Summary:

- IoT-enabled sensors integrated with 10X ERP provide real-time, automated inventory tracking, eliminating manual counts and reducing human error.

- This live data improves forecasting, prevents stockouts, speeds up fulfillment, and enables smarter, data-driven decision-making across the business.

- 10X ERP’s API-friendly design allows seamless integration with various IoT devices, creating a scalable, responsive inventory management solution for distribution.

In the world of distribution, inventory accuracy can make or break your operations. A single missed stock count can lead to backorders, late shipments, and dissatisfied customers. To keep pace with demand and maintain razor-thin margins, distributors are increasingly turning to a powerful combination: IoT-enabled sensors and ERP systems.

At 10X ERP, we recognize that real-time visibility isn’t just a nice-to-have, it’s a competitive necessity. That’s why our platform is designed to facilitate seamless integration with Internet of Things (IoT) devices, enabling smarter, faster, and more accurate inventory tracking.

The Problem with Traditional Inventory Methods

Even in 2025, many distribution businesses still rely on outdated practices for inventory tracking, including manual counts, static spreadsheets, and legacy systems that update periodically rather than in real-time. These methods are not only time-consuming but also highly prone to human error.

If your team doesn’t know exactly what’s in stock—and where—it becomes difficult to fulfill orders promptly, optimize purchasing, or prevent overstocking and stockouts. This operational fog leads to increased carrying costs, wasted labor, and customer dissatisfaction.

How IoT Bridges the Gap

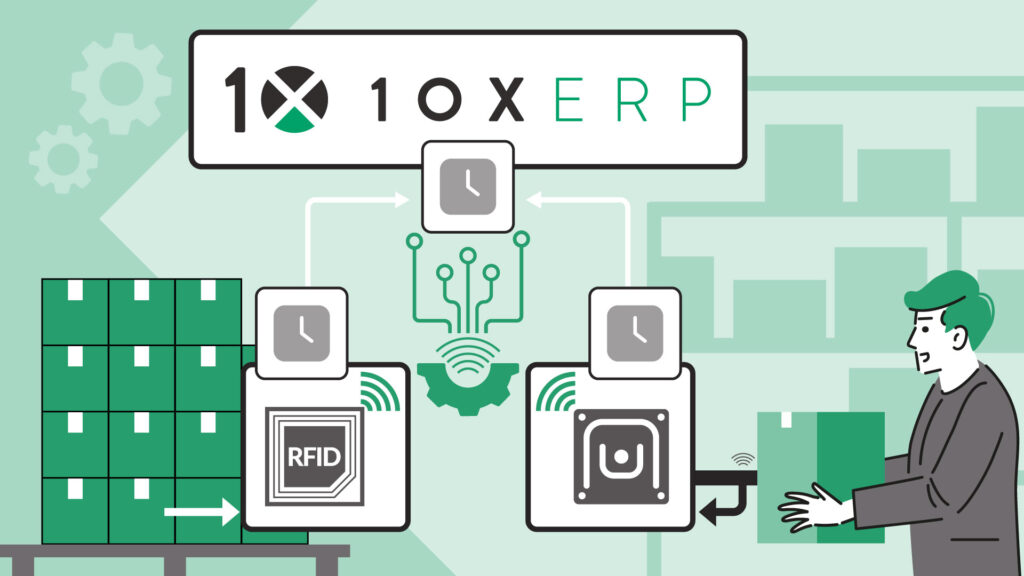

IoT, or the Internet of Things, refers to a network of connected devices that gather and transmit data automatically. In inventory management, this typically involves the deployment of smart sensors, RFID tags, beacons, and barcode scanners throughout warehouses, shelves, bins, and even delivery trucks.

When connected to an ERP system like 10X ERP, these devices create a live feedback loop that keeps inventory counts continuously up to date. Every item picked, moved, received, or shipped can be instantly logged without human intervention.

Real-Time Inventory Meets Real-World Distribution

Imagine this: a pallet of o-rings arrives at your warehouse. RFID sensors on the pallet instantly scan and register the incoming stock. That data is transmitted directly into 10X ERP, updating stock levels without a single keystroke.

