Materials for Durability and Performance

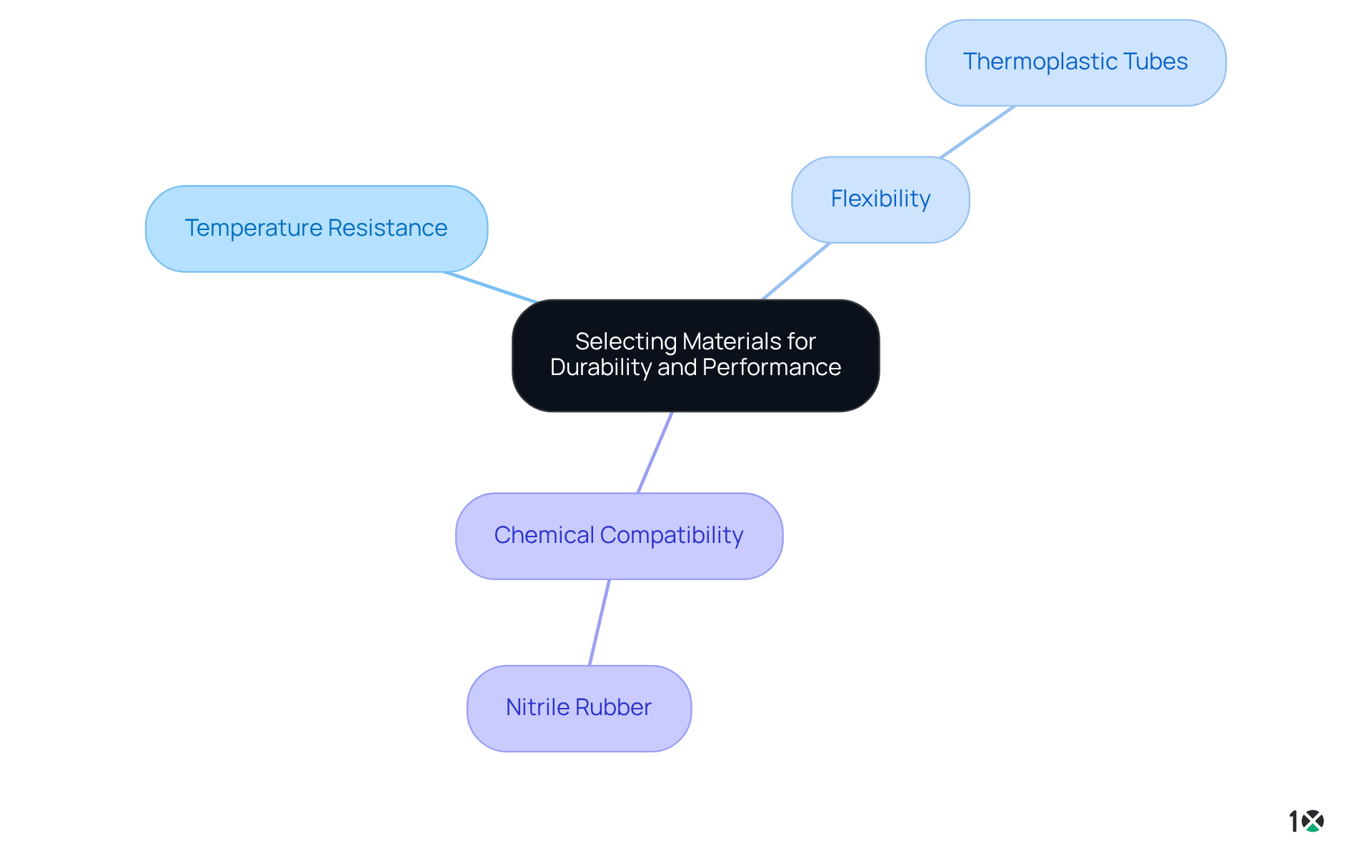

Selecting the right materials for hydraulic tubes is crucial for ensuring both durability and performance. Distributors must consider key factors such as:

- Temperature resistance

- Flexibility

- Chemical compatibility

For instance, nitrile rubber tubes excel with oil-based fluids, while thermoplastic tubes offer superior flexibility and lightweight properties. By understanding the specific applications and environments in which their products will be utilized, suppliers can recommend the most suitable options to their clients. Furthermore, staying updated on advancements in material technology, including the use of synthetic rubber blends that enhance longevity and performance, can provide suppliers with a competitive edge in the marketplace.

