Overview

A Warehouse Management System (WMS) is defined as an advanced software application that significantly enhances warehouse operations. By streamlining stock oversight, order fulfillment, and shipping processes, WMS solutions are becoming increasingly vital in modern distribution. The implementation of a WMS not only leads to substantial operational efficiencies but also reduces labor costs and improves customer satisfaction.

Real-world examples and current market trends underscore a growing reliance on WMS solutions. As Operations Managers face the challenges of managing complex supply chains, the adoption of WMS is not just beneficial but essential. By investing in this technology, organizations can optimize their operations and position themselves for success in an ever-evolving marketplace.

Introduction

A Warehouse Management System (WMS) stands as the cornerstone of contemporary distribution, fundamentally transforming the management of goods within warehouses. By automating critical processes and enhancing visibility, WMS not only elevates operational efficiency but also markedly decreases costs associated with labor and inventory management. Yet, as organizations endeavor to implement these sophisticated systems, they encounter challenges such as employee resistance and integration complexities.

What strategies can organizations adopt to navigate these obstacles and fully harness the transformative potential of WMS within their supply chains?

Define Warehouse Management System (WMS)

A WMS warehouse Management System is an advanced software application designed to elevate warehouse operations and enhance coordination within distribution centers. It streamlines the oversight of stock, order fulfillment, and shipping procedures, guaranteeing that goods are stored, tracked, and dispatched effectively. WMS solutions vary significantly, encompassing everything from basic stock monitoring systems to that integrates seamlessly with other enterprise systems, including ERP and supply chain management tools. The primary objective of a WMS warehouse is to boost operational efficiency, minimize errors, and enhance stock accuracy, which collectively leads to improved customer service and satisfaction.

Real-world examples underscore the effectiveness of WMS in optimizing warehouse functionality. For instance, DHL’s Cherwell European healthcare center utilizes a specialized WMS to manage temperature-sensitive pharmaceutical products, demonstrating how tailored solutions can address specific industry needs. Moreover, companies like ShipBob have introduced solutions that empower e-commerce brands to leverage their global network, thereby enhancing operational capabilities through integrated WMS.

Current trends reveal a marked shift towards cloud-based WMS warehouse solutions, projected to grow at a CAGR of 20.6% from 2025 to 2030, reflecting a broader trend within the WMS warehouse market. The overall WMS market is anticipated to expand at a CAGR of 12.7% from 2025 to 2032. Additionally, the transportation and logistics segment is expected to experience a CAGR of 21.2% from 2025 to 2030, highlighting the rising demand for efficient warehousing solutions in response to the burgeoning e-commerce sector.

According to industry experts, the adoption of a WMS warehouse is becoming imperative for businesses aiming to enhance their supply chain operations. The integration of advanced technologies, such as automation and analytics, is also shaping the future of WMS, establishing it as a critical component for companies seeking to thrive in a competitive market.

