Overview

This article outlines seven key benefits of utilizing a distribution processing center. These include:

- Enhanced operational efficiency

- Cost reduction

- Improved inventory management

- A superior customer experience

Such advantages arise from the centers’ capacity to streamline logistics, deliver real-time data insights, and adapt to market demands. Ultimately, these factors contribute to increased profitability and a competitive edge for businesses. By recognizing these benefits, Operations Managers can make informed decisions that drive success.

Introduction

Efficient distribution processing centers are revolutionizing the logistics and supply chain management landscape, offering a multitude of advantages for businesses aiming to enhance their operations. By optimizing processes and harnessing real-time data, these centers not only lower costs but also elevate service delivery, ultimately resulting in increased customer satisfaction. As companies navigate the complexities of contemporary distribution, the pivotal question emerges: how can organizations fully leverage the potential of these centers to secure a competitive advantage and foster sustainable growth?

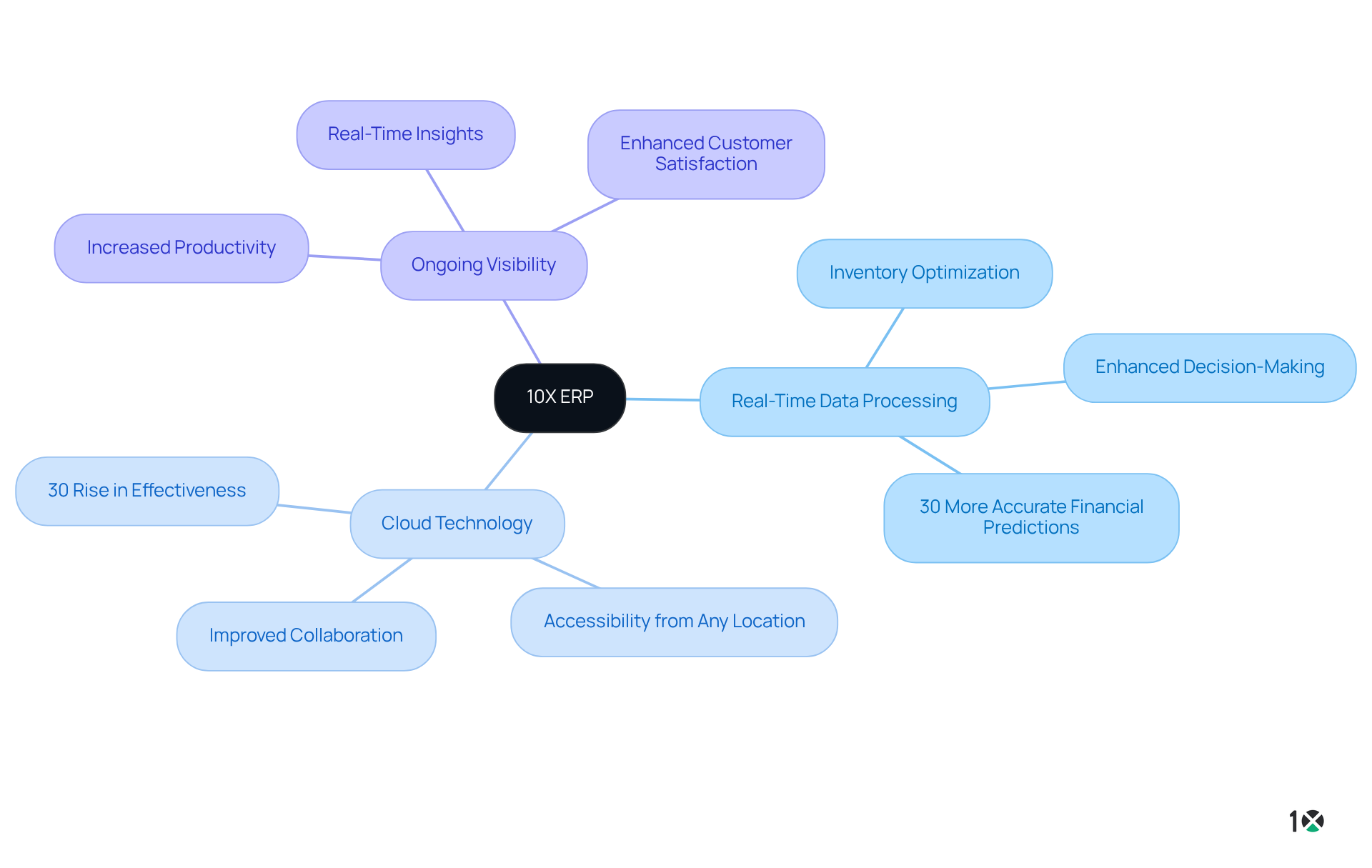

10X ERP: Enhance Operational Efficiency with Real-Time Data Processing

10X ERP empowers distributors by providing real-time data processing capabilities in their distribution processing center, delivering immediate insights into inventory levels, order statuses, and financial metrics. This feature enables companies to swiftly adapt to market changes, optimize inventory levels, and significantly enhance operational effectiveness. By leveraging cloud technology, 10X ERP ensures that critical data is accessible from any location, allowing teams to make informed decisions on the go. Organizations utilizing cloud-based ERP systems report a 30% rise in effectiveness across various departments.

Furthermore, businesses employing ongoing visibility achieve a comparable improvement, underscoring the significance of real-time insights in driving productivity and responsiveness. Expert opinions further highlight that cloud technology not only streamlines operations but also fosters collaboration among teams, ultimately leading to improved customer satisfaction and operational success.

To maximize these advantages, operations managers should consider adopting real-time data analytics tools to enhance decision-making and operational performance.