Implement Efficient Inventory Management Strategies

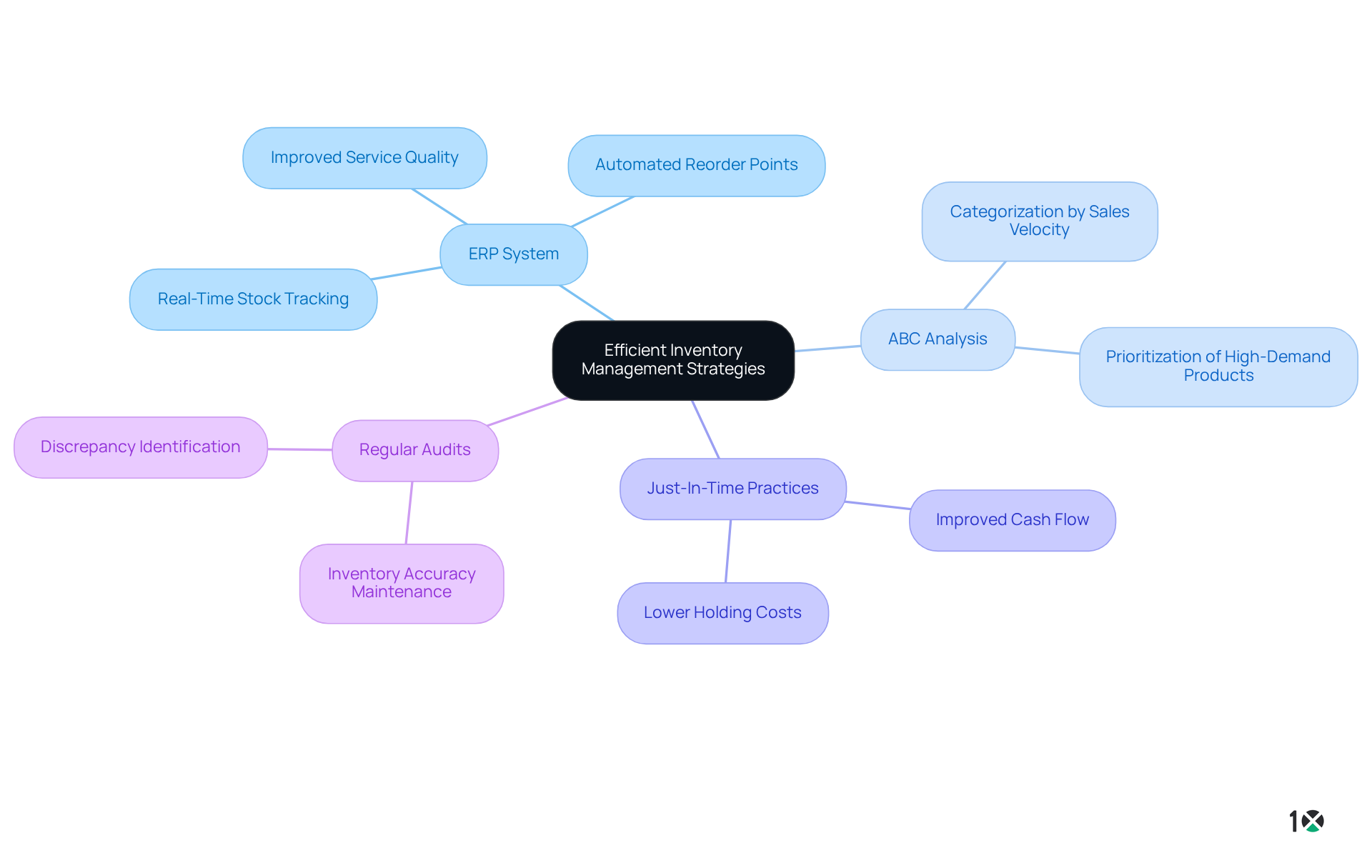

To enhance operational efficiency, hydraulic hose distributors must implement comprehensive stock management strategies, prominently featuring an ERP system for real-time stock tracking. This approach not only mitigates the risks of stockouts and overstocking but also streamlines overall stock management processes. For instance, suppliers can utilize ABC analysis to categorize stock based on sales velocity and profitability, ensuring that high-demand products receive priority.

Moreover, adopting just-in-time (JIT) stock management practices can significantly lower holding costs and improve cash flow. A notable case involves a supplier harnessing an ERP system to automate reorder points, which guarantees optimal stock levels and elevates service quality, ultimately boosting customer satisfaction. Regular audits and cycle counts are equally crucial, as they maintain inventory accuracy and swiftly identify discrepancies, fostering a more reliable inventory management system.

