Overview

This article examines the key factors influencing the cost of a Warehouse Management System (WMS). It highlights critical aspects such as:

- Initial setup costs

- Ongoing maintenance

- Training expenses

- Integration costs

- Scalability options

- Licensing models

- Customization needs

- Support levels

- Vendor reputation

Understanding these elements is essential for organizations aiming to budget effectively and avoid unexpected expenses.

By grasping these factors, companies can enhance their operational efficiency and improve financial planning. This knowledge empowers Operations Managers to make informed decisions, ultimately leading to better resource allocation and strategic growth. As you navigate the complexities of WMS costs, consider how each factor can impact your organization’s bottom line.

Introduction

Understanding the costs associated with a Warehouse Management System (WMS) is essential for organizations aiming to optimize operations and budget effectively. Various factors influence pricing—from initial setup and ongoing maintenance to training and support—creating a complex landscape that companies must navigate to make informed decisions. This article explores the key components that determine WMS costs, demonstrating how transparency and strategic planning can significantly impact financial outcomes.

How can businesses effectively balance the need for a robust system with the imperative of cost efficiency in an ever-evolving market?

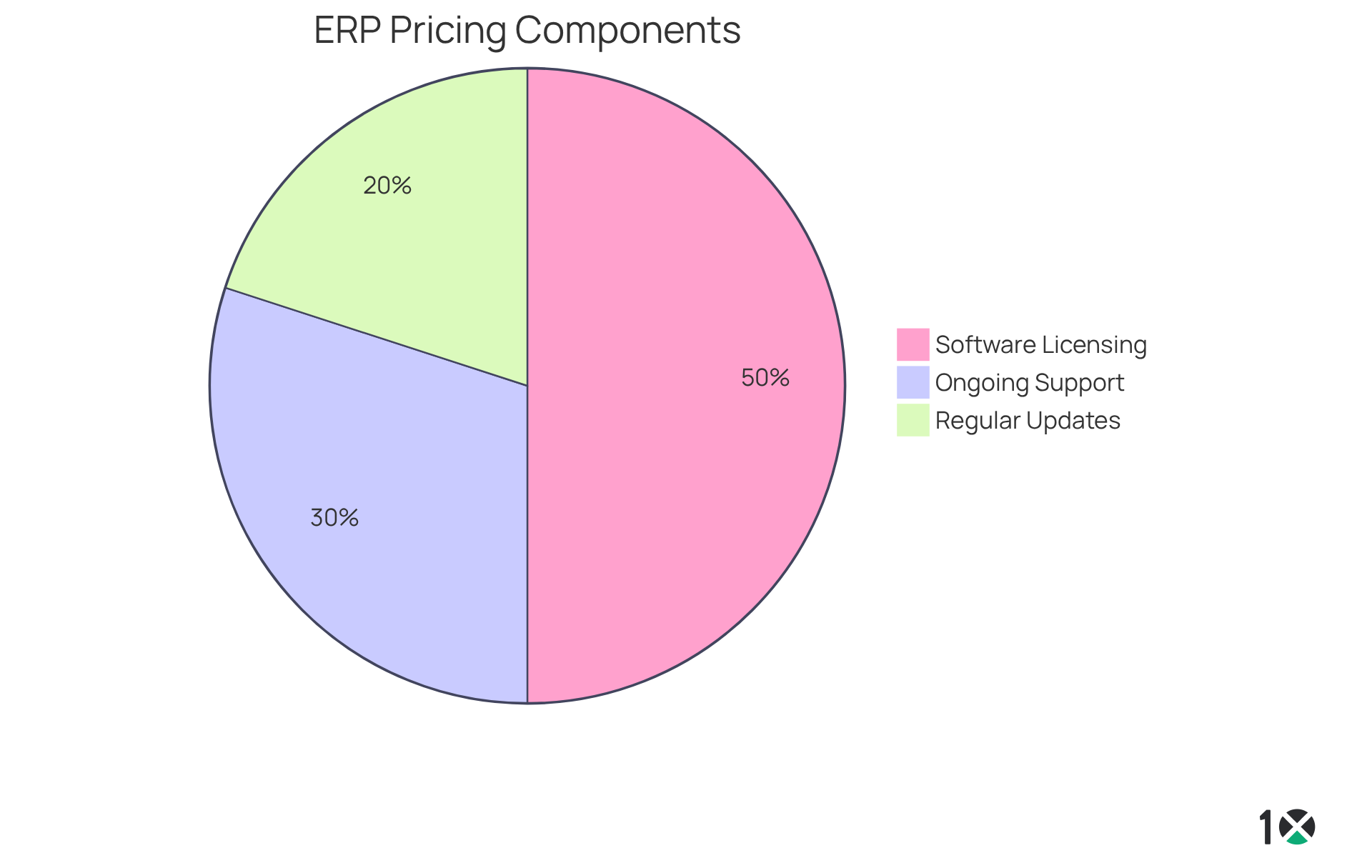

10X ERP: All-Inclusive Pricing Model for Warehouse Management

10X ERP features a comprehensive pricing structure that includes the warehouse management system cost along with all essential functionalities, without hidden charges, enabling organizations to accurately predict their expenses. This structure encompasses:

- Software licensing

- Ongoing support

- Regular updates

This ensures users are aware of the warehouse management system cost and are not blindsided by unexpected expenses. Such transparency is vital for growing distributors who must exercise stringent financial oversight while keeping track of their warehouse management system cost during expansion. By adopting this model, companies can effectively manage their budgets.

A mid-sized manufacturing firm serves as a prime example, having reduced expenses by 15% after renegotiating with their vendor for clearer pricing terms. Moreover, transparent pricing cultivates trust and satisfaction among clients, as it establishes realistic expectations and diminishes the likelihood of financial surprises. As the ERP landscape evolves, distributors stand to gain significantly from solutions that prioritize pricing clarity, facilitating improved financial planning and operational efficiency.