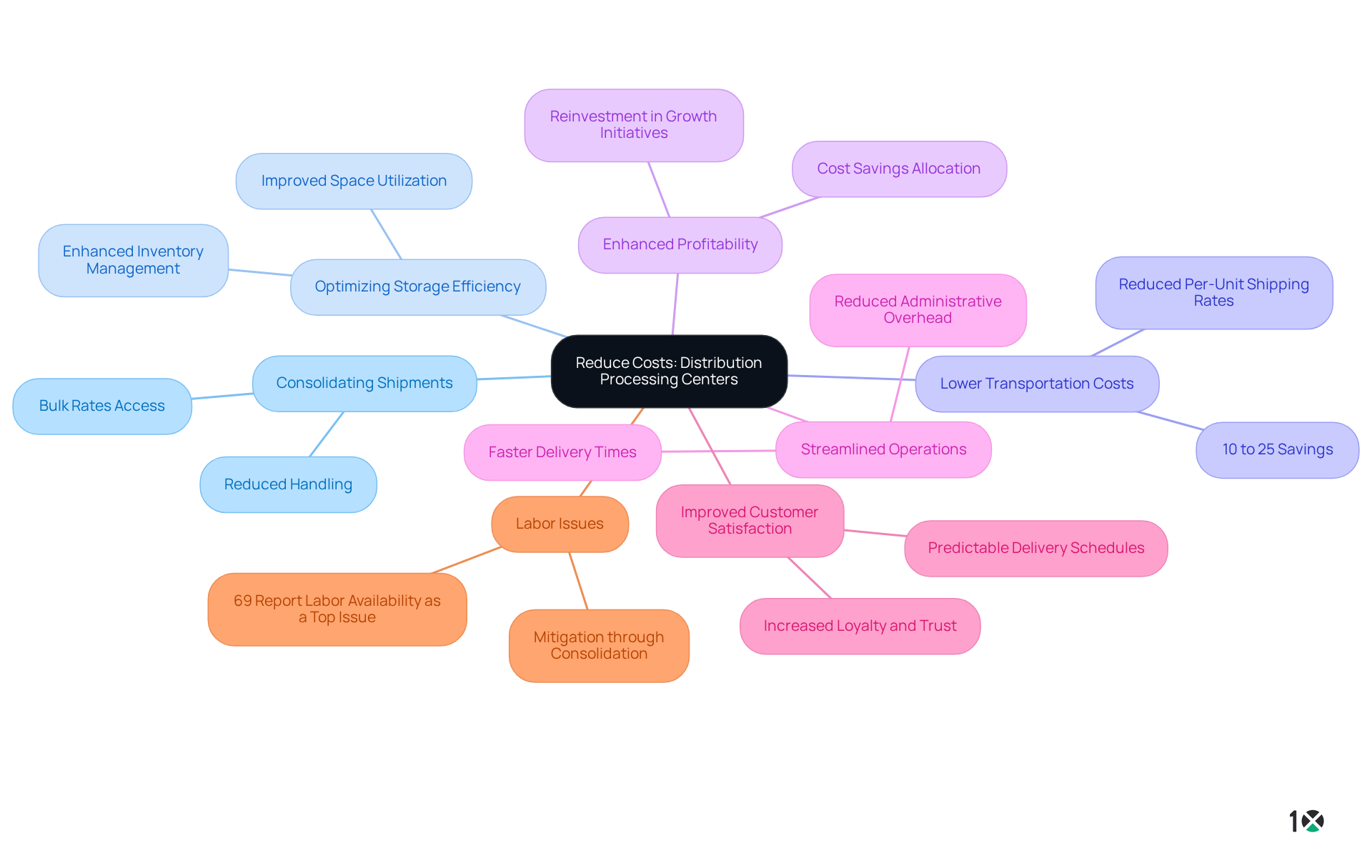

Reduce Costs: Achieve Significant Savings with Distribution Processing Centers

A distribution processing center is vital in reducing logistics costs by consolidating shipments and optimizing storage efficiency. By strategically managing inventory closer to demand centers, businesses can significantly minimize unnecessary handling and transit expenses. This approach not only lowers transportation costs but also enhances overall profitability. Inefficient distribution networks can lead to spiraling costs, with potential savings of 10% to 25% achievable through upgrades.

Furthermore, effective consolidation streamlines operations, reduces delivery times, and improves customer satisfaction, ultimately fostering loyalty and trust. Additionally, freight consolidation enhances shipment security and scheduling flexibility, allowing distributors to leverage these efficiencies to gain a competitive edge in the market. Notably, 69% of distribution processing centers report labor availability as a top issue, which consolidation can help mitigate. As a result, distributors can reinvest these savings into growth initiatives.

