Overview

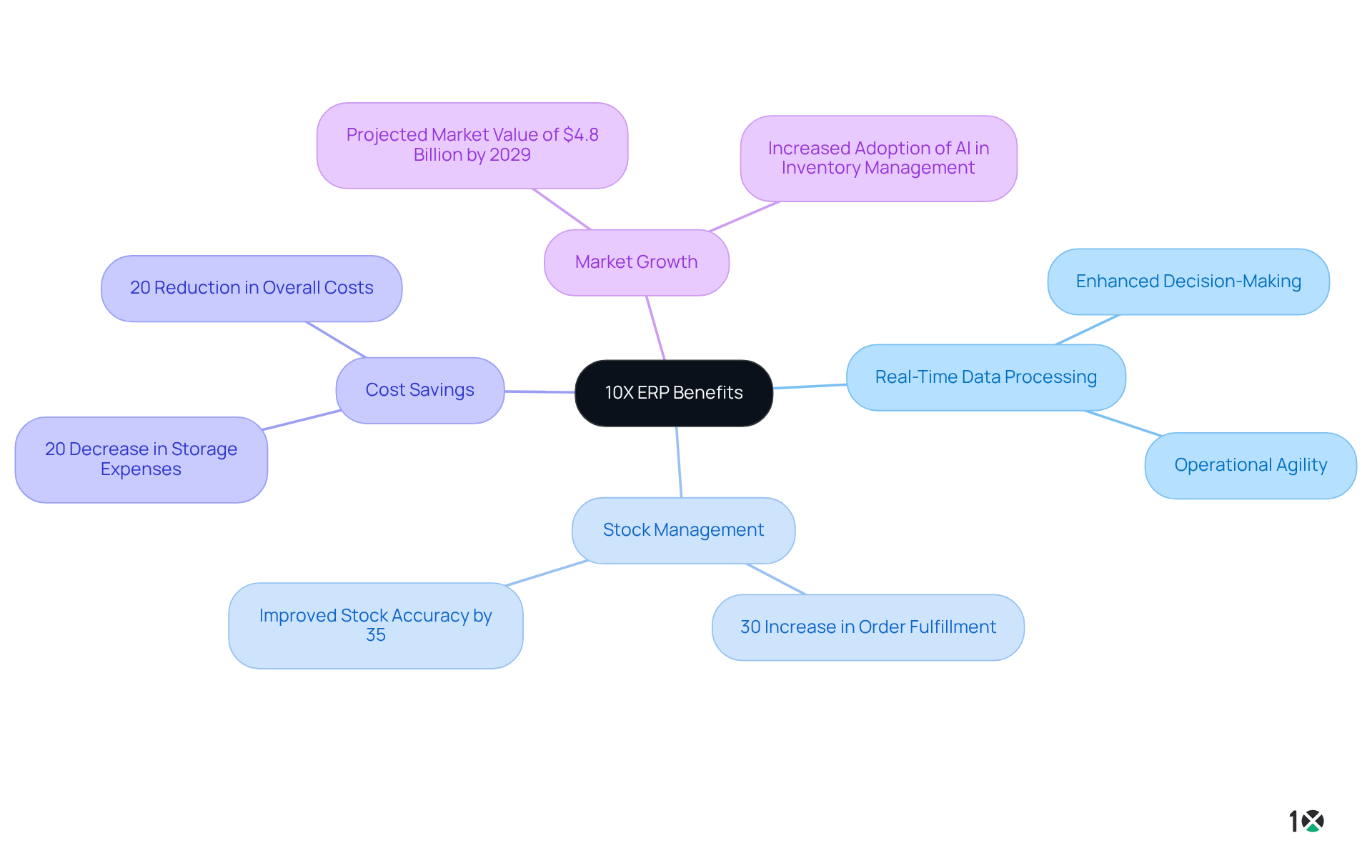

Inventory control software significantly enhances distribution efficiency by leveraging real-time data processing, automated stock monitoring, and predictive analytics. These features collectively contribute to improved inventory turnover and reduced costs.

For instance, statistics reveal increased order fulfillment rates and decreased storage expenses, underscoring the tangible benefits of integrating advanced inventory management technologies.

Operations Managers seeking effective solutions will find that adopting such software not only streamlines processes but also drives profitability.

Introduction

The landscape of distribution is rapidly evolving. Businesses are increasingly relying on technology to enhance operational efficiency. Inventory control software, particularly through platforms like 10X ERP, offers a transformative approach by enabling real-time data processing and streamlined stock management. As distributors navigate the complexities of supply chain demands, a critical question arises: how can these advanced systems not only reduce costs but also elevate customer satisfaction and improve overall inventory turnover? This article explores ten impactful ways that inventory control software can significantly enhance distribution efficiency. It provides insights that could redefine operational strategies for businesses.

10X ERP: Streamline Inventory Management with Real-Time Data Processing

harnesses the power of , enabling distributors to use for tracking stock levels, sales, and orders instantly. This functionality is essential for responding swiftly to fluctuations in demand, effectively minimizing the risks of stockouts and overstock situations through . By leveraging , users gain access to current information from any location, significantly enhancing decision-making and .

