Overview

This article presents seven key benefits of implementing a Manufacturing Execution System (MES) to streamline manufacturing operations. These benefits include:

- Increased efficiency

- Enhanced quality control

- Improved visibility

- Better compliance

- Cost reduction

- Effective inventory management

- Seamless integration with ERP systems

Each benefit is backed by evidence that illustrates how MES optimizes processes, reduces defects, and enhances decision-making. Ultimately, these advantages lead to improved productivity and operational excellence within manufacturing environments.

Introduction

The landscape of manufacturing is evolving rapidly, with technology playing a crucial role in shaping its future. Among the most impactful advancements is the Manufacturing Execution System (MES), which offers a suite of benefits designed to enhance operational efficiency and productivity. This article delves into seven key advantages of implementing an MES system, revealing how it not only streamlines processes but also addresses the pressing challenges manufacturers face today.

Can embracing this technology be the game-changer that propels organizations toward greater success in a competitive environment?

10X ERP: Streamline Manufacturing Operations with Real-Time Data Processing

10X ERP empowers producers with that facilitates real-time data processing, enabling continuous monitoring of production metrics. This capability allows businesses to make immediate adjustments to workflows and resource allocation, significantly enhancing operational efficiency.

By integrating the MES system with 10X ERP, producers can ensure seamless data flow across all operations, which leads to improved decision-making. Real-time insights into inventory levels, for instance, help prevent stockouts and overproduction, thereby optimizing supply chain management.

This proactive approach not only reduces lead times but also enhances overall productivity, as manufacturers can swiftly respond to changes in demand and operational conditions.

Increased Efficiency: Optimize Production Processes with MES

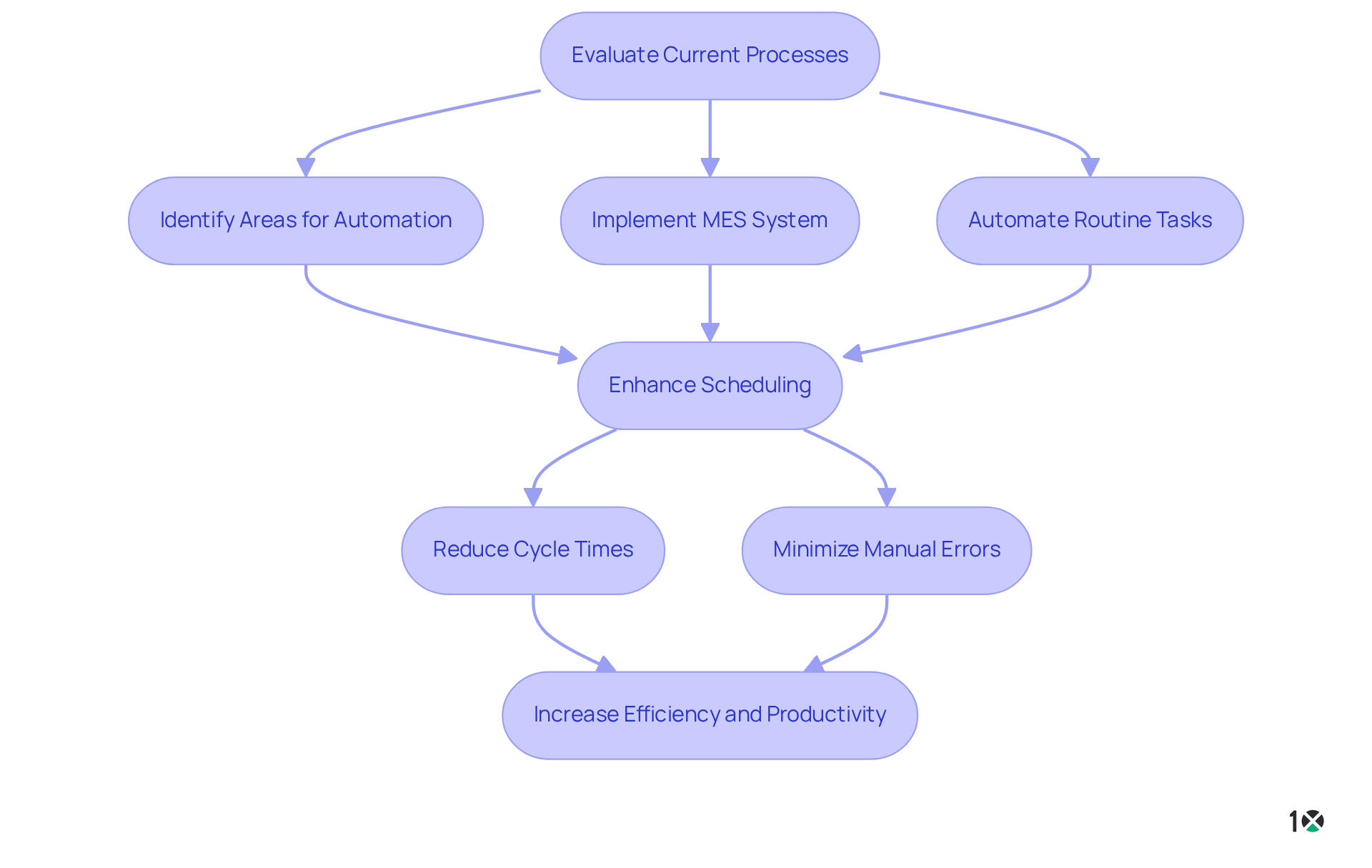

The optimization of manufacturing processes is crucially supported by the MES system. By automating routine tasks and providing real-time visibility into operations, the MES system significantly reduces cycle times and minimizes manual errors. For instance, the MES system can enhance scheduling by automatically adjusting production runs based on real-time demand data. This ensures [effective resource utilization](https://10xerp.com/?p=1560) and timely achievement of production targets. As Peter Drucker aptly stated, ‘Efficiency is doing things right; effectiveness is doing the right things,’ which highlights the vital role of the MES system in enhancing operational effectiveness.

