Overview

Achieving real-time supply chain visibility is essential for organizations aiming to enhance operational efficiency and customer satisfaction. This goal can be accomplished by implementing four key steps:

- Assessing current systems

- Selecting integration tools

- Developing a data strategy

- Training your team

By strategically leveraging technologies such as cloud-based ERP systems, IoT devices, and data analytics tools, organizations can not only address challenges like data silos and resistance to change but also significantly improve their overall performance.

Consider the impact of your current systems. Are they equipped to provide the visibility you need? Selecting the right integration tools is crucial; they serve as the backbone for seamless data flow across your supply chain. Developing a robust data strategy will enable you to harness the power of your information effectively. Finally, investing in training for your team ensures that they are equipped to utilize these technologies to their fullest potential.

In conclusion, the path to real-time supply chain visibility is clear. By following these steps and embracing modern technologies, your organization can overcome existing challenges and thrive in an increasingly competitive landscape.

Introduction

Achieving real-time supply chain visibility has become a critical necessity for organizations striving to enhance operational efficiency and customer satisfaction. This concept encompasses not only the tracking of inventory and shipments but also the integration of advanced technologies that facilitate timely decision-making. However, many businesses encounter significant challenges in effectively implementing these solutions.

How can organizations overcome these obstacles? By harnessing the full potential of real-time visibility, they can transform their supply chain operations and drive substantial improvements.

Define Real-Time Supply Chain Visibility

Real time supply chain visibility is crucial for organizations aiming to optimize their operations. It encompasses the ability to achieve real time supply chain visibility by tracking and managing inventory, shipments, and overall supply chain activities in real time. With access to on stock levels, order statuses, and delivery timelines, businesses can react swiftly to changes, minimize delays, and enhance customer satisfaction.