Consider this: companies with can anticipate a 30% increase in order fulfillment rates, reducing delivery delays and enhancing customer satisfaction. Moreover, Coca-Cola reported a within the first year of adopting real-time data analytics, illustrating the tangible advantages of integrating advanced data solutions.

As the is projected to reach an estimated value of $4.8 billion by 2029, the shift towards is becoming increasingly vital for distributors striving to optimize their operations and maintain a competitive edge.

Reduce Costs: Minimize Overhead with Efficient Inventory Control

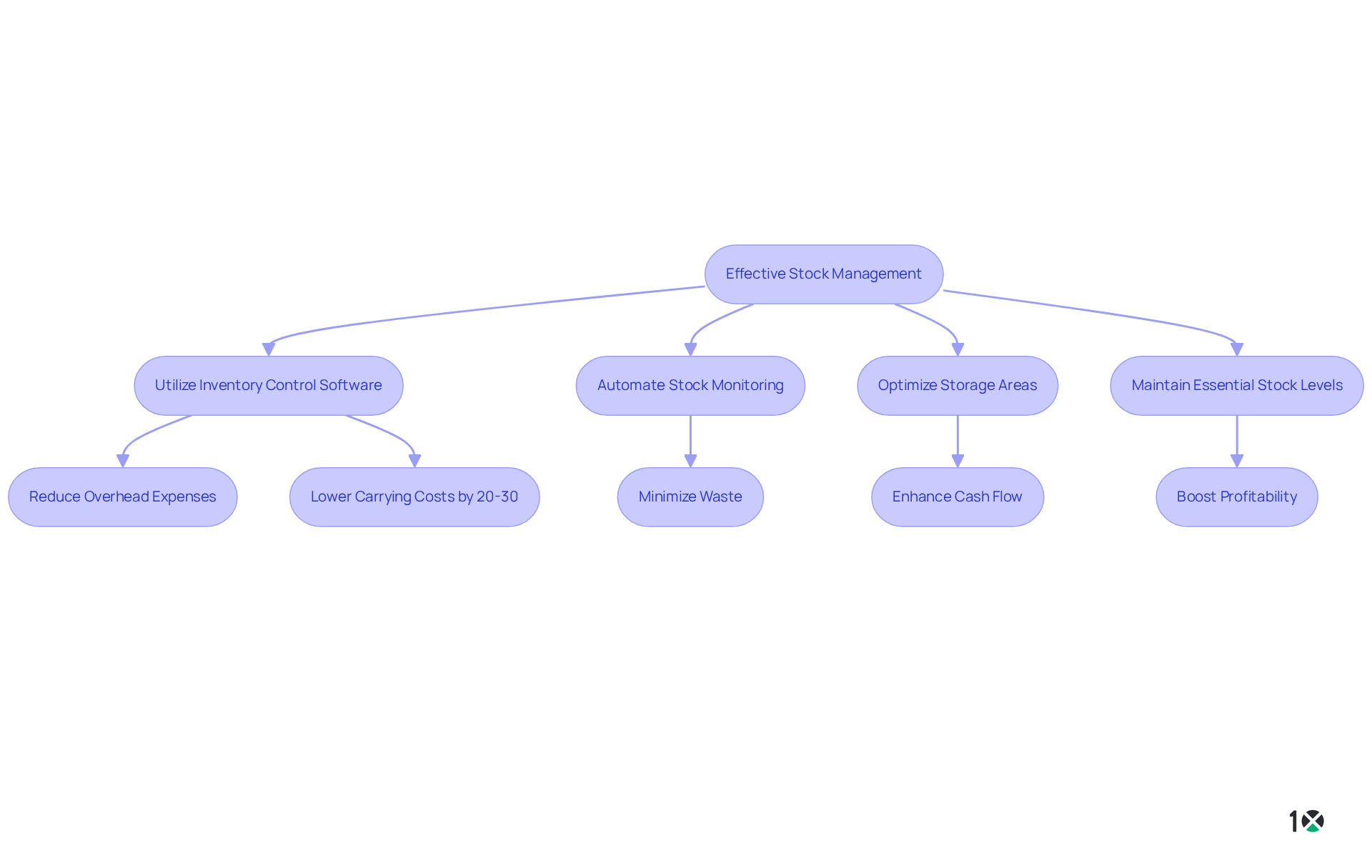

Effective stock management utilizing is vital for by reducing surplus items and optimizing storage areas. Distributors leveraging can use inventory control software to automate stock monitoring and reorder processes, ensuring they maintain only . This strategy not only significantly cuts storage costs but also minimizes waste and enhances cash flow. Consequently, businesses can allocate resources more effectively, leading to improved .

Inventory control software, as part of , has demonstrated the ability to lower carrying expenses by 20-30% and reduce stockout occurrences by 35-45%. These figures showcase the of adopting such technologies. Moreover, enhances demand prediction precision by 40%, allowing suppliers to leverage inventory control software to make informed decisions that align stock levels with actual demand. This further reduces overhead expenses and boosts profitability.

Additionally, the of 10X ERP allows businesses to swiftly start reaping the benefits of these features, ensuring minimal downtime and maximizing operational efficiency.