Research indicates that the implementation of a MES system can result in an average cycle time reduction of up to 30%. This capability enables producers to swiftly respond to market shifts and boost overall productivity. This aligns with Richard Branson’s observation that “every success story is a tale of constant adaptation, revision, and change,” emphasizing the necessity for manufacturers to continuously adapt their processes.

Furthermore, the integration of MES not only enhances efficiency but also positively influences workforce dynamics. It allows employees to concentrate on higher-value tasks instead of routine manual processes. To effectively leverage the MES system, operations managers should evaluate their current processes and for improvement. By streamlining operations, the MES system fosters a more agile manufacturing environment, ultimately enhancing customer satisfaction and providing a competitive edge.

Enhanced Quality Control: Maintain High Standards with MES

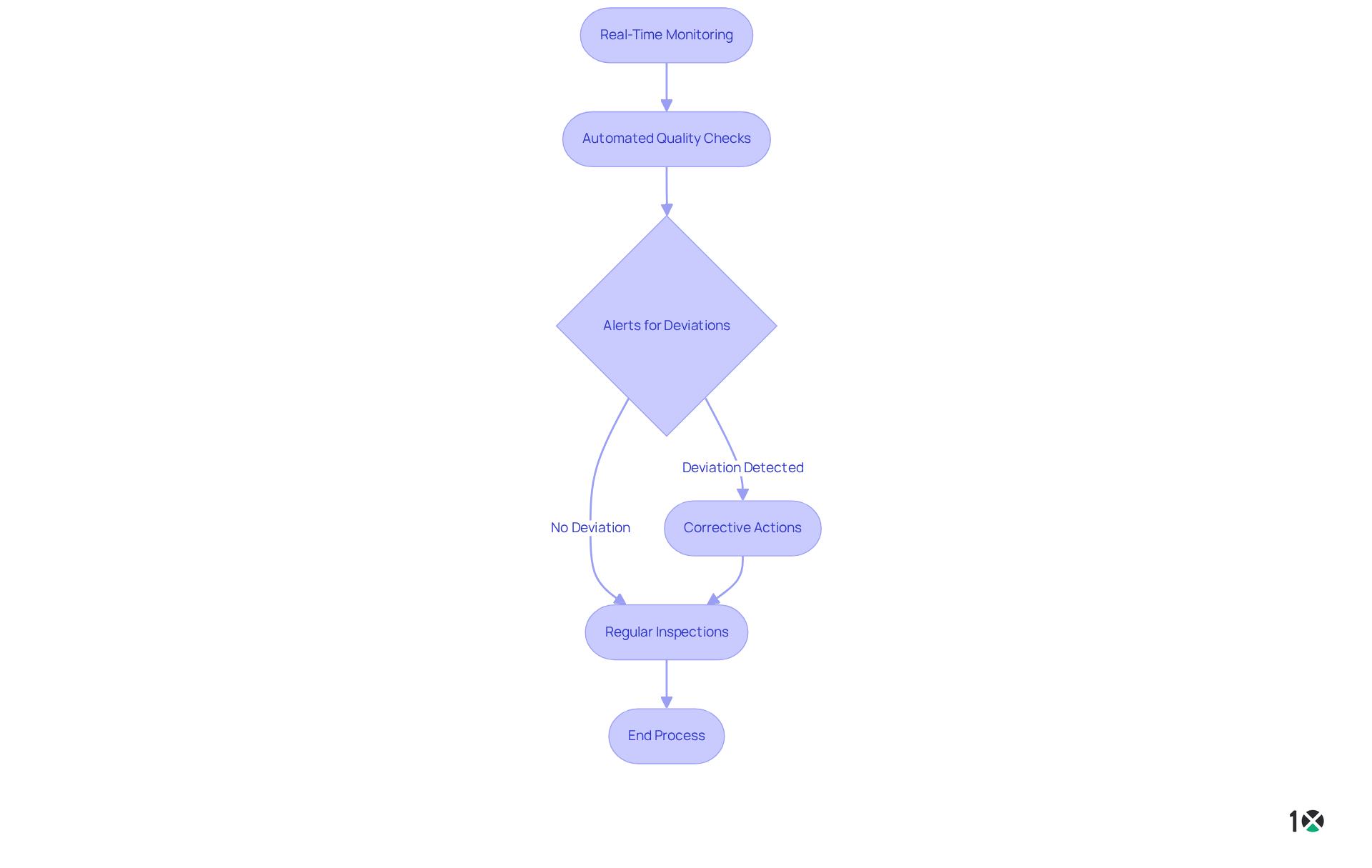

The MES system significantly enhances quality control by embedding quality management processes directly into workflow activities. This integration facilitates real-time monitoring of product quality at every manufacturing stage, allowing for immediate alerts and corrective actions when deviations from established quality standards are detected.

For instance, automated quality checks can be seamlessly implemented to verify that products meet specifications before moving to later stages of manufacturing. This proactive approach not only but also reduces the need for rework, leading to a notable decrease in product defect rates.

Statistics indicate that organizations utilizing the MES system can achieve a 25-40% reduction in defect rates, underscoring the system’s effectiveness in fostering a culture of quality. Moreover, case studies show that regular quality inspections, planned at essential manufacturing stages, allow for early identification of problems, thus improving overall operational efficiency and customer satisfaction.

For instance, a prominent bicycle manufacturer successfully addressed increased customer complaints regarding faulty brakes by implementing rigorous quality control processes, which allowed them to identify and rectify the root cause of the issue promptly.