Now, imagine a picker pulls a bin for a customer order. Weight sensors located beneath the bin detect changes and trigger an automatic stock adjustment in the system. Meanwhile, zone-based beacons monitor the location of items and equipment, helping you identify not only what you have, but exactly where it is in the facility.

All of this real-time data flows into the 10X ERP platform, giving your team accurate inventory visibility down to the second. No more guesswork. No more waiting for cycle counts.

Benefits Beyond the Warehouse

The impact of IoT-driven inventory tracking extends beyond warehouse operations:

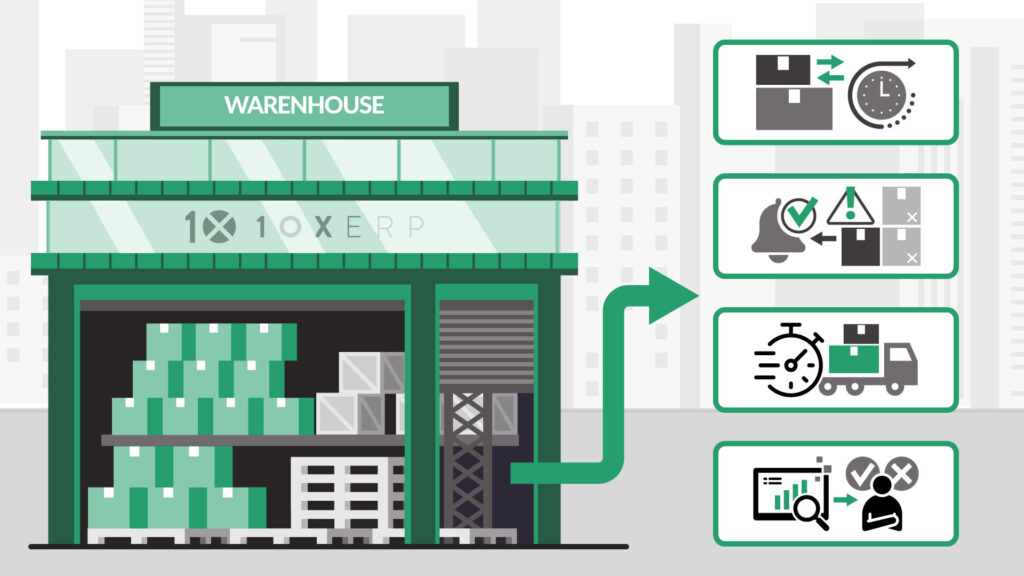

- Improved Forecasting: With accurate, real-time data, 10X ERP’s advanced reporting tools can generate better forecasts for purchasing and demand planning.

- Fewer Stockouts: Automated alerts can notify purchasing teams when items fall below threshold levels, preventing customer impact.

- Faster Fulfillment: Knowing exactly what’s in stock—and where—reduces picking time and ensures orders go out faster.

- Data-Driven Decisions: Executives can view inventory trends and movement across locations in real-time dashboards, informing smarter business decisions.

10X ERP: Built for Intelligent Integration

What sets 10X ERP apart is its modern, API-friendly architecture, which enables straightforward integration with a wide range of IoT devices. Whether you’re already deploying smart shelves or just starting to explore RFID tagging, our platform can accommodate your needs and scale with your operation.

Our ERP doesn’t just accept data from IoT devices—it’s designed to act on it. Stock movements are updated in real-time, alerts are triggered automatically, and reports reflect the most accurate information available at any given moment.

Getting Started with IoT and ERP

If you’re considering IoT inventory tracking for your distribution business, here’s how to begin:

- Assess your inventory challenges: Where are inaccuracies costing you the most—during receiving, picking, or shipping?

- Identify the right IoT tools: RFID, weight sensors, smart bins, or barcode scanners? We can help you evaluate what’s best for your needs.

- Integrate with 10X ERP: Our team will guide you through the integration setup to ensure a seamless data flow from devices to dashboards.

- Train your team: Even with automation, people matter. Equip your staff to work confidently alongside new technology.

Conclusion

Integrating IoT with ERP is more than just a technology upgrade—it’s a transformational shift in how inventory is managed. With 10X ERP at the core, distribution businesses gain not just better stock accuracy but a smarter, more responsive supply chain.

Ready to bring real-time precision to your inventory operations? Contact us to discover how 10X ERP can enhance your IoT strategy and optimize your distribution business.