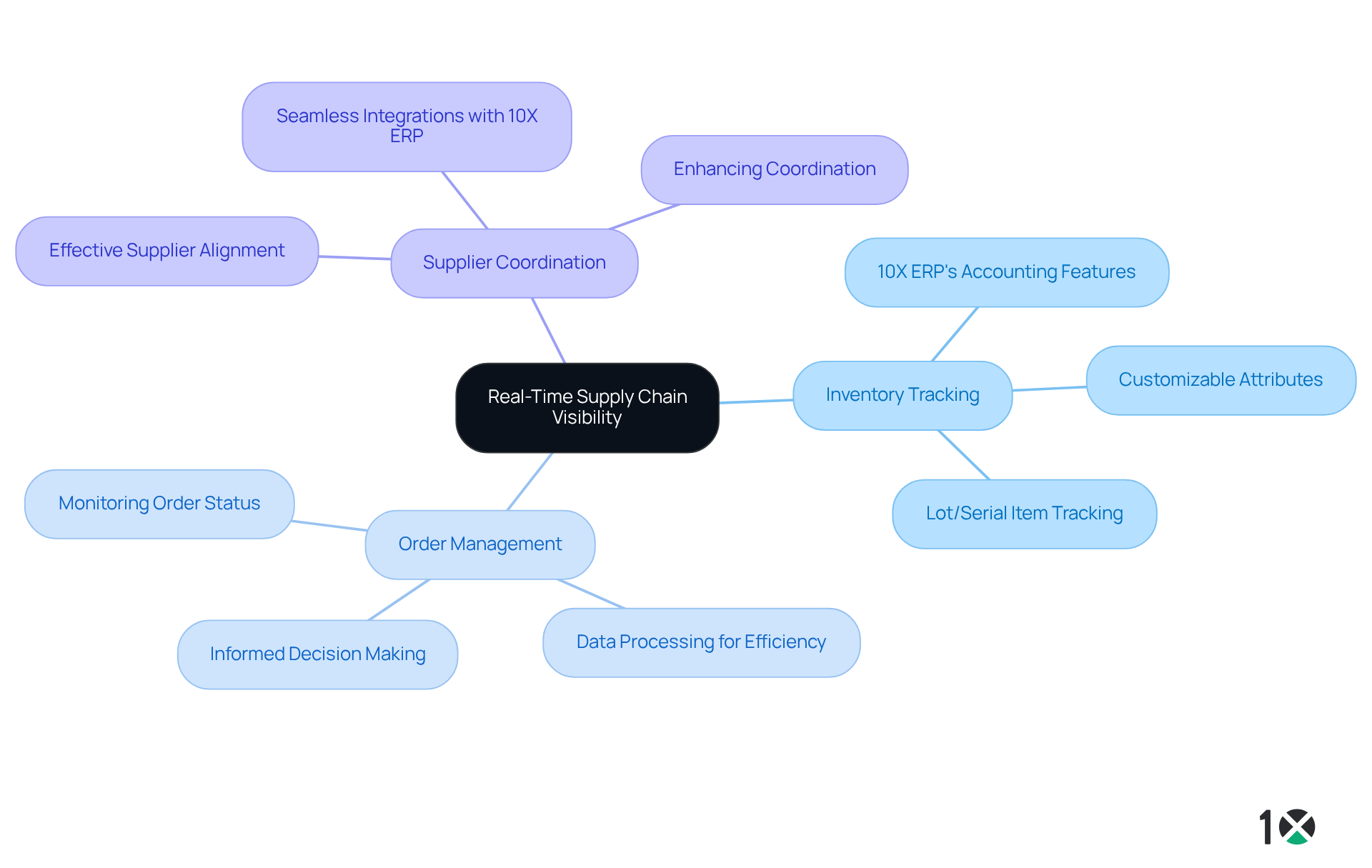

Key components of real-time supply chain awareness include:

- Inventory Tracking: This involves knowing the exact location and quantity of products at all times, facilitated by 10X ERP’s robust accounting features, which include customizable attributes and lot/serial item tracking.

- Order Management: Monitoring the status of orders from placement to delivery is essential. Real-time supply chain visibility enables stakeholders to make informed decisions through data processing, ensuring efficiency throughout the process.

- Supplier Coordination: Effective supplier alignment with your inventory needs and delivery schedules is vital. Leveraging the seamless integrations offered by 10X ERP can significantly enhance this coordination.

By clearly defining these elements, businesses can gain a comprehensive understanding of the necessary steps to implement real time supply chain visibility effectively.