Improved Visibility: Gain Insights into Manufacturing Operations with MES

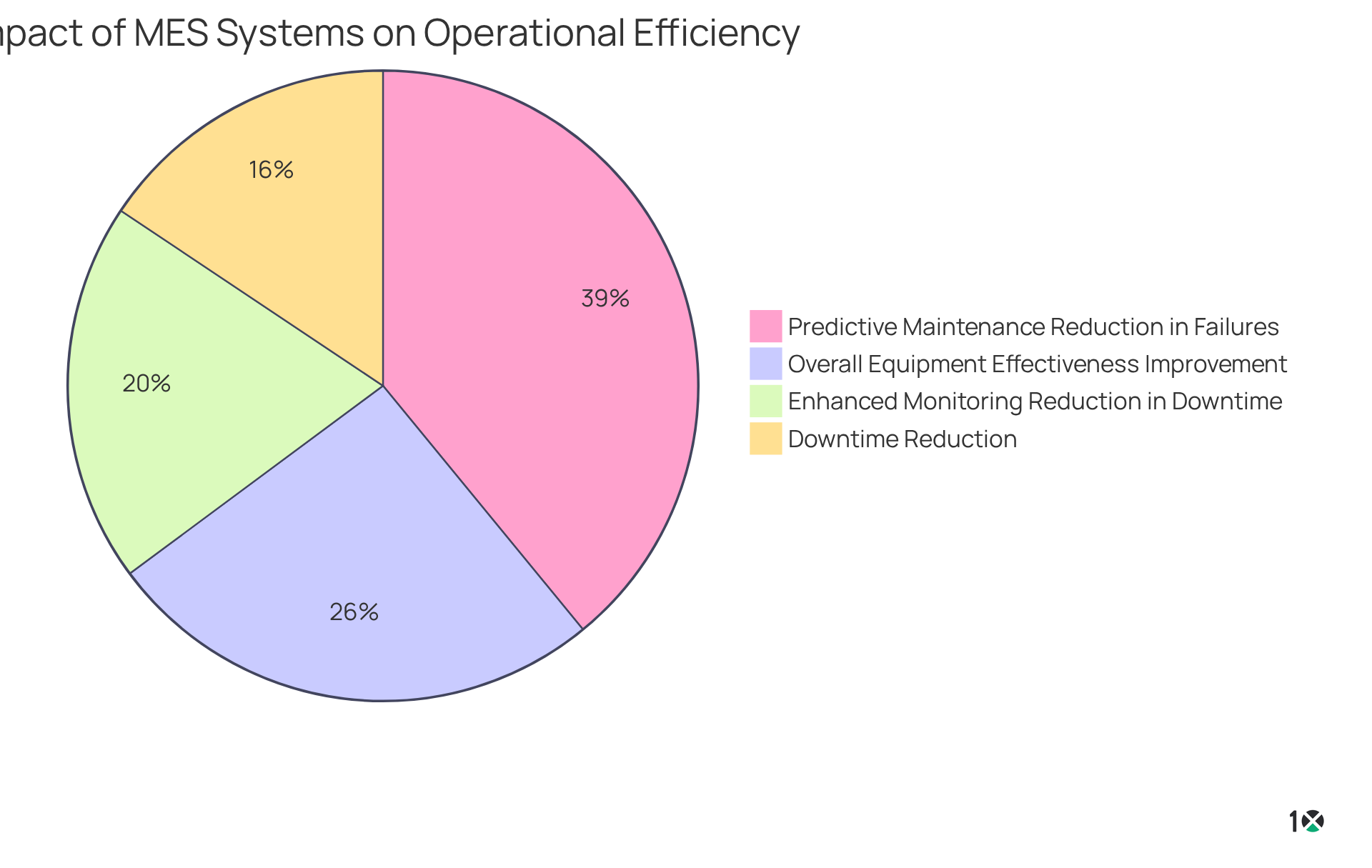

Implementing a mes system significantly enhances visibility into manufacturing operations, which is a crucial advantage for any organization. MES systems gather and analyze data from various sources, providing managers with a comprehensive perspective on performance outcomes. This visibility allows for the rapid , inefficiencies, and opportunities for improvement. For instance, real-time dashboards displaying key metrics empower managers to make informed decisions regarding resource allocation and process adjustments.

Statistics show that organizations utilizing a mes system experience a 33% improvement in overall equipment effectiveness (OEE), underscoring the system’s substantial impact on operational efficiency. Furthermore, predictive maintenance can reduce equipment failure by up to 50%, leading to significantly lower operational costs. Companies adopting connectivity strategies report a 20% decrease in downtimes, illustrating the operational advantages of the MES system. Moreover, case studies indicate that organizations leveraging the MES system have effectively decreased downtime by 20-25% through enhanced monitoring and predictive analytics, resulting in improved operational performance.

By harnessing these insights, producers can optimize their operations, ensuring a more efficient and effective manufacturing process.