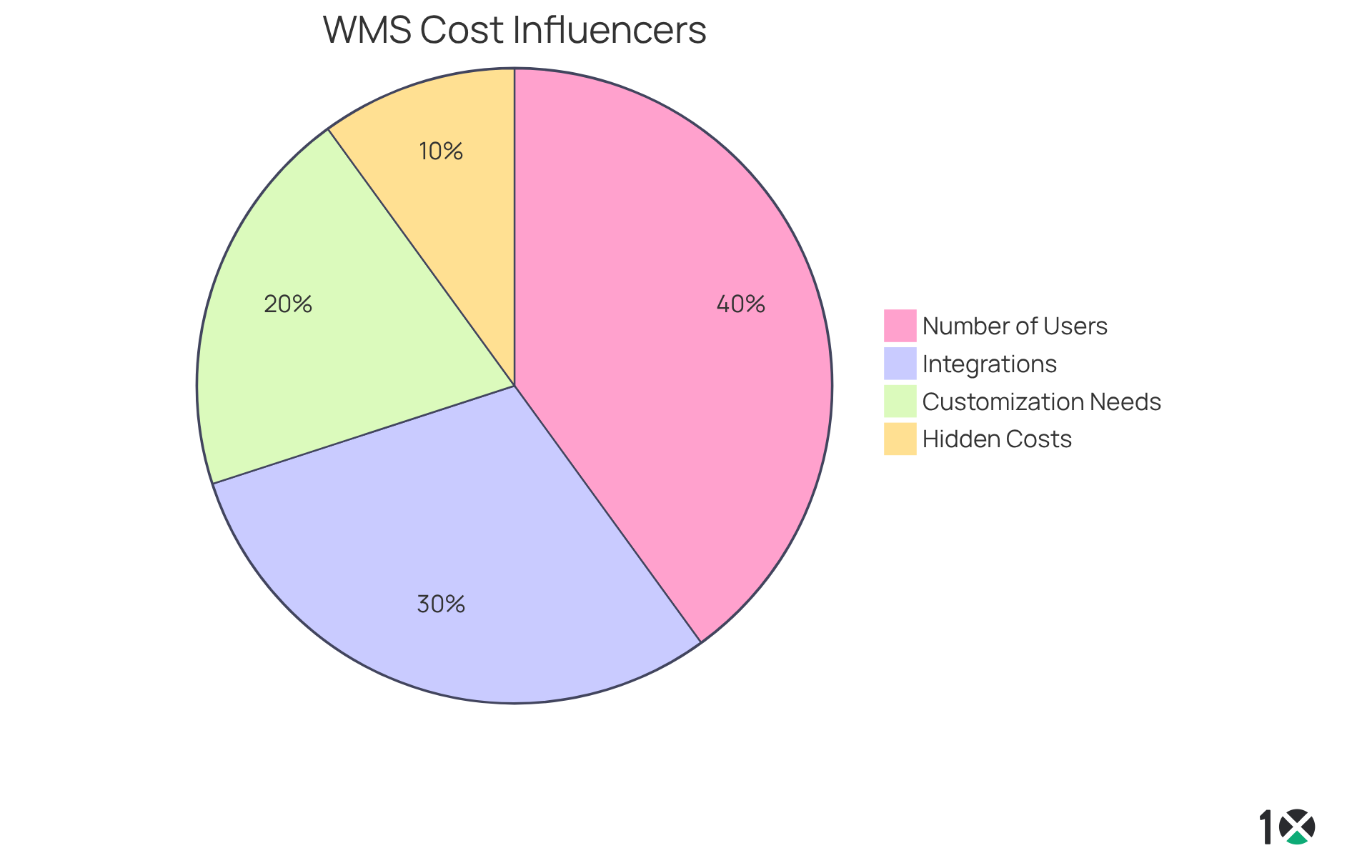

Initial Setup Costs: Evaluating Implementation Expenses

The initial setup costs for a warehouse management system can vary significantly based on the system’s complexity and specific operational requirements. For 10X ERP, these expenses typically range from $10,000 to $150,000. Several key factors influence the warehouse management system cost, including:

- The number of users

- Necessary integrations

- Customization needs

Conducting a thorough cost analysis during the planning phase is essential. This process enables businesses to allocate sufficient resources for a successful implementation. By adopting this proactive approach, organizations not only mitigate unforeseen expenses but also ensure that the chosen WMS aligns with their business objectives and scalability requirements. Investing time in understanding the warehouse management system cost is crucial for achieving long-term operational success.

Ongoing Maintenance Costs: Budgeting for Long-Term Support

Ongoing warehouse management system cost for maintenance typically ranges from 10% to 20% of the initial software license fee annually. This can significantly impact your budget. However, with 10X ERP’s all-inclusive pricing model, users benefit from a predictable per-user, per-month subscription that encompasses all functionalities, features, modules, and tools. This model not only simplifies budgeting but also guarantees users continuous updates, real-time data processing, and comprehensive support. Imagine having rapid service and assistance without hidden fees—this is what 10X ERP delivers.

Companies should factor in the warehouse management system cost in their long-term financial planning to sustain efficiency. It’s essential to recognize that 10X ERP offers a seamless user experience and unparalleled support throughout your ERP journey. By integrating these insights into your strategy, you can ensure that your operations remain efficient and effective in the long run.