Enhance Customer Service: Deliver Accurate Stock Information

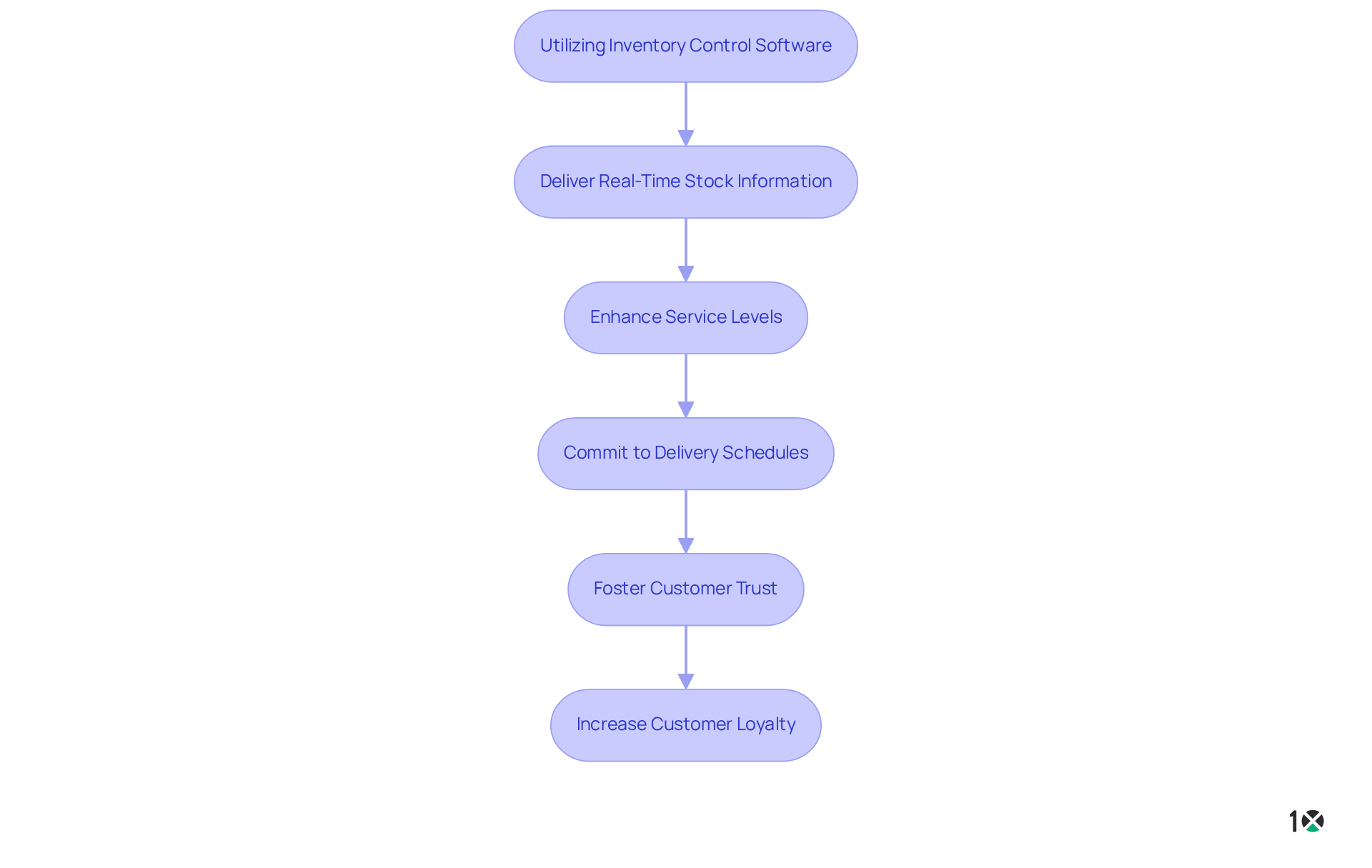

to utilize for delivering information, significantly enhancing service levels. By providing through inventory control software, sales teams can confidently commit to , fostering greater . This capability is essential for with clients, as it not only meets customer expectations but also establishes businesses as dependable partners in their supply chain. The ability to use inventory control software for allows suppliers to respond swiftly to customer inquiries and adapt to changing needs, ultimately leading to increased .