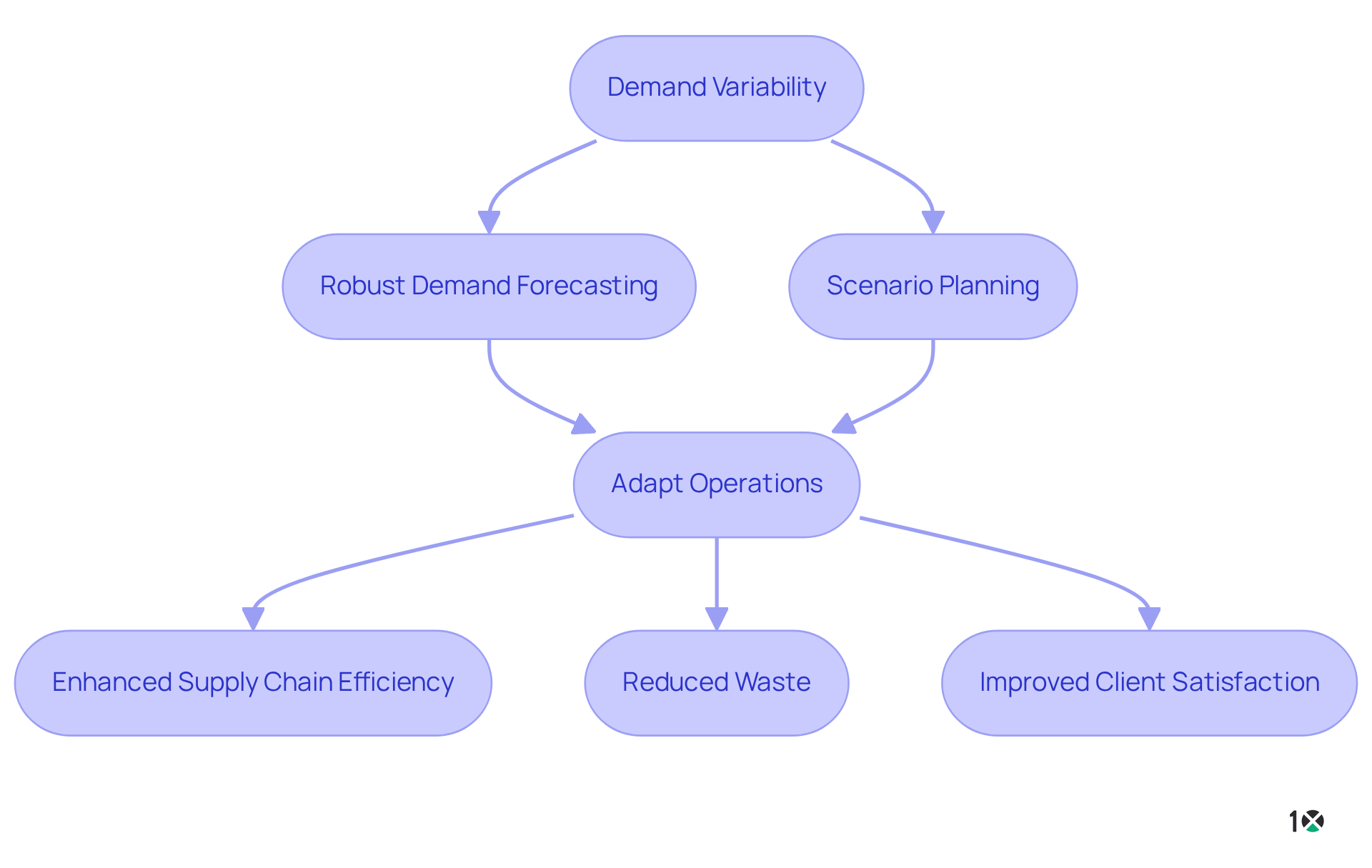

Scale Operations: Adapt and Grow with Flexible Distribution Processing Centers

Flexible distribution processing centers enable enterprises to effectively scale operations in response to demand fluctuations. These distribution processing centers have the ability to adapt their capacity and resources, enabling distributors to meet client demands without exceeding their budgets.

Companies that implement robust demand forecasting and scenario planning can anticipate changes and adjust their operations accordingly. Statistics reveal that effective management of demand variability can enhance supply chain efficiency, reduce waste, and improve client satisfaction.

Businesses that proactively address fluctuations often experience significant sales growth during peak periods. Demand variability can result in stockouts or delays in product delivery, making this adaptability essential for maintaining a competitive edge in today’s fast-paced market environment, where consumer preferences and economic conditions can shift rapidly.

A notable example is Zara’s fast fashion model, which exemplifies effective responsiveness to changes in consumer demand.

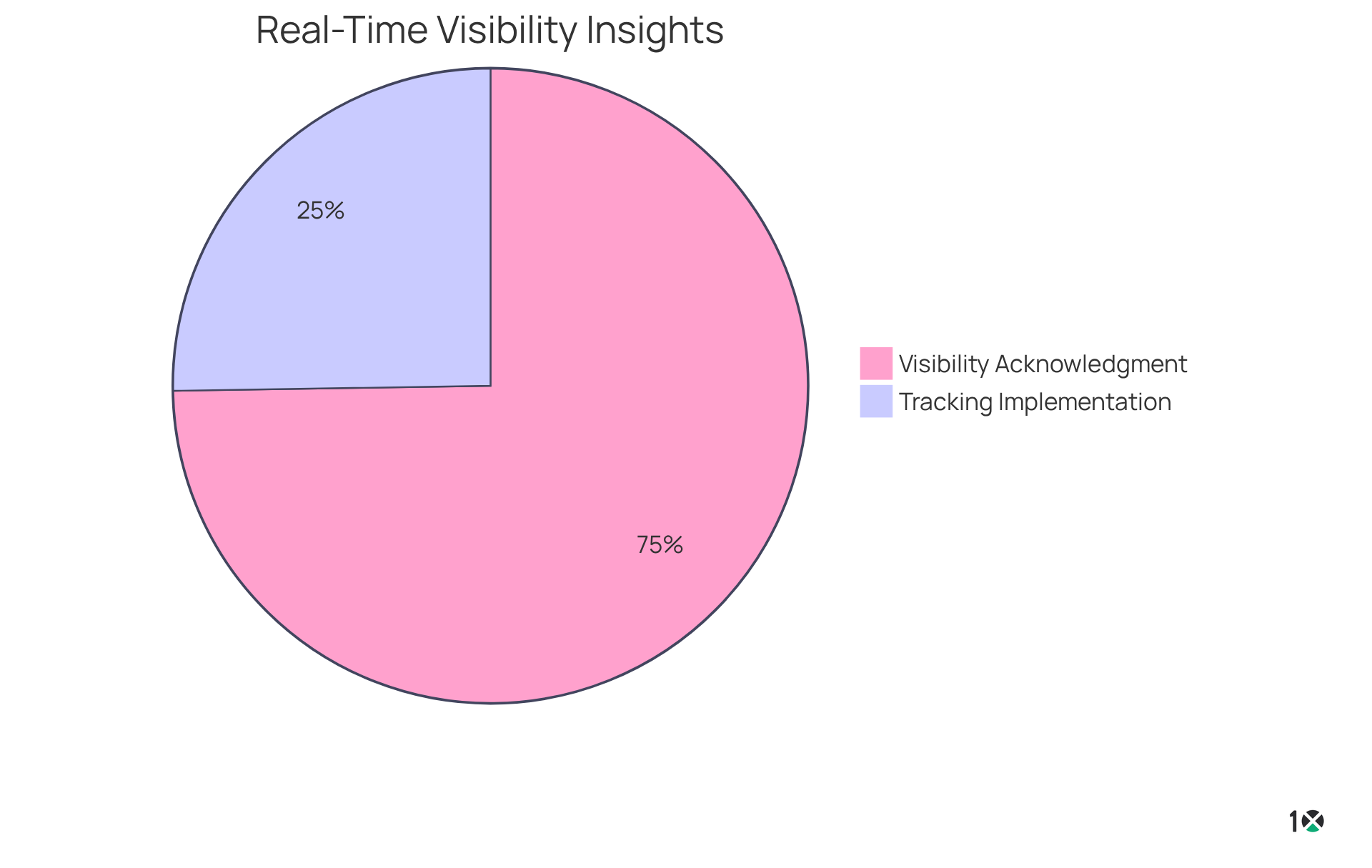

Improve Inventory Management: Streamline Stock Control with Distribution Processing Centers

Distribution processing centers significantly improve inventory management by offering real-time visibility into stock levels and movements. Advanced tracking systems empower businesses to monitor inventory with precision, effectively mitigating the risks of stockouts and overstock situations. Companies that utilize real-time tracking have reported improvements in client lead times by as much as 39%, underscoring the direct impact on service delivery (source: Business Wire). This streamlined approach not only boosts operational efficiency but also ensures that clients receive their orders promptly, fostering greater satisfaction and loyalty.

Moreover, with 74% of supply chain leaders acknowledging the critical role of real-time visibility (source: EY), adopting these systems is becoming essential for maintaining a competitive edge in the market. However, it is concerning that only 25% of supply chain and logistics leaders currently implement real-time tracking for their shipments, revealing a significant opportunity for enhancement. Additionally, 63% of companies do not utilize technology to monitor supply chain performance, highlighting the challenges many face in achieving effective real-time visibility.