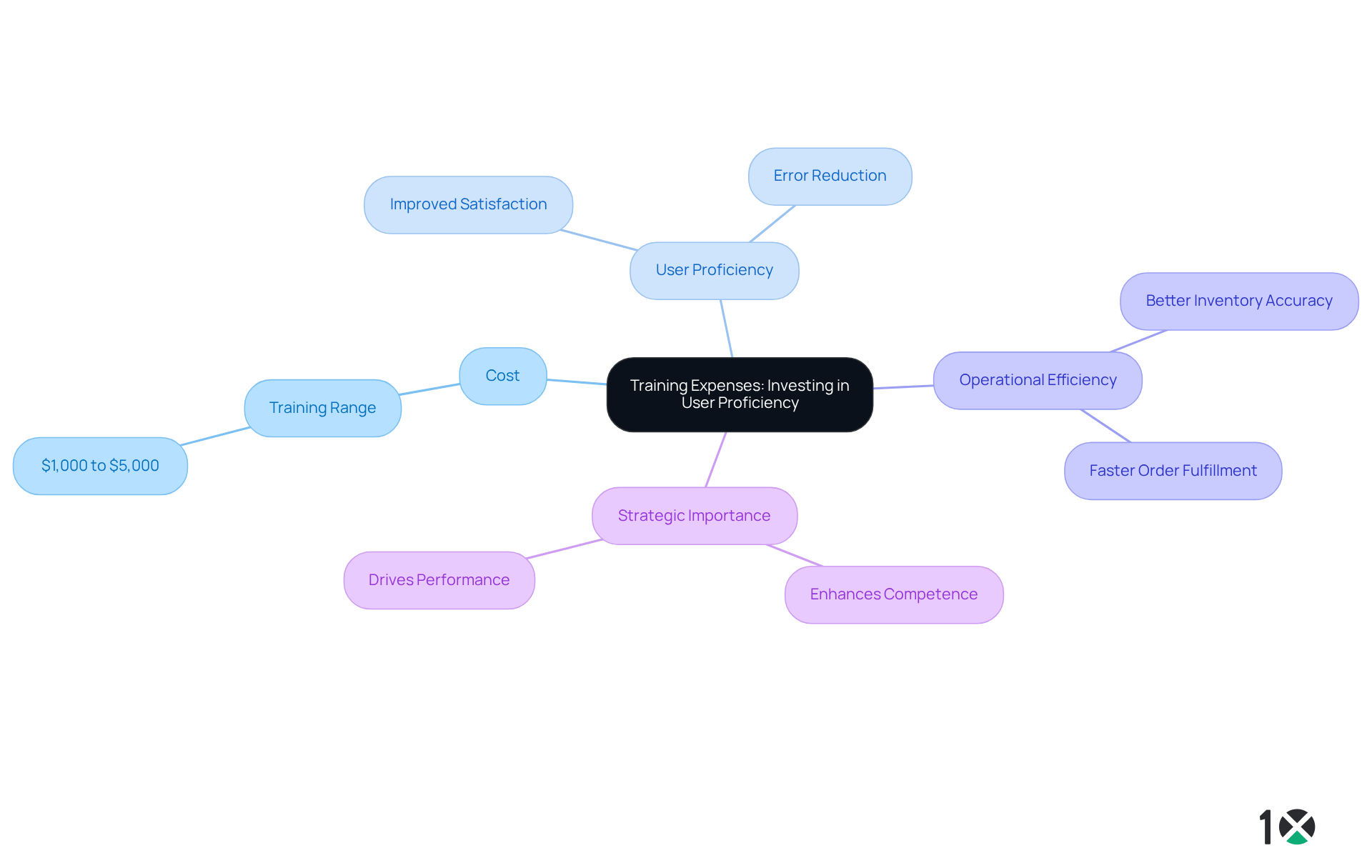

Training Expenses: Investing in User Proficiency

Training expenses for a warehouse management system cost can vary significantly, typically ranging from $1,000 to $5,000 depending on team size and system complexity. For 10X ERP, implementing comprehensive training programs is essential. Such training ensures that users can navigate the system proficiently and leverage its full range of features. This investment not only boosts user satisfaction but also enhances operational efficiency, leading to a notable decrease in errors within warehouse management processes.

Effective training programs have been shown to improve overall warehouse management efficiency. They equip employees with the necessary skills to handle various roles, particularly during demand surges. By prioritizing user proficiency, organizations can anticipate a more streamlined operation. This focus ultimately contributes to better inventory accuracy and faster order fulfillment.

In conclusion, investing in training is not merely a warehouse management system cost; rather, it is a strategic move that fosters competence and drives performance in warehouse management.