Improve Inventory Turnover: Keep Stock Moving Efficiently

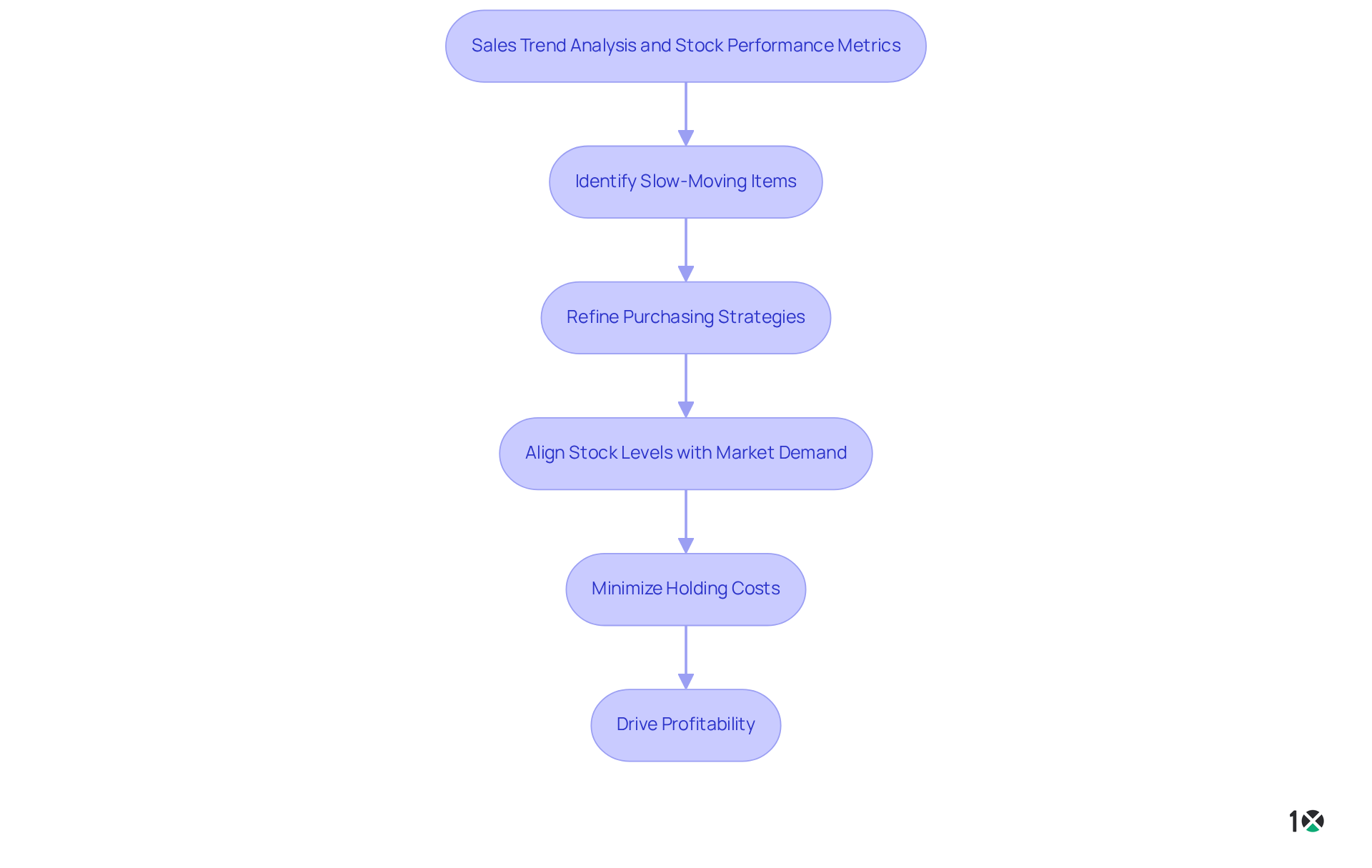

empowers distributors to by leveraging insights derived from and stock performance metrics through the use of . By systematically analyzing this data with inventory control software, businesses can identify slow-moving items and . This proactive approach not only aligns stock levels with market demand through but also , ultimately driving profitability.

For instance, Iris Chan, founder of Cote d’Or Fine Wines, underscored the importance of technology in , stating, “Being tech-savvy, and with her extensive wine industry experience, I knew exactly what I needed.” By implementing a tailored ERP solution like 10X ERP and incorporating inventory control software, Cote d’Or Fine Wines improved their stock management, achieving HK$20M in revenue within a year of implementation. Statistics reveal that companies utilizing inventory control software for sales trend analysis can reduce surplus stock by up to 30%, highlighting the critical role of in stock management.

By adopting such strategies, suppliers can ensure their operations remain agile and responsive to market fluctuations.