Enhance Customer Experience: Deliver Faster and More Reliable Service

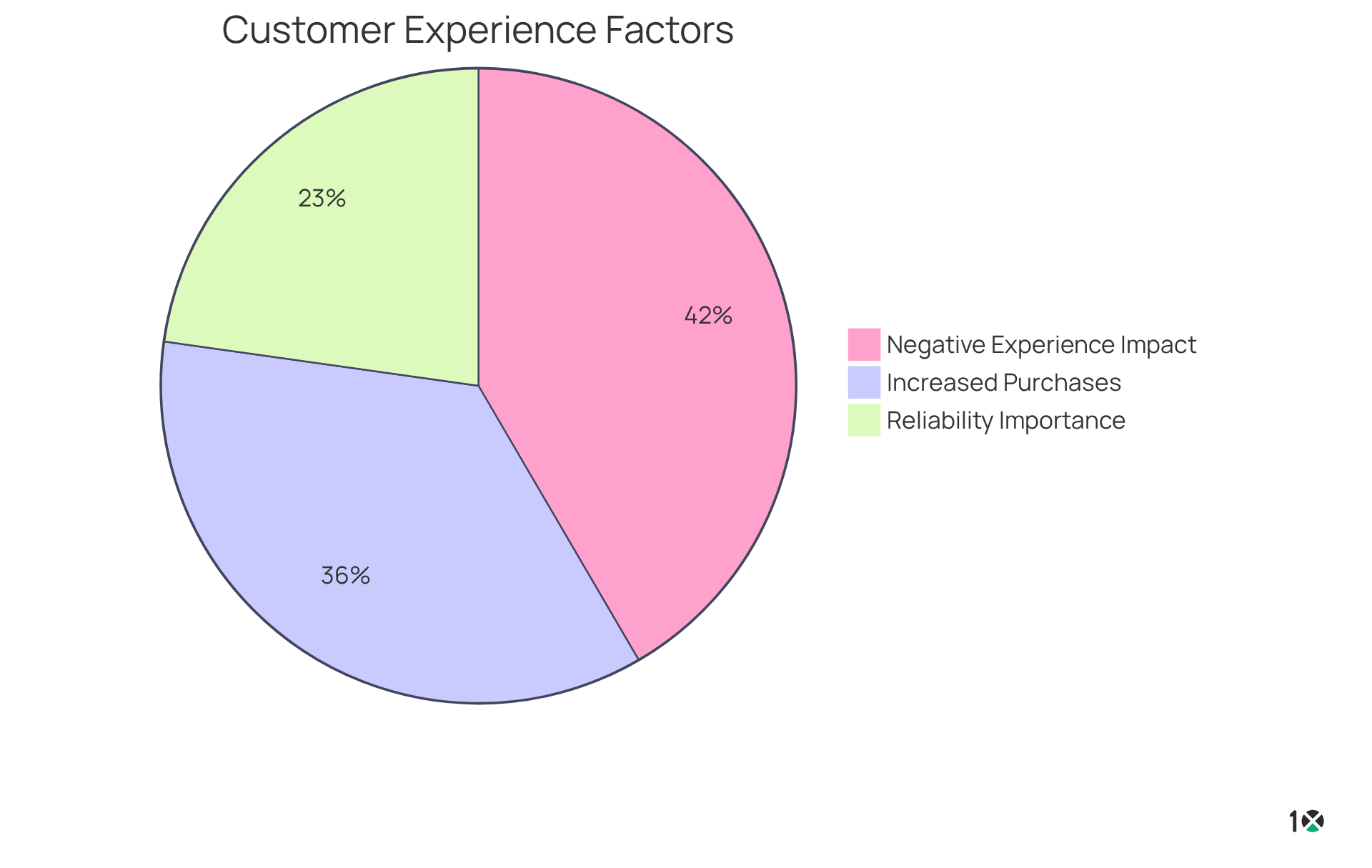

Employing a distribution processing center significantly enhances client experience by streamlining order fulfillment. These centers enable faster order processing and shipping, which translates to improved delivery times. For example, average delivery speeds have improved from 6.6 days in 2020 to approximately 3.7 days as of November 2024. This improvement highlights the effectiveness of distribution centers in meeting client expectations.

Reliability in service is paramount; 46% of online shoppers prioritize dependability when choosing retailers, and 84% of clients will not return after a negative delivery experience. Such reliability fosters trust and loyalty, which are essential for long-term business success.

Moreover, research indicates that 72% of clients satisfied with their delivery service are likely to increase their purchase levels by 12%. This statistic underscores the direct correlation between effective order handling and client loyalty. Companies such as WARRRL and Husk Bakery have successfully implemented real-time tracking systems, resulting in increased transparency and improved satisfaction metrics.

By investing in distribution processing centers, companies not only enhance operational efficiency but also cultivate a positive client experience that encourages repeat patronage.