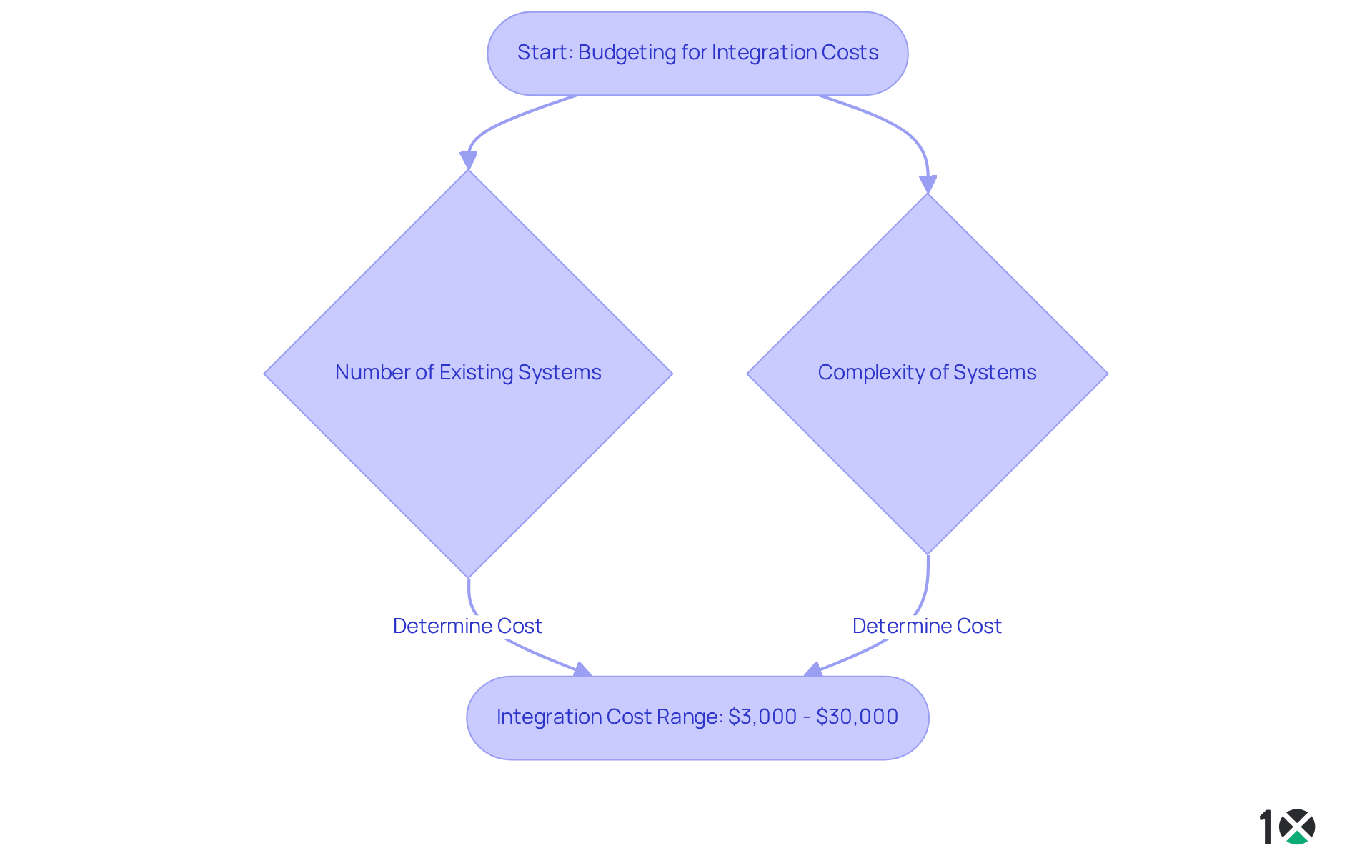

Integration Costs: Ensuring Compatibility with Existing Systems

The warehouse management system cost for integration can vary significantly, particularly depending on the number of existing systems that require connection. For 10X ERP, businesses should expect to budget between $3,000 and $30,000 for integration, a range influenced by the complexity of the systems involved. This investment is not merely an expense; it is essential for ensuring a smooth data flow and operational efficiency—both vital for distributors aiming to enhance their capabilities while considering the warehouse management system cost.

Successful integrations do more than streamline processes; they significantly boost overall productivity, making them a crucial consideration when assessing warehouse management system cost in the budgeting process. Ensuring compatibility with existing systems is paramount for maximizing the advantages of ERP solutions. As highlighted in industry insights, this strategic alignment ultimately leads to improved performance outcomes, prompting businesses to take action and invest wisely in their integration efforts.