Gain Visibility and Control: Monitor Stock Levels in Real-Time

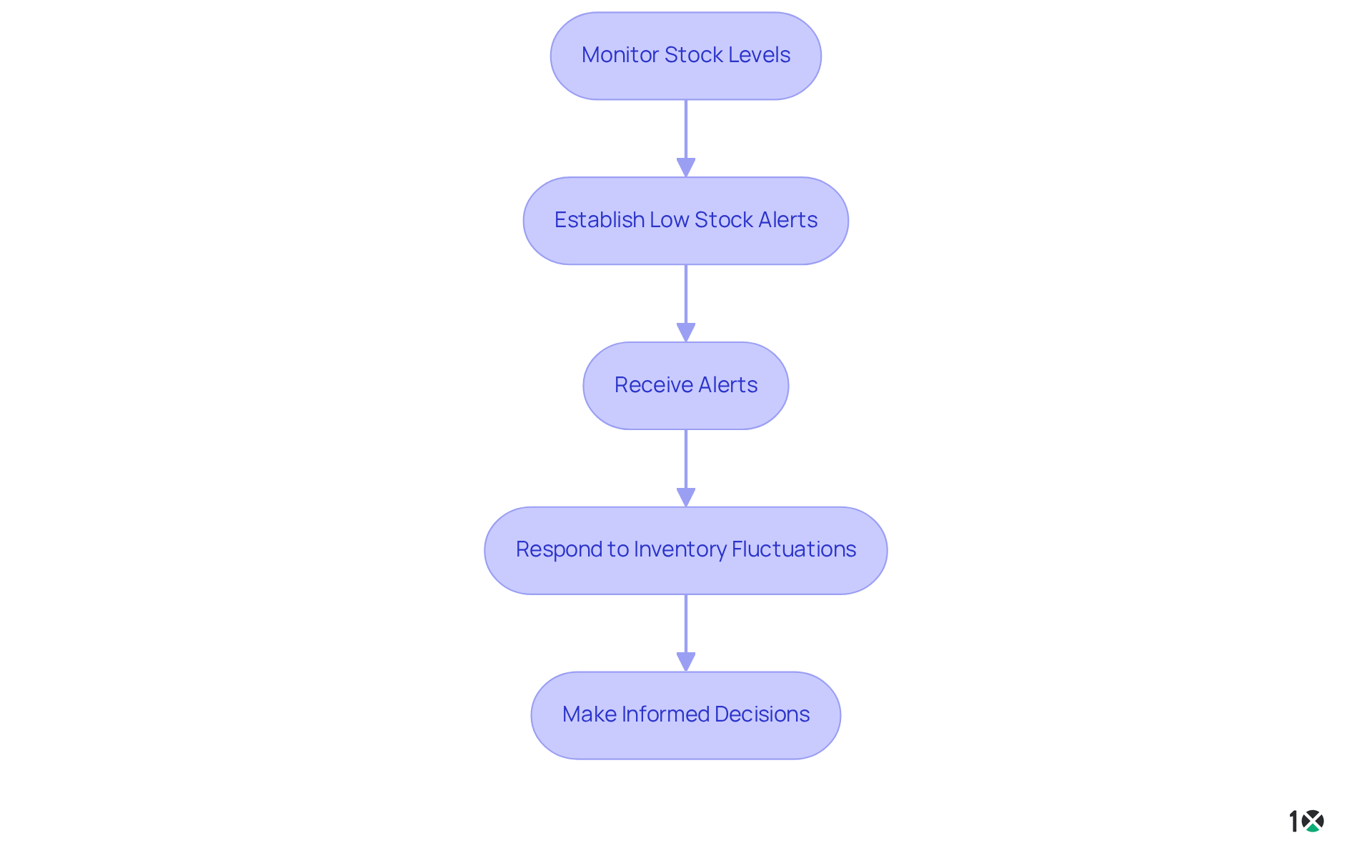

via empowers suppliers to maintain precise control over their . By establishing alerts for low stock levels, users can ensure , effectively preventing stockouts that could disrupt operations. This proactive strategy not only boosts but also facilitates . For instance, distributors leveraging real-time item-level visibility have reported improved stock turnover and reduced carrying costs, as highlighted in recent case studies.

Bart De Muynck, a member of the Forbes Technology Council, underscores that achieving is crucial for effective stock management. Furthermore, utilizing inventory control software to configure allows companies to respond swiftly to , safeguarding profitability and enhancing customer satisfaction. To implement alerts for low stock levels, users can easily set thresholds within the , ensuring they receive timely notifications that support informed decision-making and operational agility, particularly in managing distributed supplies and complying with food safety regulations.