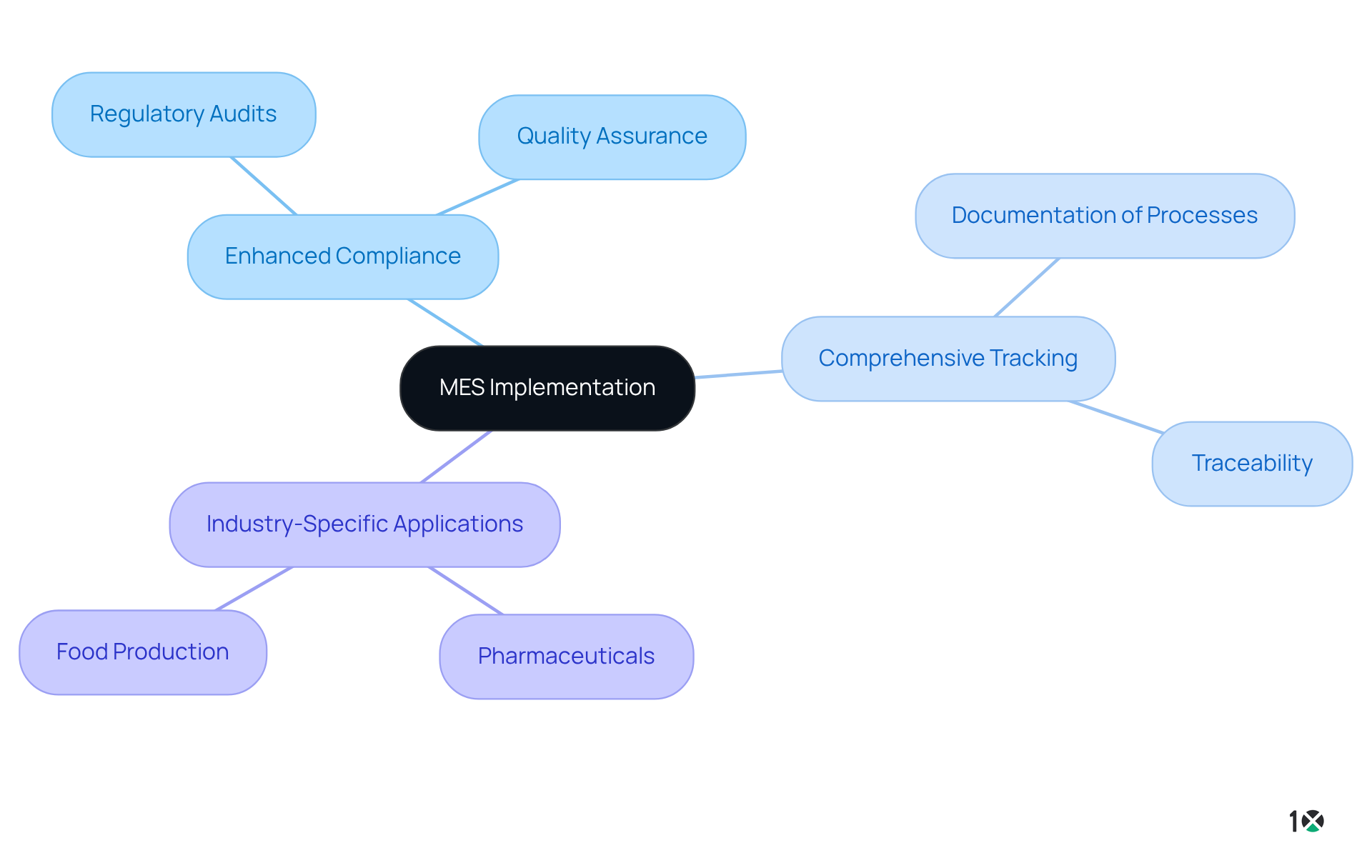

Better Compliance: Meet Industry Standards with MES Implementation

Implementing a MES system significantly enhances a manufacturer’s capability to meet industry compliance standards. The MES system provides comprehensive tracking and documentation of manufacturing processes, which is essential for regulatory audits. In industries such as pharmaceuticals and food production, for instance, MES ensures that all processes are meticulously documented and traceable. This capability not only facilitates compliance with , such as FDA guidelines, but also reinforces the manufacturer’s commitment to quality and safety. By adopting an MES system, manufacturers can confidently navigate the complexities of regulatory requirements, thereby positioning themselves as leaders in their respective fields.

Cost Reduction: Achieve Savings through MES Optimization

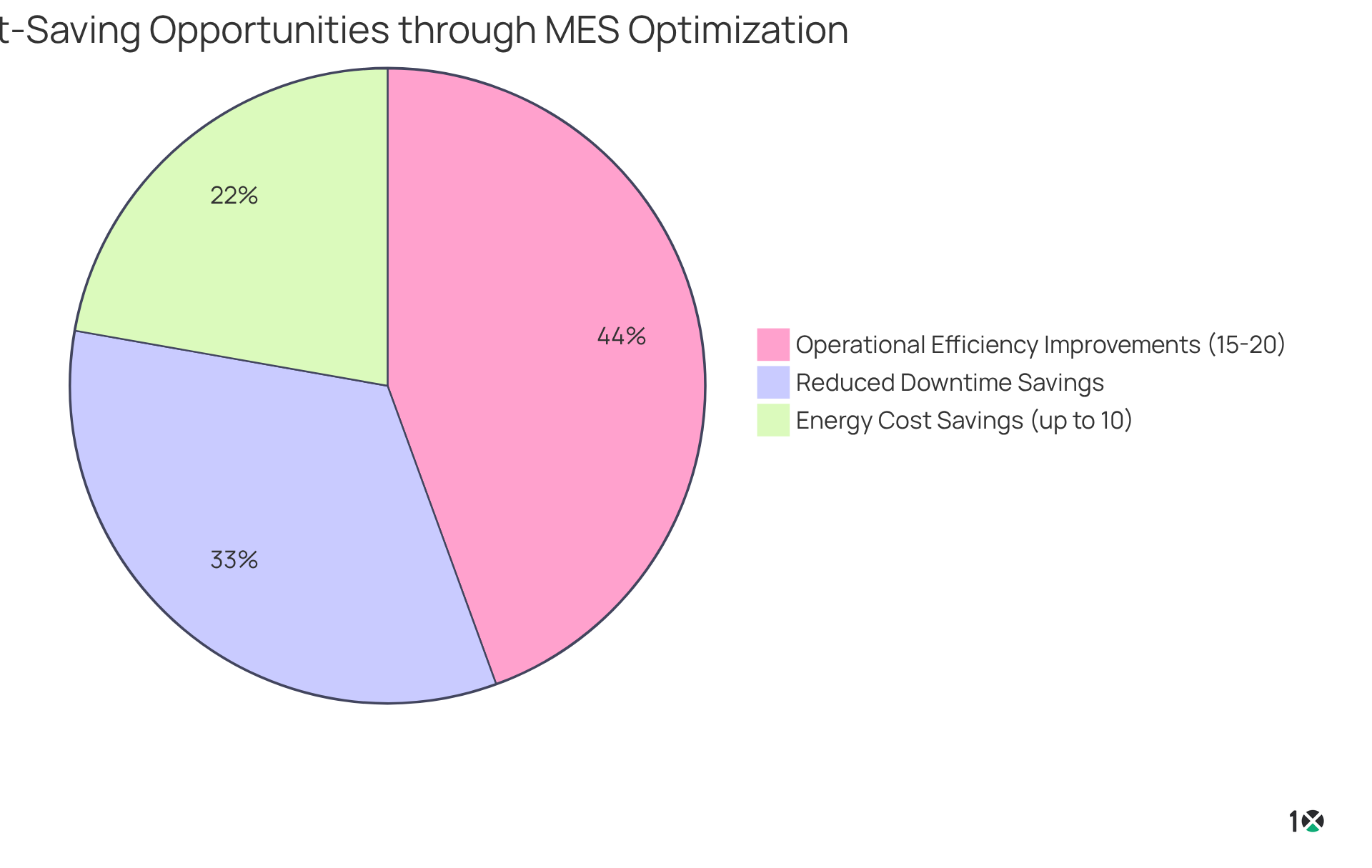

Optimizing the mes system presents a compelling opportunity for substantial cost reductions in manufacturing operations. By enhancing process efficiency and minimizing waste, producers can significantly lower their operational expenses. For example, the MES system effectively identifies excess inventory levels, facilitating streamlined inventory management that cuts carrying costs. Moreover, the predictive maintenance features within the mes system play a crucial role in reducing downtime, thereby elevating productivity and mitigating costs linked to unplanned outages.