Leverage Technology for Operational Efficiency

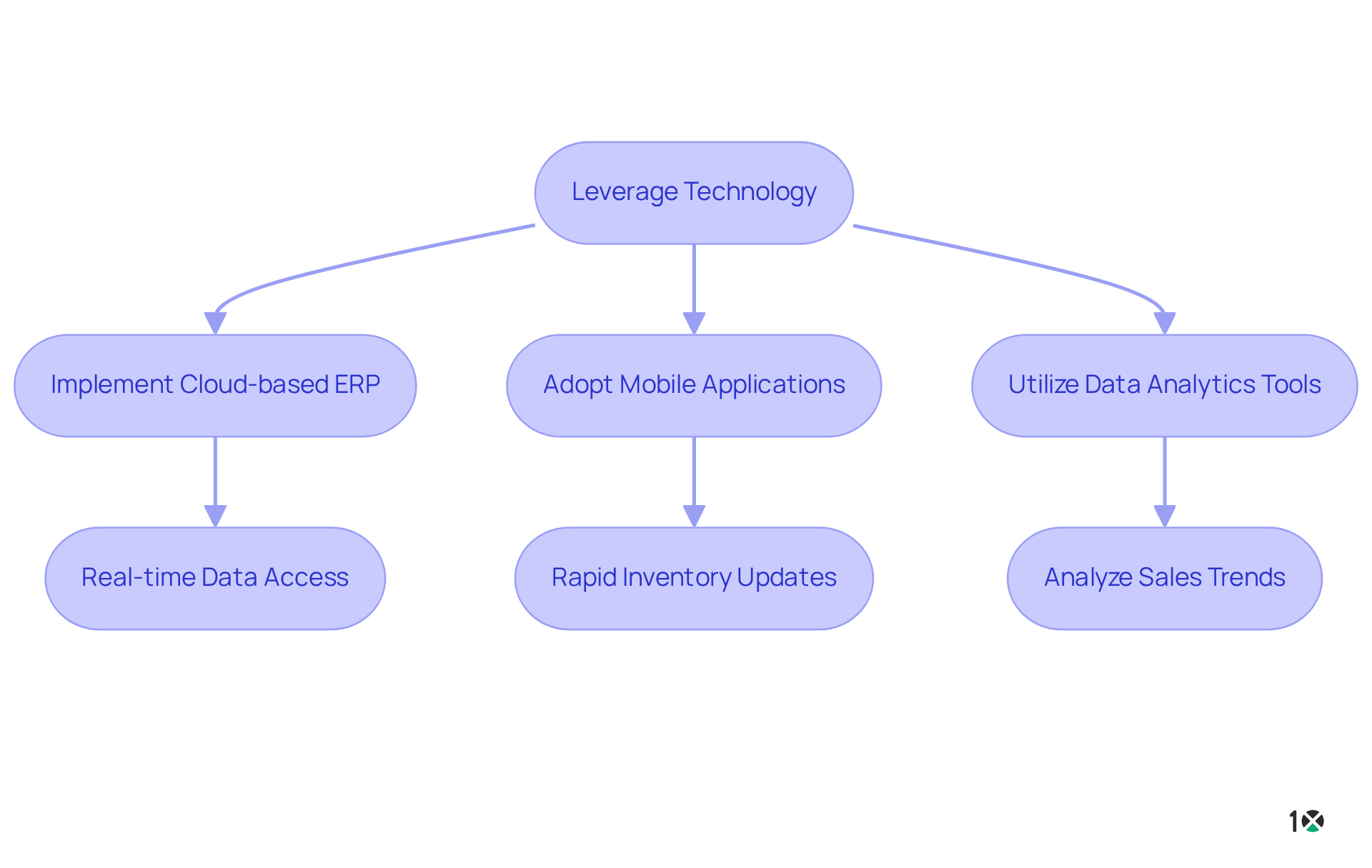

It is essential for hydraulic hose distributors to leverage technology in order to enhance operational efficiency. By implementing a cloud-based ERP system like 10X ERP, businesses can gain real-time data access, significantly improving various processes, from order management to client relationship management. Additionally, mobile applications for stock management and service can boost responsiveness and precision.

For instance, suppliers can utilize mobile devices to scan barcodes, allowing for rapid inventory updates that minimize manual errors and save time. Moreover, adopting data analytics tools enables hydraulic hose distributors to analyze sales trends and customer preferences, which empowers them to make informed, data-driven decisions that strengthen their competitive position in the market.

Conclusion

Enhancing efficiency in hydraulic hose distribution is crucial for maintaining a competitive edge in a rapidly evolving market. By comprehensively understanding the hydraulic hose manufacturing process, selecting suitable materials, implementing effective inventory management strategies, and leveraging advanced technology, distributors can significantly elevate their operations and enhance client satisfaction.

This article outlines four pivotal strategies:

- Acquiring in-depth knowledge of manufacturing processes

- Opting for durable and high-performance materials

- Adopting efficient inventory management practices

- Utilizing technology for operational advancements

Each strategy contributes to a holistic approach that not only streamlines operations but also aligns with current industry trends, such as sustainability and real-time data access.

In conclusion, the path to greater efficiency in hydraulic hose distribution is paved with informed decision-making and proactive strategies. By embracing these practices, distributors can not only enhance their operational capabilities but also position themselves as leaders in the market. The time to act is now—adopting these strategies will not only meet the demands of today but also prepare businesses for the challenges of tomorrow in the hydraulic hose industry.

