Overview

To achieve distribution success through ERP programming, it is essential to grasp ERP fundamentals, leverage its benefits for enhanced efficiency, adhere to a structured implementation process, and prioritize user training alongside continuous support. These key practices are not merely recommendations; they are foundational to fostering improved operational efficiency, reducing order fulfillment times, and enhancing user satisfaction. By recognizing their critical role, organizations can ensure successful ERP deployment and utilization within the distribution sector.

Introduction

In the fast-paced world of distribution, the ability to streamline operations and enhance efficiency can make or break a business. Companies are increasingly turning to Enterprise Resource Planning (ERP) systems, making it essential to understand how to effectively program these solutions. This article explores four key practices that not only optimize ERP implementation but also drive substantial improvements in distribution processes. With a multitude of options available, organizations must consider:

- How can they leverage ERP systems to their fullest potential while avoiding common pitfalls?

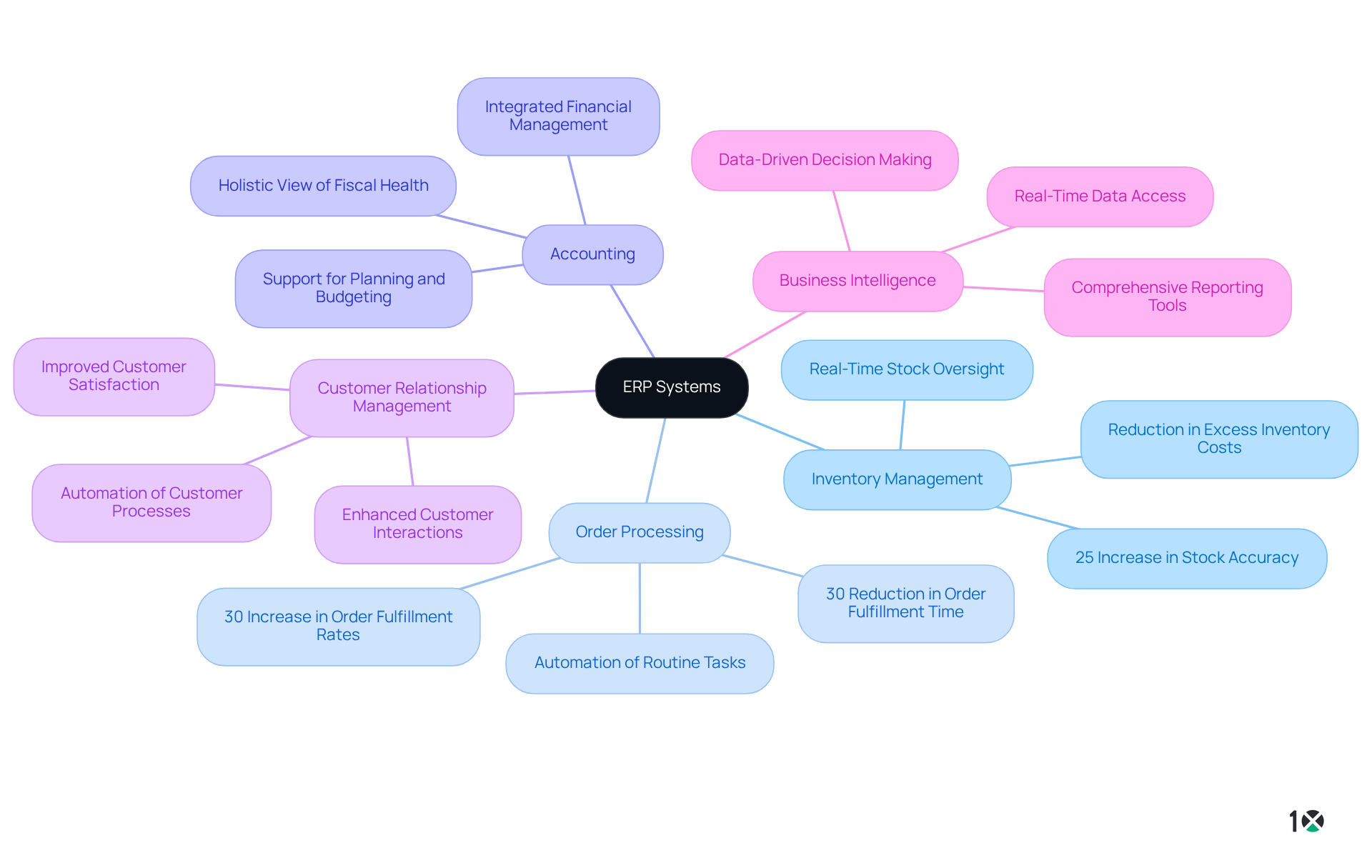

Understand the Fundamentals of ERP Systems

The program ERP applications serve as integrated software solutions that enhance and automate critical business processes across various departments. For suppliers, grasping the essential components of ERP—such as inventory management, order processing, accounting, and customer relationship management—is vital. These systems create a centralized platform that boosts visibility and control over operations, empowering distributors to respond swiftly to market demands.

Understanding the fundamentals of program ERP allows organizations to identify specific functionalities that can optimize their operations, ultimately paving the way for successful implementation. Notably, companies that adopt automated solutions report a remarkable 30% increase in order fulfillment rates, underscoring the transformative potential of program ERP in enhancing operational efficiency.

Moreover, a supplier that implemented the program ERP witnessed a 30% reduction in order fulfillment time and a 25% increase in stock accuracy. This illustrates the tangible benefits of effective ERP utilization in the distribution sector. By leveraging these insights, operations managers can make informed decisions that lead to improved performance and competitiveness in their markets.