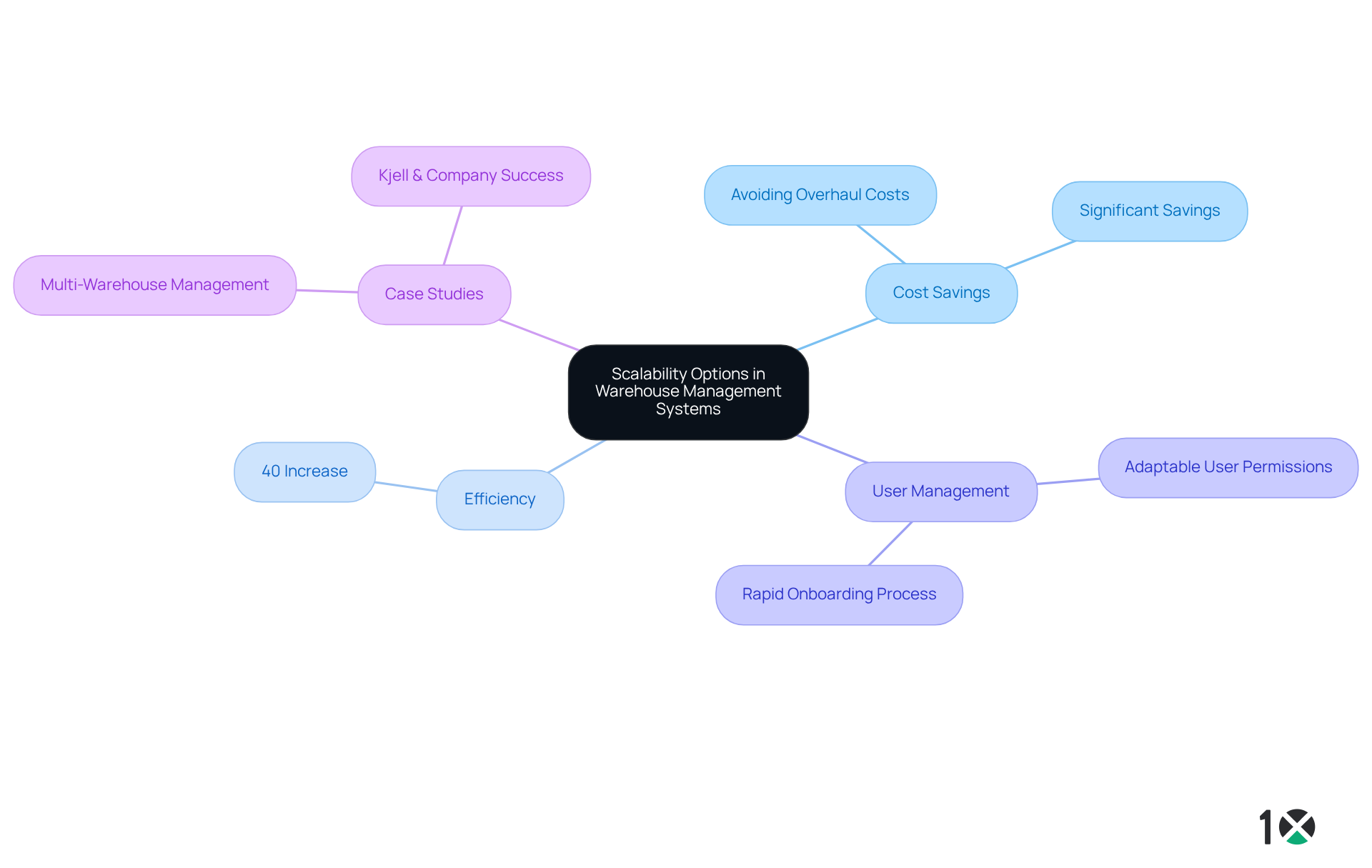

Scalability Options: Planning for Future Growth

Selecting a Warehouse Management System (WMS) requires a sharp focus on scalability. 10X ERP is expertly designed to support business growth, allowing organizations to seamlessly add users and features as their needs evolve, all while avoiding substantial additional costs. This flexibility is crucial for adapting to changing market demands. Companies that have adopted scalable WMS solutions often report significant cost savings, as they can avoid the high warehouse management system cost associated with a complete system overhaul during expansion phases. A notable case involves a client who expanded from one to five warehouses, achieving an impressive 40% increase in efficiency through effective multi-warehouse management.

Moreover, 10X ERP offers adaptable user permissions and roles, enabling organizations to tailor access according to individual responsibilities, thereby enhancing operational efficiency. By leveraging the flexibility of 10X ERP, enterprises can ensure they remain competitive and efficient, ultimately leading to improved profitability and customer satisfaction. The seamless user experience and rapid onboarding process also facilitate a smooth transition, making it easier for teams to adapt and utilize the system effectively. This combination of features positions 10X ERP as a vital tool for organizations aiming to thrive in a dynamic market.