Explore the Role of WMS in Modern Distribution

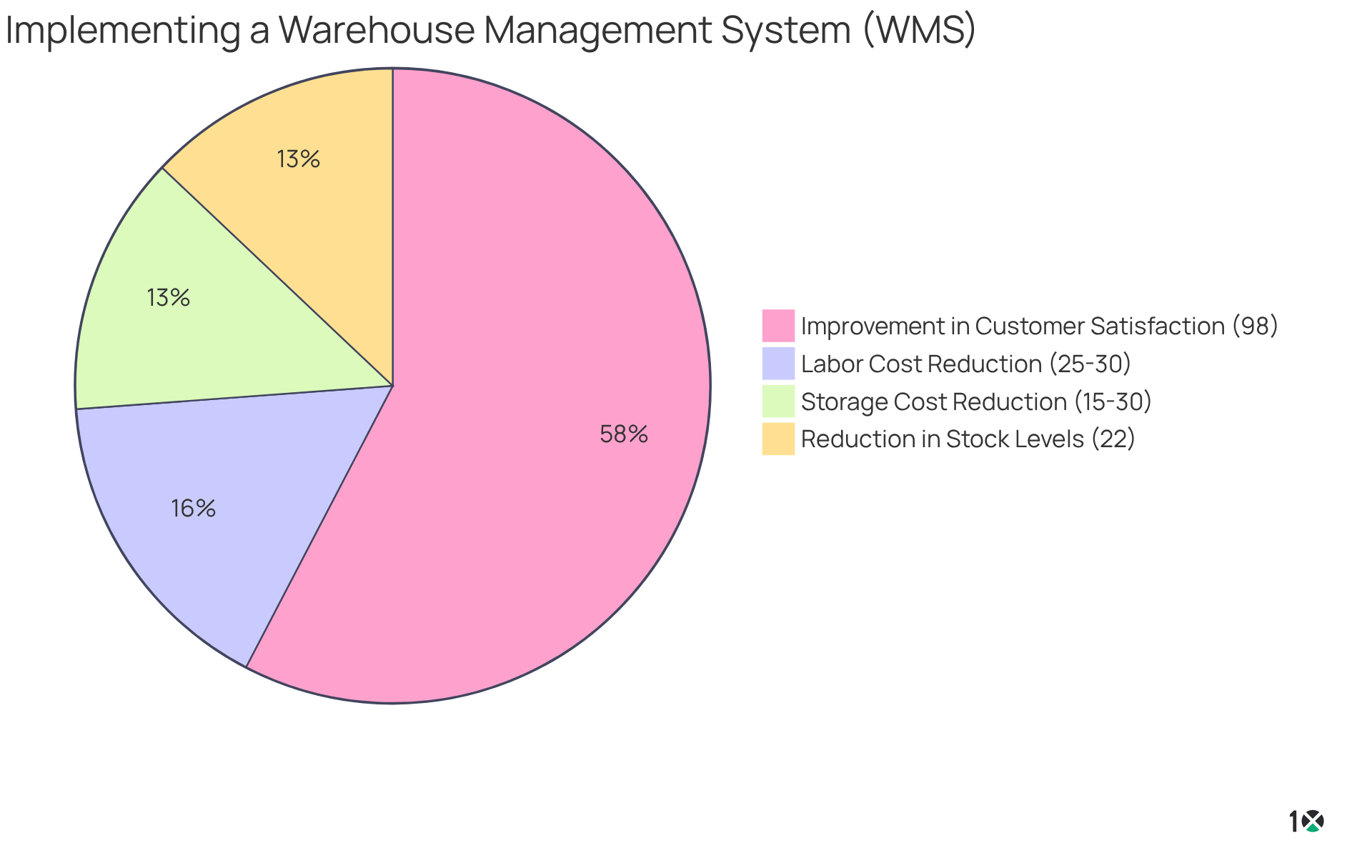

In contemporary distribution, a WMS warehouse is indispensable for optimizing operations and enhancing productivity. By automating critical processes such as stock monitoring, order selection, and shipping, WMS significantly reduces reliance on manual labor, which is often susceptible to errors. Companies that have adopted a WMS warehouse report a remarkable 20% to 30% reduction in labor costs, with automation in the WMS warehouse estimated to lower these costs by 25-30%. Furthermore, a 15% to 30% decrease in storage costs underscores the financial advantages of automation.

Real-time stock visibility empowers distributors to make informed decisions about inventory levels, effectively minimizing the risks of overstocking or shortages. Organizations leveraging a WMS warehouse have experienced an average reduction of 22% in stock levels, which highlights the tangible benefits of improved stock oversight. Additionally, WMS can seamlessly integrate with systems such as 10X ERP, facilitating a smooth flow of information throughout the supply chain. This integration ensures that all stakeholders have access to accurate data, thereby enhancing collaboration and responsiveness to market demands.

As a result, businesses can achieve greater efficiency, reduced operational costs, and increased customer satisfaction, with 98% of companies reporting an improvement in customer satisfaction after implementing a WMS warehouse solution. Moreover, companies with a WMS warehouse are 73% more likely to utilize data analytics to enhance operational efficiency, emphasizing the analytical advantages of adopting a WMS warehouse. With the projected to reach $869.32 billion by 2025, the significance of WMS in the evolving WMS warehouse landscape cannot be overstated.