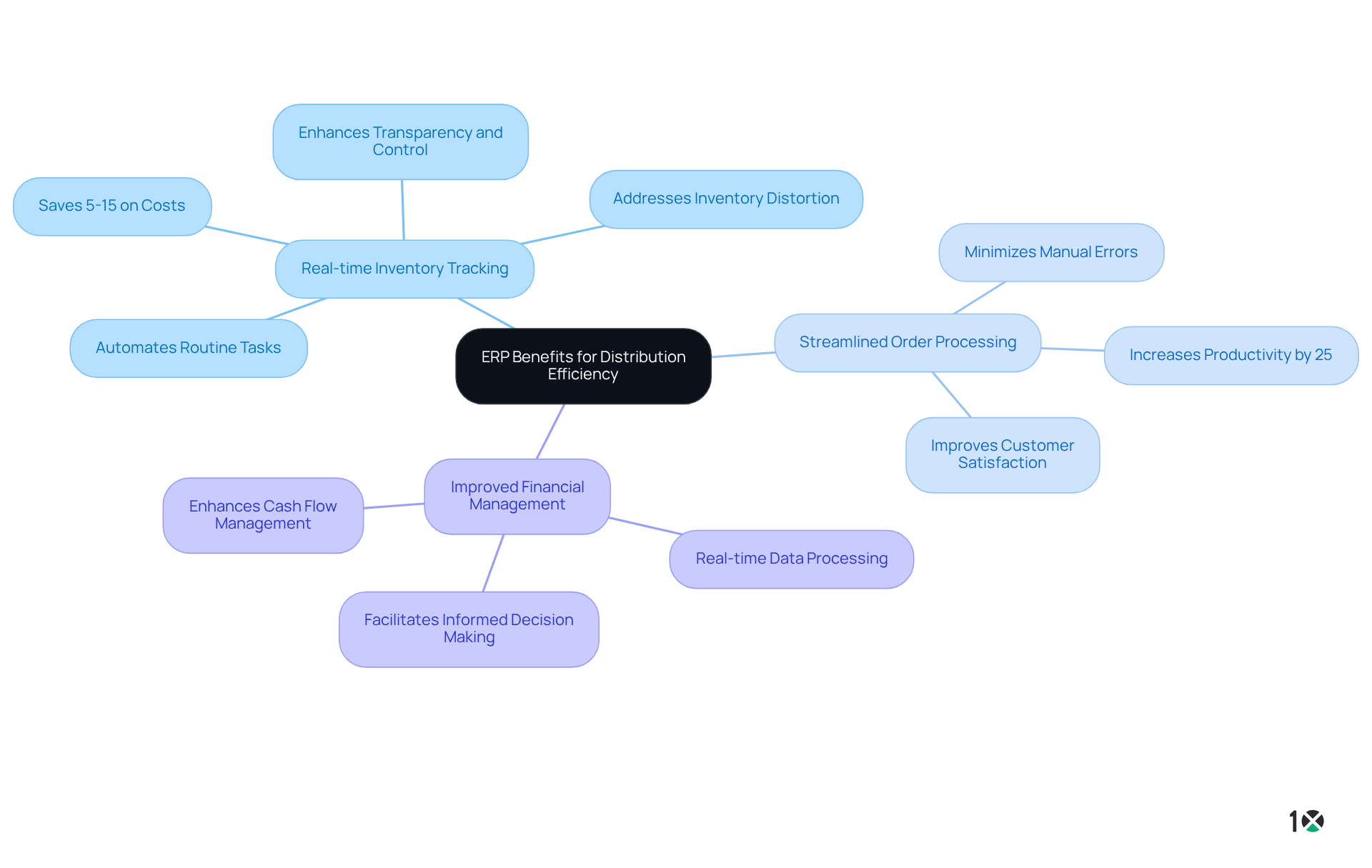

Leverage ERP Benefits for Distribution Efficiency

Program ERP systems offer a myriad of benefits that significantly enhance distribution efficiency, particularly when leveraging a comprehensive solution like 10X ERP. Key advantages include:

- Real-time inventory tracking

- Streamlined order processing

- Improved financial management

By automating routine tasks, suppliers can minimize manual errors and conserve valuable time, allowing staff to concentrate on strategic initiatives. Moreover, 10X ERP delivers powerful analytics and reporting features, enabling suppliers to make informed, data-driven decisions that optimize operations. For example, suppliers utilizing 10X ERP can swiftly identify slow-moving stock, facilitating efficient adjustments to purchasing strategies. This proactive approach not only enhances cash flow but also mitigates excess stock, addressing the critical issue of inventory distortion that costs businesses an estimated $1.6 trillion annually (Source: Meteor Space).

Real-time tracking enhances transparency and control over logistics operations, empowering distributors to continuously monitor stock levels and locations. Statistics indicate that implementing real-time tracking can save businesses between 5% and 15% annually on operational costs (Source: Webinarcare), underscoring its significance in modern distribution management. Furthermore, 62% of business finances are impacted by failures in inventory tracking (Source: Supply Chain Dive), highlighting the necessity of accurate inventory management. Experts agree that integrating real-time inventory monitoring within the program ERP solutions, like 10X ERP, is essential for maintaining a competitive edge in the rapidly evolving distribution landscape.