Identify Key Technologies for Implementation

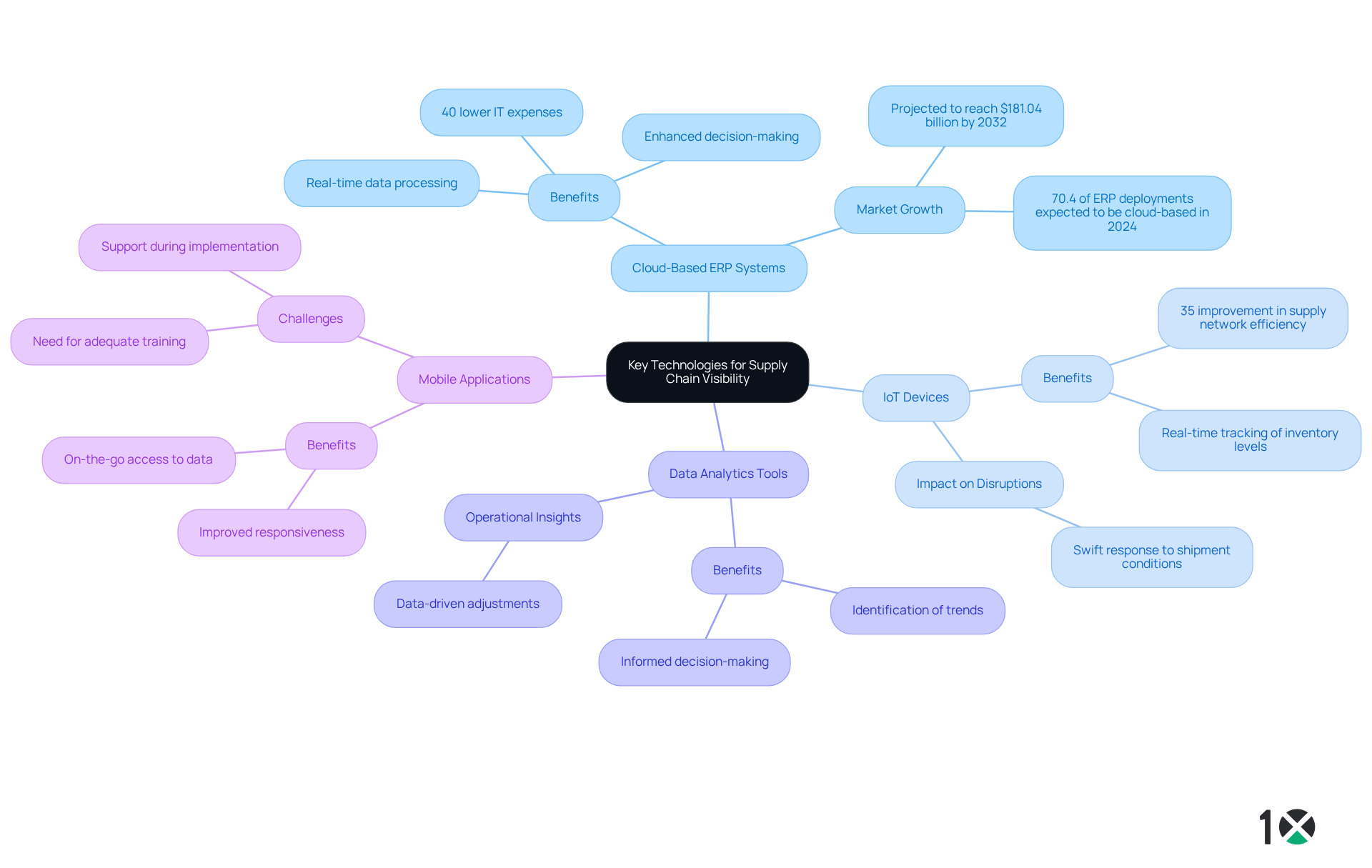

Organizations must implement key technologies that drive efficiency and responsiveness to achieve real-time supply chain visibility.

- Cloud-Based ERP Systems: Solutions like 10X ERP provide integrated platforms that facilitate real-time data processing and visibility across all operations. As a fully cloud-based ERP, 10X ERP is fast, powerful, and responsive on any device, ensuring businesses have access to accurate, up-to-date information whenever needed. These frameworks not only simplify processes but also enhance decision-making capabilities through features such as adaptable user permissions, comprehensive audit trails, and integrated reporting. Notably, 40% of businesses report lower IT expenses following ERP implementation, underscoring the financial advantages of such solutions.

- IoT Devices: Internet of Things (IoT) sensors are vital for tracking inventory levels and monitoring shipment conditions. By providing real-time supply chain visibility, these devices enable organizations to respond swiftly to disruptions, thereby enhancing overall supply network efficiency. The combination of ERP systems with IoT can improve supply network efficiency by 35%, illustrating the significant impact of this technology.

- Data Analytics Tools: Utilizing advanced analytics software allows businesses to interpret vast amounts of data and generate actionable insights. This capability is essential for informed decision-making, enabling organizations to identify trends and optimize operations effectively. Companies that leverage analytics tools gain a deeper understanding of their operations, allowing for data-driven adjustments.

- Mobile Applications: Providing on-the-go access to supply network data empowers teams to address issues promptly, improving responsiveness and agility. With mobile solutions, stakeholders can , ensuring they remain informed and capable of making swift adjustments as necessary. While the advantages of mobile applications are clear, organizations must also consider potential challenges, such as the need for adequate training and support during implementation.

By strategically leveraging these technologies, organizations can establish a robust framework for achieving real-time supply chain visibility, which ultimately results in enhanced efficiency and customer satisfaction. However, it is essential to define project scope and costs before initiating an ERP implementation, as 64% of ERP projects face budget overruns. Addressing these considerations will help maximize the benefits of these technologies.