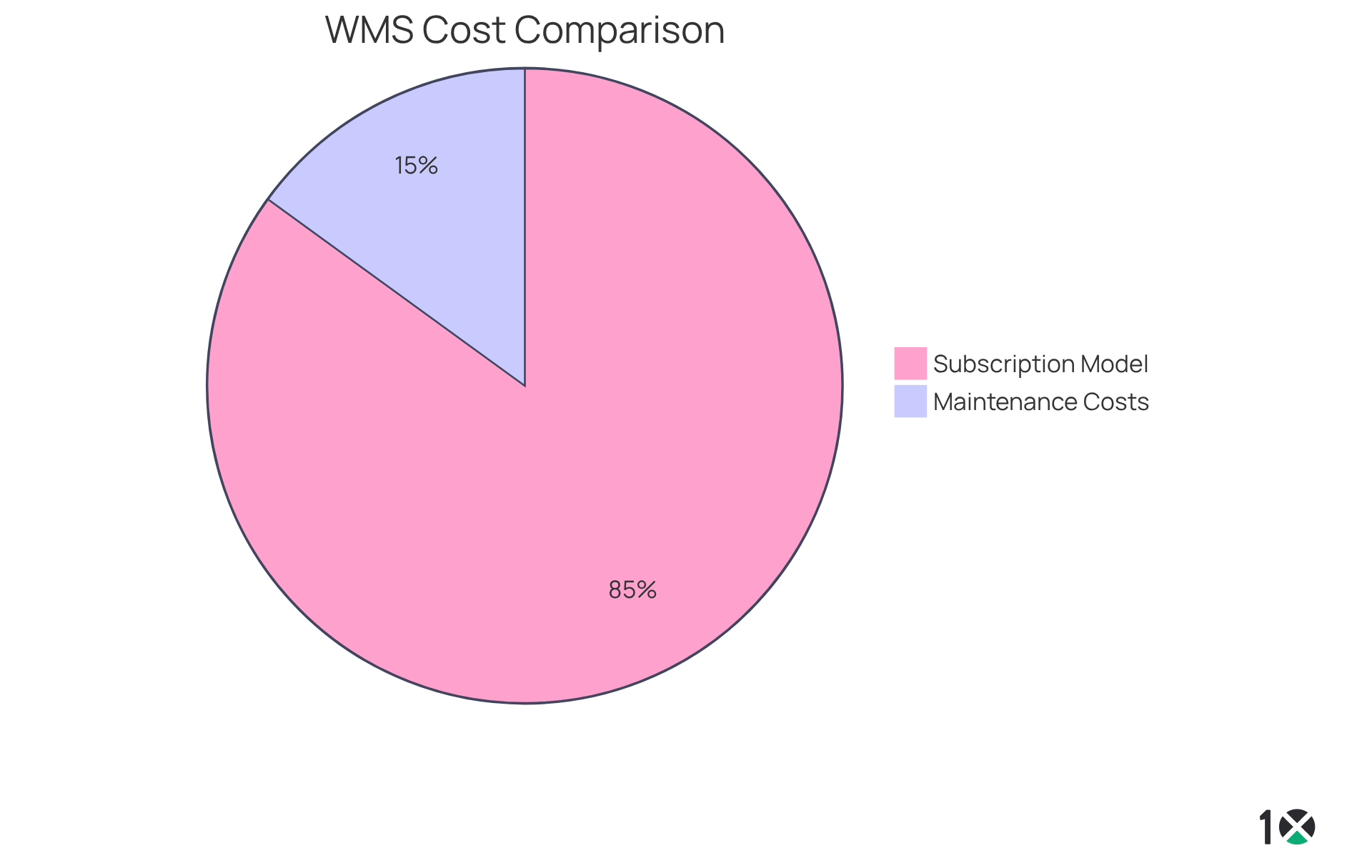

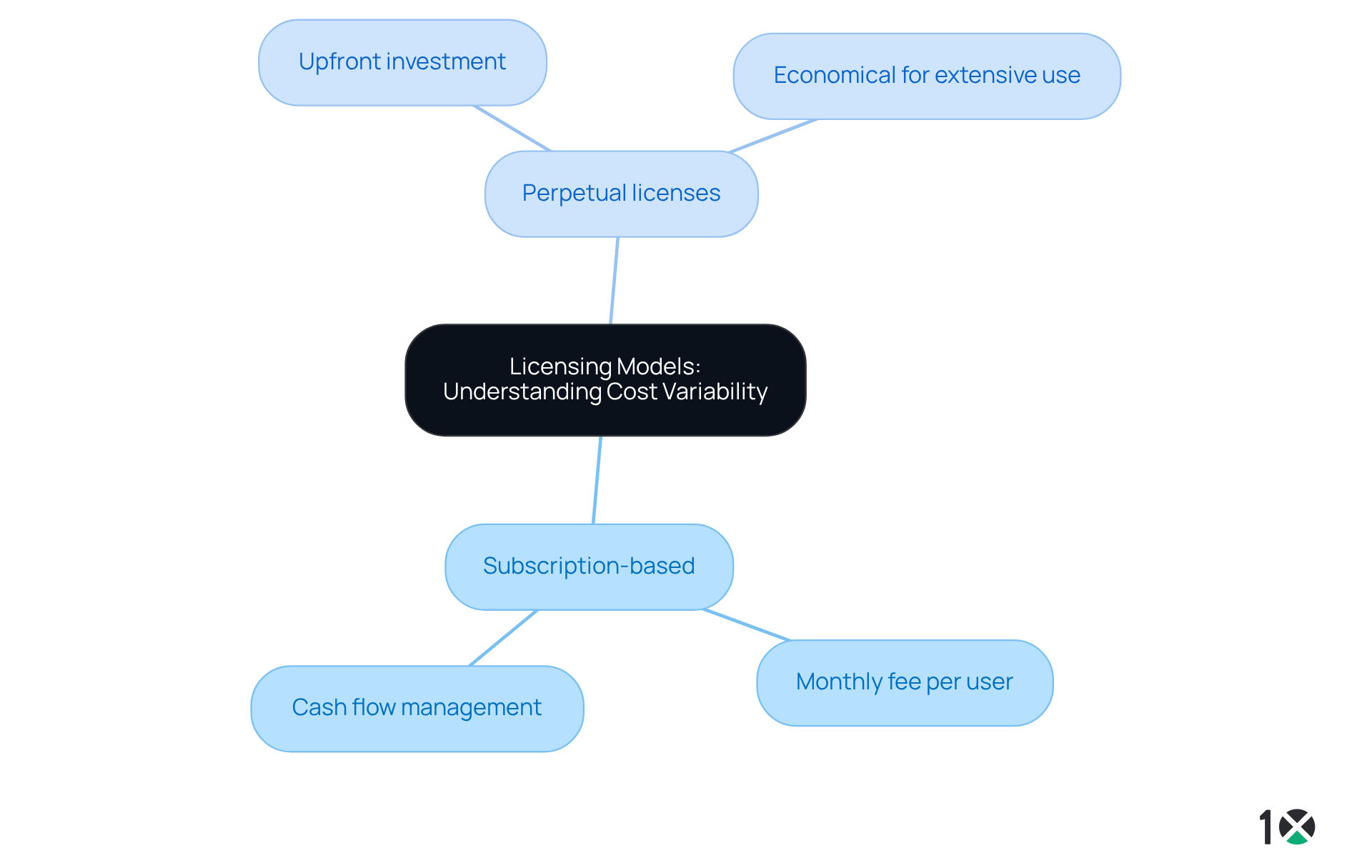

Licensing Models: Understanding Cost Variability

Warehouse Management System (WMS) solutions typically provide companies with two primary licensing models:

- Subscription-based

- Perpetual licenses

The subscription model from 10X ERP offers organizations flexibility, allowing them to pay a monthly fee per user, which varies based on the selected features. This approach is particularly beneficial for companies aiming to manage cash flow effectively, as it distributes costs over time.

On the other hand, a perpetual license requires a significant upfront investment, which can prove to be more economical in the long run for larger organizations that intend to use the software extensively.

Understanding these licensing options is crucial for companies to align their choices regarding warehouse management system cost with their financial strategies and requirements. This alignment ensures that they select the model that best supports their growth and efficiency objectives.

Customization Needs: Assessing Tailoring Requirements

Customization requirements can vary significantly among companies, and 10X ERP provides flexible options to tailor its system to meet specific needs. However, organizations should anticipate additional costs related to the warehouse management system cost associated with these customizations, which can range from $5,000 to over $50,000, depending on the complexity and extent of the modifications. Recognizing that the pricing structure for 10X ERP is transparent and predictable—covering all functionality, features, modules, tools, and dashboards—will enable you to plan your budget effectively and mitigate surprises during the implementation process.

Typical implementation considerations include:

- Existing systems and applications

- The volume of data to migrate

- The number of users (with a minimum of five)

- Any specialization requirements

Early evaluation of customization needs is crucial to avoid budget overruns and ensure that the warehouse management system cost aligns effectively with the company’s functional objectives. A comprehensive understanding of the desired features and functionalities not only aids in budgeting but also enhances the overall effectiveness of the ERP solution, ultimately leading to improved efficiency and productivity in warehouse operations.

Additionally, with best-in-class cloud hosting and continuous data backup, 10X ERP guarantees that your operations remain seamless and secure.