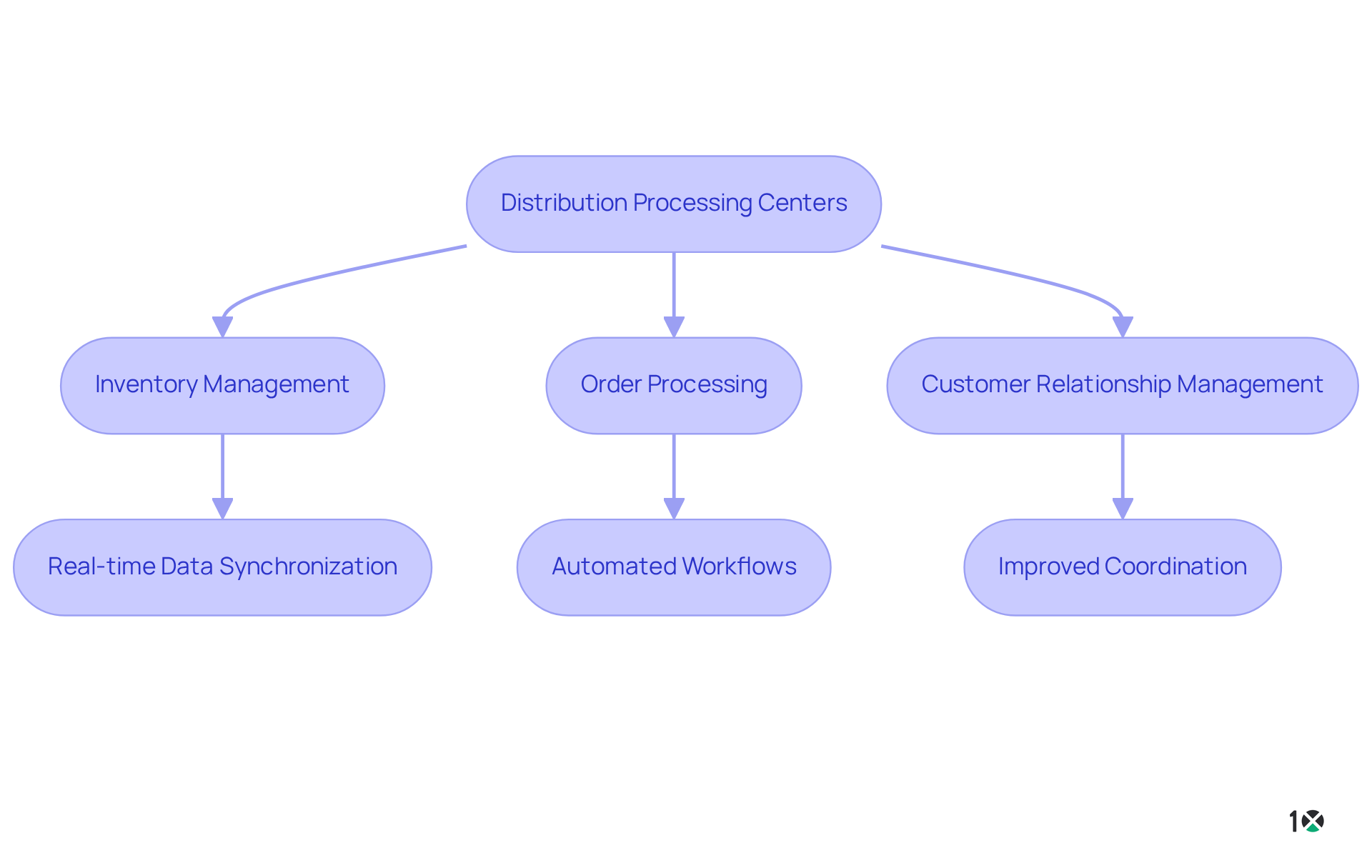

Integrate Systems: Achieve Seamless Operations with Distribution Processing Centers

Distribution processing centers play a crucial role in integrating systems like inventory management, order processing, and customer relationship management. This seamless integration minimizes errors and significantly boosts productivity. By fostering effective communication among all systems, organizations can streamline operations, leading to enhanced decision-making processes. For example, in inventory management, real-time data synchronization ensures accurate stock levels, thereby reducing the risk of overstocking or stockouts. In order management, automated workflows enhance order accuracy and speed, facilitating timely fulfillment. Moreover, in logistics management, seamless operations improve coordination between suppliers and distributors, optimizing delivery schedules and minimizing delays.

According to Data Bridge Market Research, the system integration market is projected to grow from USD 520.9 billion in 2025 to USD 1,521 billion by 2035, underscoring the growing importance of seamless operations. However, organizations often encounter challenges in maintaining integrations, with 50% reporting difficulties due to discontinued applications. The advantages of seamless operations extend beyond mere effectiveness; they foster a more agile and responsive corporate environment, essential for thriving in today’s competitive distribution processing center.

By leveraging the API-first strategy and real-time data management features of solutions like 10X ERP, organizations can effectively address these challenges and enhance their operational efficiency.

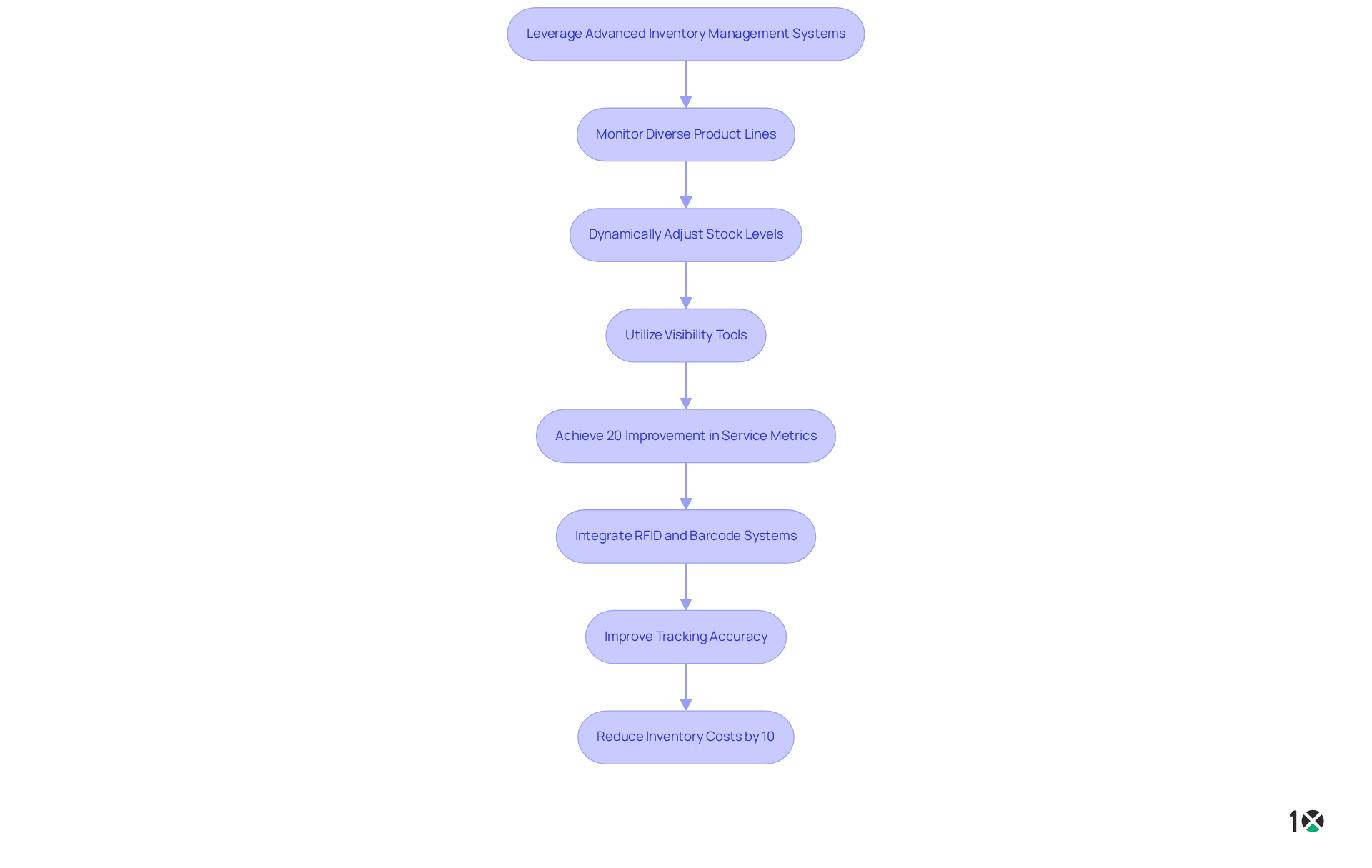

Achieve Flexibility: Manage Diverse Inventory with Distribution Processing Centers