Integrate Real-Time Visibility into Your Operations

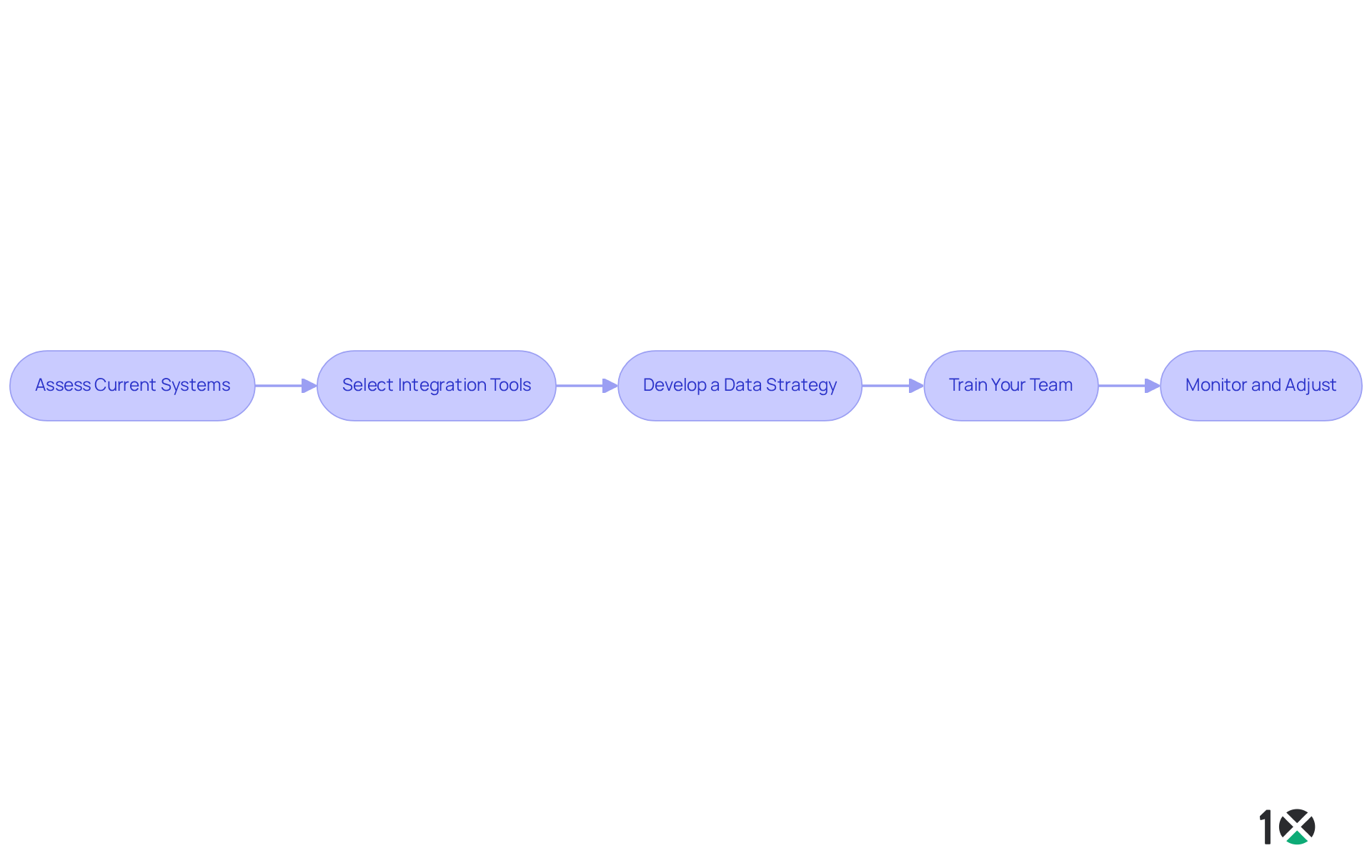

To effectively integrate real-time visibility into your operations, consider the following steps:

- Assess Current Systems: Begin with a thorough evaluation of your existing software and processes to identify gaps in visibility. Recent studies reveal that 43% of consumer markets companies are establishing technology integration support resources to enhance real time supply chain visibility.

- Select Integration Tools: Choose middleware or APIs that facilitate seamless connections between your ERP platform and other technologies, such as IoT devices and analytics tools. Industry leaders emphasize, “If you’re already on the road of integration, explore how AI can help address data challenges.” Selecting the right integration tools is crucial for enhancing the efficiency of your ERP solution.

- Develop a Data Strategy: Formulate comprehensive protocols for data collection, storage, and analysis to ensure consistency across all platforms. This strategy should prioritize improving data quality and accessibility, which are essential for informed decision-making.