Frequently Asked Questions

Why is it important for hydraulic hose distributors to understand the manufacturing process?

Understanding the hydraulic hose manufacturing process helps distributors evaluate the quality of the piping they procure, ensuring compliance with client specifications and enhancing operational efficiency.

What materials are commonly used in hydraulic hose production?

Common materials used in hydraulic hose production include synthetic rubber and thermoplastics.

What are some key manufacturing techniques used in hydraulic hose production?

Key manufacturing techniques include extrusion and braiding.

How do manufacturing standards like SAE and ISO impact hydraulic hose quality?

Familiarity with manufacturing standards such as SAE and ISO is vital for maintaining compliance and ensuring quality assurance in product offerings.

What is the significance of the reinforcement layer in hydraulic tubing?

The reinforcement layer, which is fortified with multiple layers of steel wire spirals, enables hydraulic hoses to withstand high pressures and harsh conditions.

How can understanding the manufacturing process improve client satisfaction?

By selecting products that meet high-quality standards and are capable of withstanding demanding conditions, distributors can enhance client satisfaction and minimize return rates.

What recent trends are affecting the hydraulic hose industry?

Recent trends indicate that companies adopting sustainable practices are experiencing efficiency improvements of up to 25%.

Why are customization options important in hydraulic tubing?

Customization options, such as varying lengths and fittings, are essential for meeting specific client requirements.

How does quality control play a role in hydraulic tubing manufacturing?

Quality control is critical in ensuring that hydraulic tubing meets industry standards and client expectations, reinforcing the importance of understanding manufacturing processes.