Distribution processing centers play a crucial role in offering essential flexibility for effective inventory management. By leveraging advanced inventory management systems, businesses can monitor diverse product lines and dynamically adjust stock levels in response to fluctuating demand. This adaptability not only enhances operational effectiveness but also empowers distributors to swiftly respond to changing client preferences. For instance, organizations utilizing visibility tools have reported a remarkable 20% improvement in service metrics, showcasing how real-time data can significantly enhance responsiveness.

Moreover, the integration of technologies such as RFID and barcode systems markedly improves tracking accuracy and operational efficiency in inventory management. Consequently, distributors can maintain optimal stock levels and minimize costs associated with overstocking or stockouts—potentially reducing inventory costs by 10%—thereby enhancing overall customer satisfaction. This strategic approach not only streamlines operations but also positions businesses to thrive in a competitive marketplace.

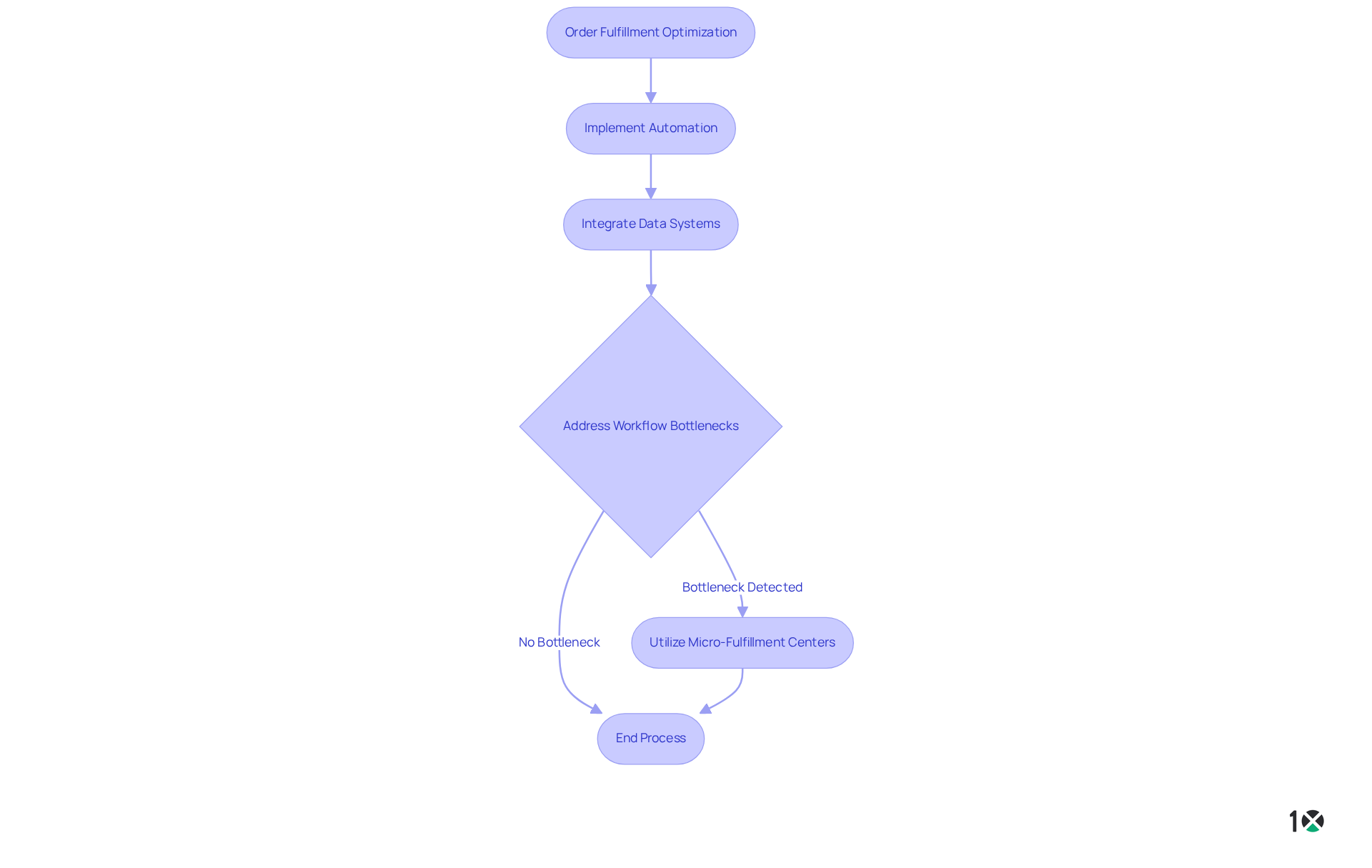

Accelerate Order Fulfillment: Speed Up Delivery Processes with Distribution Processing Centers

Distribution processing centers play a crucial role in expediting the processes of order fulfillment. By optimizing workflows and leveraging advanced technologies, businesses can substantially reduce order handling and shipping times. For instance, the implementation of automation can cut processing times by as much as 70% and decrease error rates from 5% to below 1%. This efficiency not only enhances customer satisfaction—77% of online shoppers expect delivery within two hours for certain products—but also establishes distributors as leaders in their respective markets.

Optimized workflows in a distribution processing center may encompass strategies such as integrating data systems to minimize errors and bolster order fulfillment capabilities. Statistics indicate that consolidating data systems leads to reduced errors and improved fulfillment effectiveness. Companies that offer two-day shipping experience 25% higher repeat purchase rates, underscoring the importance of speed in e-commerce. Moreover, as consumer preferences evolve, with over 40% of U.S. consumers expecting deliveries within two to three days, the need for effective order management becomes increasingly critical. Addressing workflow bottlenecks, which account for 32% of delivery delays, is essential for improving overall productivity. By adopting best practices and focusing on operational efficiency—such as the trend of micro-fulfillment centers in urban areas that position inventory closer to consumers—distributors can not only meet but exceed client expectations, thereby enhancing their competitive edge in the rapidly changing logistics landscape.