- Train Your Team: Implement training programs for employees to familiarize them with new technologies and enhance their ability to interpret data effectively. A well-trained workforce is vital for maximizing the full capabilities of integrated networks.

- Monitor and Adjust: Continuously evaluate the integration process and make necessary adjustments to optimize performance. Regular monitoring helps identify areas for enhancement and ensures that the framework adapts to shifting business requirements.

By adhering to these steps, organizations can establish an integrated framework that significantly improves real time supply chain visibility, ultimately resulting in enhanced operational effectiveness and customer satisfaction. For example, the implementation of the AI-Powered Automated Facilities Management Solution has demonstrated how effective integration can lead to better workforce allocation and improved operational efficiency.

Overcome Challenges in Achieving Visibility

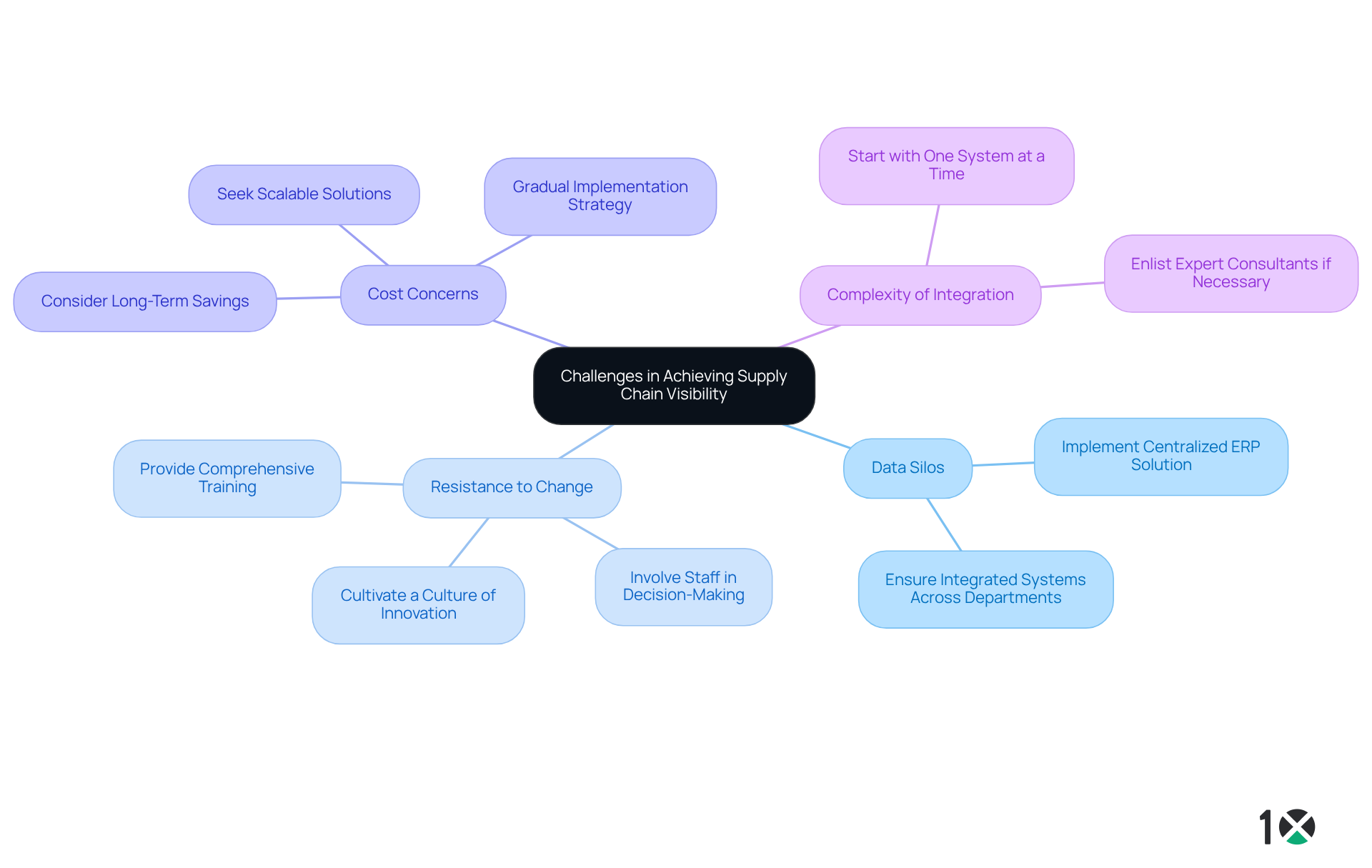

Organizations must navigate effectively through the challenges of achieving real time supply chain visibility. Understanding these obstacles is essential for .