Leverage Technology: Utilize Advanced Tools for Inventory Optimization

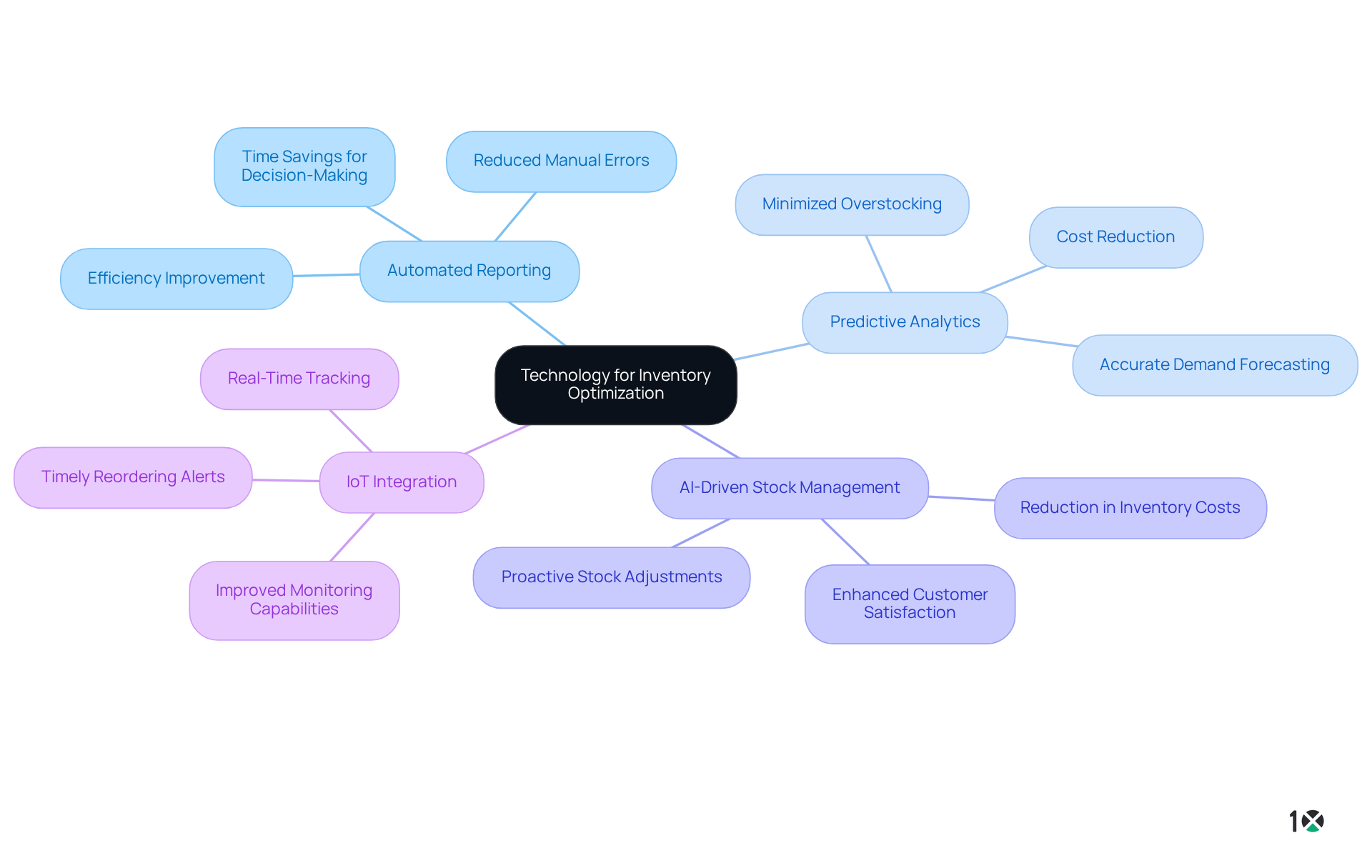

10X ERP equips suppliers with advanced tools, including and , which significantly enhance the efficiency of for stock management. Predictive analytics empowers companies to accurately forecast demand, enabling proactive adjustments to stock levels and preventing shortages or excess inventory by utilizing inventory control software. For instance, firms leveraging AI-driven stock management have reported an average reduction of 25% in stock expenses, while distributors utilizing these analytics have noted a 30% decrease in surplus stock alongside a notable improvement in customer satisfaction ratings.

Automated reporting simplifies , minimizing manual errors and liberating valuable time for strategic decision-making. This efficiency is critical, as studies reveal that employees frequently spend 60% to 80% of their time searching for data, resulting in considerable , as highlighted by Dan Vesset. By integrating seamlessly with other software systems, , promoting a cohesive workflow that ensures all operational components are synchronized and data-driven decisions are made promptly. Furthermore, the importance of and monitoring through IoT integration cannot be overstated, as it further enhances . As we approach 2025, the relevance of these technologies will only grow, with to refine their stock management processes and .