Key Features of a Warehouse Management System

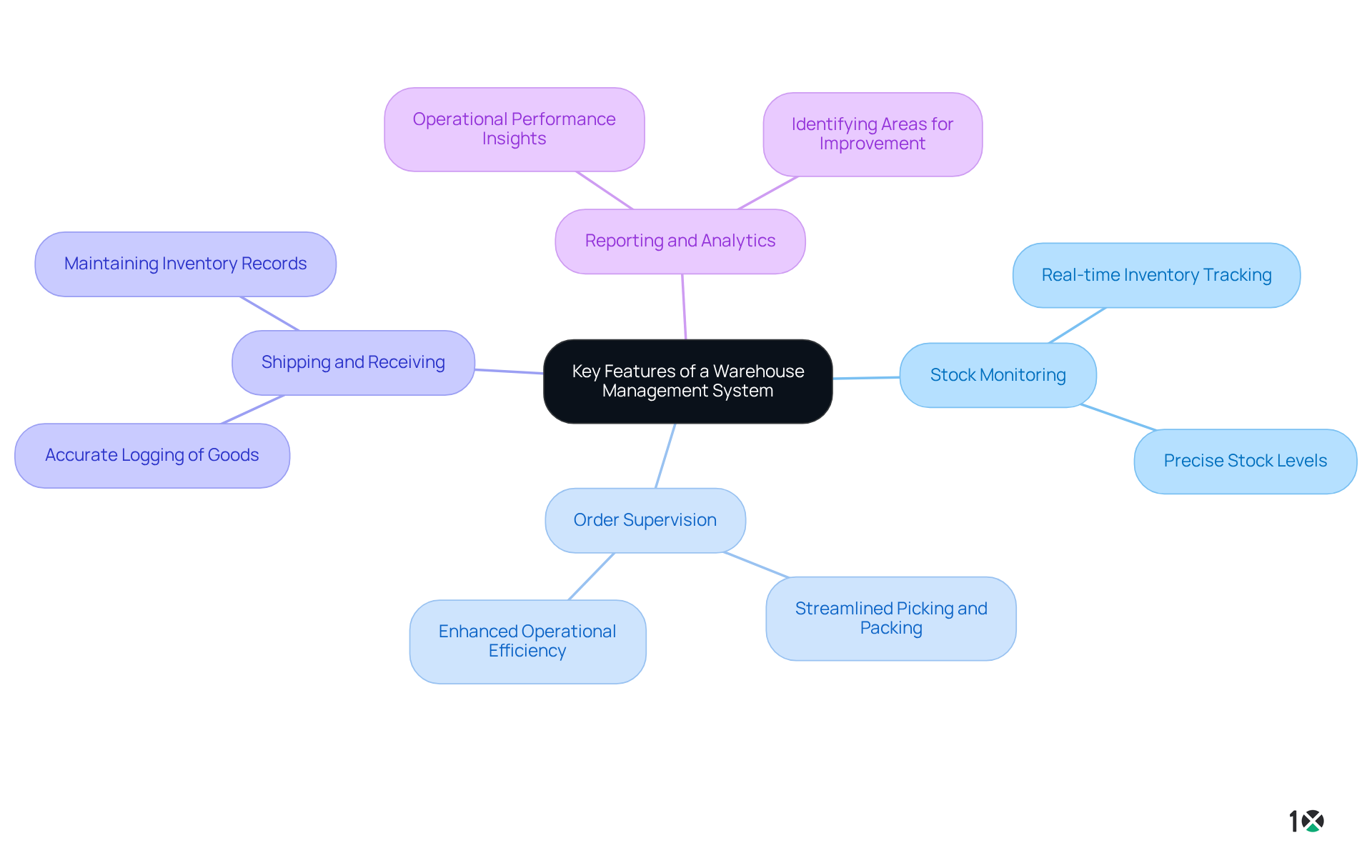

The essential aspects of a WMS warehouse Control System encompass:

- Stock monitoring

- Order supervision

- Shipping and receiving functionalities

- Robust reporting and analytics

First, inventory tracking empowers businesses to monitor stock levels in real-time, ensuring they remain informed about their resources. Next, order management streamlines the processes of picking, packing, and shipping products, enhancing operational efficiency. Furthermore, shipping and receiving functionalities guarantee that goods are accurately logged as they enter and leave the warehouse, maintaining precise inventory records. Finally, advanced reporting and analytics tools provide valuable insights into operational performance, enabling businesses to identify areas for improvement. Collectively, these features foster a more efficient and responsive warehouse environment, equipping distributors to effectively meet customer demands.