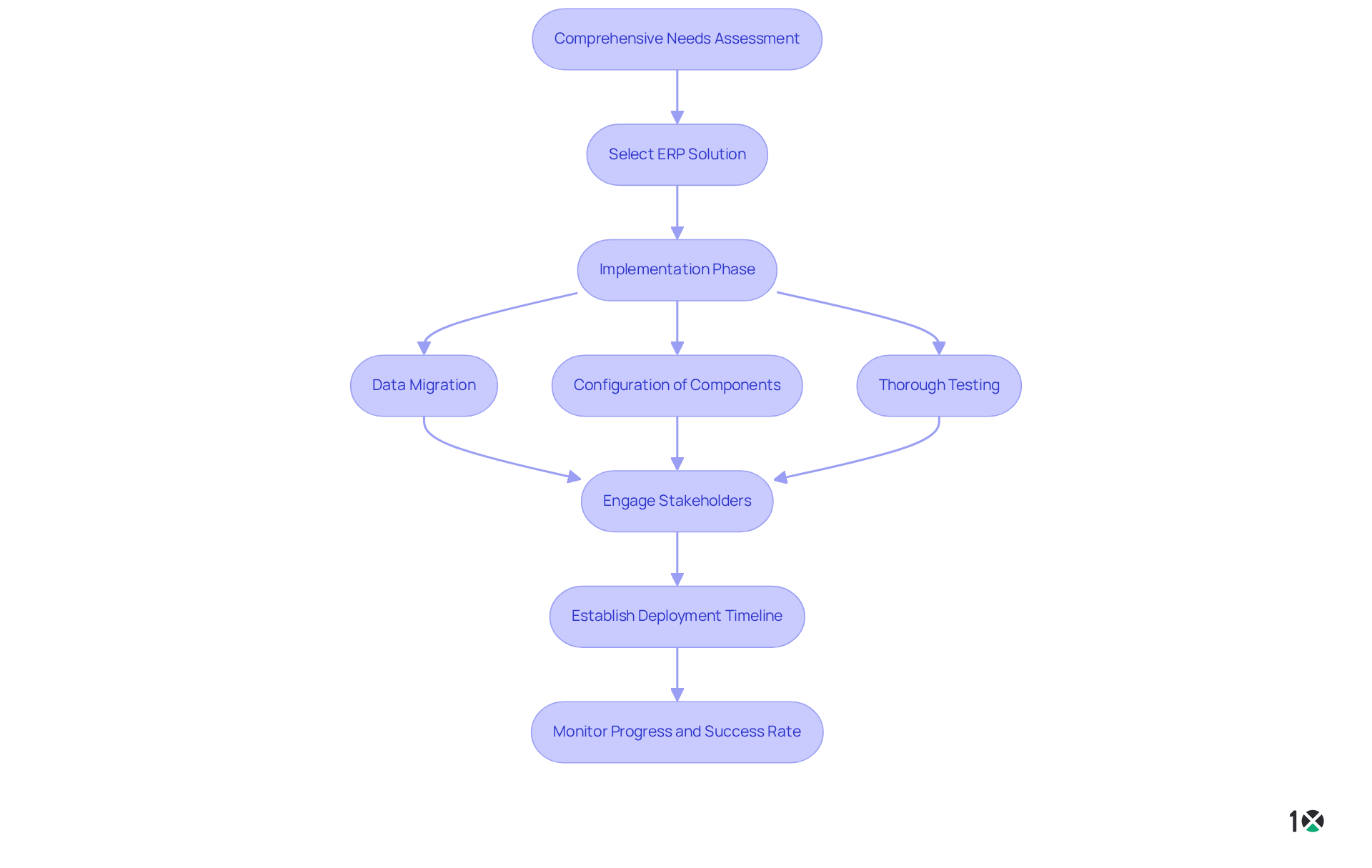

Follow a Structured Implementation Process

Implementing a program ERP solution necessitates a meticulously defined process to ensure success, particularly with innovative approaches like 10X ERP. Start with a comprehensive needs assessment to pinpoint specific business requirements and objectives. Selecting a program ERP solution that aligns with these needs is crucial, especially regarding scalability and integration capabilities. 10X ERP, created specifically for wholesale suppliers, offers robust features such as real-time data processing, accounting, and inventory management, making it an ideal choice for high transaction volumes.

The implementation phase must include data migration, configuration of components, and thorough testing to confirm functionality. Engaging stakeholders throughout the process is vital for securing buy-in and addressing any concerns. 10X ERP supports this with a streamlined onboarding process, providing real-time status reporting and expectation alignment to ensure a smooth transition.