Research highlights that organizations implementing a mes system typically observe ranging from 15% to 20%, as noted by industry expert Louis Columbus, which translates into considerable savings. Additionally, findings from Energy Star research indicate that companies can achieve energy cost savings of up to 10% through optimized resource management, further bolstering overall cost reduction strategies.

By harnessing these capabilities, producers not only enhance their operational performance but also cultivate a culture of continuous improvement and efficiency. Importantly, the timeline for the MES system implementation generally spans approximately 8 to 12 weeks, enabling businesses to realize these benefits in a relatively short period.

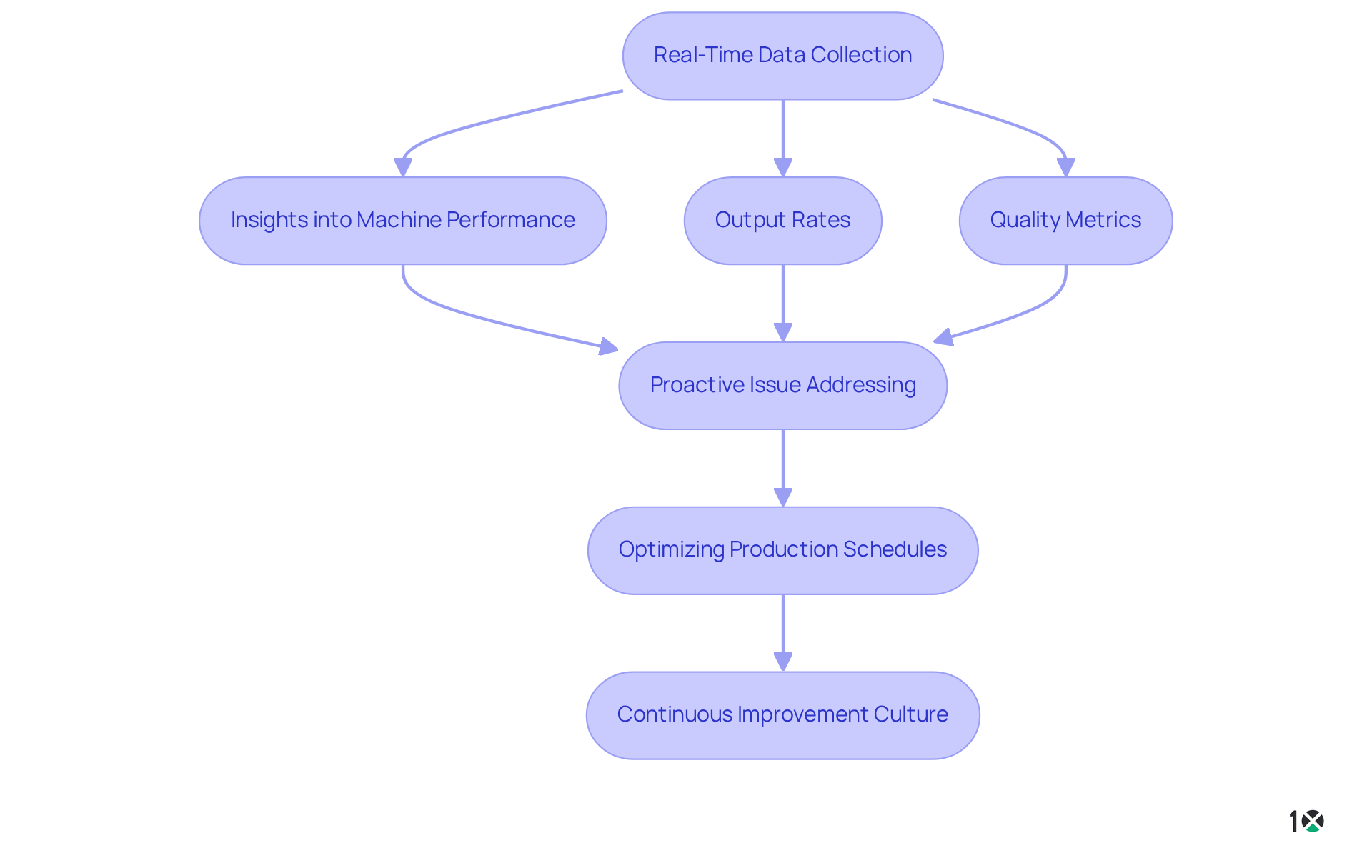

Real-Time Data Collection: Enhance Decision-Making with MES

Real-time data collection is essential for the effective operation of the MES system, enabling manufacturers to make swift and informed decisions. By consistently gathering data from manufacturing lines, the MES system provides invaluable insights into machine performance, output rates, and quality metrics. This capability allows managers to proactively address issues as they arise, thereby and resource allocation effectively.

For instance, when a machine shows signs of wear, real-time alerts can prompt immediate maintenance actions, preventing costly downtime. Moreover, with 10X ERP’s modern cloud-based platform that offers real-time data processing and responsive design, operations managers can access critical information anytime, anywhere.

The integration of real-time information not only streamlines decision-making processes but also fosters a culture of continuous improvement, enabling producers to adapt swiftly to changing circumstances and maintain their competitive edge.