Benefits of Implementing a WMS

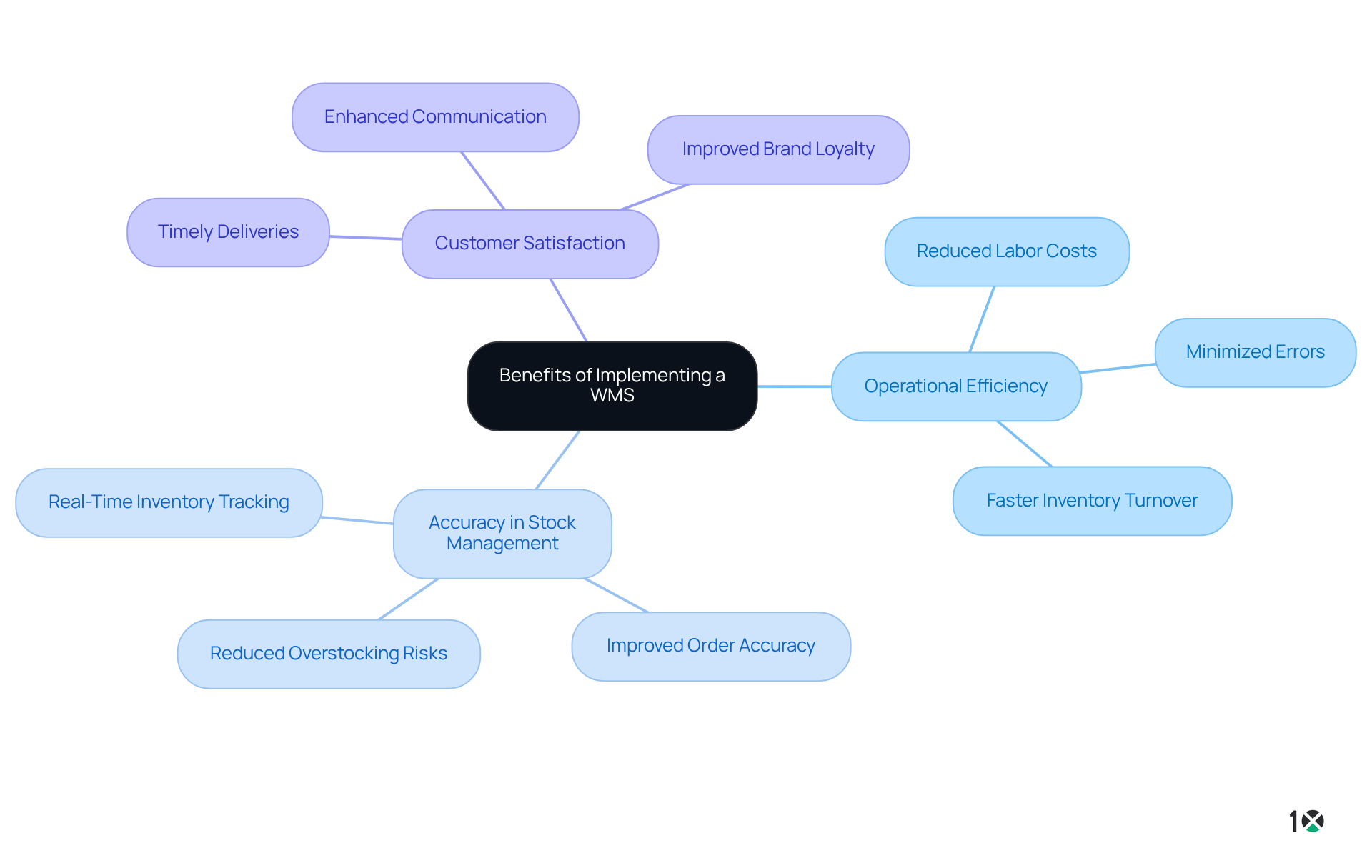

Implementing a WMS warehouse can offer substantial benefits that can transform your operations. These include:

- Heightened operational efficiency

- Enhanced accuracy in stock management

- Improved customer satisfaction

By automating manual processes, businesses can significantly reduce labor costs and minimize errors typically associated with human intervention. Furthermore, a WMS lowers staffing requirements by standardizing stock transportation, picking procedures, and storage areas.

The precision in stock management enables better control over supplies, effectively reducing the chances of shortages and surplus. Additionally, a WMS accelerates order fulfillment, directly boosting customer satisfaction through timely deliveries. Companies that have adopted WMS warehouse solutions often report significant improvements in their overall operational performance, such as minimizing back orders and mitigating overstocking risks via real-time inventory tracking.

Notably, 87% of businesses that have implemented WMS warehouse solutions indicate better order accuracy, underscoring the effectiveness of WMS warehouse technology in enhancing operational performance. Moreover, a WMS can elevate employee morale and productivity by simplifying processes and reducing physical strain. This makes it a strategic investment for distributors aiming to and enhance customer experiences.