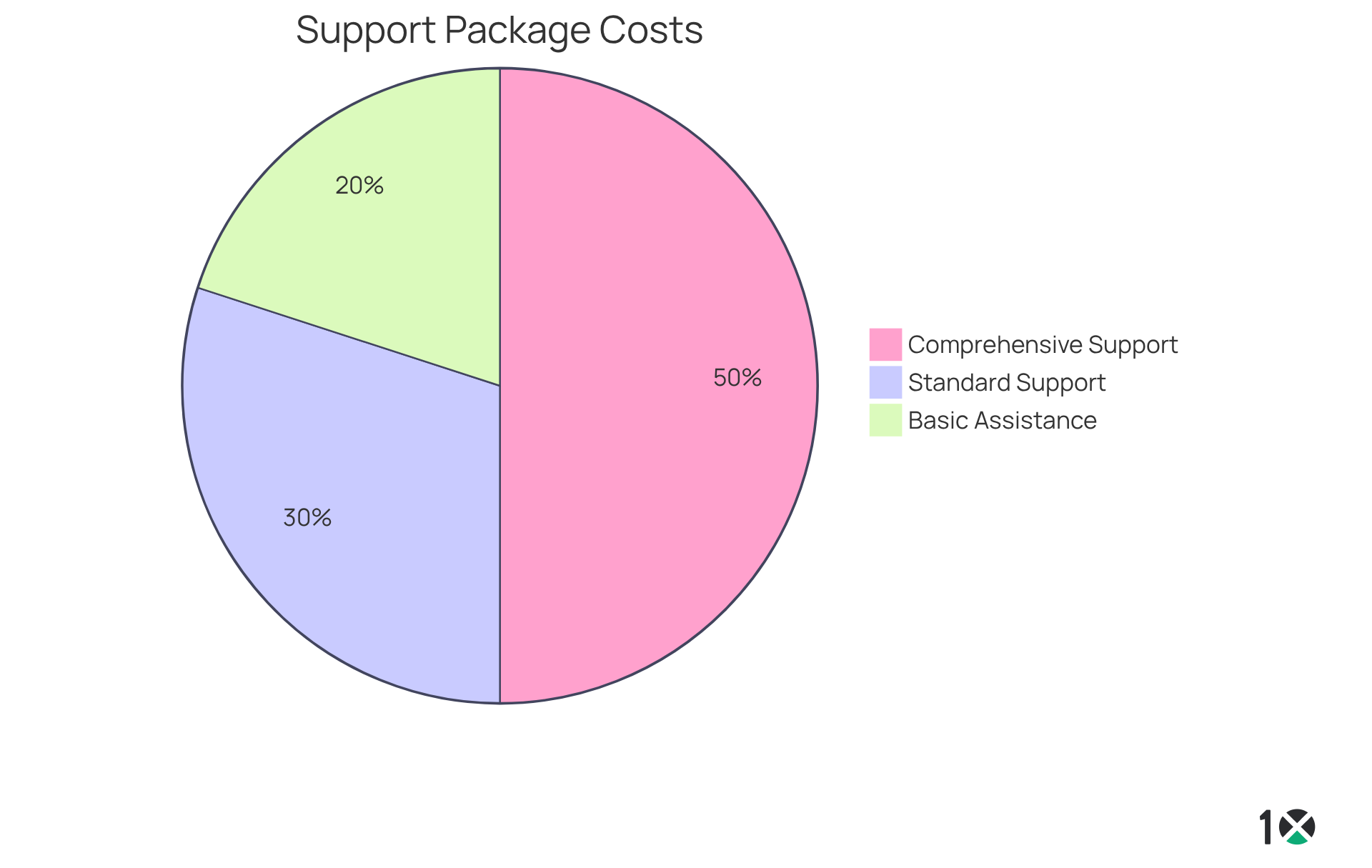

Support and Service Levels: Evaluating Cost vs. Value

Support and service levels are pivotal when assessing a Warehouse Management System (WMS). 10X ERP offers a range of support packages, from basic email assistance to comprehensive 24/7 support.

Opting for higher service levels may incur additional costs related to the warehouse management system cost; however, the value they deliver often outweighs these expenses. By significantly reducing downtime and ensuring rapid issue resolution, companies investing in robust support packages frequently report increased efficiency and fewer disruptions. This can lead to improved customer satisfaction and loyalty.

Therefore, evaluating the warehouse management system cost in relation to its potential functional impact is crucial for making informed decisions that align with long-term objectives.