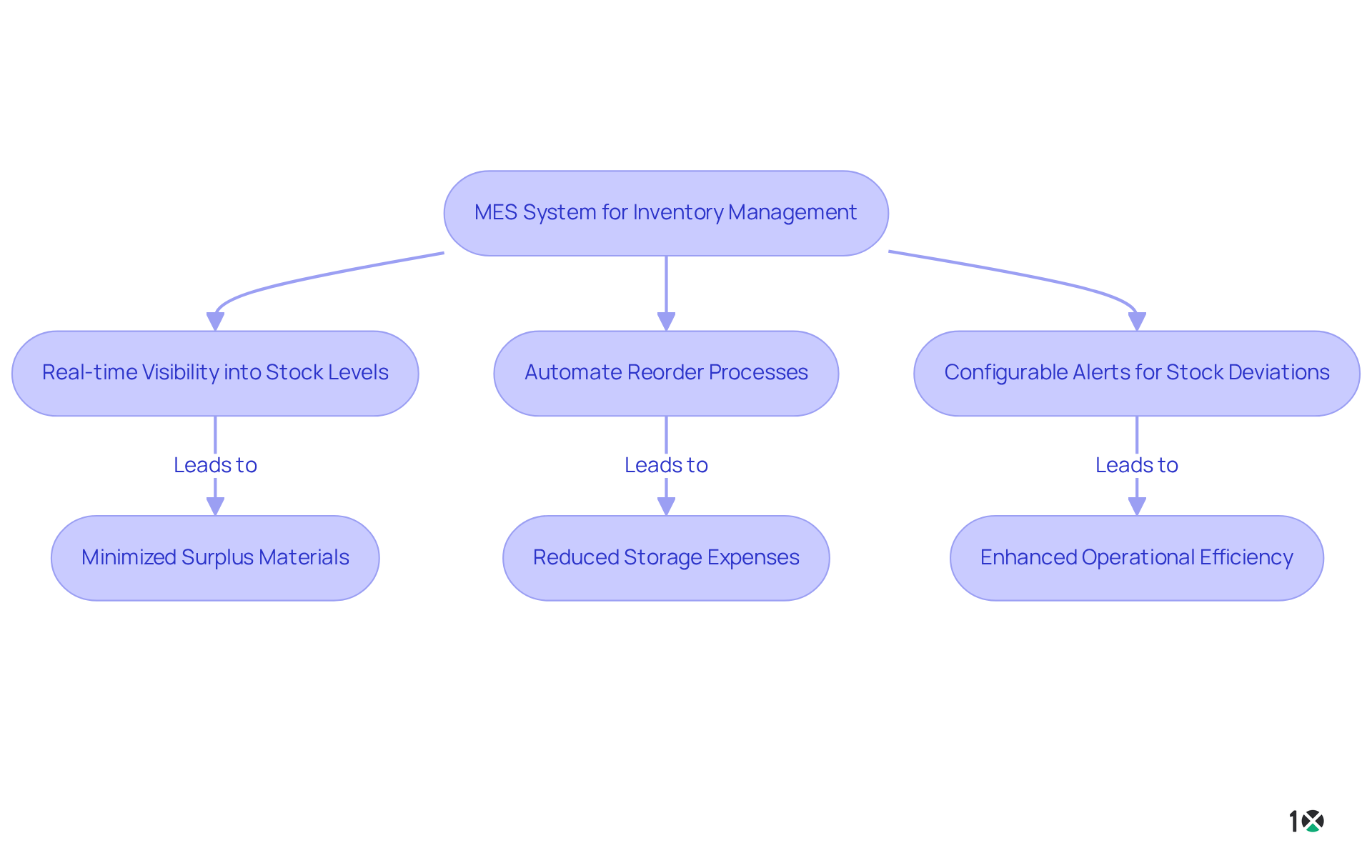

Effective Inventory Management: Optimize Stock Levels with MES

The MES system is instrumental in enhancing stock management by providing real-time visibility into stock levels and consumption rates. This capability empowers manufacturers to adjust their stock levels, effectively minimizing surplus materials while ensuring that essential supplies remain readily accessible. For example, the MES system can automate reorder processes based on usage data, which not only prevents stockouts but also reduces carrying costs.

Moreover, when integrated with advanced stock management solutions like 10X ERP—known for its robust accounting features, customizable tracking, and flexible user permissions—MES guarantees that production processes continue uninterrupted due to material shortages. Statistics reveal that stock precision in U.S. retail operations stands at 63%, underscoring the necessity of precise tracking. Companies that implement a MES system often experience a 10% reduction in storage expenses by addressing overstocking and understocking issues.

Additionally, configurable alerts in the MES system notify staff of stock deviations in real-time, further enhancing operational efficiency. This optimization not only fosters overall business growth by but also reinforces the principle that ‘What Gets Measured, Gets Managed,’ as articulated by Peter Drucker.