Customize and Scale: Tailor Inventory Solutions to Your Business

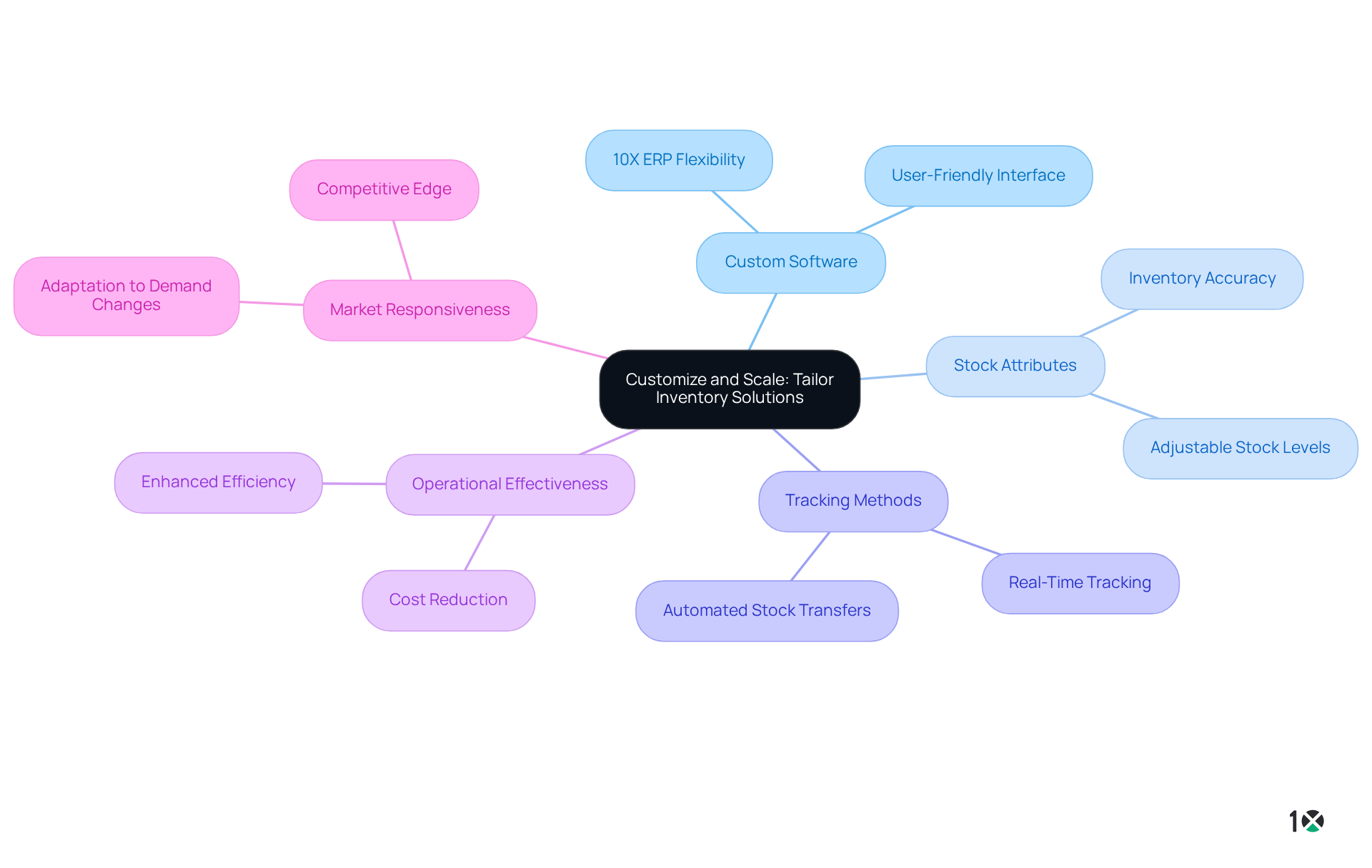

10X ERP empowers suppliers to customize their to meet their specific needs. By adjusting stock attributes or implementing distinct , the inherent flexibility of inventory control software allows businesses to without sacrificing efficiency. This is vital for suppliers aiming to expand while preserving their . In a rapidly changing marketplace, the ability to tailor solutions not only but also positions businesses to .