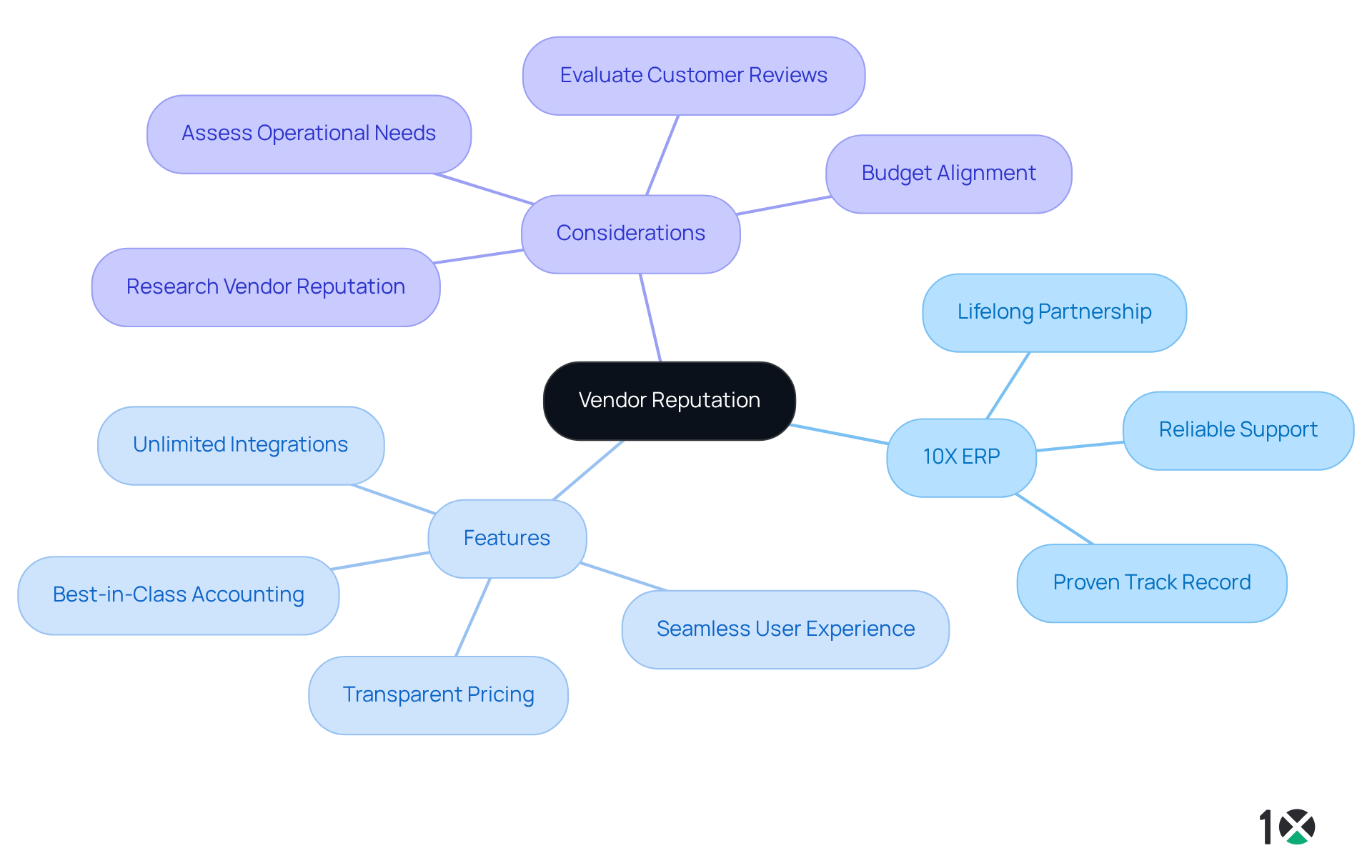

Vendor Reputation: Assessing Trustworthiness and Cost Implications

When selecting a Warehouse Management System (WMS), assessing the vendor’s reputation is crucial. A well-established vendor like 10X ERP not only offers reliable support and a proven track record but also provides a comprehensive cloud-based ERP solution tailored for distributors. With features such as:

- Best-in-class accounting

- Seamless user experience

- Unlimited integrations through modern APIs

- Transparent pricing

the warehouse management system cost of 10X ERP is justified by its value, even at a higher price. Furthermore, the dedication to a lifelong partnership and ongoing product advancements guarantees that companies receive continuous assistance and upgrades. In contrast, lesser-known vendors may offer lower prices but could lack the necessary support and reliability. Conducting thorough research and reading customer reviews can help businesses make informed decisions that align with their operational needs and budget.

Conclusion

Understanding the various factors that influence warehouse management system costs is essential for organizations seeking to optimize their operations and budget effectively. A comprehensive approach to evaluating these costs—including software licensing, ongoing maintenance, training, integration, and customization—can lead to informed financial decisions that align with business goals.

Key insights illustrate the importance of transparent pricing models, such as those offered by 10X ERP, enabling businesses to anticipate expenses without hidden surprises. By considering initial setup costs, ongoing maintenance, and the long-term implications of training and integration, companies can navigate the complexities of warehouse management systems more effectively. Additionally, factors like vendor reputation and support levels significantly impact the overall value derived from these systems.

Ultimately, organizations are encouraged to adopt a proactive stance in assessing their warehouse management system needs. By investing in the right tools and understanding the associated costs, businesses can enhance operational efficiency, adapt to growth, and ensure a competitive edge in their respective markets. Embracing this strategic approach not only leads to improved financial planning but also fosters long-term success in warehouse management.

Frequently Asked Questions

What is the pricing model for 10X ERP’s warehouse management system?

10X ERP features an all-inclusive pricing model that covers the warehouse management system cost along with software licensing, ongoing support, and regular updates, ensuring no hidden charges.

How does the all-inclusive pricing model help organizations?

This model allows organizations to accurately predict their expenses, which is vital for financial oversight, especially for growing distributors, enabling them to manage their budgets effectively.

What are the typical initial setup costs for a warehouse management system with 10X ERP?

Initial setup costs for 10X ERP typically range from $10,000 to $150,000, depending on factors such as the number of users, necessary integrations, and customization needs.

Why is it important to conduct a cost analysis during the planning phase?

Conducting a thorough cost analysis helps businesses allocate sufficient resources for successful implementation, mitigating unforeseen expenses and ensuring alignment with business objectives and scalability.

What are the ongoing maintenance costs associated with a warehouse management system?

Ongoing maintenance costs typically range from 10% to 20% of the initial software license fee annually, which can significantly impact a budget.

How does 10X ERP simplify budgeting for ongoing costs?

10X ERP offers a predictable per-user, per-month subscription that includes all functionalities, features, modules, and tools, which simplifies budgeting and guarantees continuous updates and comprehensive support.

What benefits does 10X ERP provide in terms of support and updates?

10X ERP ensures users receive rapid service and assistance without hidden fees, continuous updates, and real-time data processing, contributing to a seamless user experience.

How can companies ensure long-term operational success with their warehouse management system?

Companies should factor in the warehouse management system cost in their long-term financial planning to sustain efficiency and integrate insights into their strategy for effective operations.