Challenges in WMS Implementation

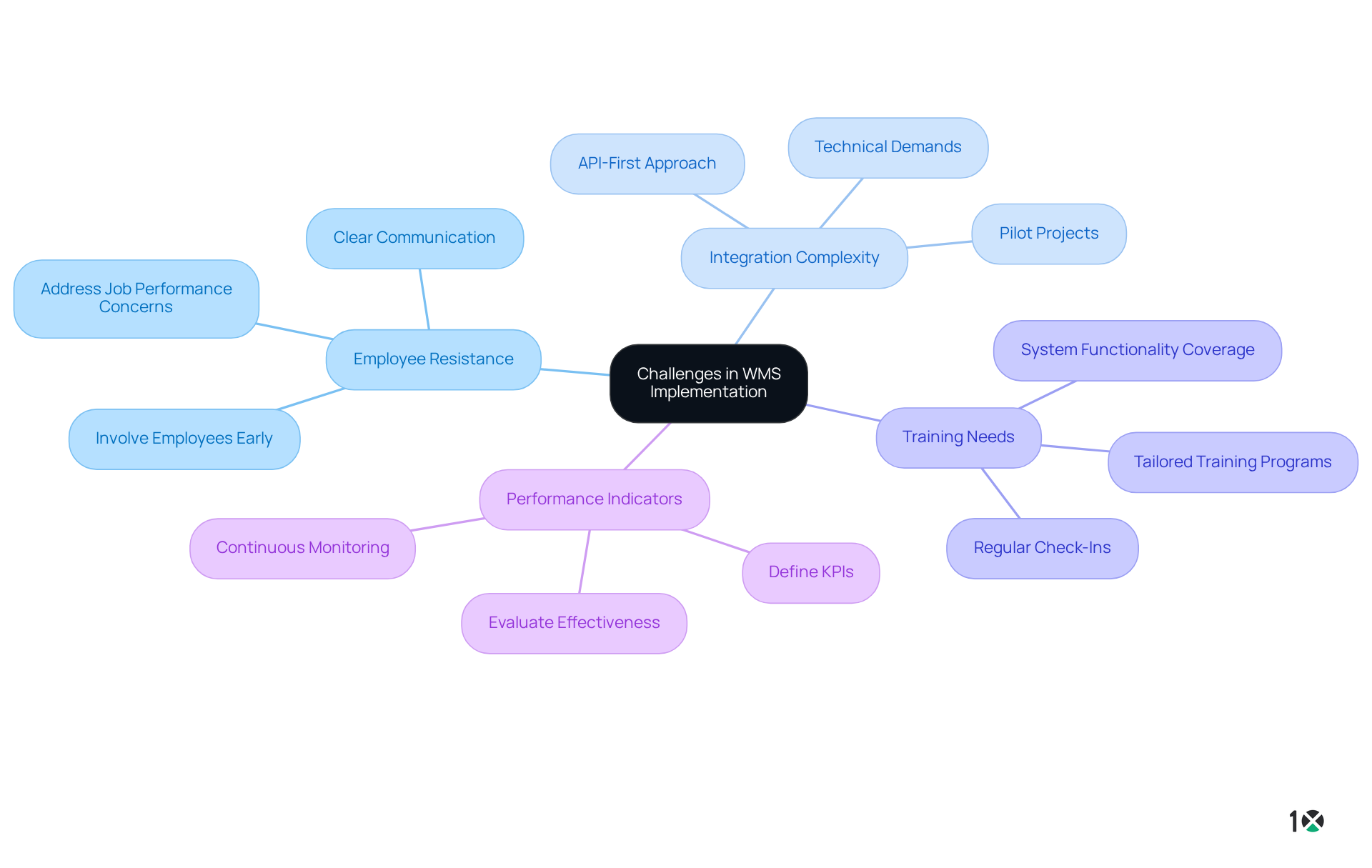

Implementing a WMS warehouse offers substantial advantages, yet it presents several challenges that organizations must navigate. A primary hurdle is the resistance to change from employees who may be accustomed to traditional methods. Research indicates that a significant portion of employees opposes new implementations, often due to concerns regarding job performance and productivity. To effectively address this, companies should involve employees early in the process, providing clear communication about the benefits of the new framework and its alignment with organizational objectives. As Keith Moore, CEO of AutoScheduler.AI, emphasizes, ‘Change initiatives can assist in guaranteeing a successful transition for new technology adoption within the warehouse.’