Leverage Data Analytics: Gain Insights for Better Decision-Making

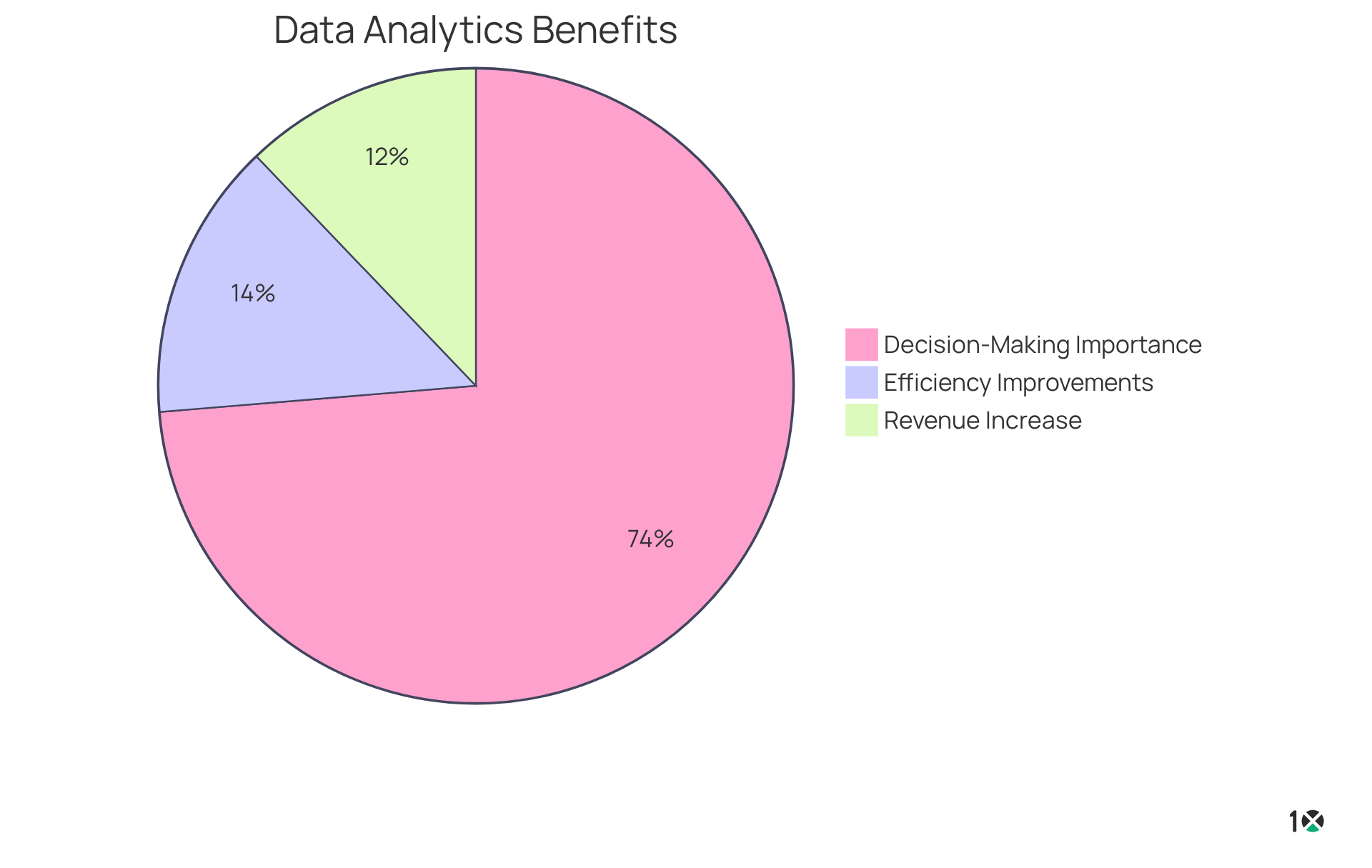

Leveraging data analytics empowers distribution processing centers to deliver critical insights that enhance superior decision-making. By examining data related to inventory levels, order patterns, and customer preferences, companies can identify trends and make proactive adjustments. This data-driven approach not only enhances operational productivity but also supports strategic planning. Notably, companies utilizing predictive analytics have reported an average revenue increase of 15%, while 91% of businesses affirm that data-driven decision-making is vital to their success. Furthermore, organizations that embrace data-driven cultures commonly experience operational efficiency improvements of 15-20%. As Jose A. Rodriguez-Serrano asserts, ‘Data-driven decision-making has become an essential strategy for companies aiming to optimize their operations and remain competitive.’ By harnessing data effectively, organizations can ensure optimal resource allocation and prioritize client satisfaction, positioning themselves to surpass competitors and achieve sustainable growth.

Gain Competitive Advantage: Stand Out with Efficient Distribution Processing Centers