Establishing a clear timeline for deployment with defined milestones allows for effective progress tracking. Research indicates that 54% of companies cite poor project management as a barrier to successful program ERP implementation, underscoring the necessity of a well-organized strategy. Moreover, organizations that adhere to a systematic implementation process report a higher success rate, with 67% of implementations of program ERP by manufacturers considered successful. As highlighted by industry specialists, “A comprehensive needs assessment is essential to guarantee that the selected ERP solution fulfills the distinct requirements of the business.” By prioritizing these steps and leveraging the exceptional support offered by 10X ERP, distributors can navigate the complexities of ERP deployment more effectively.

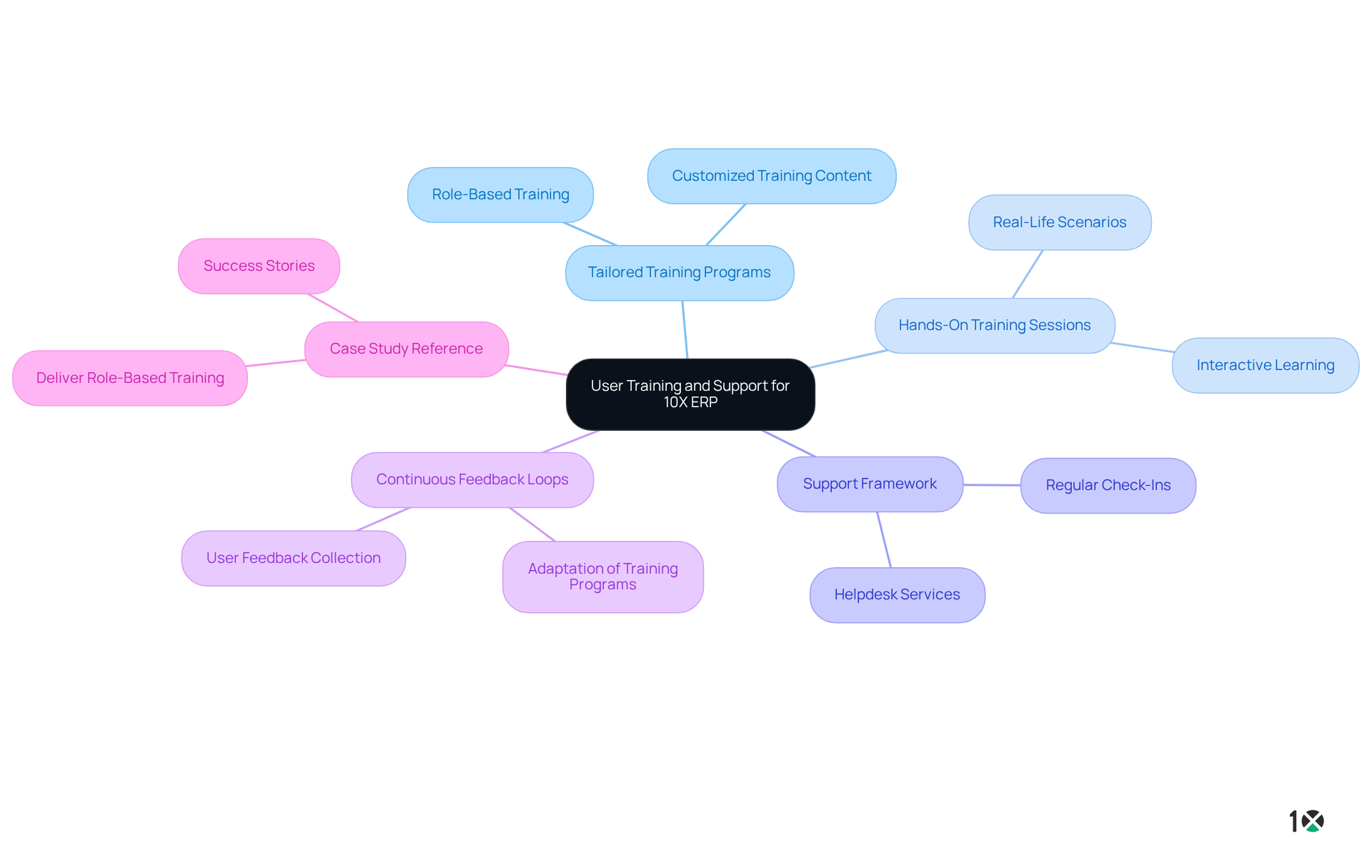

Prioritize User Training and Continuous Support

To fully harness the capabilities of a program ERP solution like 10X ERP, organizations must prioritize user training and ongoing support. Tailored training programs designed for various user roles are essential, ensuring employees can navigate the system and utilize its features effectively.

With 10X ERP’s rapid onboarding process and intuitive user interface, incorporating hands-on training sessions and real-life scenarios significantly enhances learning outcomes, as employees can relate their training to actual tasks. Furthermore, establishing a robust support framework, including helpdesk services and regular check-ins, allows organizations to address user challenges promptly.

Continuous feedback loops are vital, especially considering that 50% of ERP implementations fail on the first attempt; this underscores the necessity for ongoing support and adaptation. By referencing the case study on ‘Deliver Role-Based Training,’ organizations can appreciate the effectiveness of focusing on relevant functionalities for specific job roles. This approach not only boosts user satisfaction but also contributes to overall operational efficiency, as 78% of companies report improved productivity following the adoption of program ERP.

Additionally, with 10X ERP’s transparent pricing structure and all-inclusive money-back guarantee, organizations can confidently invest in effective training and support. By leveraging the unmatched support offered by the program ERP, organizations can significantly reduce the risk of failures in ERP projects, which often stem from inadequate user preparation.

Conclusion