Another challenge lies in the complexity of integrating a WMS warehouse with existing software solutions, such as ERP applications. This integration can be technically demanding, necessitating a well-structured [change management approach](https://10xerp.com/blog/10-enterprise-resource-planning-software-solutions-for-distributors/). Organizations should consider pilot projects to test a smaller portion of the warehouse or specific processes in a controlled environment, enabling adjustments based on user feedback prior to full implementation.

Moreover, adequate training is crucial for a successful transition. Training programs must be tailored for various user groups, addressing functionality and its impact on daily operations. Regular check-ins with staff can facilitate the gathering of insights on new processes and help identify any inefficiencies early on. Additionally, defining key performance indicators (KPIs) related to warehouse performance is essential for evaluating the effectiveness of the new system. By proactively addressing these challenges through comprehensive training and effective communication, organizations can facilitate a smoother transition to the WMS warehouse, ultimately enhancing operational efficiency and productivity.

Conclusion

A Warehouse Management System (WMS) serves as a crucial tool that revolutionizes warehouse operations, significantly enhancing efficiency and accuracy in distribution processes. By integrating advanced technologies and automating essential functions, WMS solutions streamline inventory management and greatly improve order fulfillment and shipping procedures. This evolution in warehouse management is vital for businesses striving to excel in an increasingly competitive market.

The article underscores several key aspects regarding the role of WMS in contemporary distribution. It examines how automation:

- Reduces labor and storage costs

- Boosts stock visibility

- Elevates customer satisfaction

Real-world examples illustrate the practical applications of WMS, while current trends indicate a shift towards cloud-based solutions poised to dominate the market. Additionally, the challenges linked to implementing a WMS are addressed, highlighting the necessity for effective change management and employee training to facilitate a smooth transition.

Ultimately, the importance of a WMS cannot be overstated, as it acts as a cornerstone for optimizing supply chain operations. With the growing demand for efficient warehousing solutions, organizations must prioritize the adoption of WMS technologies to maintain competitiveness. Embracing these systems not only enhances operational performance but also positions businesses to better meet the evolving needs of their customers in a dynamic marketplace.

Frequently Asked Questions

What is a Warehouse Management System (WMS)?

A Warehouse Management System (WMS) is an advanced software application designed to enhance warehouse operations and coordination within distribution centers. It streamlines the oversight of stock, order fulfillment, and shipping procedures, ensuring effective storage, tracking, and dispatch of goods.

What are the primary objectives of a WMS?

The primary objectives of a WMS are to boost operational efficiency, minimize errors, and enhance stock accuracy, which collectively lead to improved customer service and satisfaction.

Can you provide examples of how WMS is used in real-world applications?

Yes, for instance, DHL’s Cherwell European healthcare center uses a specialized WMS to manage temperature-sensitive pharmaceutical products. Additionally, companies like ShipBob offer solutions that enable e-commerce brands to leverage their global network through integrated WMS.

What are the current trends in the WMS market?

There is a marked shift towards cloud-based WMS solutions, projected to grow at a CAGR of 20.6% from 2025 to 2030. The overall WMS market is anticipated to expand at a CAGR of 12.7% from 2025 to 2032, with the transportation and logistics segment expected to grow at a CAGR of 21.2% during the same period.

Why is adopting a WMS becoming imperative for businesses?

Adopting a WMS is becoming imperative for businesses aiming to enhance their supply chain operations, as it integrates advanced technologies like automation and analytics, which are critical for thriving in a competitive market.

How does WMS impact labor and storage costs?

Companies that adopt a WMS report a 20% to 30% reduction in labor costs, with automation estimated to lower these costs by 25-30%. Additionally, there is a 15% to 30% decrease in storage costs due to improved efficiency.

What benefits does real-time stock visibility provide?

Real-time stock visibility allows distributors to make informed decisions about inventory levels, minimizing the risks of overstocking or shortages. Organizations using WMS have experienced an average reduction of 22% in stock levels.

How does WMS integrate with other systems?

WMS can seamlessly integrate with systems such as 10X ERP, facilitating a smooth flow of information throughout the supply chain, which enhances collaboration and responsiveness to market demands.

What improvements do companies experience after implementing a WMS?

Companies report a 98% improvement in customer satisfaction after implementing a WMS solution. Additionally, those with a WMS are 73% more likely to utilize data analytics to enhance operational efficiency.

What is the projected market value of the global WMS market?

The global WMS market is projected to reach $869.32 billion by 2025, highlighting its significance in the evolving warehouse landscape.