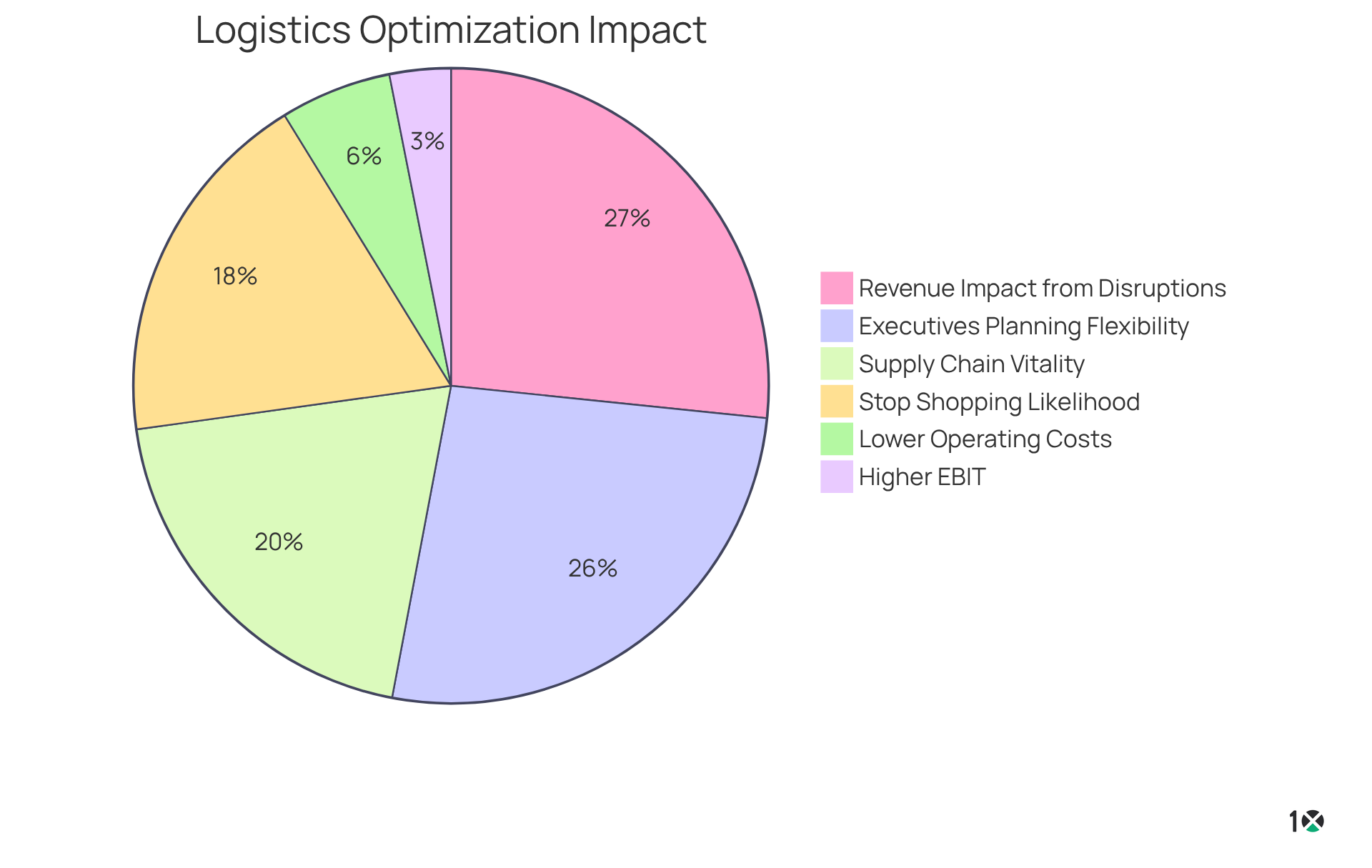

Efficient distribution processing centers enable businesses to achieve a significant competitive advantage by streamlining operations and enhancing service delivery. By optimizing logistics, companies can reduce costs and enhance client satisfaction—critical factors for differentiation in a saturated market. Organizations that embrace logistics optimization report up to 20% lower operating costs and 11% higher earnings before interest and taxes (EBIT). This not only increases profitability but also fosters loyalty among clients, as 65% of individuals are likely to stop shopping with a retailer after just two to three late deliveries.

Moreover, companies that effectively oversee their distribution procedures can swiftly respond to market needs, adapting to evolving consumer tastes and seasonal variations. This agility is crucial, particularly as 93% of senior supply chain executives plan to make their networks more flexible and resilient. By utilizing advanced tracking and real-time data, companies can ensure prompt order fulfillment, resulting in heightened customer satisfaction and repeat patronage.

In conclusion, the integration of efficient distribution processing centers not only streamlines operations but also helps businesses stand out in the marketplace, driving long-term success and growth. With 63% of organizations now employing digital tools to monitor and assess supply-chain efficiency, the trend towards digitalization is increasingly relevant. Furthermore, 94% of companies reported that their revenue was negatively impacted by supply-chain disruptions, underscoring the financial implications of inefficient distribution processes. Finally, 70% of companies consider their supply chain vital for delivering excellent customer service, reinforcing the direct link between efficient distribution processing centers and ensuring customer satisfaction.

Conclusion

Efficient distribution processing centers are indispensable for modern businesses aiming to enhance operational effectiveness and achieve sustainable growth. By integrating advanced technologies and real-time data processing, these centers streamline logistics while significantly elevating customer satisfaction, ultimately providing a competitive edge in a crowded marketplace.

The article outlines several key benefits of utilizing distribution processing centers. These include:

- Cost reduction through optimized logistics

- Improved inventory management with real-time tracking

- Accelerated order fulfillment processes

Furthermore, the flexibility offered by these centers empowers businesses to scale operations in response to market demands, while system integration fosters seamless communication and enhances overall productivity.

In conclusion, embracing the advantages of distribution processing centers is essential for any organization striving to thrive in today’s fast-paced business environment. By leveraging data analytics and adopting best practices, companies can not only meet but exceed customer expectations, ensuring long-term loyalty and success. Investing in these innovations will enable businesses to navigate challenges effectively, capitalize on opportunities, and ultimately secure their position as leaders in their respective industries.

Frequently Asked Questions

What is 10X ERP and how does it benefit distributors?

10X ERP enhances operational efficiency for distributors by providing real-time data processing capabilities. It offers immediate insights into inventory levels, order statuses, and financial metrics, allowing companies to adapt swiftly to market changes and optimize inventory levels.

How does cloud technology contribute to the effectiveness of 10X ERP?

Cloud technology ensures that critical data is accessible from any location, enabling teams to make informed decisions on the go. Organizations using cloud-based ERP systems report a 30% increase in effectiveness across various departments.

What role does ongoing visibility play in operational performance?

Ongoing visibility through real-time insights significantly improves productivity and responsiveness, leading to enhanced operational effectiveness.

What should operations managers consider to maximize the advantages of 10X ERP?

Operations managers should consider adopting real-time data analytics tools to enhance decision-making and operational performance.

How do distribution processing centers help in reducing logistics costs?

Distribution processing centers reduce logistics costs by consolidating shipments and optimizing storage efficiency, which minimizes unnecessary handling and transit expenses.

What potential savings can businesses achieve through upgrades to their distribution networks?

Businesses can achieve potential savings of 10% to 25% by upgrading their distribution networks, which can help lower transportation costs and enhance overall profitability.

How does effective consolidation benefit distributors?

Effective consolidation streamlines operations, reduces delivery times, improves customer satisfaction, enhances shipment security, and provides scheduling flexibility, giving distributors a competitive edge.

What challenges do distribution processing centers face regarding labor availability?

69% of distribution processing centers report labor availability as a top issue, which can be mitigated through consolidation.

How do flexible distribution processing centers support scaling operations?

Flexible distribution processing centers allow enterprises to scale operations effectively in response to demand fluctuations, adapting their capacity and resources to meet client demands without exceeding budgets.

What strategies can companies implement to manage demand variability?

Companies can implement robust demand forecasting and scenario planning to anticipate changes and adjust their operations accordingly, enhancing supply chain efficiency and improving client satisfaction.

Why is adaptability crucial for businesses in today’s market?

Adaptability is essential for maintaining a competitive edge as consumer preferences and economic conditions can shift rapidly, leading to stockouts or delays in product delivery if not managed effectively.