Forecast Demand Accurately: Anticipate Needs to Avoid Stockouts

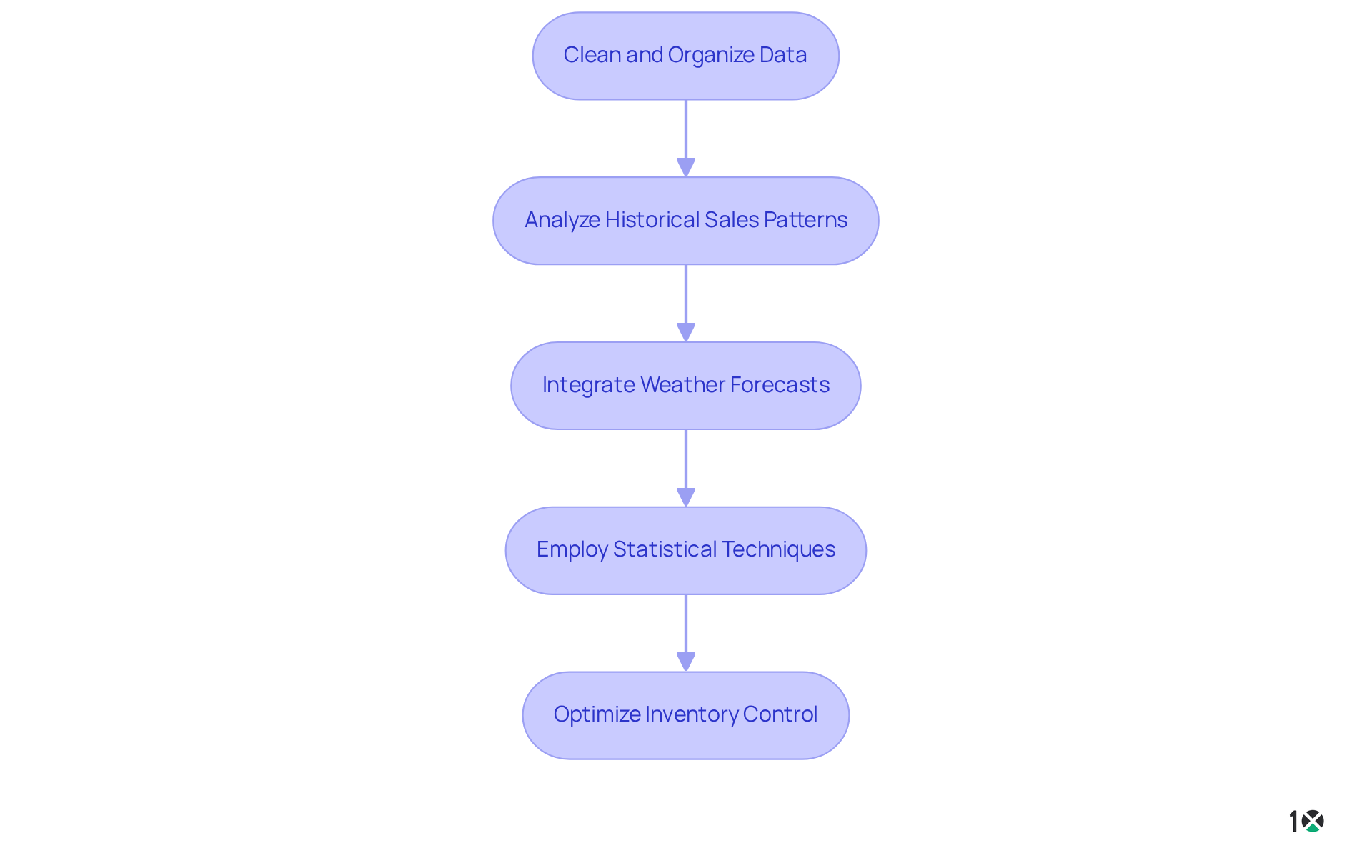

The forecasting capabilities of empower suppliers to leverage for precise . This proactive approach is vital for , guaranteeing that the right products are accessible when customers require them. Prior to analysis, it is essential to clean and organize the data, ensuring accuracy and reliability in forecasting. By scrutinizing previous , suppliers can anticipate customer needs, leading to and optimized stock levels.

For instance, a beverage distributor effectively combined weather forecasts with historical data and employed statistical techniques such as moving averages to forecast sales surges, thereby ensuring sufficient stock during peak demand periods. Such not only bolster stock availability but also improve , allowing businesses to respond swiftly to market fluctuations and customer preferences.

Furthermore, the of 10X ERP facilitates seamless integration with other software, enhancing operational capabilities and supporting .

Implement Effective Control Methods: Optimize Your Inventory Practices

Implementing effective control methods, such as ABC analysis and cycle counting, is crucial for enhancing stock accuracy. These practices are not merely suggestions; they are essential strategies for .

by providing robust tools that facilitate regular audits and stock assessments. By refining , suppliers can significantly minimize discrepancies, ultimately .

This proactive approach not only streamlines processes but also and reliability in .

Maximize Efficiency: Unlock the Full Potential of Inventory Control Software

To maximize efficiency with , distributors must leverage the platform’s latest features, including:

- Seamless integration with other business systems

Immediate data enhances clarity in warehouse activities, enabling more and . Regular training sessions are essential; in fact, 88% of employees using automation tools trust their accuracy and reliability. This trust ensures that users are proficient in the software’s functionalities and can adapt to updates effectively. By fully harnessing the potential of , businesses can achieve . A compelling case study on illustrates the benefits of transitioning to an , demonstrating how inventory control software can lead to increased efficiency and a reduction in manual errors.

Conclusion

The integration of inventory control software, particularly through platforms like 10X ERP, revolutionizes distribution efficiency by harnessing real-time data and advanced analytics. This technology streamlines stock management and empowers businesses to respond effectively to market demands, ensuring competitiveness in an ever-evolving landscape.

Key insights from the article highlight the multifaceted benefits of such software:

- Significant cost reductions

- Enhanced customer service

- Improved inventory turnover

By automating processes and providing accurate data, distributors can minimize overhead expenses, elevate customer satisfaction through reliable stock information, and make informed decisions that align inventory levels with actual demand. Furthermore, the ability to customize and scale these solutions allows businesses to adapt swiftly to changing market conditions, reinforcing operational agility.

Ultimately, embracing advanced inventory control software is not merely a choice but a strategic necessity for distributors aiming to optimize their operations. The call to action is clear: leveraging these technologies can lead to substantial improvements in efficiency, cost savings, and customer loyalty. As the industry continues to evolve, those who prioritize effective inventory management will undoubtedly position themselves for long-term success.

Frequently Asked Questions

What is 10X ERP and how does it benefit inventory management?

10X ERP is an inventory control software that utilizes real-time data processing to help distributors track stock levels, sales, and orders instantly. This allows for swift responses to demand fluctuations, minimizing risks of stockouts and overstock situations.

How does real-time data processing improve decision-making for distributors?

By leveraging cloud technology, users can access current information from any location, enhancing decision-making and operational agility.

What impact does effective stock management have on order fulfillment rates?

Companies with improved stock management systems can anticipate a 30% increase in order fulfillment rates, reducing delivery delays and enhancing customer satisfaction.

Can you provide an example of a company that benefited from real-time data analytics?

Coca-Cola reported a 20% decrease in storage expenses within the first year of adopting real-time data analytics, illustrating the advantages of integrating advanced data solutions.

What is the projected market value for inventory control software by 2029?

The inventory control software market is projected to reach an estimated value of $4.8 billion by 2029.

How does 10X ERP help in minimizing overhead expenses?

10X ERP helps minimize overhead expenses by automating stock monitoring and reorder processes, ensuring that businesses maintain only essential stock levels, which cuts storage costs and enhances cash flow.

What are the financial advantages of using inventory control software?

Inventory control software can lower carrying expenses by 20-30% and reduce stockout occurrences by 35-45%, leading to significant financial benefits.

How does real-time data analysis affect demand prediction?

Real-time data analysis enhances demand prediction precision by 40%, allowing suppliers to align stock levels with actual demand, further reducing overhead expenses and boosting profitability.

What is the onboarding process like for 10X ERP?

The rapid onboarding process of 10X ERP allows businesses to quickly start reaping the benefits of its features, ensuring minimal downtime and maximizing operational efficiency.

How does 10X ERP enhance customer service?

10X ERP enables suppliers to provide real-time stock availability information, allowing sales teams to confidently commit to delivery schedules and product availability, which fosters customer trust and satisfaction.