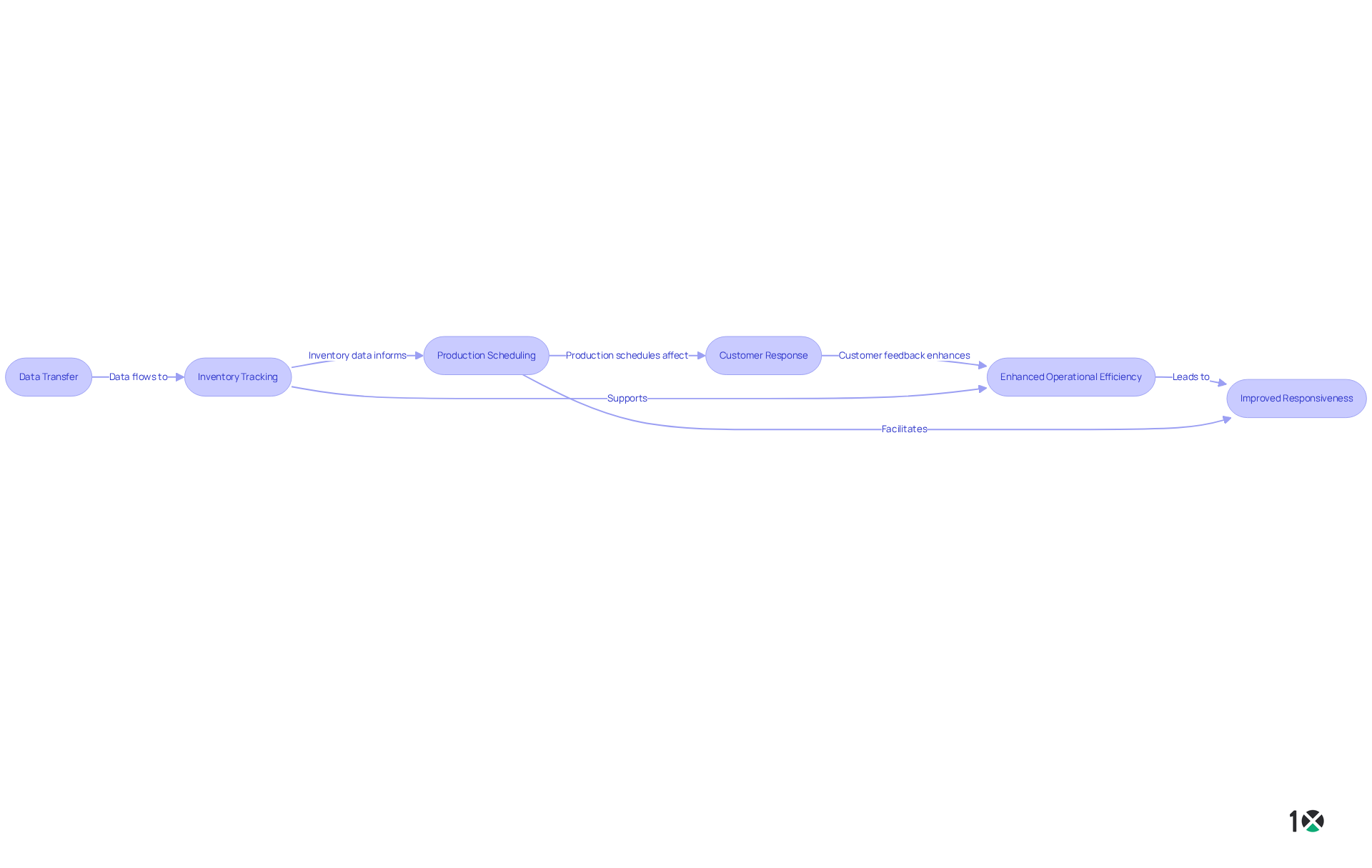

Seamless Integration: Connect MES with ERP for Enhanced Operations

Integrating the MES system with Enterprise Resource Planning (ERP) systems creates a powerful synergy that significantly enhances operational efficiency. This integration facilitates seamless data transfer between operational and business management functions, ensuring that all departments access the same real-time information. For instance, sales orders can be directly linked to production schedules, which allows manufacturers to respond swiftly to customer demands while optimizing resource utilization. This holistic approach minimizes delays and improves responsiveness across the organization.

With 10X ERP’s , organizations can achieve precise tracking of their supplies through features such as simplified item types and powerful cross-referencing. The lot and serial item tracking feature guarantees that you will always know the exact location of your stock, further enhancing operational efficiency. Additionally, 10X ERP’s API-first approach allows for seamless integration with virtually any other software your business utilizes now or in the future, providing a superior user experience for distributors.

Statistics reveal that 91.7% of enterprises that completed their ERP projects report overall success, with many achieving a return on investment (ROI) within an average of 2.5 years. This success is frequently linked to the enhanced insight into operational progress and precise resource management that arise from merging the MES system with ERP systems. A case study involving a global automotive firm demonstrated a 15% decrease in inventory holding costs directly attributed to aligning raw material purchases with real-time manufacturing needs through MES-ERP integration.

Expert views emphasize the significance of this integration, showcasing that it allows producers to track production delays and promptly revise delivery schedules, thus improving overall productivity. As Therese Snow, a digital marketing specialist, observes, ‘Integrating the MES system with ERP systems is a budget-friendly solution that provides significant advantages to producers.’ By adopting this integrated approach, organizations can streamline their operations and position themselves for long-term success in a competitive market.