The successful programming of ERP systems in the distribution sector relies heavily on a comprehensive understanding of their functionalities and strategic implementation. Recognizing the core components of ERP enables organizations to leverage the full potential of these integrated solutions, thereby enhancing operational efficiency and responsiveness to market dynamics.

Key practices include:

- Leveraging ERP benefits to improve distribution efficiency

- Adhering to a structured implementation process

- Prioritizing user training and continuous support

Real-time inventory tracking and streamlined order processing stand out as crucial advantages that can significantly reduce costs and enhance customer satisfaction. Moreover, a systematic approach to implementation equips organizations to navigate potential challenges effectively, while ongoing training and support foster user confidence and operational success.

Ultimately, integrating robust ERP solutions like 10X ERP not only transforms distribution operations but also positions organizations for sustained growth and competitiveness in an ever-evolving market. Embracing these best practices can lead to remarkable improvements in productivity and profitability, making it imperative for distributors to invest in effective ERP strategies and support systems.

Frequently Asked Questions

What is the purpose of ERP applications?

ERP applications serve as integrated software solutions that enhance and automate critical business processes across various departments.

Why is it important for suppliers to understand ERP components?

Grasping the essential components of ERP, such as inventory management, order processing, accounting, and customer relationship management, is vital for suppliers to boost visibility and control over operations.

How do ERP systems benefit distributors?

ERP systems create a centralized platform that empowers distributors to respond swiftly to market demands, leading to improved operational efficiency.

What are some reported benefits of adopting automated ERP solutions?

Companies that adopt automated ERP solutions report a remarkable 30% increase in order fulfillment rates, a 30% reduction in order fulfillment time, and a 25% increase in stock accuracy.

How can understanding ERP fundamentals impact an organization’s operations?

Understanding the fundamentals of ERP allows organizations to identify specific functionalities that can optimize their operations, paving the way for successful implementation and improved performance.

What insights can operations managers gain from effective ERP utilization?

Operations managers can leverage insights from effective ERP utilization to make informed decisions that lead to improved performance and competitiveness in their markets.