- Data Silos: Preventing data isolation is critical. All departments must utilize integrated systems to ensure seamless information flow across the organization. Implementing a centralized ERP solution can unify data access, enhancing visibility and fostering collaboration among teams.

- Resistance to Change: A significant number of employees often resist adopting new technologies, hindering progress. To combat this, organizations should cultivate a culture of innovation by involving staff in the decision-making process and providing comprehensive training. Engaging employees from the outset can alleviate anxieties and facilitate a smoother transition to new processes.

- Cost Concerns: The initial investment in new technologies may appear daunting; however, it is vital to consider the long-term savings and efficiency gains. Organizations should seek scalable solutions that align with their budget, allowing for gradual implementation without jeopardizing financial stability.

- Complexity of Integration: Incorporating new frameworks can be intricate. To simplify this process, organizations should start with one system at a time and gradually expand. If necessary, enlisting the help of expert consultants can streamline integration, ensuring a smooth transition.

By proactively addressing these challenges, organizations can significantly improve their chances of achieving real time supply chain visibility. This ultimately leads to improved operational efficiency and heightened customer satisfaction.

Conclusion

Achieving real-time supply chain visibility is not merely a technical upgrade; it represents a fundamental shift that empowers organizations to optimize operations and enhance customer satisfaction. By understanding and implementing the key components of visibility—such as inventory tracking, order management, and supplier coordination—businesses can respond swiftly to changes and minimize delays, ultimately fostering a more efficient supply chain.

Essential technologies driving this transformation include:

- Cloud-based ERP systems

- IoT devices

- Data analytics tools

- Mobile applications

Each technology plays a pivotal role in streamlining processes, improving decision-making, and ensuring that stakeholders have access to real-time data. Furthermore, integrating these technologies necessitates a strategic approach that includes:

- Assessing current systems

- Selecting appropriate integration tools

- Developing a robust data strategy

Training employees and continuously monitoring the integration process are crucial for maximizing the benefits of real-time visibility.

The journey to achieving real-time supply chain visibility is fraught with challenges, including:

- Data silos

- Resistance to change

- Cost concerns

However, by proactively addressing these obstacles and leveraging the right technologies, organizations can significantly enhance operational efficiency and customer satisfaction. Embracing this shift not only prepares businesses for the future but also positions them to meet the evolving demands of the marketplace. Taking the first step towards real-time visibility can lead to transformative results—it’s time to seize the opportunity.

Frequently Asked Questions

What is real-time supply chain visibility?

Real-time supply chain visibility refers to the ability to track and manage inventory, shipments, and overall supply chain activities in real time, allowing organizations to optimize their operations.

Why is real-time supply chain visibility important for businesses?

It is important because it provides access to up-to-the-minute data on stock levels, order statuses, and delivery timelines, enabling businesses to react swiftly to changes, minimize delays, and enhance customer satisfaction.

What are the key components of real-time supply chain visibility?

The key components include inventory tracking, order management, and supplier coordination.

How does inventory tracking contribute to real-time supply chain visibility?

Inventory tracking involves knowing the exact location and quantity of products at all times, which is facilitated by robust accounting features such as customizable attributes and lot/serial item tracking.

What role does order management play in real-time supply chain visibility?

Order management involves monitoring the status of orders from placement to delivery, which allows stakeholders to make informed decisions and ensures efficiency throughout the process.

How can supplier coordination enhance real-time supply chain visibility?

Effective supplier coordination aligns inventory needs and delivery schedules, and leveraging seamless integrations can significantly enhance this coordination.

What steps should businesses take to implement real-time supply chain visibility effectively?

Businesses should clearly define the elements of inventory tracking, order management, and supplier coordination to gain a comprehensive understanding of how to implement real-time supply chain visibility effectively.