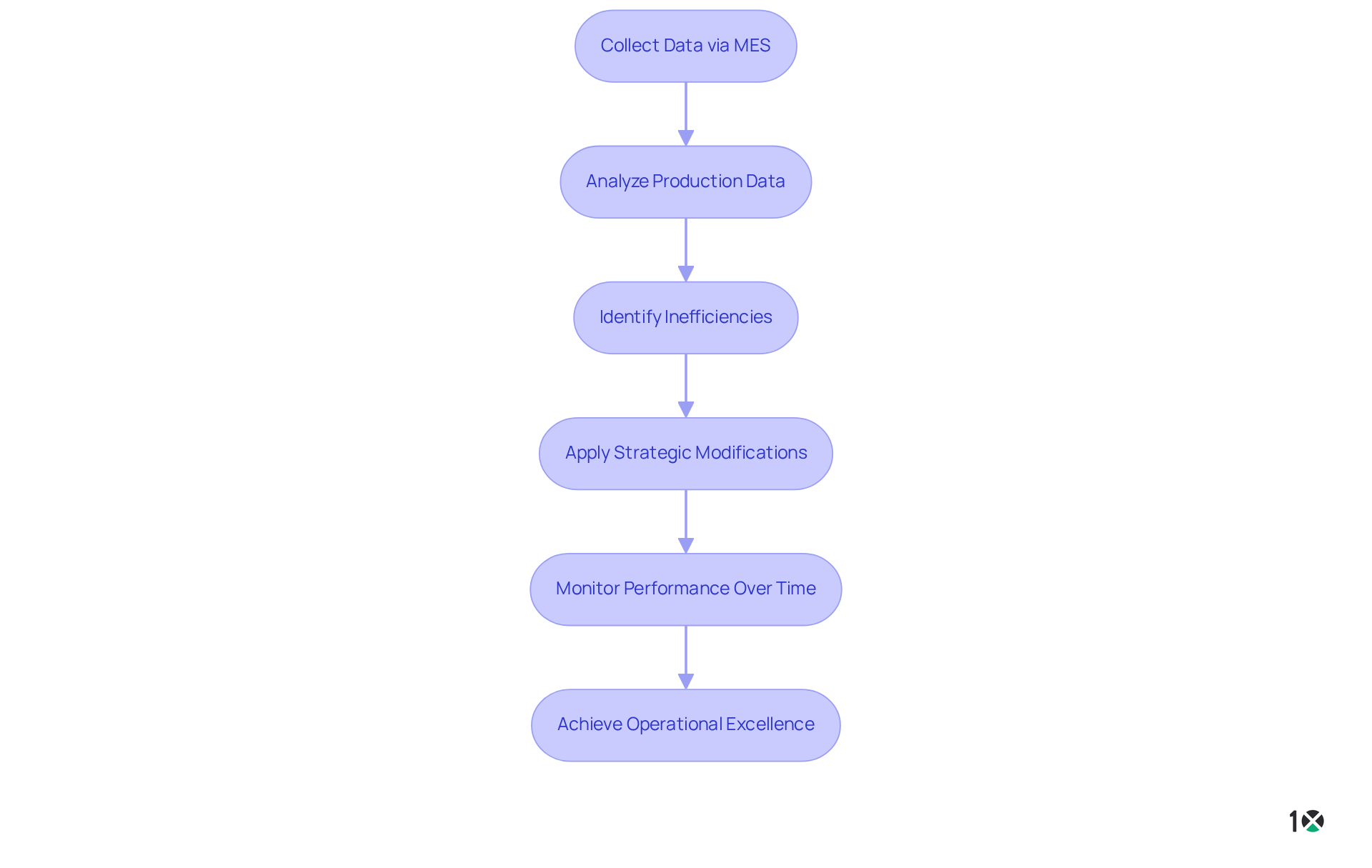

Continuous Improvement: Drive Operational Excellence with MES

The MES system is pivotal in cultivating a culture of continuous improvement by delivering critical data and insights that help identify inefficiencies and monitor performance over time. By utilizing SMART (Specific, Measurable, Achievable, Realistic, Timebound) goals, producers can maintain a sharp focus on their most important objectives. This ensures that every improvement initiative is clear and actionable.

Analyzing production data enables producers to pinpoint specific areas requiring enhancement and apply strategic modifications that boost productivity and quality. For instance, regular evaluations of the MES system can reveal patterns in machine performance. This allows producers to develop focused maintenance plans that and improve overall equipment efficiency.

Such a commitment to transparency and continuous improvement empowers manufacturers to remain competitive in an ever-evolving market landscape. By embracing these practices, organizations position themselves for sustained success and operational excellence.

Conclusion

The implementation of a Manufacturing Execution System (MES) represents a transformative strategy for manufacturers aiming to enhance operational efficiency and competitiveness. By leveraging real-time data processing and seamless integration with ERP systems, businesses can optimize production processes, improve quality control, and maintain compliance with industry standards. The MES system not only streamlines workflows but also empowers organizations to make informed decisions that drive continuous improvement.

Key insights from the article underscore the numerous benefits of adopting an MES system, including:

- Increased efficiency through automation

- Enhanced visibility into operations

- Significant cost reductions

By automating routine tasks and providing real-time insights, manufacturers can respond swiftly to market demands, reduce cycle times, and improve inventory management. Furthermore, the system’s ability to uphold high-quality standards and ensure compliance with regulatory requirements positions manufacturers as leaders in their respective industries.

Embracing the MES system transcends mere technology adoption; it fosters a culture of continuous improvement and operational excellence. Manufacturers are encouraged to assess their current processes and identify opportunities for automation and optimization. By doing so, they can enhance productivity and efficiency while securing a competitive edge in an increasingly dynamic market. The journey toward streamlined manufacturing operations commences with the strategic implementation of an MES system—an investment promising substantial returns in both performance and profitability.

Frequently Asked Questions

What is 10X ERP and how does it benefit manufacturers?

10X ERP is a robust platform that facilitates real-time data processing for manufacturers, enabling continuous monitoring of production metrics. This allows businesses to make immediate adjustments to workflows and resource allocation, significantly enhancing operational efficiency.

How does integrating the MES system with 10X ERP improve decision-making?

Integrating the MES system with 10X ERP ensures seamless data flow across all operations, leading to improved decision-making. Real-time insights into inventory levels help prevent stockouts and overproduction, optimizing supply chain management.

What impact does real-time data processing have on lead times and productivity?

Real-time data processing reduces lead times and enhances overall productivity by allowing manufacturers to swiftly respond to changes in demand and operational conditions.

How does the MES system optimize production processes?

The MES system optimizes production processes by automating routine tasks and providing real-time visibility into operations, which significantly reduces cycle times and minimizes manual errors.

What are the benefits of automated scheduling in the MES system?

Automated scheduling in the MES system adjusts production runs based on real-time demand data, ensuring effective resource utilization and timely achievement of production targets.

What is the potential reduction in cycle times when implementing an MES system?

Research indicates that implementing an MES system can result in an average cycle time reduction of up to 30%.

How does the MES system influence workforce dynamics?

The MES system allows employees to focus on higher-value tasks instead of routine manual processes, fostering a more agile manufacturing environment.

What role does the MES system play in quality control?

The MES system enhances quality control by embedding quality management processes into workflow activities, facilitating real-time monitoring and immediate corrective actions when quality standards are not met.

How much can defect rates be reduced by utilizing the MES system?

Organizations using the MES system can achieve a 25-40% reduction in defect rates, showcasing its effectiveness in fostering a culture of quality.

Can you provide an example of how the MES system improves quality control?

A bicycle manufacturer implemented rigorous quality control processes through the MES system to address customer complaints about faulty brakes, enabling prompt identification and rectification of the root cause of the issue.